Patents

Literature

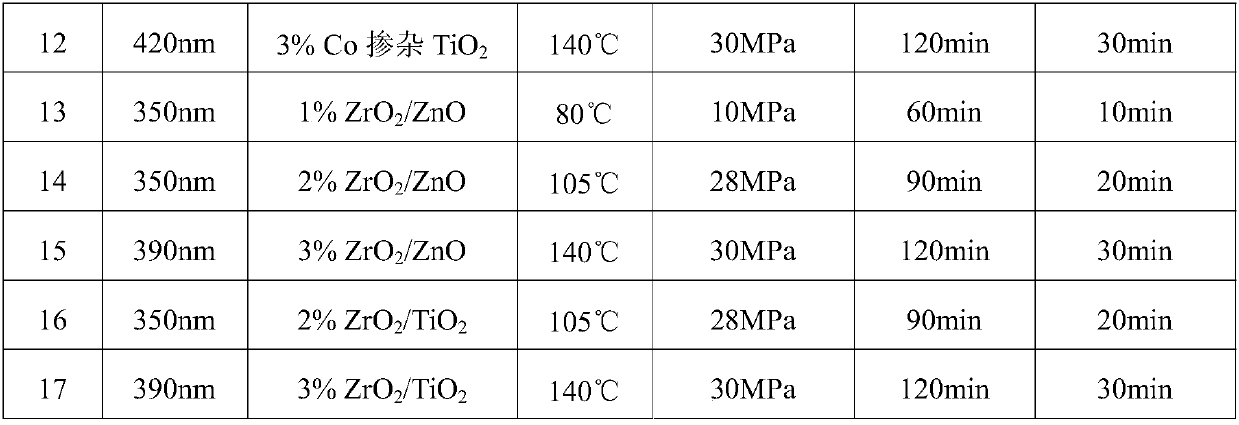

38results about "Reclaimed rubber coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

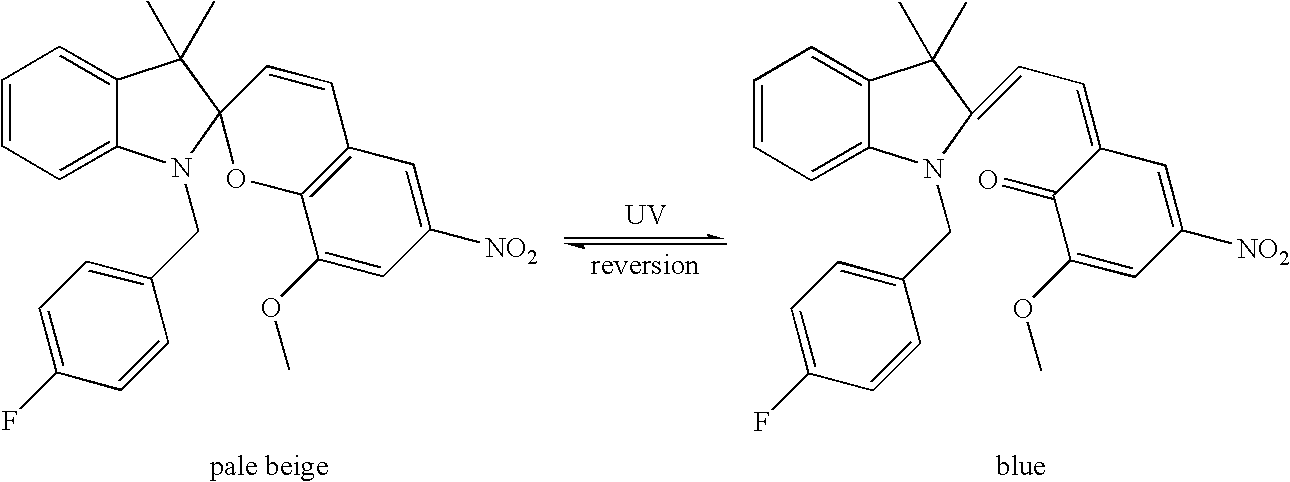

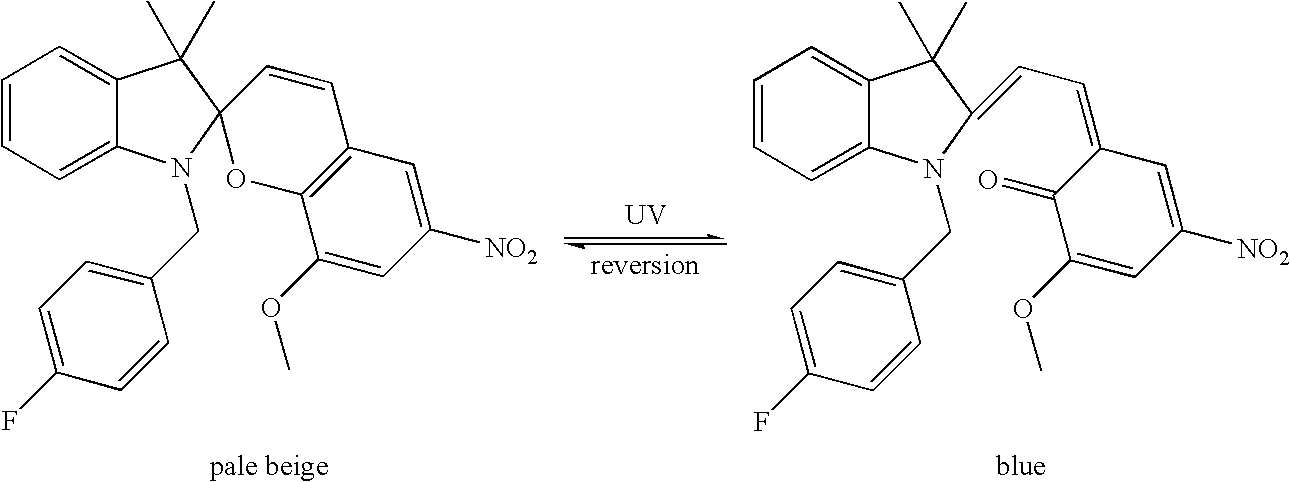

Light absorbing layer for photo-chromic systems

InactiveUS20080167183A1Easy to printIncrease speedThermometers using mean/integrated valuesPaper coatingUltraviolet lightsLength wave

Owner:BASF AG

EPT rubber waterproofing paint and process for preparing the same

InactiveCN101113262AImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsVertical planePolymer science

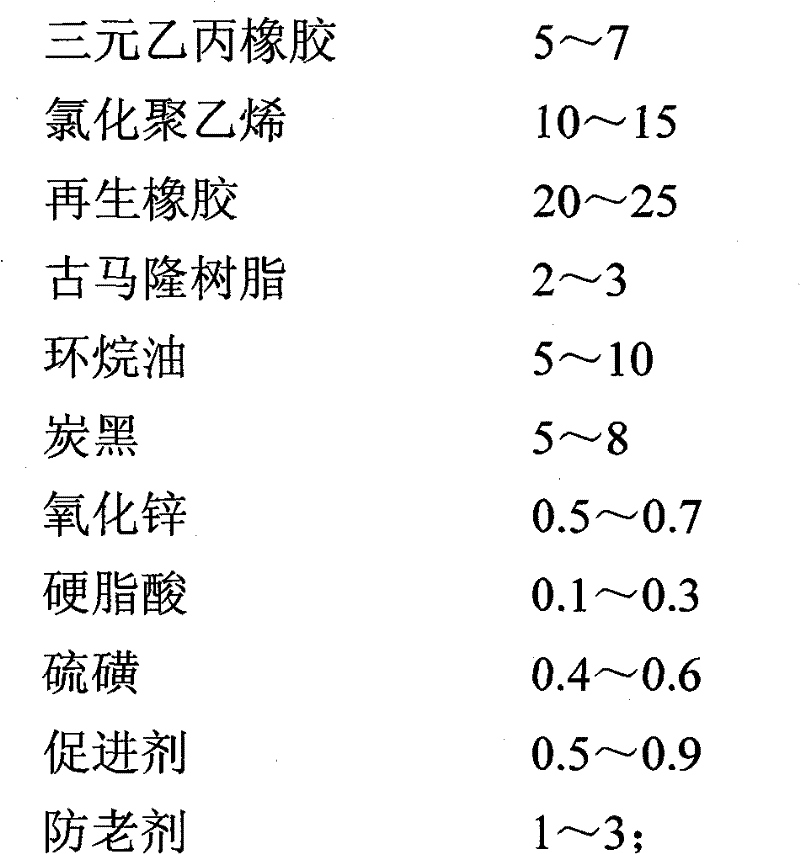

The invention relates to an epdm rubber waterproof coating and a preparation method thereof. The total weight portions of dry raw material component of the waterproof coating are: epdm rubber 5-7, chlorinated polyethylene 10-15, reclaimed rubber 20-25, coumarone resin 2-3, naphthenic oil 5-10, carbon black 5-8, zinc oxide 0.5-0.7, stearic acid 0.1-0.3, sulfur 0.4-0.6, accelerator 0.5-0.9 and antioxidant 1-3. The waterproof coating adopts epdm rubber, reclaimed rubber and chlorinated polyethylene as film forming main bodies and also various modified promoter and fillings, which results in that the waterproof coating not only has excellent waterproof, ageing and cold resistance, but also has the advantages of convenient construction and low cost, and the components and construction thereof meet the requirements of national environmental standards. The invention has simple preparation process steps, is convenient to be widely industrially produced, and the store property and life service of the waterproof coating obtained is greatly prolonged. The waterproof coating can be widely applied to the waterproof construction in building, engineering, vertical plane and various waterproof datum planes.

