Method for preparing micro-ammonium perchlorate

An ammonium perchlorate and fine technology, applied in the directions of ammonium perchlorate composition, perchloric acid, perchlorate, etc., can solve the problems of high cost and high equipment requirements, and achieve flexible output, flexible adjustment, and continuous reaction. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

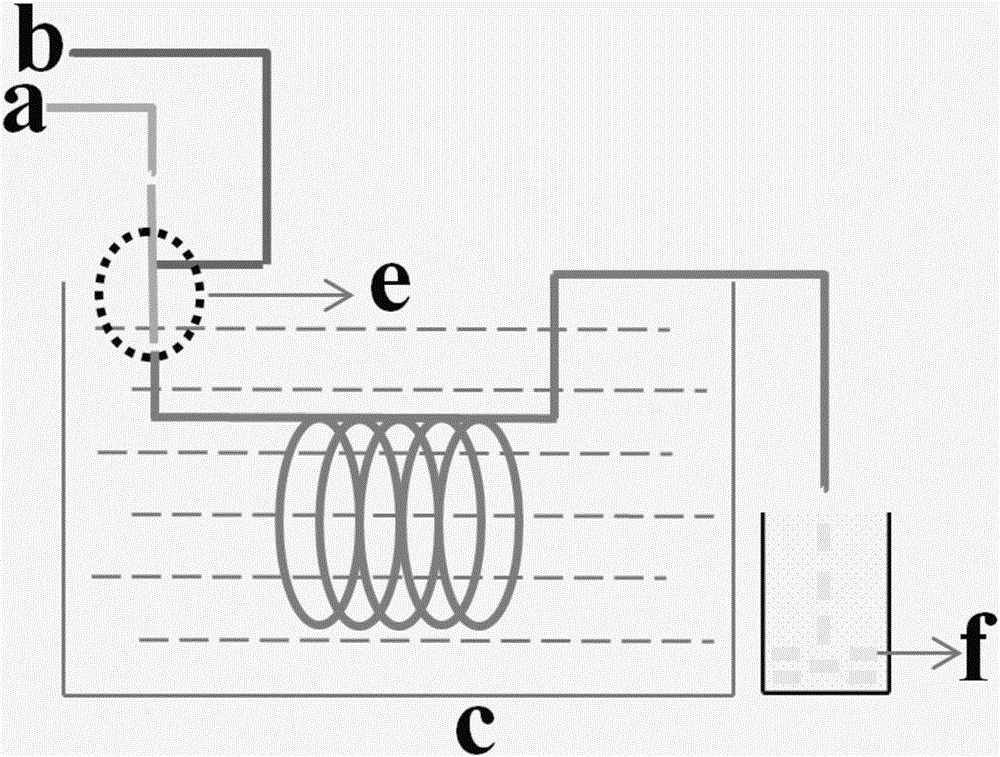

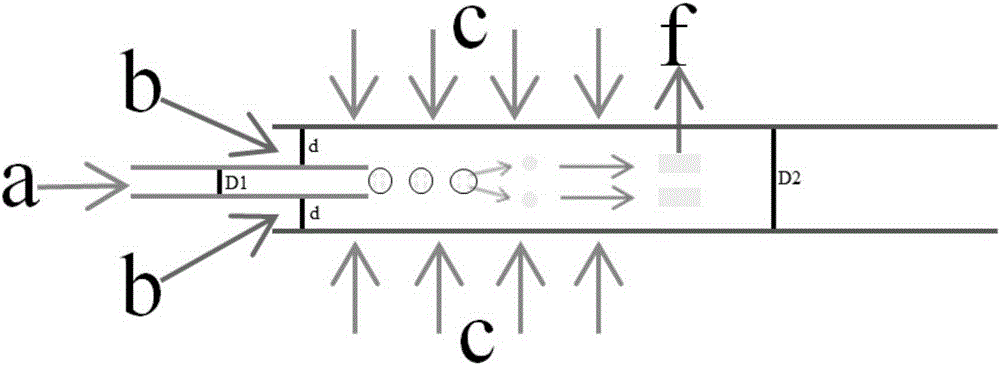

[0029] A flow-focused micro-mixer consisting of an imperial Φ1 / 64 stainless steel pipe as the inner channel, that is, the inner diameter of the inner channel is about 0.3mm, and a metric Φ0.5mm FEP tube as the outer channel, that is, the inner diameter of the outer channel is about 0.5mm. The residence time of the total material in the outer channel is 0.6s, ethyl acetate is used as anti-solvent, and the volume ratio of saturated solution to anti-solvent is 1:20. The ultrasonic power is 100W, the ultrasonic frequency is 40KHz, and the ultrasonic water temperature is 13°C.

