Potassium perchlorate effluent brine treatment apparatus, and technology for recovering potassium perchlorate and sodium chloride from potassium perchlorate effluent brine

A technology of potassium perchlorate and waste brine, applied in the direction of perchlorate, perchloric acid, multi-stage water treatment, etc., can solve the problems of high impurity content of sodium chloride, long-term environmental pollution, and insignificant economic benefits, etc., to achieve High purity, sufficient separation and recovery, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

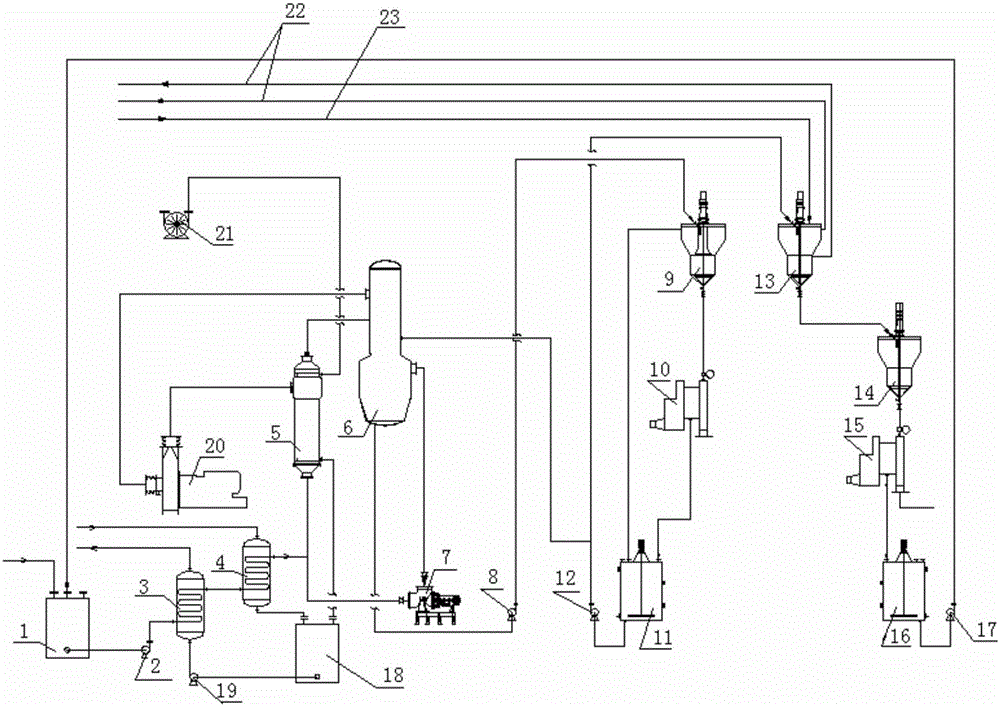

Method used

Image

Examples

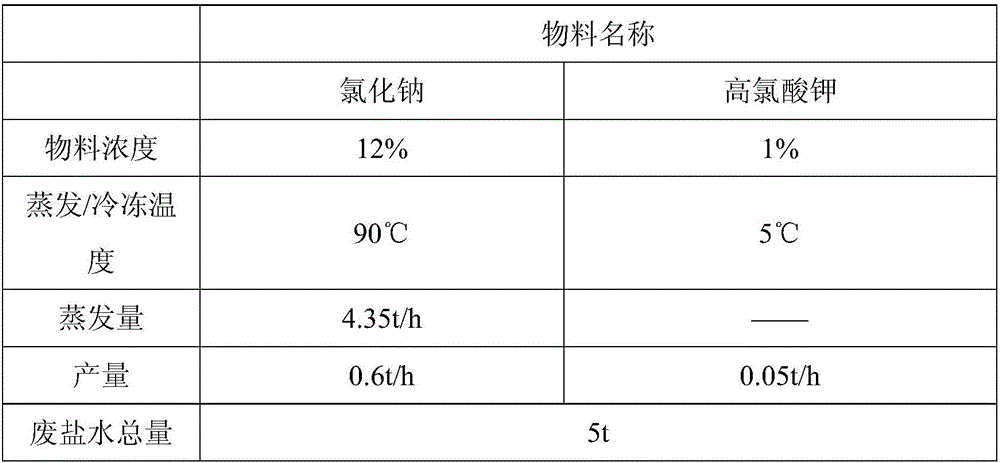

Embodiment 1

[0046] Pump 5 tons of waste brine containing 1% potassium perchlorate and 12% sodium chloride (by mass percentage) into the MVR crystallization evaporator for concentration: heat the waste brine to 90°C, pump it into the crystallization evaporator, start the compressor, Start to evaporate. When the waste brine is concentrated to the saturated crystallization of sodium chloride, it is pumped into the sodium chloride thickener to start discharging the sodium chloride material, and the material in the thickener enters the sodium chloride centrifuge for centrifugation to obtain sodium chloride solid and mother liquor I. The mother liquor I is collected in the mother liquor tank I, and when the concentration of potassium perchlorate does not reach near saturation, it is transported to the crystallization evaporator through the mother liquor pump I to continue to evaporate. When the concentration of potassium perchlorate in the evaporative crystallizer was nearly saturated (when the...

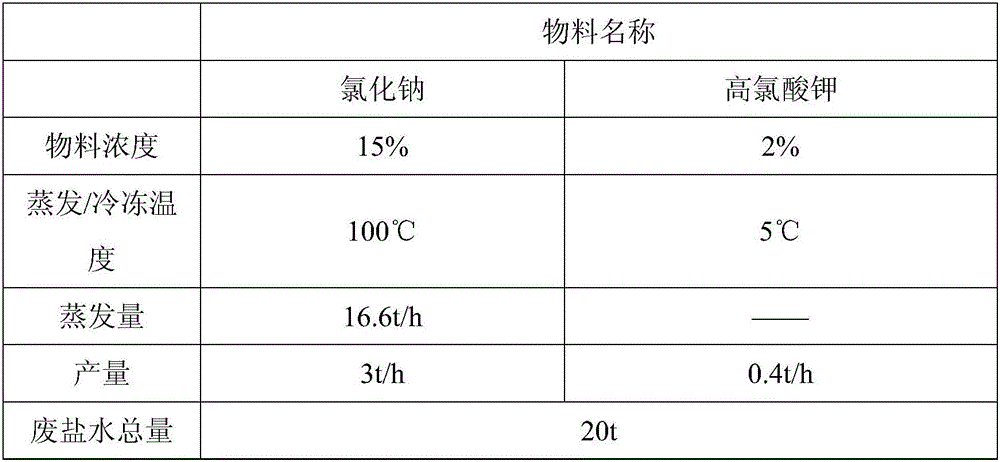

Embodiment 2

