Potassium perchlorate production method and recycling method of sodium chloride mother liquid

A technology of potassium perchlorate and recovery method, applied in the direction of perchloric acid, perchlorate, alkali metal halide purification, etc., can solve the problems of short circuit of electrode plates of electrolytic cells, burning electrolytic cells, etc., to reduce production and operation costs, increase Yield, the effect of improving the quality of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

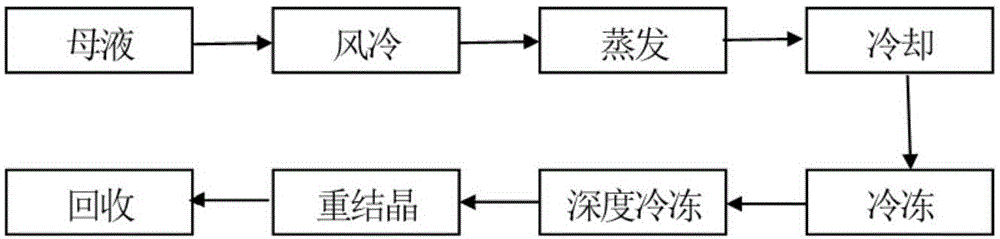

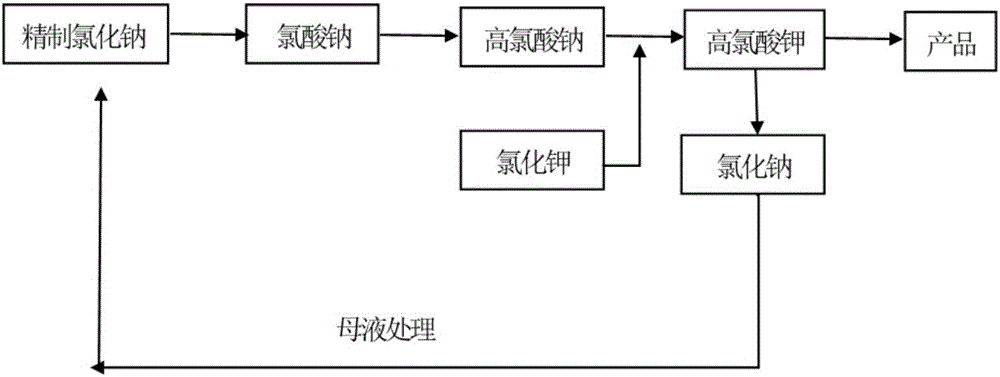

Method used

Image

Examples

Embodiment 1

[0045] The concentration of sodium perchlorate is set to be 850g / L, the volume is 1L, the concentration of potassium chloride is 290g / L, and the potassium chloride 517g can be calculated by mass balance, and the volume is 1.78L. The total volume before reaction is 1+1.78=2.78L.

[0046] Potassium perchlorate quality is 961g, and solid phase volume is 961 / 2.53 (potassium perchlorate density)=380ml, so the volume of sodium chloride mother liquor is 2.78-0.38=2.4L. Sodium chloride quality is 405.9g, then the mass concentration of sodium chloride mother liquor is 405.9 / 2.4=169g / L. From the above data and the solubility of potassium perchlorate, it can be calculated that the concentration of dissolved potassium perchlorate in the mother liquor (the first mother liquor) when the temperature is 40° C. is 34.1 g / L. Potassium ion content is 34.1 * 39 / 138.5=9.6g / L, is far greater than the potassium ion content (4g / L) that mother liquor recovery requires, so mother liquor can't reclaim ...

Embodiment 2

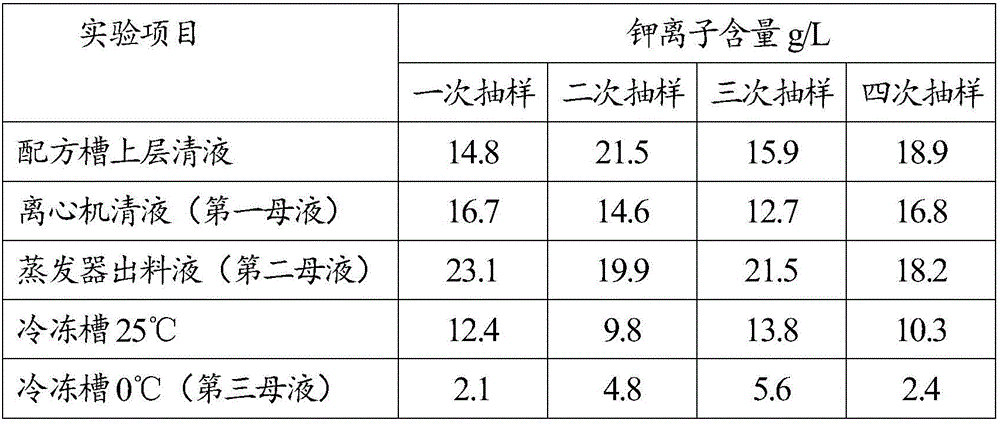

[0052] Table 1 Production experiment data table

[0053]

[0054]

[0055] As can be seen from Table 1, when the sodium chloride mother liquor is obtained after the deep freezing step, the potassium ion content is lower than the standard of 4g / L for four samplings, and can return to the electrolytic solution to participate in the production of potassium perchlorate again. Production.

[0056] In the process of producing potassium perchlorate, the loss of raw sodium chloride salt is 0.45 tons per ton of potassium perchlorate. The annual production of 20,000 tons of potassium perchlorate requires 9,000 tons of raw salt. Recycling all the waste mother liquor can save 8,400 tons of raw salt and raw materials. The cost is 3.78 million yuan (calculated at the price of raw salt 450 yuan / ton).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com