Owner:北京立高科技股份有限公司

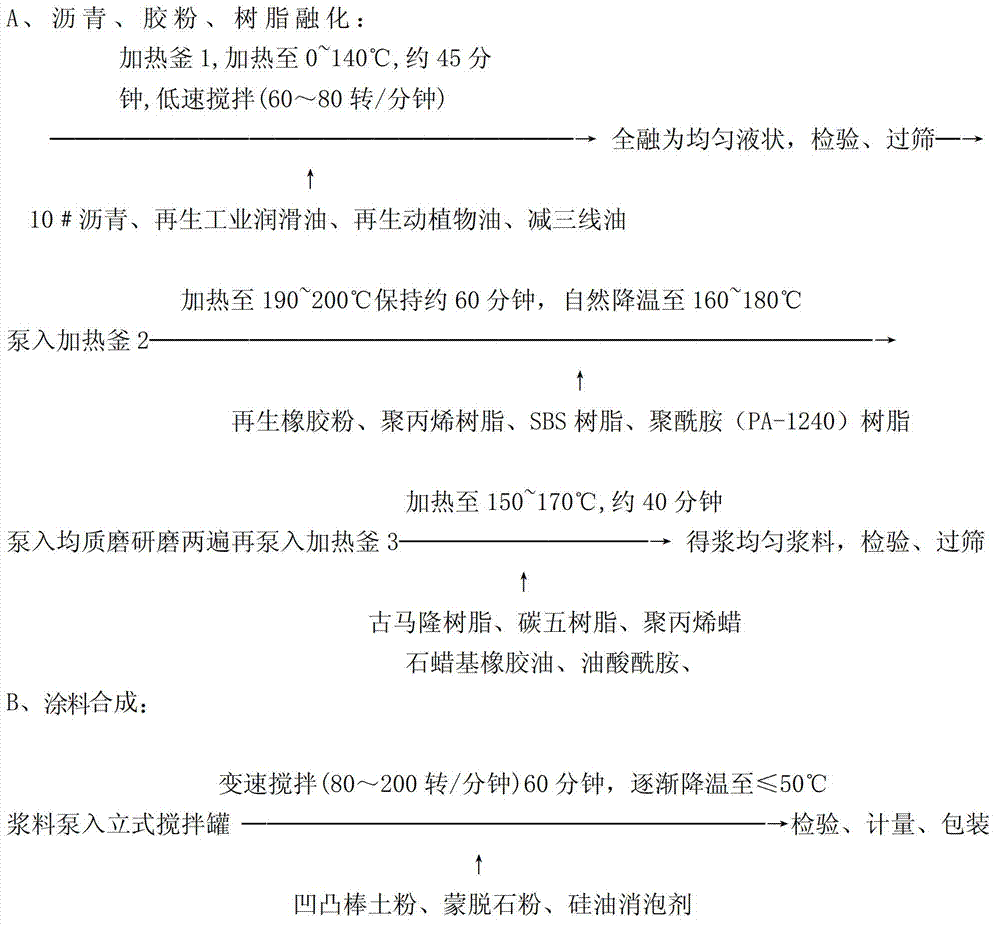

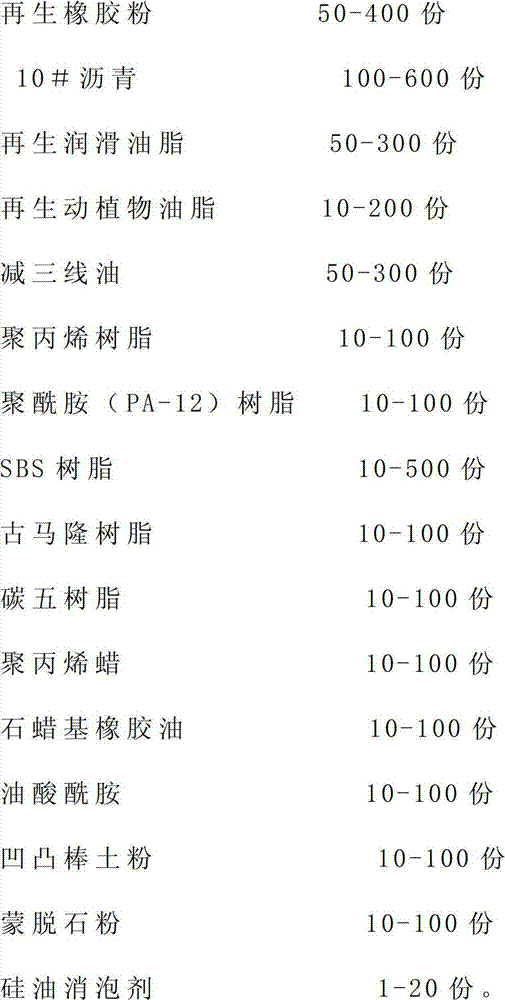

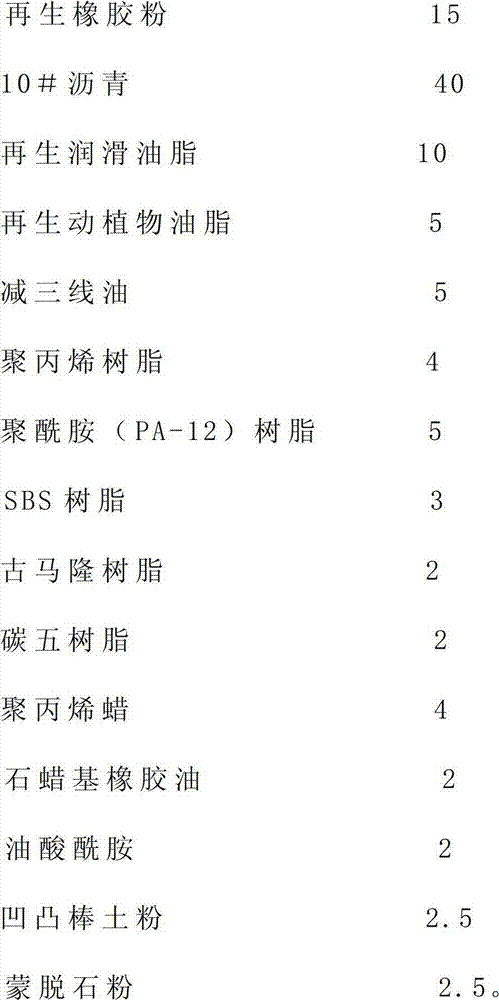

Non-solidifying rubber asphalt building waterproof coating

InactiveCN102925058AReduce pollutionImprove stabilityReclaimed rubber coatingsPolyamide coatingsDistilled oilFlora

