Preparation method of low-temperature anti-displacement non-cured rubber asphalt

A non-curing rubber, anti-displacement technology, used in building insulation materials, building components, buildings, etc., can solve the problems of materials that cannot meet the requirements and are rarely mentioned, achieve good stability and durability, and ensure production and processing. , the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

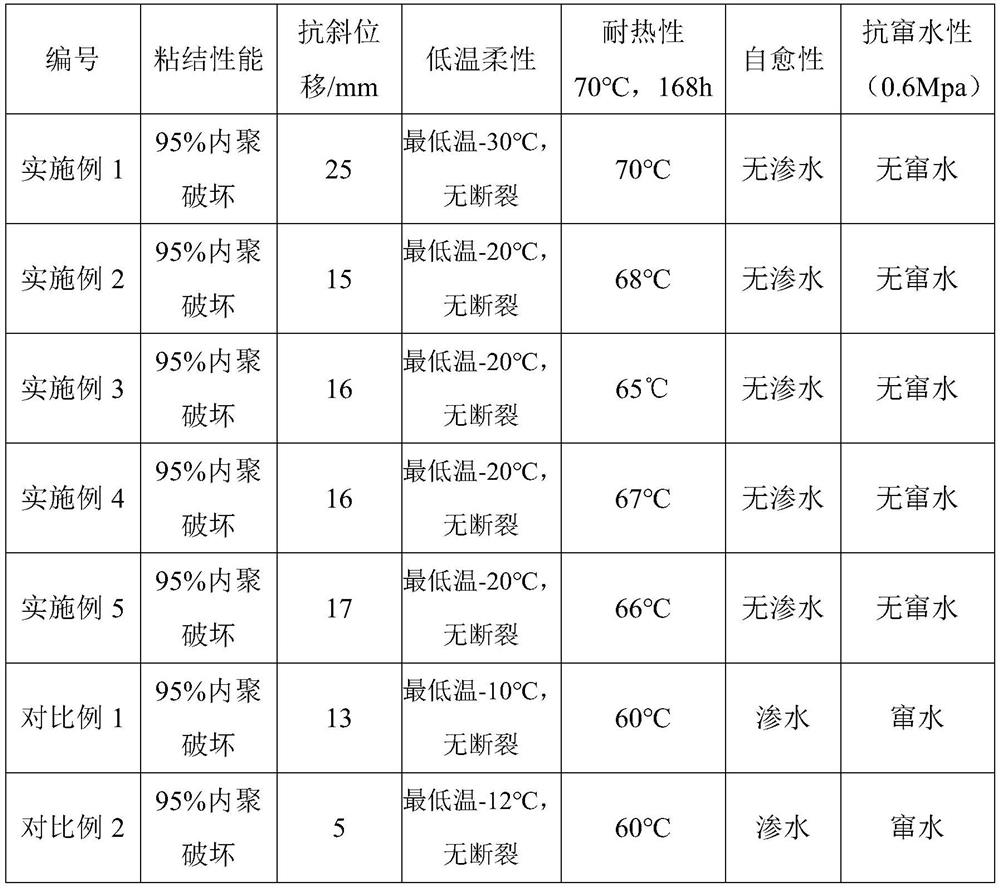

Examples

Embodiment 1

[0030] (1) Take 100 parts of anhydrous phosphogypsum whiskers with a length of 1 μm and an aspect ratio of 5:1, disperse them in 100 parts of ethyl acetate, and add 5 parts of aminosilane coupling agent Dow Corning 6020 under the condition of mechanical stirring, After reacting at room temperature for 2 hours, add 5 parts of sodium nitrite, 10 parts of hydrochloric acid with a mass concentration of 37% and 10 parts of polyetheramine D3000, continue the reaction with mechanical stirring at room temperature for 2 hours, fully wash with saturated sodium bicarbonate solution, and distill under reduced pressure , to obtain modified anhydrous phosphogypsum whiskers.

[0031] (2) Mix 100 parts of 70# asphalt, 10 parts of carboxyl-terminated liquid nitrile rubber NBR-1704 and 15 parts of engine oil, and shear and homogenize at 3000 rpm for 30 minutes at 170 ° C, add 5 parts of Triton 100, 10 parts of polyhydroxyalkanoate PHI 008 and 8 parts of BASF nylon PA6 in Germany were subjected ...

Embodiment 2

[0034] (1) Take 100 parts of anhydrous desulfurized gypsum whiskers with a length of 1 μm and an aspect ratio of 12:1, disperse them in 100 parts of butyl acetate, and add 10 parts of mercaptosilane coupling agent HD112 under the condition of mechanical stirring. After reacting for 4 hours, add 8 parts of sodium nitrite, 14 parts of hydrochloric acid with a mass concentration of 37% and 5 parts of polyetheramine ED900, continue the reaction with mechanical stirring at room temperature for 1 hour, fully wash with saturated sodium bicarbonate solution, and distill under reduced pressure. The modified anhydrous desulfurized gypsum whiskers are obtained.

[0035] (2) Mix 100 parts of 70# asphalt, 15 parts of carboxyl-terminated liquid nitrile rubber NBR-1704 and 10 parts of engine oil, and shear and homogenize at 3000 rpm at 150°C for 30 minutes, add 1 part of Tween 80, 4 One part of LE-6706 urethane acrylate and 4 parts of BASF nylon PA6 in Germany were sheared and homogenized at...

Embodiment 3

[0038] (1) Take 100 parts of anhydrous phosphogypsum whiskers with a length of 10 μm and an aspect ratio of 12:1, disperse them in 100 parts of ethyl acetate, and add 5 parts of epoxy silane coupling agent KH560 under the condition of mechanical stirring, After reacting at room temperature for 2 hours, add 7 parts of sodium nitrite, 12 parts of hydrochloric acid with a mass concentration of 37% and 5 parts of polyetheramine D3000, continue the reaction with mechanical stirring at room temperature for 1 hour, wash thoroughly with saturated sodium carbonate solution, and distill under reduced pressure. The modified anhydrous phosphogypsum whiskers were obtained.

[0039] (2) Mix 100 parts of 70# asphalt, 10 parts of carboxyl-terminated liquid silicone rubber LR5040 and 10 parts of engine oil, and shear homogenize at 3000 rpm at 150°C for 30 minutes, add 5 parts of Tween 80, 4 parts of polymer Hydroxyalkanoate PHI 008 and 4 parts of nylon PA66 from BASF in Germany were sheared an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com