Heat-resistant non-cured rubber asphalt waterproof coating, preparation method and coiled material thereof

A kind of asphalt waterproof coating and non-curing rubber technology, which is applied in the direction of asphalt coating, recycled rubber coating, coating, etc., can solve the problems of low heat resistance, easy slipping, and poor creep performance, so as to improve heat resistance , good creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

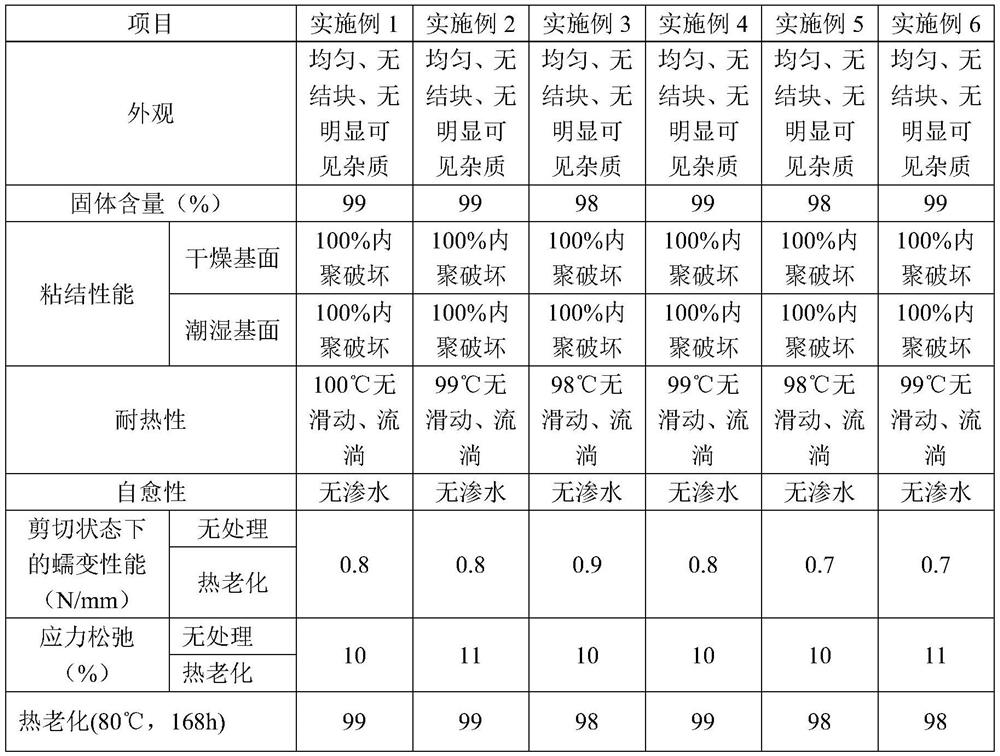

Examples

Embodiment 1

[0022] A heat-resistant non-curing rubber asphalt waterproof coating, its preparation method is as follows:

[0023] (1) will be 70 # After mixing 55 parts of asphalt, 1 part of tackifying resin, 20 parts of naphthenic oil, 1 part of modified SBR, 10 parts of desulfurized rubber powder, and 2 parts of silane coupling agent KH550, the temperature was raised to 125 °C at a heating rate of 2 °C / min. Stir for 40 min at a stirring rate of 1100 r / min.

[0024] (2) Add 0.2 parts of allyl methacrylate, raise the temperature to 160°C at a heating rate of 1°C / min, stir for 1 hour at a stirring rate of 400r / min, make it evenly mixed, then cool to room temperature, and the preparation is completed , inspection, barreling, storage.

Embodiment 2

[0026] A heat-resistant non-curing rubber asphalt waterproof coating, its preparation method is as follows:

[0027] (1) will be 90 # After mixing 65 parts of asphalt, 5 parts of tackifying resin, 35 parts of naphthenic oil, 5 parts of modified SBR, 17 parts of desulfurized rubber powder, and 4 parts of silane coupling agent KH560, the temperature was raised to 140 °C at a heating rate of 2 °C / min. Stir for 50 min at a stirring rate of 1100 r / min.

[0028] (2) Then add 0.5 parts of heat-resistant modifier 8903, raise the temperature to 170°C at a heating rate of 2°C / min, stir at a stirring rate of 500r / min for 1.2h, make it evenly mixed, and then cool to room temperature to prepare Completion, inspection, barreling, storage.

Embodiment 3

[0030] A heat-resistant non-curing rubber asphalt waterproof coating, its preparation method is as follows:

[0031] (1) will be 70 # After mixing 60 parts of asphalt, 4 parts of tackifying resin, 25 parts of naphthenic oil, 4 parts of modified SBR, 15 parts of desulfurized rubber powder, and 2 parts of silane coupling agent KH570, the temperature was raised to 130 °C at a heating rate of 1 °C / min. Stir for 45min at a stirring rate of 1100r / min.

[0032] (2) Then add 0.3 parts of heat-resistant modifier 8903, raise the temperature to 165°C at a heating rate of 1°C / min, stir at a stirring rate of 500r / min for 1.1h, make it evenly mixed, then cool to room temperature, and prepare Completion, inspection, barreling, storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com