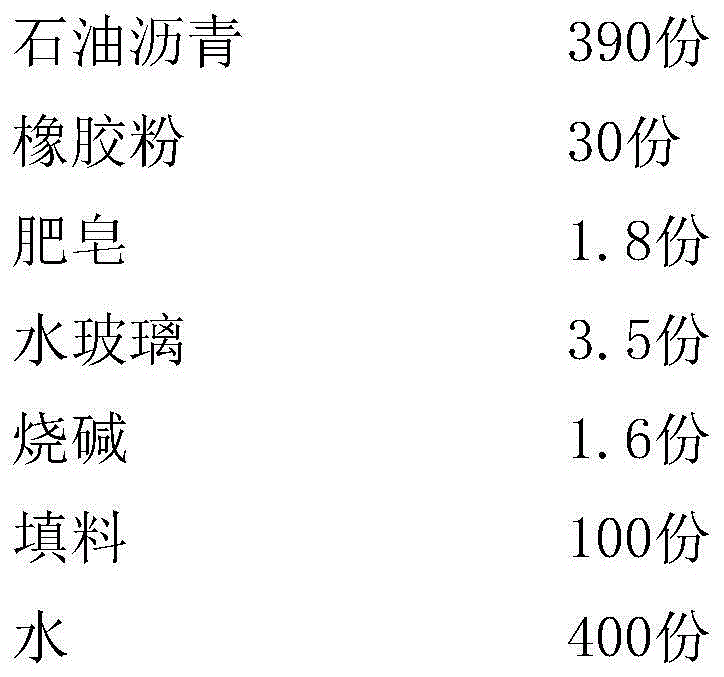

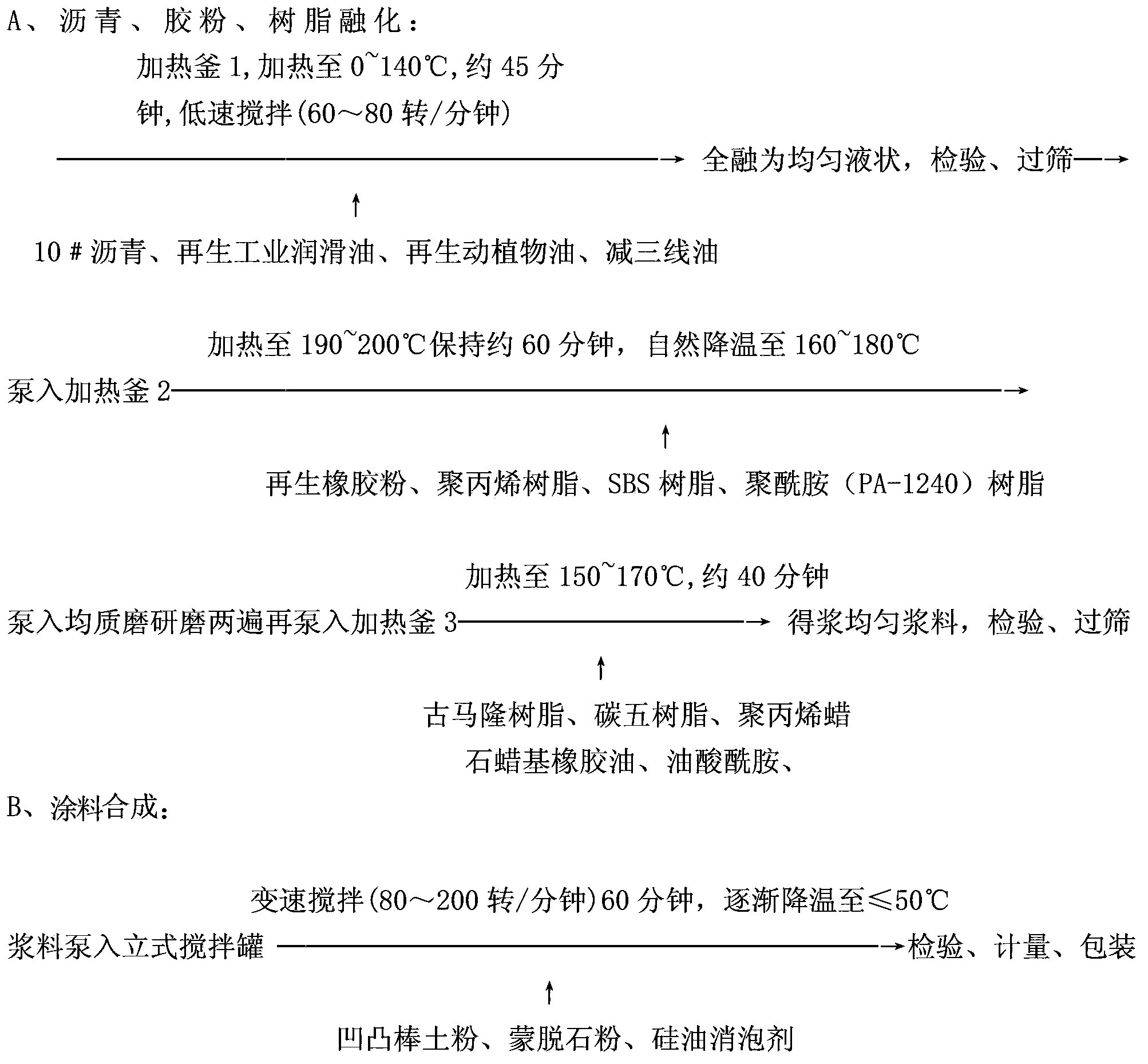

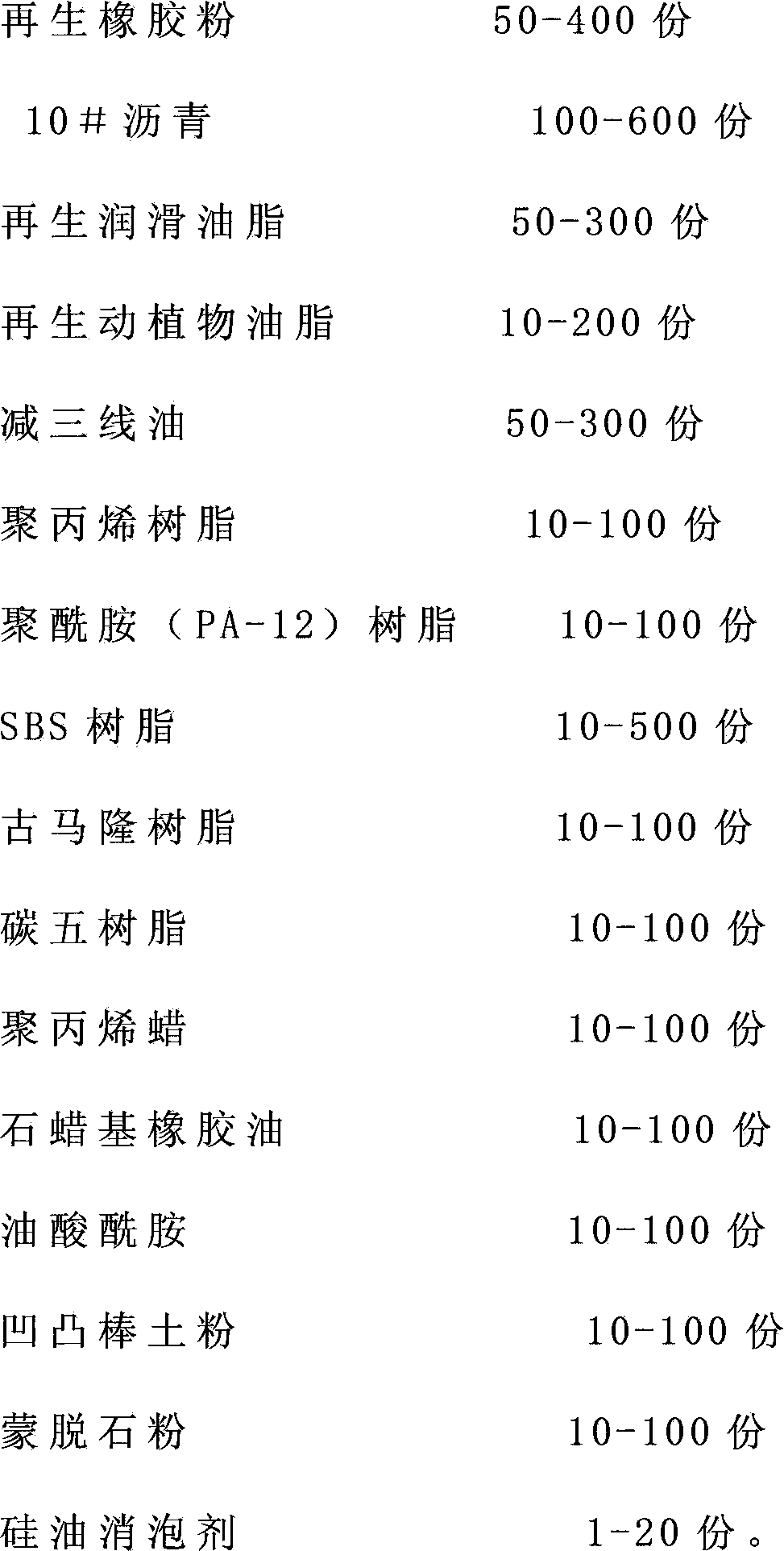

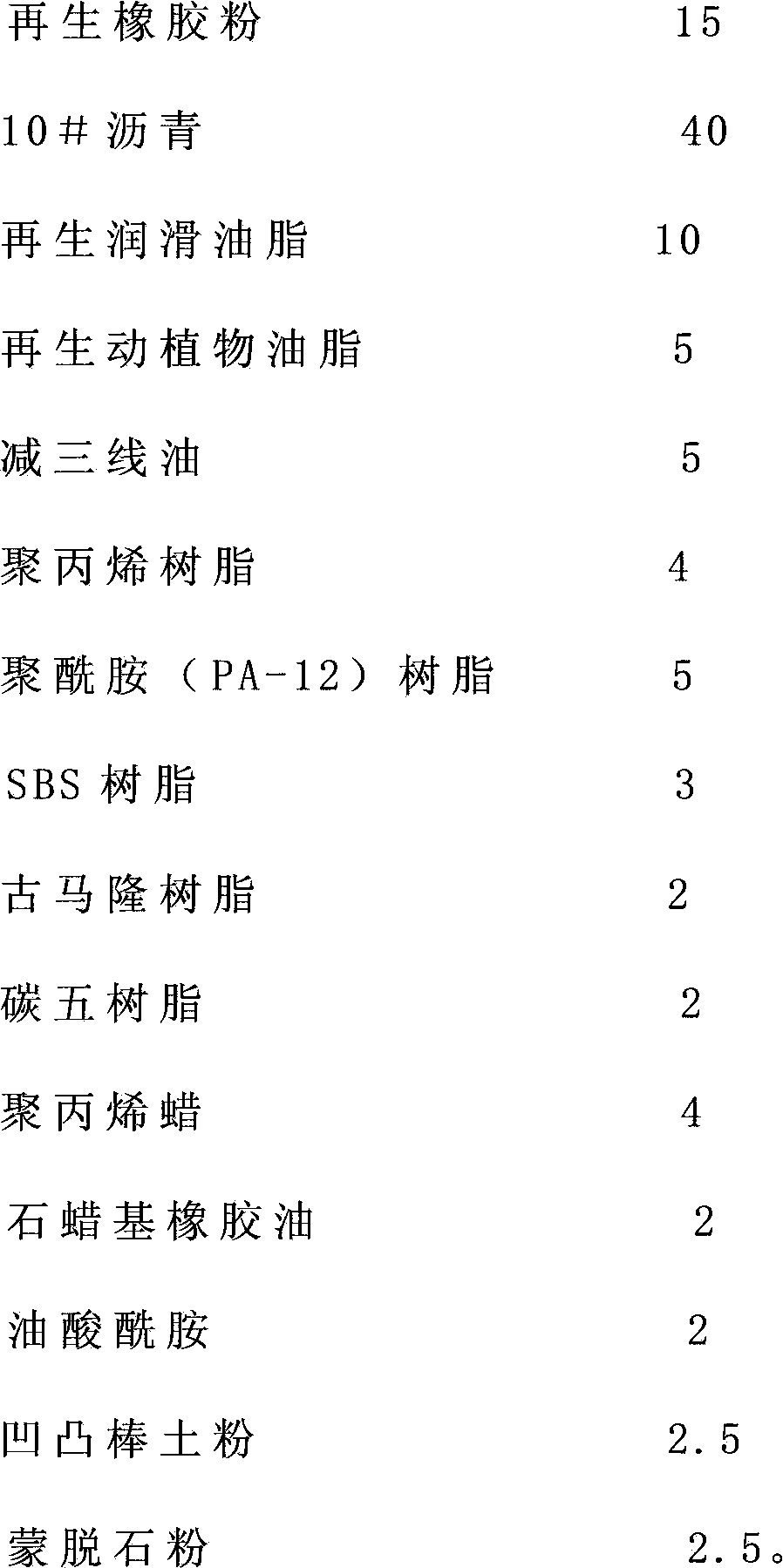

The invention discloses a non-solidifying (wriggling) rubber asphalt building waterproof coating and belongs to the field of chemical material building. The coating is prepared by processing the following raw materials: 50-400 parts of regenerated rubber powder, 100-600 parts of 10# asphalt, 50-300 parts of regenerated lubricating grease, 10-200 parts of regenerated flora and fauna grease, 50-300 parts of tertiary-distilled oil, 10-100 parts of polypropylene resin, 10-100 parts of polyamide (PA-12) resin, 10-500 parts of styrene butadiene styrene (SBS), 10-100 parts of coumarone resin, 10-100 parts of carbon 5 resin, 10-100 parts of polypropylene wax, 10-100 parts of paraffin base rubber oil, 10-100 parts of oleamide, 10-100 parts of attapulgite powder, 10-100 parts of smectite and 1 part to 20 parts of silicone oil defoamer. Inspections show that technical indexes of the non-solidifying (wriggling) rubber asphalt building waterproof coating are superior to JC / T864-2008 national material building industry standard of the 'polymer emulsion building waterproof coating', and stability and aging resistance of the coating are greatly improved.

Owner:刘力

Waterproof paint for roads and bridges and preparation method thereof

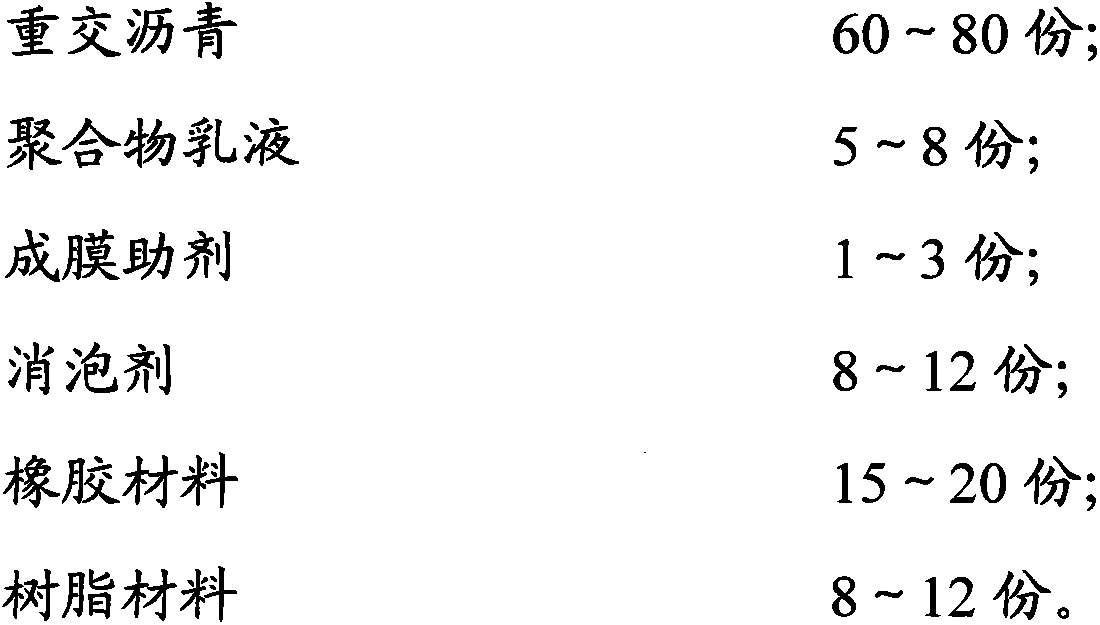

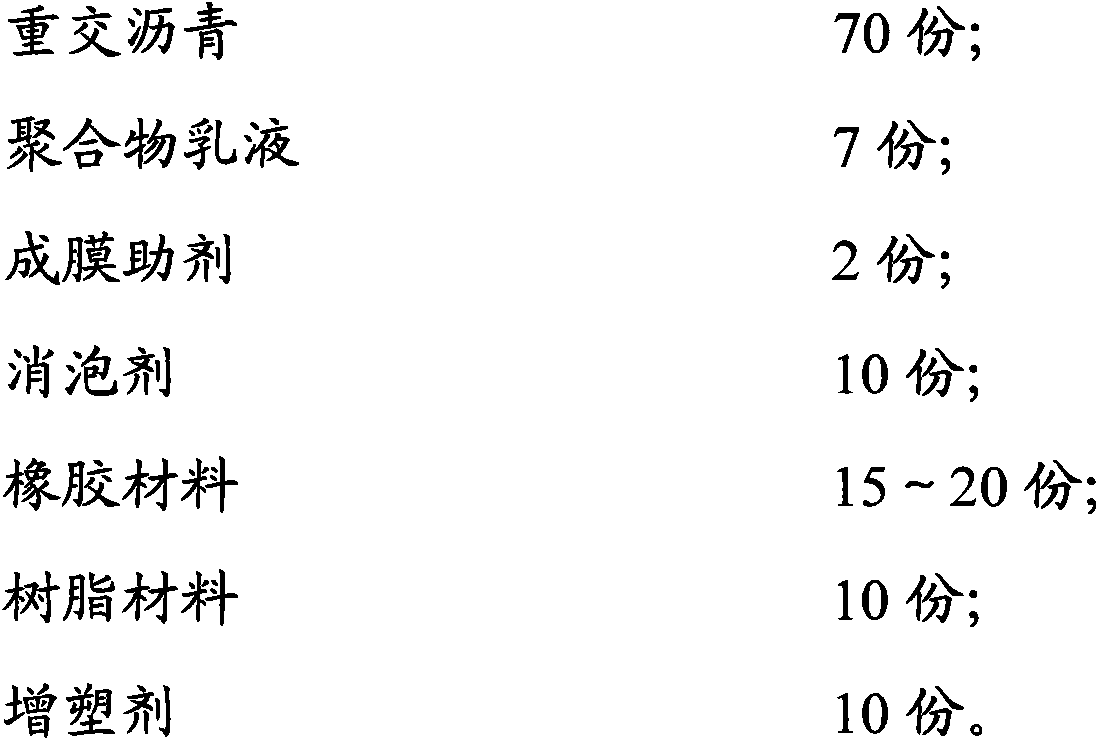

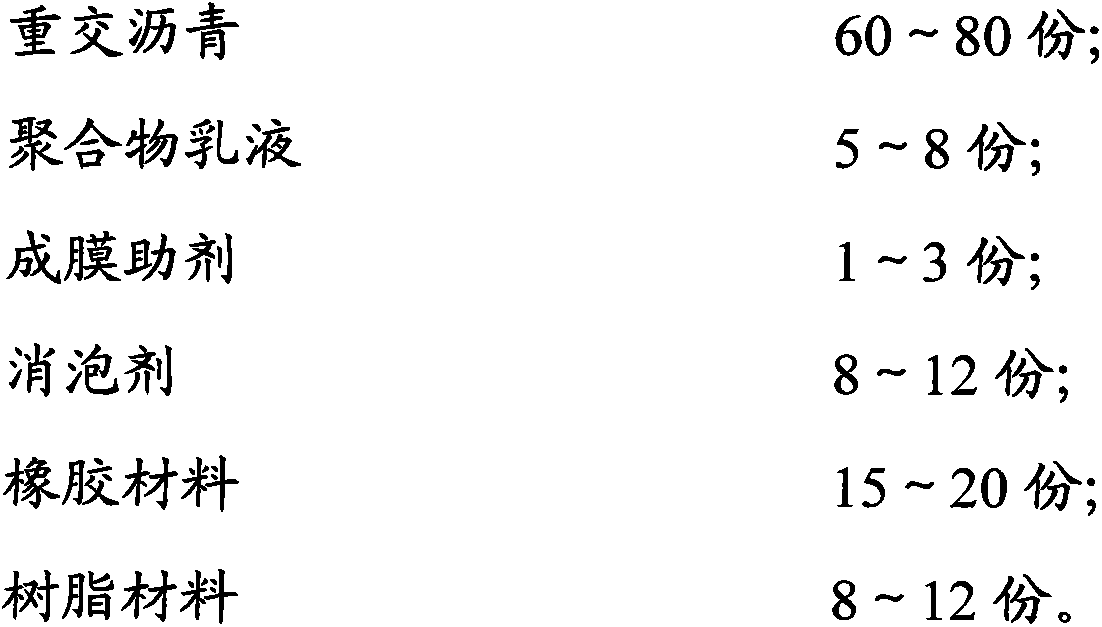

InactiveCN103642393AHigh softening pointExtended service lifeReclaimed rubber coatingsConjugated diene hydrocarbon coatingsRubber materialPolymer science

The invention provides a waterproof paint for roads and bridges and a preparation method thereof. The preparation method comprises the following steps: emulsifying 15-20 parts of rubber material, 5-8 parts of polymer emulsion and 8-12 parts of resin material in an emulsifying machine at 60-70 DEG C to obtain a rubber latex emulsifier mixed solution; and mixing the obtained rubber latex emulsifier mixed solution with 60-80 parts of heavy-duty road asphalt, 1-3 parts of film-forming assistant and 8-12 parts of defoaming agent in the emulsifying machine at 120-130 DEG C. The waterproof paint for roads and bridges has the advantages of heat resistance, cold resistance, acid resistance, alkali resistance, high softening point, long service life, favorable waterproof and impervious effects, wide raw material sources, accessible raw materials and simple preparation method.

Owner:宋传松

Macromolecule waterproof coating capable of being subjected to microwave heating and preparation method thereof

ActiveCN102732155AShorten the construction periodShort construction periodReclaimed rubber coatingsPolyurea/polyurethane coatingsPolymer scienceConductive polymer

The invention relates to thermoplastic macromolecule waterproof coatings, in particular relates to a thermoplastic macromolecule waterproof coating capable of being subjected to microwave heating and a preparation method thereof. The macromolecule waterproof coating capable of being subjected to microwave heating is prepared by shearing at high temperature and stirring the following components in percentage by weight: 10-50 percent of elastic thermoplastic polymer, 20-60 percent of asphalt, 5-20 percent of diluting agent, proper amount of compatilizer and 6-30 percent of absorption microwave materials. The absorption microwave materials comprise 0.5-5 percent of conducting polymer and 5-25 percent of waste vulcanized rubber powder. The macromolecule waterproof coating can be formed by the first time, so that the working period is greatly shortened, a sealing basic layer is effectively solved, the tension fracture of a waterproof layer caused by cracking of the basic layer is overcome, and the waterproofing reliability is improved; and meanwhile, the macromolecule waterproof coating can be used for multiple purposes to fully play a role in the advantages and the characteristics of respective materials, so that the process is simple and convenient, the macromolecule waterproof coating can be quickly constructed, the maintenance is avoided, and the working period is short.

