A discontinuous crystallization unit for the production of ball-shaped crystals

A technology of crystallization units and spherical crystals, applied in the field of discontinuous crystallization units, to achieve excellent control, easy process, precise and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

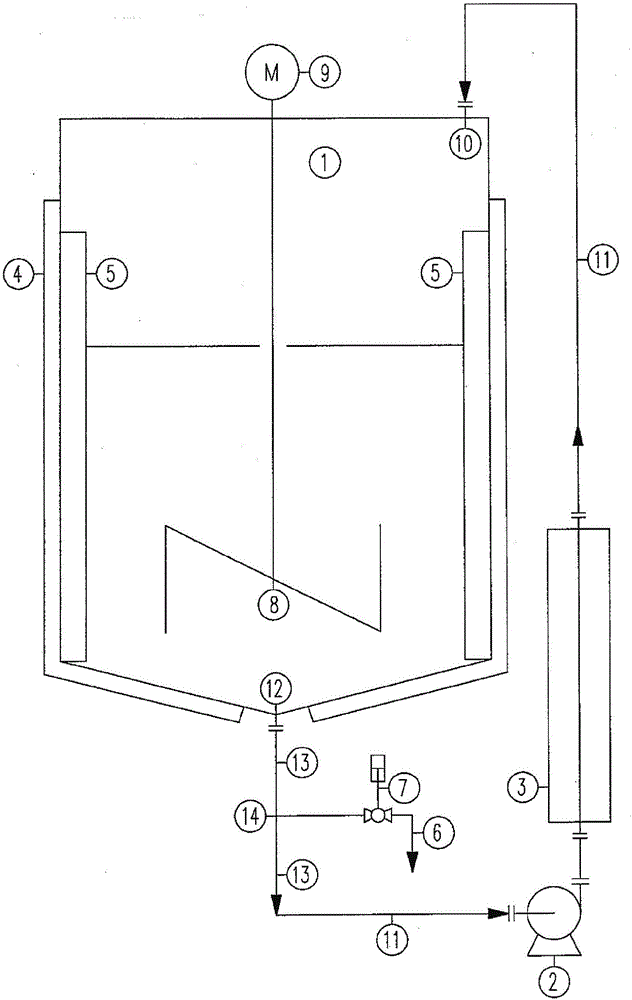

[0050] For the preparation of spherical crystals of ammonium perchlorate, a discontinuous crystallization unit is used, comprising a crystallizer (1) consisting of a metal cylindrical container of enamelled metal, the metal The internal surface of the cylindrical vessel is polished stainless steel, has an oval or circular cross-section, has a tapered or arched bottom (12), and is fitted with a double jacket (4 ), for cooling the solution and / or the suspension of the solution and crystals; and a stainless steel high-speed stirrer (8) having a drive (9) for speed control and thus Together with the internal surface of the vessel containing 2 polished stainless steel baffles (5) to control the impact rate of the mechanical action of the stirrer on the roundness of the crystals inside the vessel, at the same time an orifice (10) is installed on the top of the vessel, which will be independent from the outside 1 loop of the circulation line (11) is connected to said orifice (10) for...

Embodiment 2

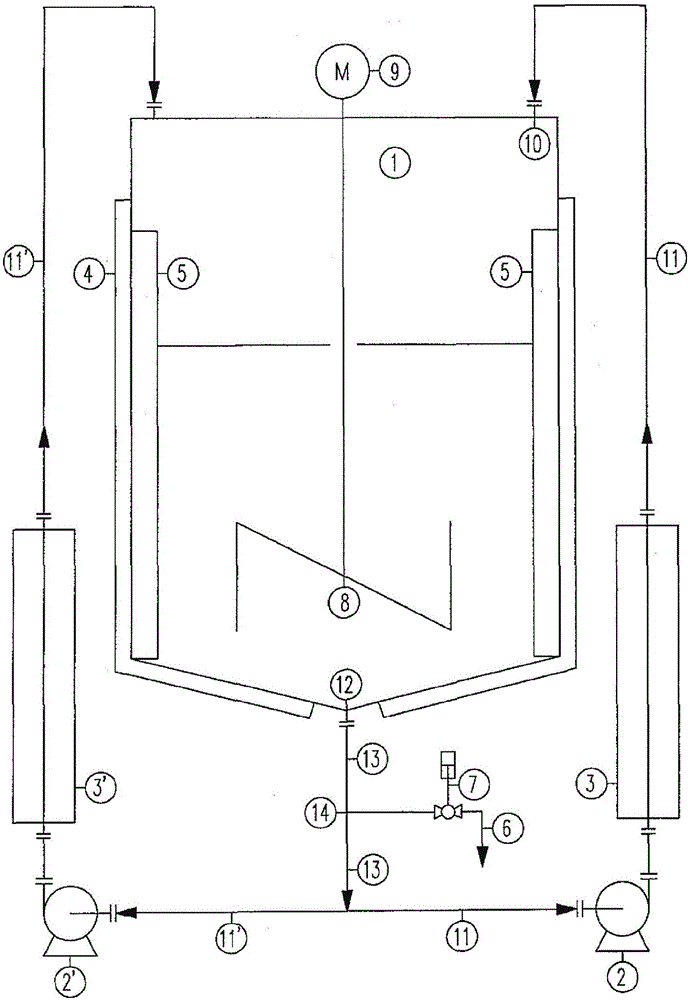

[0065] The same discontinuous crystallization unit as in Example 1 is used, but it comprises 2 circulation loops 11,11' for feeding heated solution or solutions using circulation pumps 2,2' and via heat exchangers 3,3' and Heated suspensions of crystals, such as figure 2 shown.

[0066] This arrangement of the unit makes it possible to increase the number of crystallization cycles with the same cooling rate and / or to reduce the flow rate in the branches of the circulation loop.

[0067] The overall APC crystal preparation process is the same as that in Example 1.

[0068] The resulting crystals have a more rounded shape; moreover, compared to Example 1, they exhibit the same purity and particle distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com