[0049] Pump 20 tons of waste brine containing 2% potassium perchlorate and 15% sodium chloride (by mass percentage) into the MVR crystallization evaporator for concentration: heat the waste brine to 100°C, pump it into the crystallization evaporator, start the compressor, Start to evaporate. When the waste brine is concentrated to the saturated crystallization of sodium chloride, it is pumped into the sodium chloride thickener to start discharging the sodium chloride material, and the material in the thickener enters the sodium chloride centrifuge for centrifugation to obtain sodium chloride solid and mother liquor I. The mother liquor I is collected in the mother liquor tank I, and when the concentration of potassium perchlorate does not reach near saturation, it is transported to the crystallization evaporator through the mother liquor pump I to continue to evaporate. When the concentration of potassium perchlorate in the evaporative crystallizer was nearly saturated (when t...

Embodiment 3

[0052] Pump 100 tons of waste brine containing 3% potassium perchlorate and 17% sodium chloride (by mass percentage) into the MVR crystallization evaporator for concentration: heat the waste brine to 110°C, pump it into the crystallization evaporator, start the compressor, Start to evaporate. When the waste brine is concentrated to the saturated crystallization of sodium chloride, it is pumped into the sodium chloride thickener to start discharging the sodium chloride material, and the material in the thickener enters the sodium chloride centrifuge for centrifugation to obtain sodium chloride solid and mother liquor I. The mother liquor I is collected in the mother liquor tank I, and when the concentration of potassium perchlorate does not reach near saturation, it is transported to the crystallization evaporator through the mother liquor pump I to continue to evaporate. When the concentration of potassium perchlorate in the evaporative crystallizer was nearly saturated (when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com