Owner:浙江鲁班建筑防水有限公司

Coating composition

An aqueous coating composition comprising a mixture of recycled rubber particles, and particles at least one of glass or plastic particles, graphite particles and fluorinated resin particles such as polytetrafluoroethytlene and a suspension agent or resin. Various embodiments are useful for coating suitable for highways and parking lots, roofs or swimming pools and metal surfaces and for “rubberizing” marine and other manufactured products.

Owner:SAVIN RONALD R

Non-cured rubber asphalt waterproof coating material

InactiveCN105238269AImprove flame retardant performanceImprove high temperature resistanceFireproof paintsReclaimed rubber coatingsEpoxyStearic acid

The present invention discloses a non-cured rubber asphalt waterproof coating material, wherein the raw materials comprise, by weight, 25-35 parts of modified asphalt, 3-5 parts of styrene-butadiene rubber, 18-24 parts of methyl acrylate, 3-5 parts of a 120* solvent oil, 8-15 parts of regeneration glue powder, 23-26 parts of light calcium carbonate, 5-7 parts of carbon black, 4-9 parts of a rosin resin, 0.5-2.5 parts of an epoxy resin, 2-4 parts of calcium stearate, 3-5 parts of epoxyfuroic-oleic butyl, 2-3 parts of dihydroquinoline, 0.5-0.7 part of a light stabilizer 994, 0.6-0.8 part of phenyl salicylate, 0.5-1 part of PE-g-TS, 1-3 parts of diethylene triamine, 0.1-0.5 part of stearic acid, 0.05-0.1 part of zinc oxide, and 3-5 parts of vinyl triethoxysilane. The non-cured rubber asphalt waterproof coating material of the present invention has characteristics of good waterproof performance, good fire-retardant property, and high mechanical property.

Owner:天长市金牛防水防腐材料有限公司

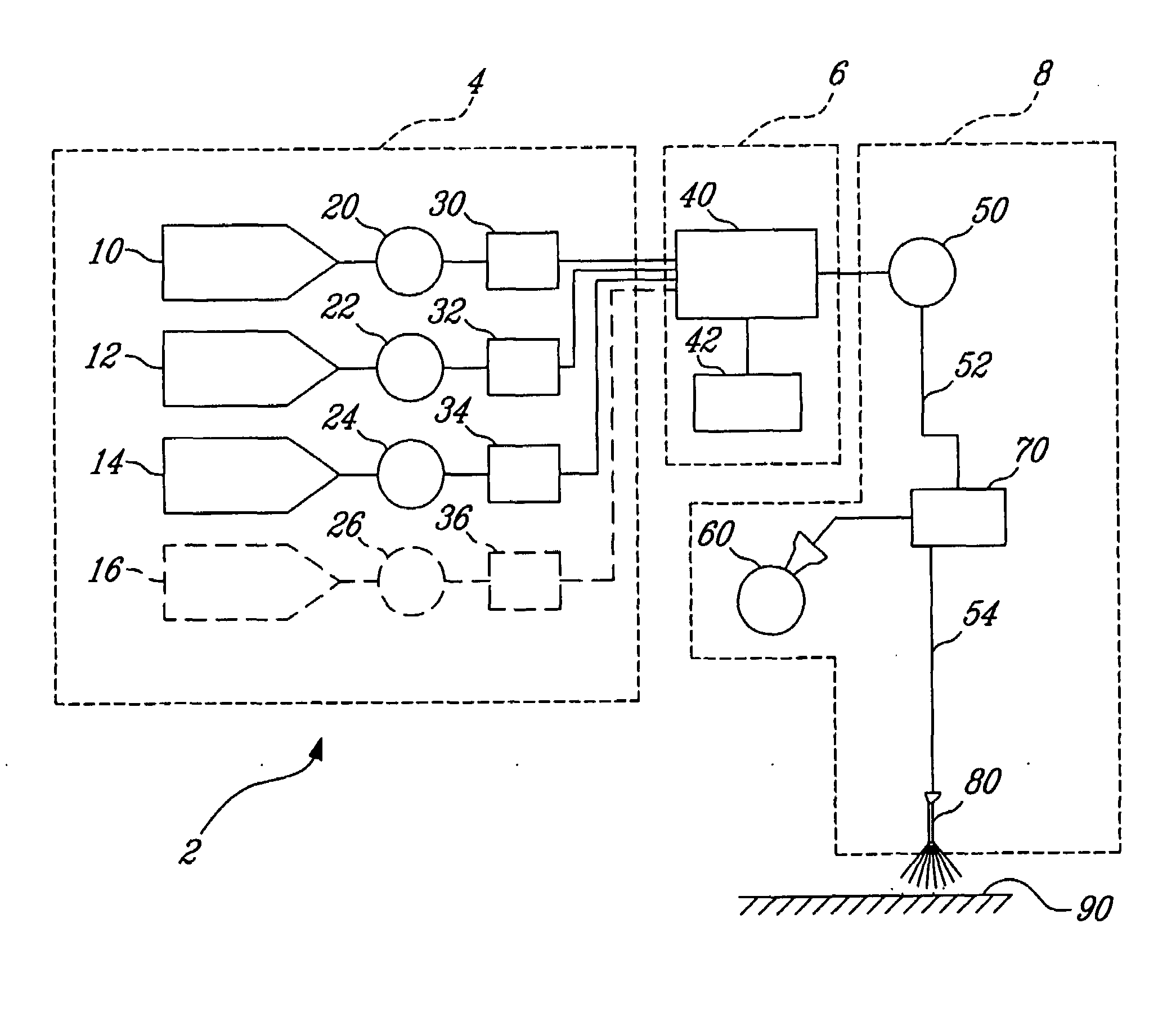

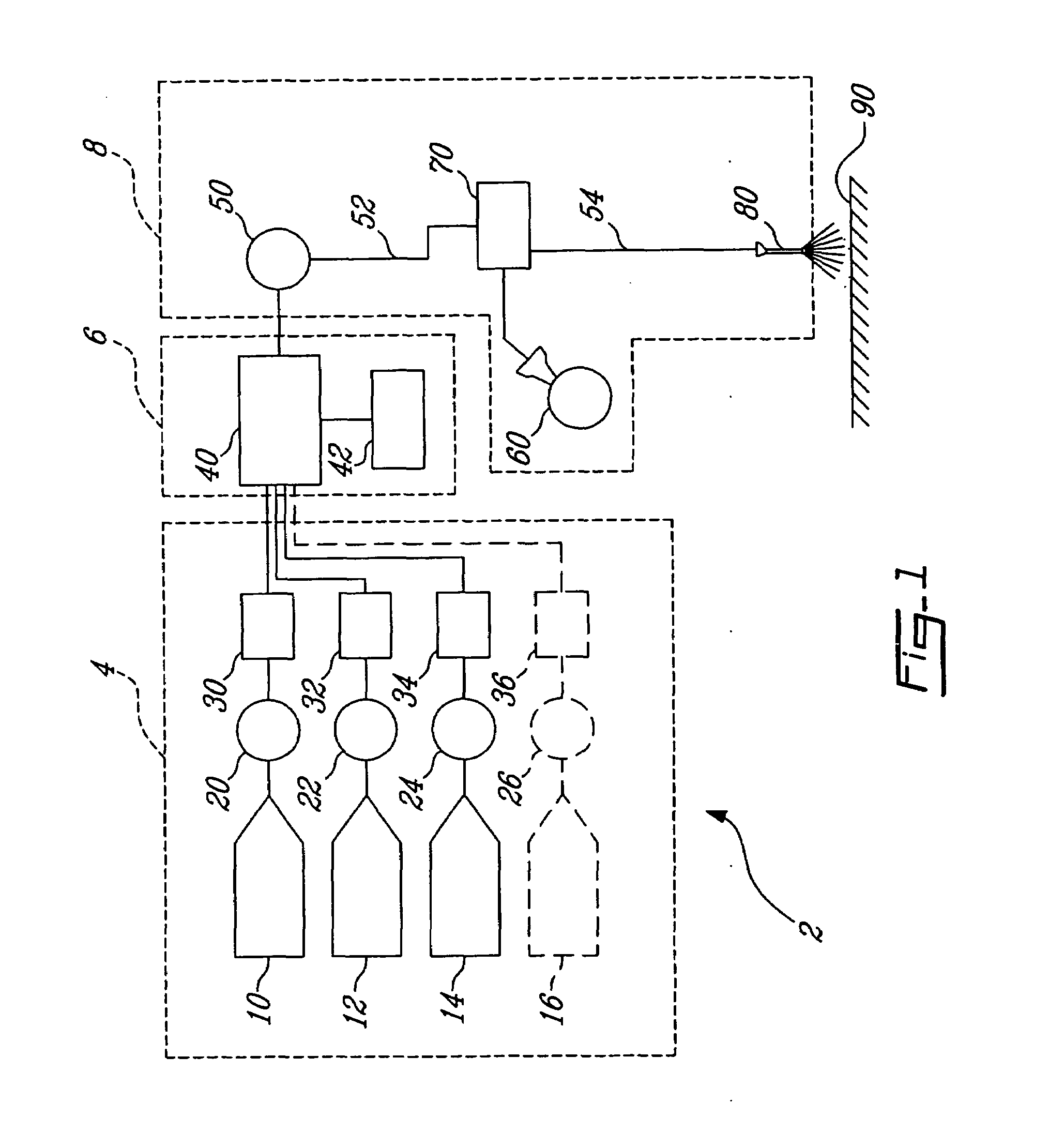

Sprayable waste rubber-based coating

The invention generally relates to surface coating composition, method and apparatus for coating a surface. The surface coating composition is comprising a recycled rubber product, one or more binding agent and optionally one or more additional agent.

Owner:MALBOEUF MATHIEU +1

Preparation method of liquid rubber asphalt water-proof paint

ActiveCN102492365AHeat resistantImprove aging resistanceReclaimed rubber coatingsChloropene polymer coatingsCrack resistancePolymer science

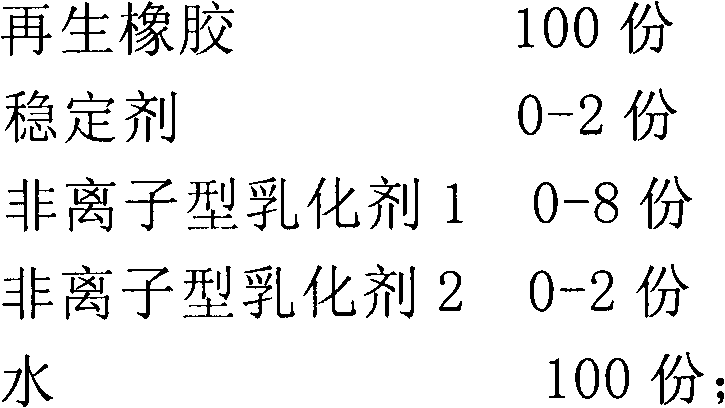

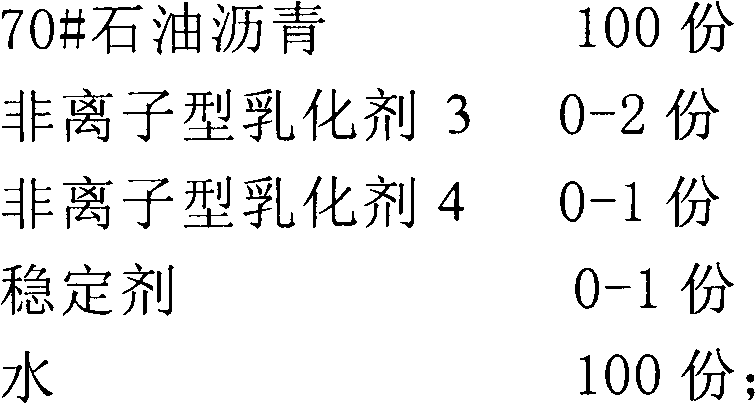

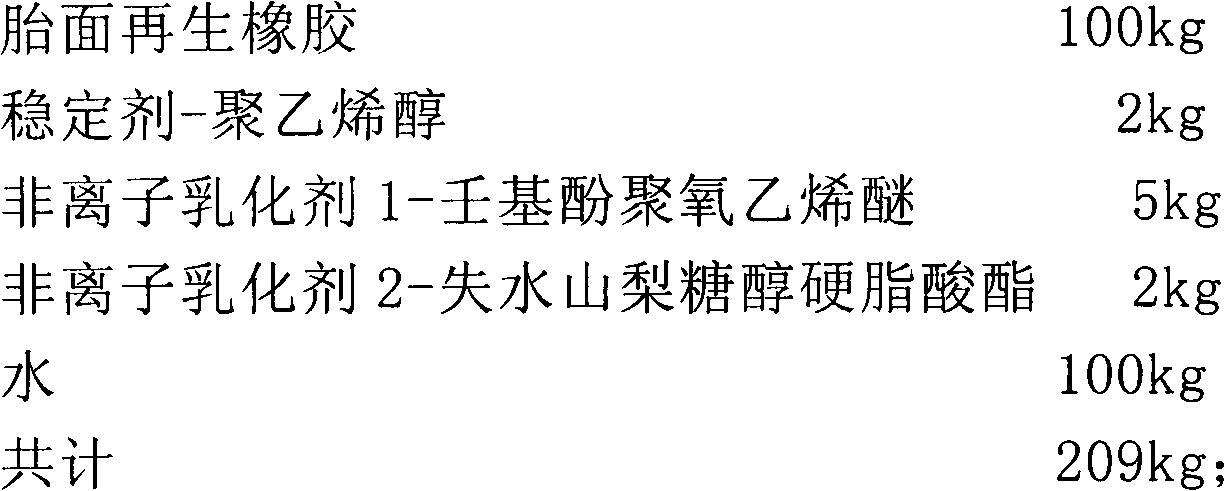

The invention provides a preparation method of liquid rubber asphalt water-proof paint and relates to a preparation method of water-proof paint. The preparation method provided by the invention is a preparation method of a rubber asphalt emulsion by taking a non-ionic surfactant as an emulsifying agent. The preparation method comprises the following steps: 1, preparing a non-ionic reclaimed rubber emulsion from the following components in parts by weight: 100 parts of reclaimed rubber, 0-2 parts of stabilizing agent, 0-8 parts of non-ionic emulsifying agent 1, 0-2 parts of non-ionic emulsifying agent 2 and 100 parts of water; 2, preparing a non-ionic asphalt emulsion from the following components in parts by weight: 100 parts of 70# petroleum asphalt, 0-2 parts of non-ionic emulsifying agent 1, 0-1 part of non-ionic emulsifying agent 2, 0-1 part of stabilizing agent and 100 parts of water; and 3, preparing the liquid rubber asphalt water-proof paint from the following components in parts by weight: 70-80 parts of non-ionic reclaimed rubber emulsion, 20-30 parts of chloroprene rubber latex and 100 parts of non-ionic asphalt emulsion. The liquid rubber asphalt water-proof paint prepared by using the method can be widely used in projects with high thermal resistance requirement and railway, highway, municipal bridges and building waterproof and anticorrosive projects which have high crack resistance requirements.