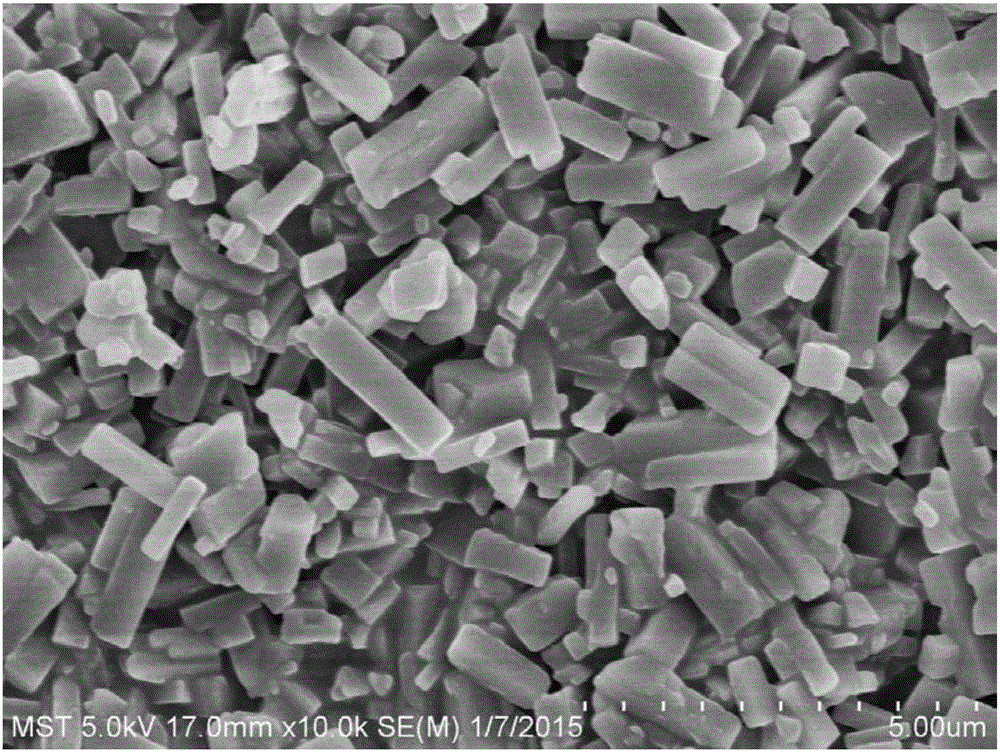

[0030] Mix 0.5 g of ammonium perchlorate, 10 ml of methanol and 0.1% sodium lauryl sulfate based on the total mass of ammonium perchlorate and methanol to prepare a clear solution. Firstly, ethyl acetate enters the outer channel at a flow rate of 40ml / min, and the ultrasound is turned on. The methanol solution was delivered to the inner channel at a flow rate of 2 ml / min. The resulting sample (denoted as ...

example 2-4

[0032] Experiments were carried out in the same manner as in Example 1. By fixing the inner diameter of the outer channel and changing the inner diameter of the inner channel, the spacing between the inner and outer channels of the flow-focusing micromixer was changed to 0.24, 0.4, and 0.44, respectively. The ammonium perchlorate crystals obtained successively are A2, A3, and A4. From the scanning electron microscope pictures of the obtained crystals, it can be seen that the crystal shape of A2 is regular and cuboid, the average particle size is 0.58 μm, and the particle size distribution is 0.34-1.01 μm. The crystal morphology of A3 is cuboid, the average particle size is 0.59 μm, and the particle size distribution is 0.23-1.07 μm. The crystal morphology of A4 is cuboid, the average particle size is 0.66 μm, and the particle size distribution is 0.35-1.1 μm. It can be seen that the channel spacing of the flow focusing micro-mixer has a great influence on the particle size of...

example 5

[0034] Experiments were carried out using the same experimental method as in Example 1, and the inner diameter of the inner channel was changed from 0.3 mm to 0.1 mm when the distance between the inner and outer channels was fixed at 0.2 mm. From the scanning electron microscope image of the product, it can be seen that the crystal morphology of A5 is cuboid, the average particle size is 0.41 μm, and the particle size distribution is 0.2-0.68 μm. It can be seen that when the distance between the inner and outer channels of the flow-focusing type is fixed, the average particle size of ammonium perchlorate crystals decreases as the inner diameter of the inner channel decreases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com