Owner:天津四十二站检测技术有限公司

Light absorbing layer for photo-chromic systems

InactiveUS8007900B2Unwanted exposureGuaranteed accuracyThermometers using mean/integrated valuesPaper coatingUltraviolet lightsWavelength

A composition which comprises a light absorbing layer adhered to an underlying layer containing a photo-chromic colorant, which photo-chromic colorant has been activated by exposure to UV light to undergo a reversible color change, and wherein the rate of color reversion is dependent on temperature, is provided. The ultraviolet light and / or visible light absorbing layer may also contain components which reflect rather than absorb light and can be conveniently applied via thermal transfer or ink jet to a substrate comprising the photo-chromic colorant to protect it from unwanted exposure to UV and / or certain wavelengths visible light. The composition is conveniently employed in a temperature time indicator (TTI).

Owner:BASF AG

Method for chemical-modification reclaimed rubber asphalt waterproofing paint

InactiveCN101113261AHigh bonding strengthHigh tensile strengthReclaimed rubber coatingsAntifouling/underwater paintsPolymer scienceBituminous waterproofing

The invention relates to a preparation method of a chemical modified bitumen reclaimed rubber and asphalt waterproof coating. According to the proportions of 200g 40 mesh tread compound power, 40g No. 60 petroleum asphalt, 10g No. 200 petroleum asphalt, 4g 420 activator and 4g rosin, materials are put into a reactor provided with a high-speed stirring device and reacted for 2 hours when the reaction temperature is about 220 DEG C; then 14g modifier maleic anhydride is added at the same temperature and the mixture is continued to be stirred at 200 DEG C and reacted for 15min; after mixing, the modified reaction reclaimed rubber is added with 850g toluene and the mixture is dispersed by a high speed stirrer. The invention has the advantages of improving adhesive strength and tensile strength.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

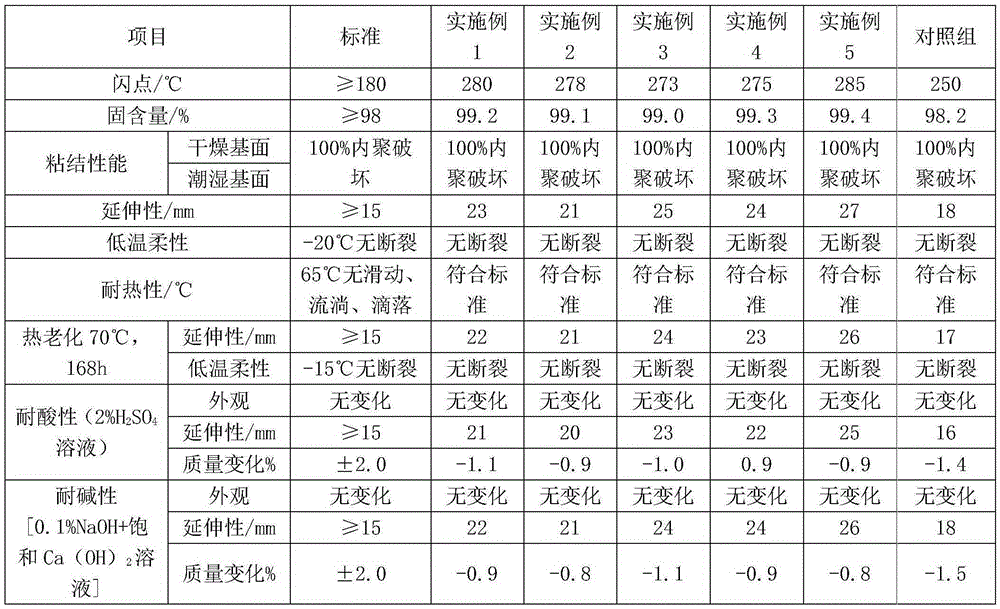

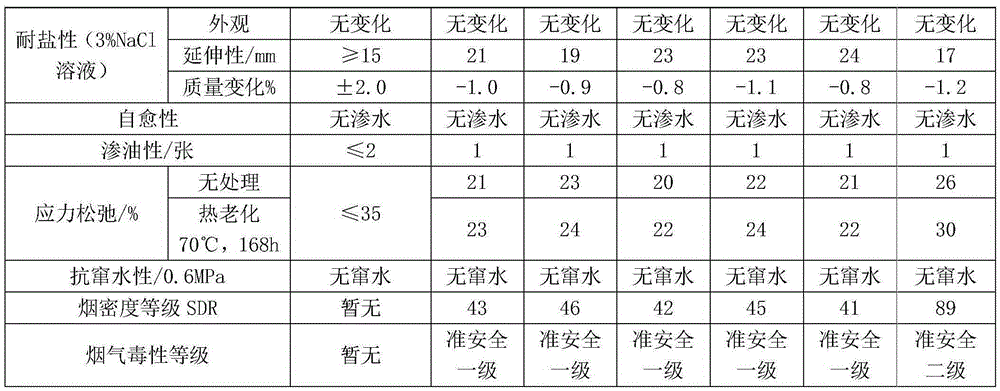

Flame-retardant and smoke-inhibition type non-cured rubber asphalt waterproof coating material

InactiveCN105238270ARich pore structureImprove adsorption capacityFireproof paintsReclaimed rubber coatingsParaffin waxBituminous waterproofing

The present invention discloses a flame-retardant and smoke-inhibition type non-cured rubber asphalt waterproof coating material, wherein the raw materials comprise, by weight, 25-30 parts of asphalt, 3-7 parts of a styrene-butadiene-styrene block copolymer, 12-16 parts of octane oil, 4-7 parts of paraffin oil, 10-16 parts of recycled rubber powder, 22-28 parts of talc powder, 3-5 parts of limestone powder, 5-8 parts of a rosin resin, 1-3 parts of a C5 petroleum resin, 2-4 parts of paraffin, 1-2 parts of p-phenylenediamine, 0.2-0.6 part of a light stabilizer 622, 0.4-0.7 part of 2-hydroxy-4-methoxy benzophenone, 1-2 parts of PP-g-MAH, 0.4-0.8 part of dicumyl peroxide, 0.2-0.4 part of stearic acid, 0.1-0.2 part of zinc oxide, 1-2 parts of 3-aminopropyl triethoxysilane, 5-9 parts of a flame retardant agent, 1-3 parts of a modified smoke suppressant, and 0.8-1.2 parts of a coumarone resin. The flame-retardant and smoke-inhibition type non-cured rubber asphalt waterproof coating material of the present invention has characteristics of good waterproof performance, good flame retardant performance, and good smoke suppression performance.

Owner:天长市金牛防水防腐材料有限公司

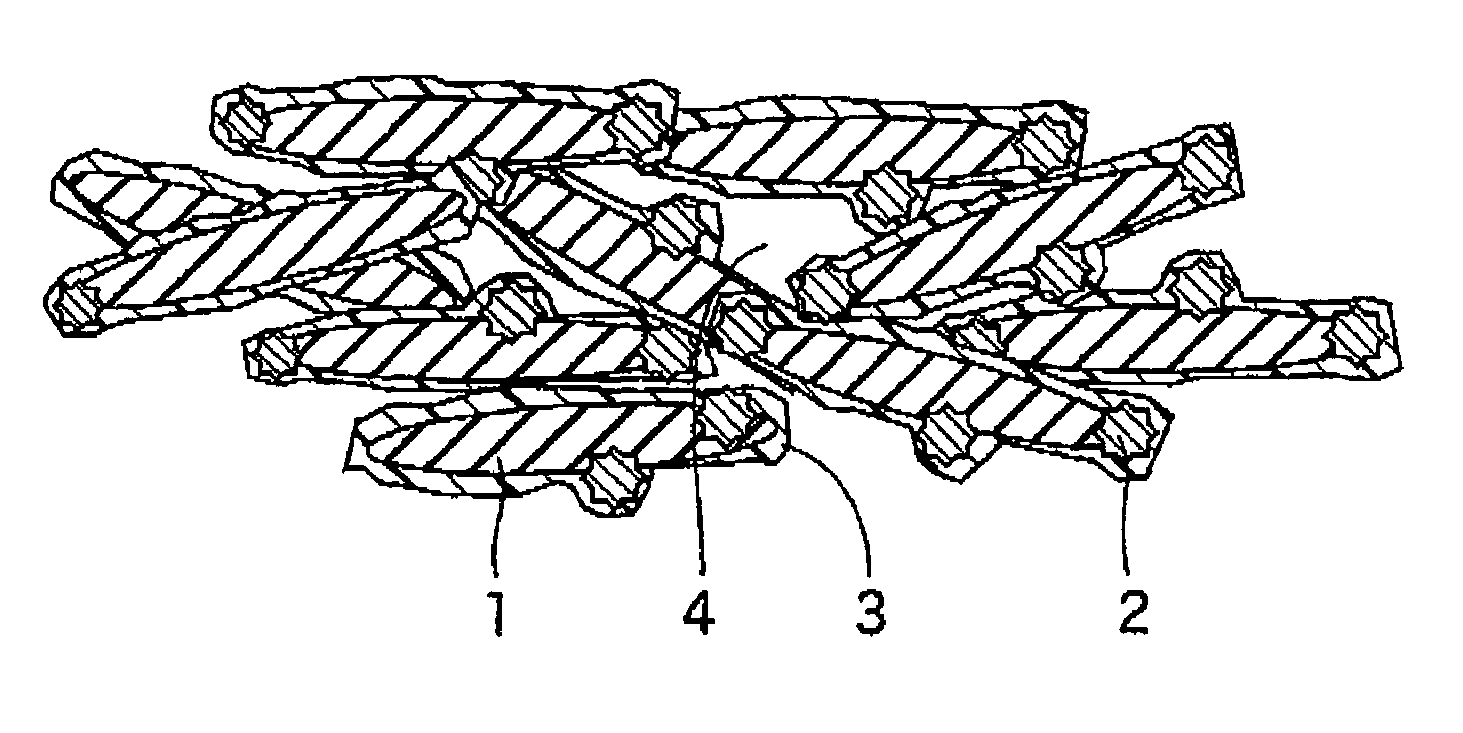

Porous elastic pavement material

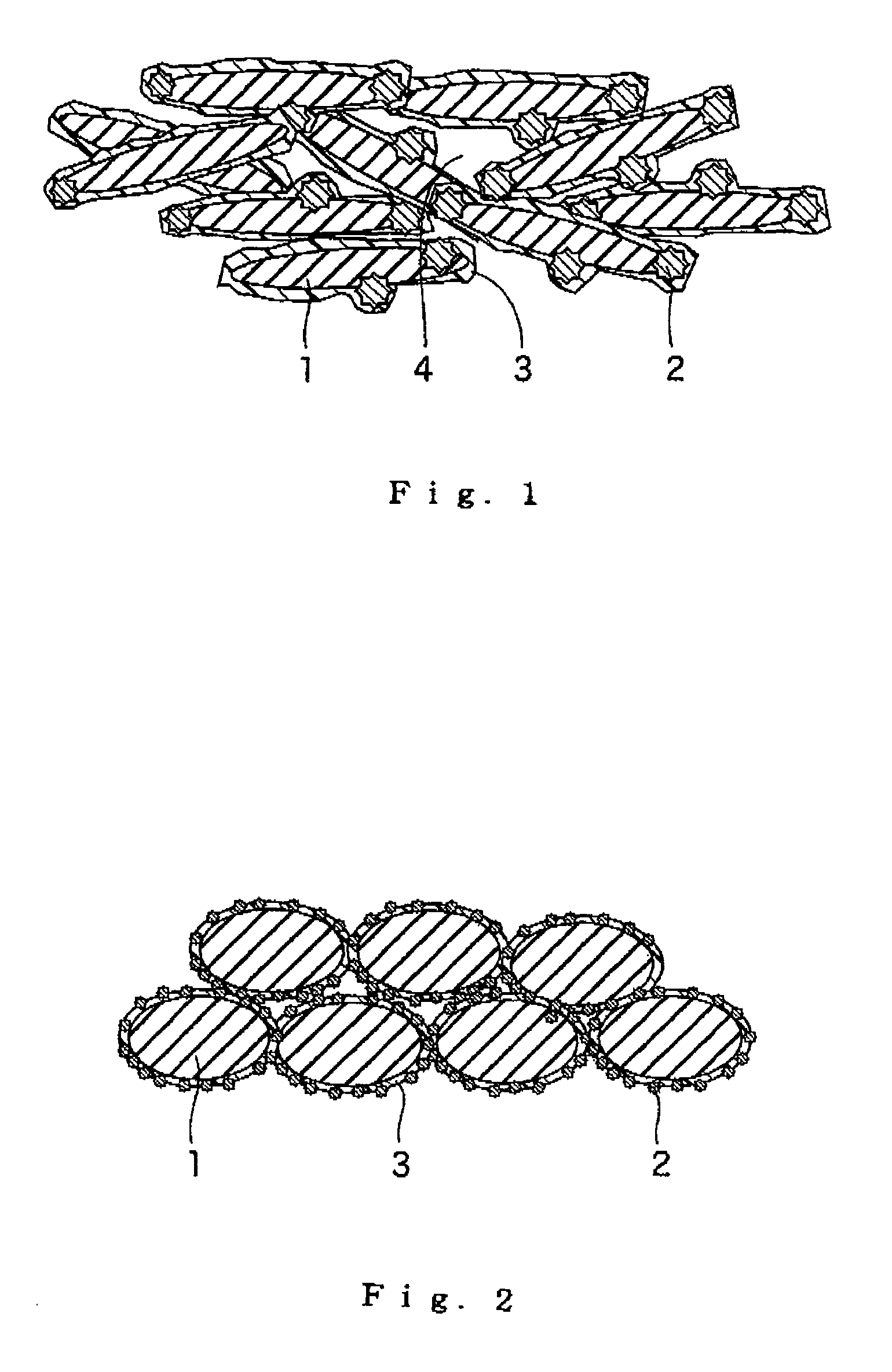

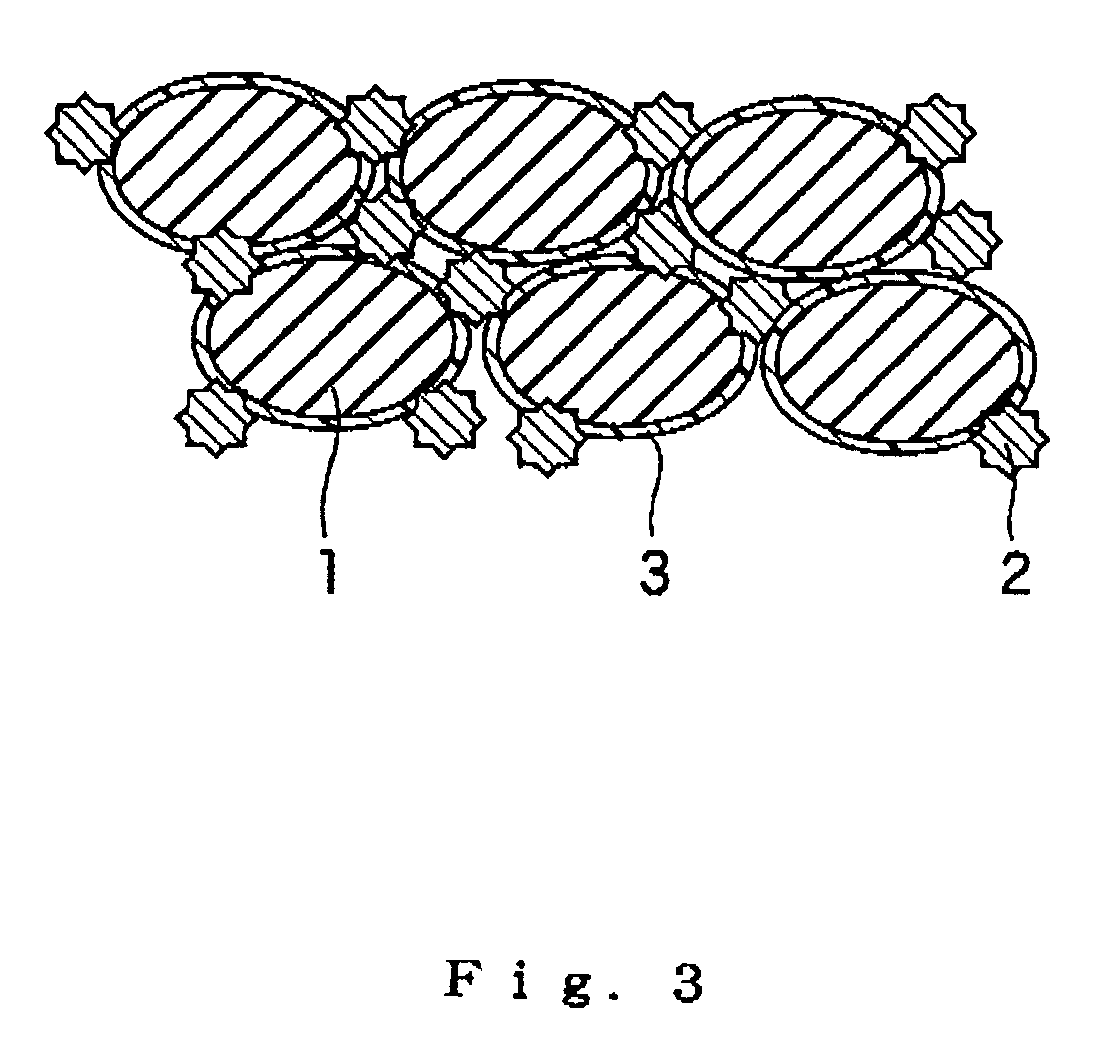

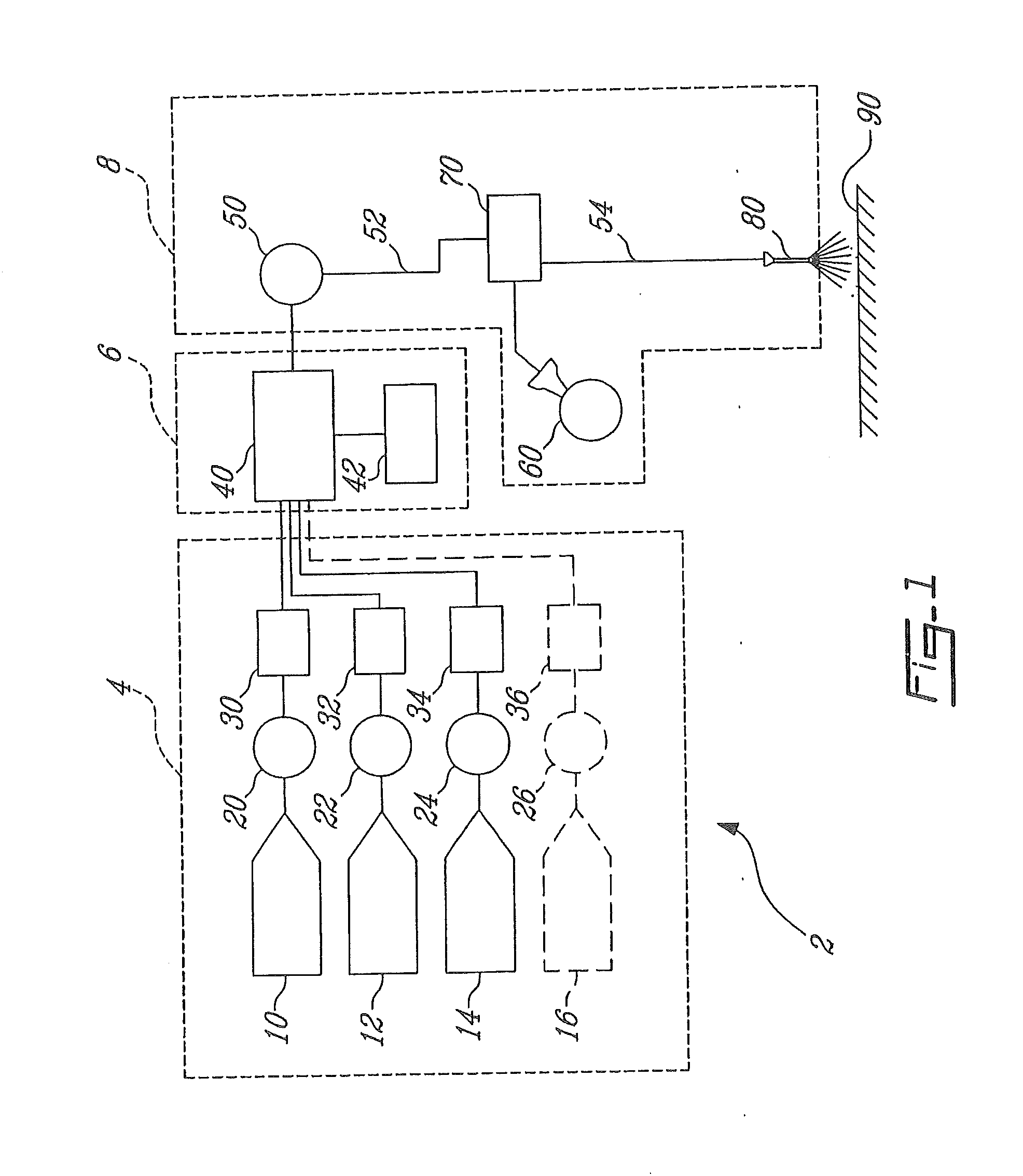

InactiveUS7384469B2Without deteriorationReclaimed rubber coatingsIn situ pavingsRoad surfaceMaterials science

A porous elastic pavement material is provided which is excellent in noise reducing effect and yet sustainably has a wet state slip resistance for a long period of time. The porous elastic pavement material comprises elastic aggregates (1), hard aggregates (2) and a binder (3) which binds the elastic aggregates (1) and the hard aggregates (2), wherein the hard aggregates (2) have an average particle diameter of 0.2 to 2 mm, and are present in a proportion of 25 to 65 vol % based on the elastic aggregates (1).

Owner:SUMITOMO RIKO CO LTD

Non-oil-penetrating type creep rubber waterproof coating and a preparing method thereof

ActiveCN106566324AHas never solidified and become brittleLow VOCReclaimed rubber coatingsConjugated diene hydrocarbon coatingsPolymer sciencePolystyrene

The invention relates to non-oil-penetrating type creep rubber waterproof coating. The coating is characterized in that the coating includes, by mass, 3-20% of butyl rubber, 5-10% of styrene-butadiene rubber, 35-60% of rubber powder, 5-20% of a polymer modifying agent, 5-25% of asphalt and 5-15% of an inorganic modifying material; the polymer modifying agent is one of or a mixture of materials selected from a group consisting of polypropylene, polystyrene, bis(triethoxysilylpropyl) tetrasulfide, bis(triethoxysilylpropyl) disulfide, gamma-mercaptopropyl trimethoxysilane, oxidized polyethylene wax and ethylene-vinyl acetate copolymer wax; and the inorganic modifying material is glass microbeads, precipitated calcium carbonate powder, talcum powder, ground calcium carbonate powder or a mixture thereof. The actually measured VOC content of the coating is less than 10, and no oil is penetrated at 60 DEG C.

Owner:明象新材料科技(上海)有限公司

Sprayable waste rubber-based coating

InactiveUS20120252927A1Reclaimed rubber coatingsAntifouling/underwater paintsWaste rubberSurface coating

Surface coating composition, method and apparatus for coating a surface. The surface coating composition comprises a recycled rubber product, one or more binding agent and optionally one or more additional agent.

Owner:MALBOEUF MATHIEU +1

Method for preparing polymer modified reclaimed rubber waterproofing paint

InactiveCN101117475AHigh bonding strengthHigh elongation at breakReclaimed rubber coatingsAntifouling/underwater paintsPolymer sciencePolymer modified

A preparation method of polymer modified reclaimed rubber waterproof paint is provided, wherein waste rubber powder is mixed with proper oleic acid, potassium hydroxide, ammonia and polyvinyl alcohol after desulfurization reaction, and made into reclaimed latex; 10 number and 100 number petroleum asphalt mixture, OP emulsifier, water, sodium hydroxide, water glass and polyvinyl alcohol are mixed according to a certain proportion and made into bitumen emulsion; the reclaimed latex and bitumen emulsion are uniformly stirred to become reclaimed adhesive asphalt emulsion; styrene, butyl acrylate and acrylic acid are added into the deionized aqueous solution containing ammonium persulfate, anionic emulsifier and nonionic surfactant, executed with polymerization for 2 hours under the temperature of 100 DEG C, and added with ammonia at last to be neutralized and made into stable emulsion; reclaimed adhesive asphalt emulsion is mixed with phenylacetic acid-acrylate copolymer. The present invention has the advantages of improved adhesive strength and elongation at break.

Owner:ZHONGHONG (TIANJIN) IND CO LTD

One-pack type unhardening adhesive film waterproofing material using waste rubber and method for manufacturing same

ActiveCN103298896AIncrease elasticityViscosity adjustmentReclaimed rubber coatingsOther rubber coatingsWaste rubberBitumen emulsion

The present invention relates to a one-pack type unhardening adhesive film waterproofing material using waste rubber and to a method for manufacturing same, by mixing waste rubber chips with oil, heating, and grinding same into fine powder using mechanical breaking stress, and more particularly, to an one-pack type unhardening adhesive film waterproofing material using waste rubber and to a method using waste rubber that is extracted by adding heat to waste rubber to suppress the elasticity of the material, grinding the waste rubber chips into fine powder using mechanical breaking stress, and mixing with emulsified asphalt, SBR, and NR to extract the waste rubber. The present invention comprises the following steps: mixing 10 to 15 parts by weight of the waste rubber chips and 20 to 25 parts by weight of oil and heating same to 200 to 230 DEG C, and then using mechanical breaking stress to render the waste rubber chips into fine powder; mixing with 29.6 to 40 parts by weight of emulsified asphalt; mixing with 8 to 13 parts by weight of filler material, 1 to 2 parts by weight of a surfactant, and 0.1 to 0.4 parts by weight of anti-aging material while maintaining the temperature at 90 to 100 DEG C; and mixing 3 to 6 parts by weight of SBR for adjusting viscosity.

Owner:瑞新株式会社

Self-adhesive polymer modified bituminous waterproof roll material and preparation method thereof

The invention provides a self-adhesive polymer modified bituminous waterproof roll material and a preparation method thereof. The self-adhesive polymer modified bituminous waterproof roll material isprepared from, by weight, 37-55 parts of bitumen, 25-50 parts of a modifying agent and 10-25 parts of first filler. The modifying agent comprises linearized activated rubber, second filler and a rubber cross-linking additive. The linearized activated rubber is obtained by desulfurization of waste rubber powder, and the weight percentage content of linearized molecules is larger than or equal to 75%. The modifying agent comprises the highly linearized activated rubber obtained by desulfurization of waste rubber powder, and close interface combination can be formed between the modifying agent and components of the roll material. The linearized activated rubber intrinsically comprises some gradient small molecules to serve as a softening agent, and adhesiveness of the roll material can be effectively improved without adding of a micromolecular softening agent and the like in an application process. Further, due to a proportional relation of the components, the roll material has advantagesof excellent mechanical performances, high adhesiveness and low micromolecular mobility.

Owner:北京路德永泰环保科技有限公司

Macromolecule waterproof coating capable of being subjected to microwave heating and preparation method thereof

ActiveCN102732155BShorten the construction periodShort construction periodReclaimed rubber coatingsPolyurea/polyurethane coatingsPolymer scienceConductive polymer

The invention relates to thermoplastic macromolecule waterproof coatings, in particular relates to a thermoplastic macromolecule waterproof coating capable of being subjected to microwave heating and a preparation method thereof. The macromolecule waterproof coating capable of being subjected to microwave heating is prepared by shearing at high temperature and stirring the following components in percentage by weight: 10-50 percent of elastic thermoplastic polymer, 20-60 percent of asphalt, 5-20 percent of diluting agent, proper amount of compatilizer and 6-30 percent of absorption microwave materials. The absorption microwave materials comprise 0.5-5 percent of conducting polymer and 5-25 percent of waste vulcanized rubber powder. The macromolecule waterproof coating can be formed by the first time, so that the working period is greatly shortened, a sealing basic layer is effectively solved, the tension fracture of a waterproof layer caused by cracking of the basic layer is overcome, and the waterproofing reliability is improved; and meanwhile, the macromolecule waterproof coating can be used for multiple purposes to fully play a role in the advantages and the characteristics of respective materials, so that the process is simple and convenient, the macromolecule waterproof coating can be quickly constructed, the maintenance is avoided, and the working period is short.

Owner:浙江鲁班建筑防水有限公司

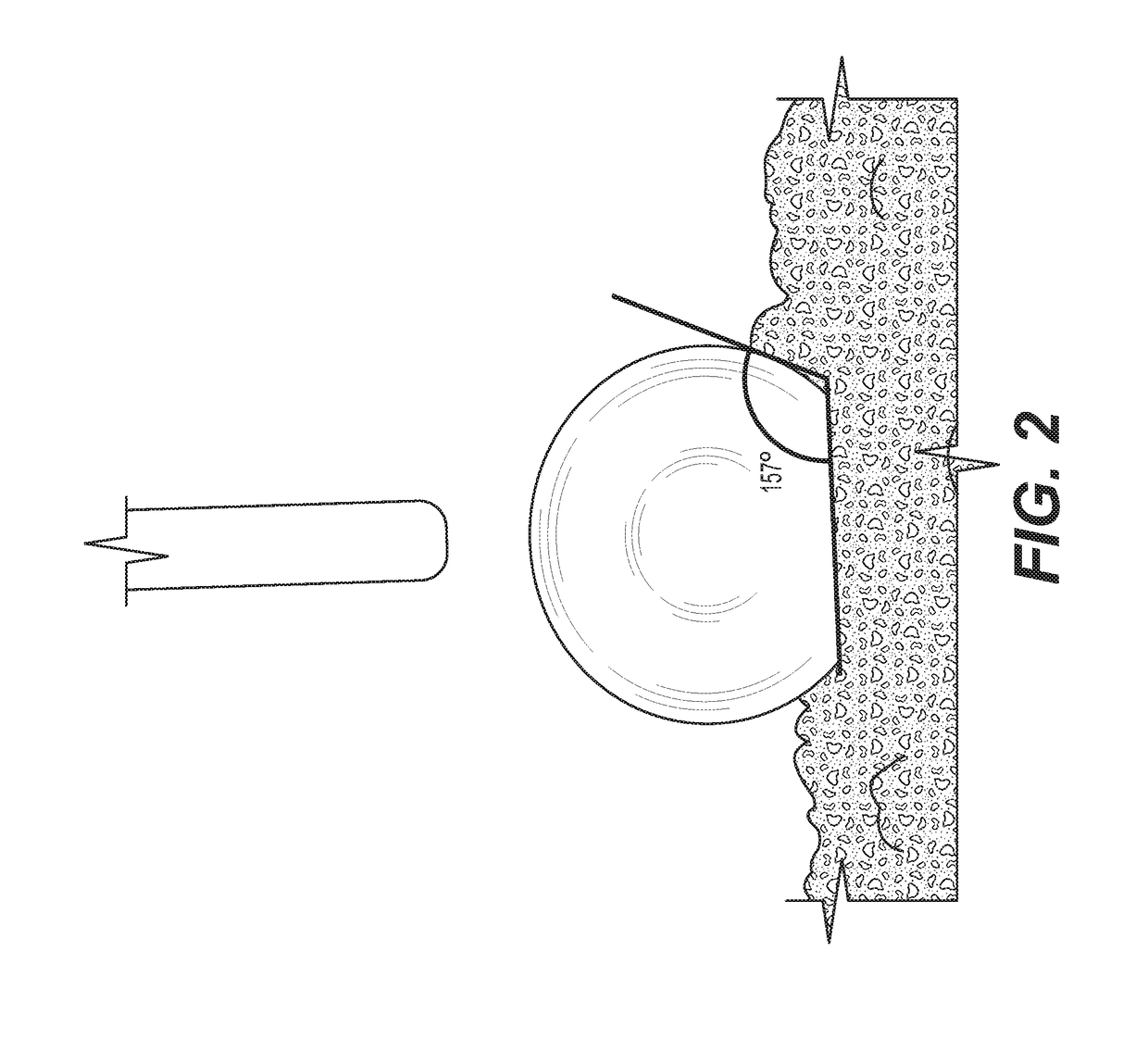

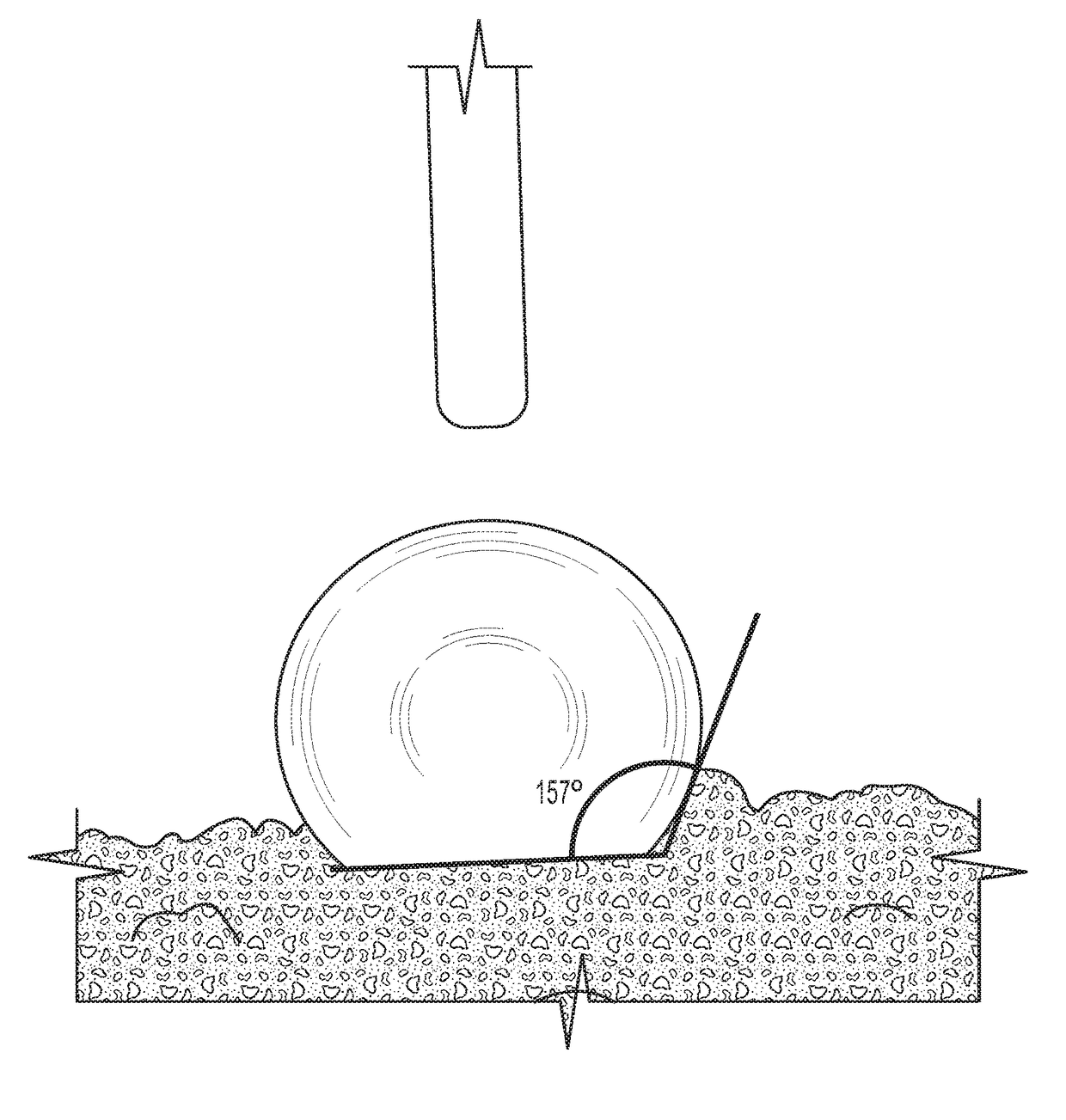

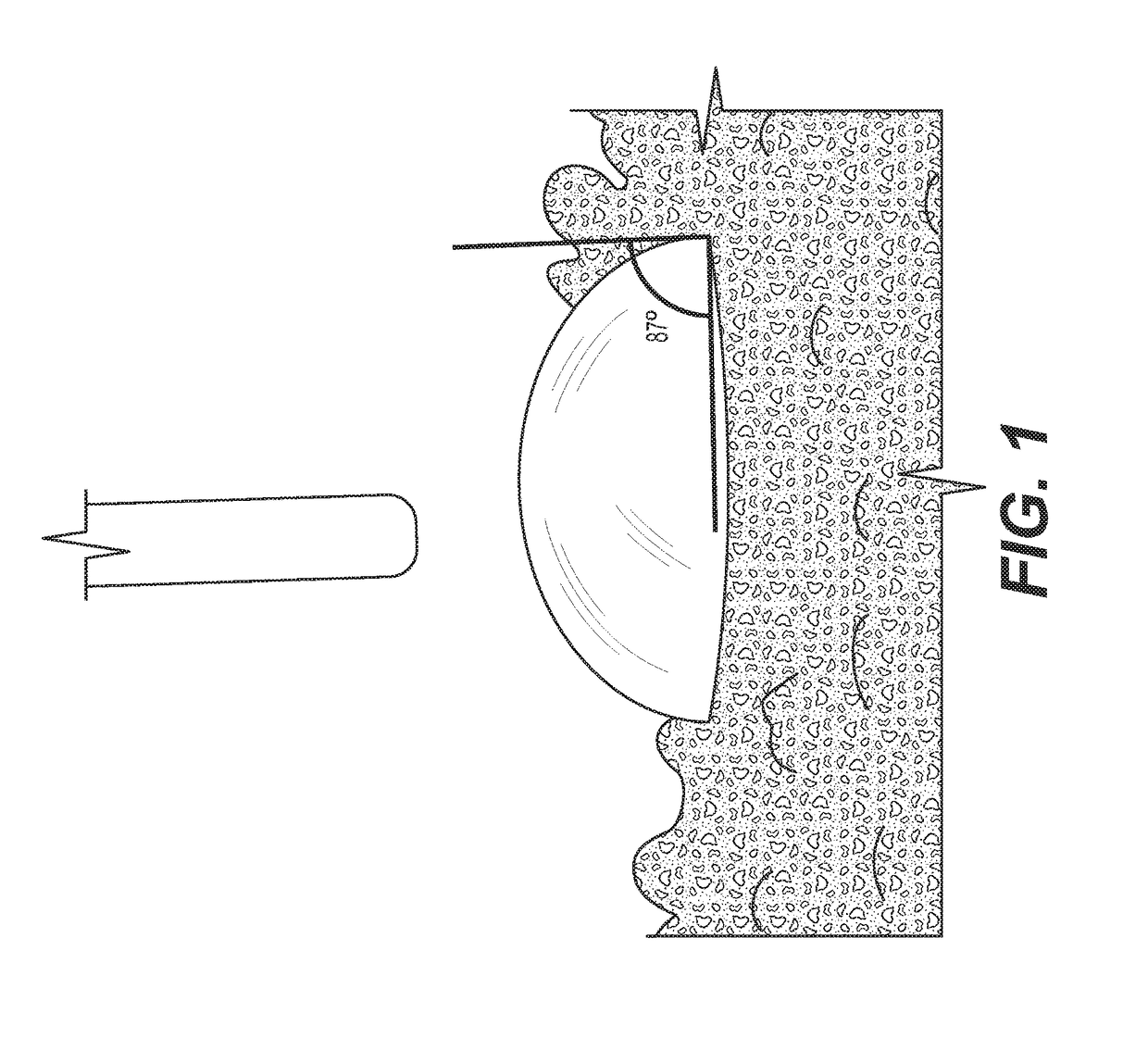

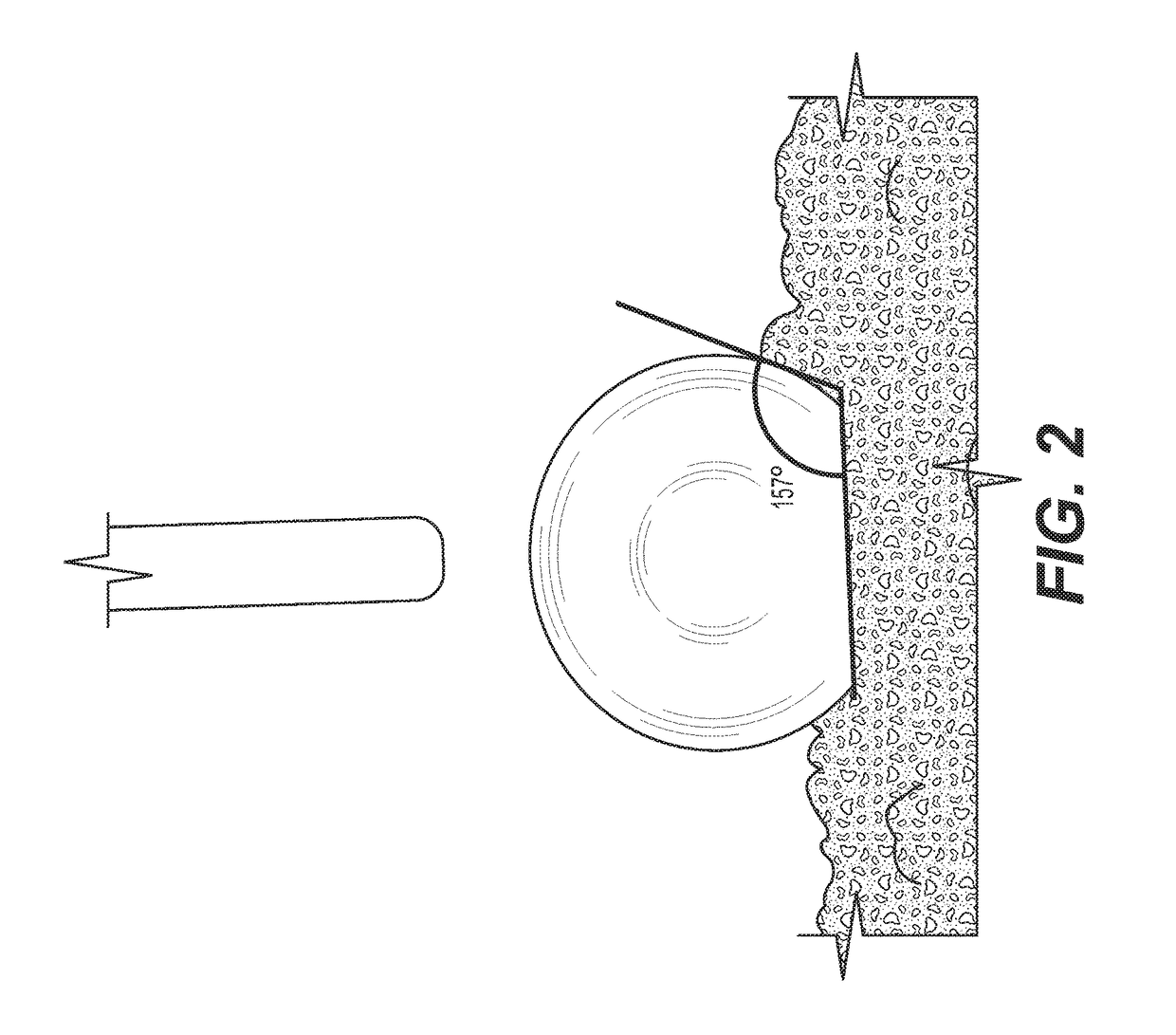

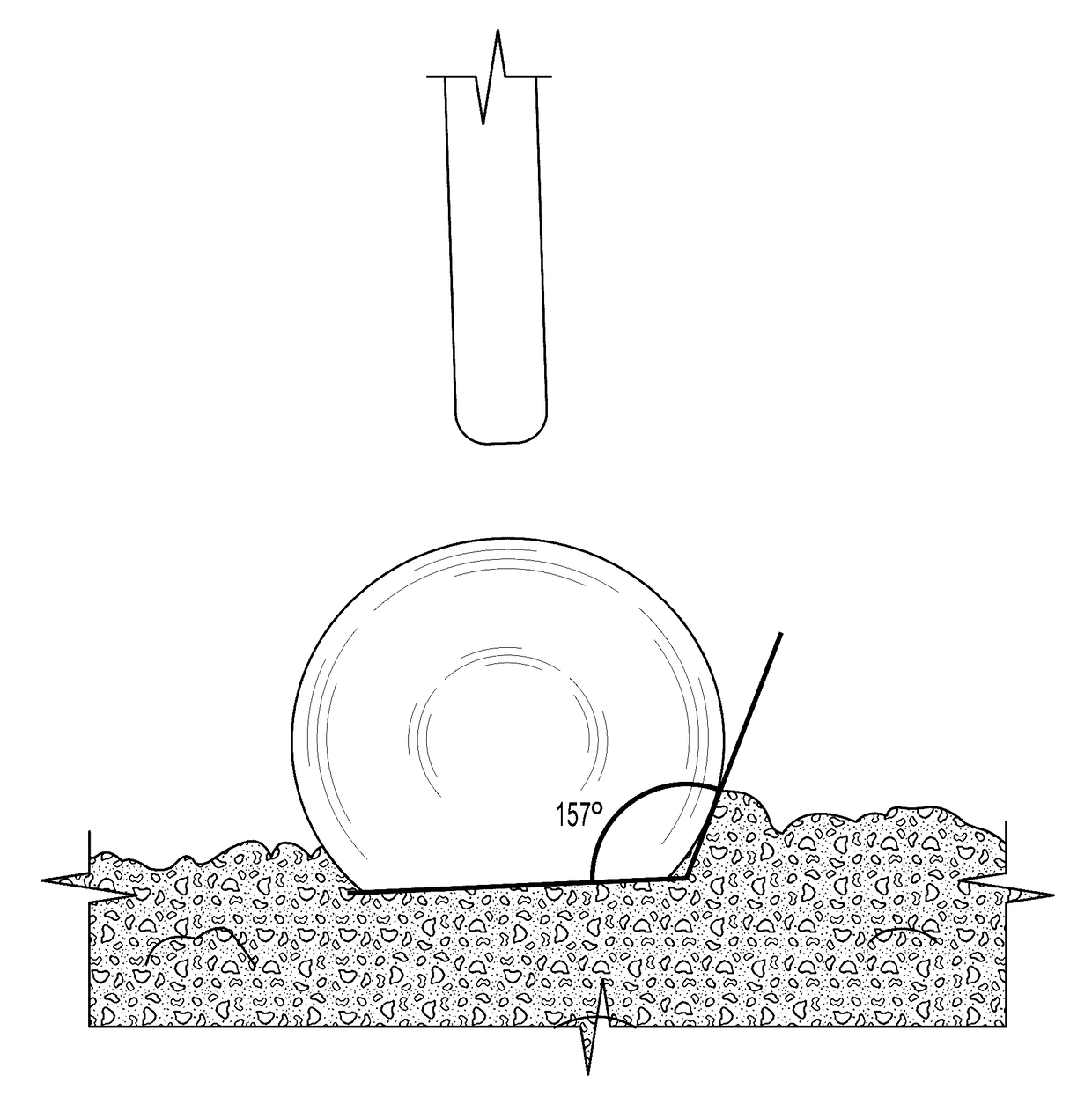

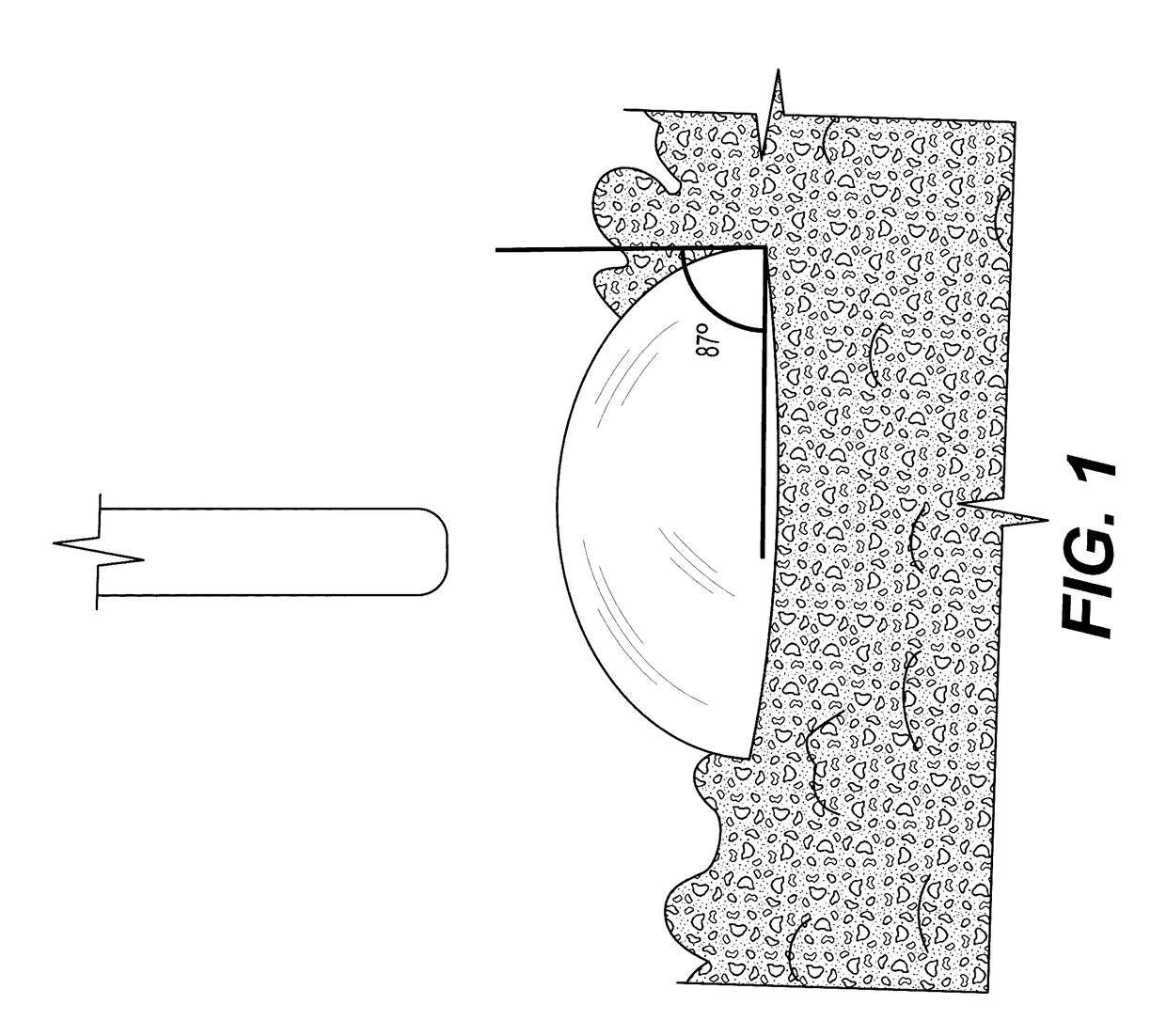

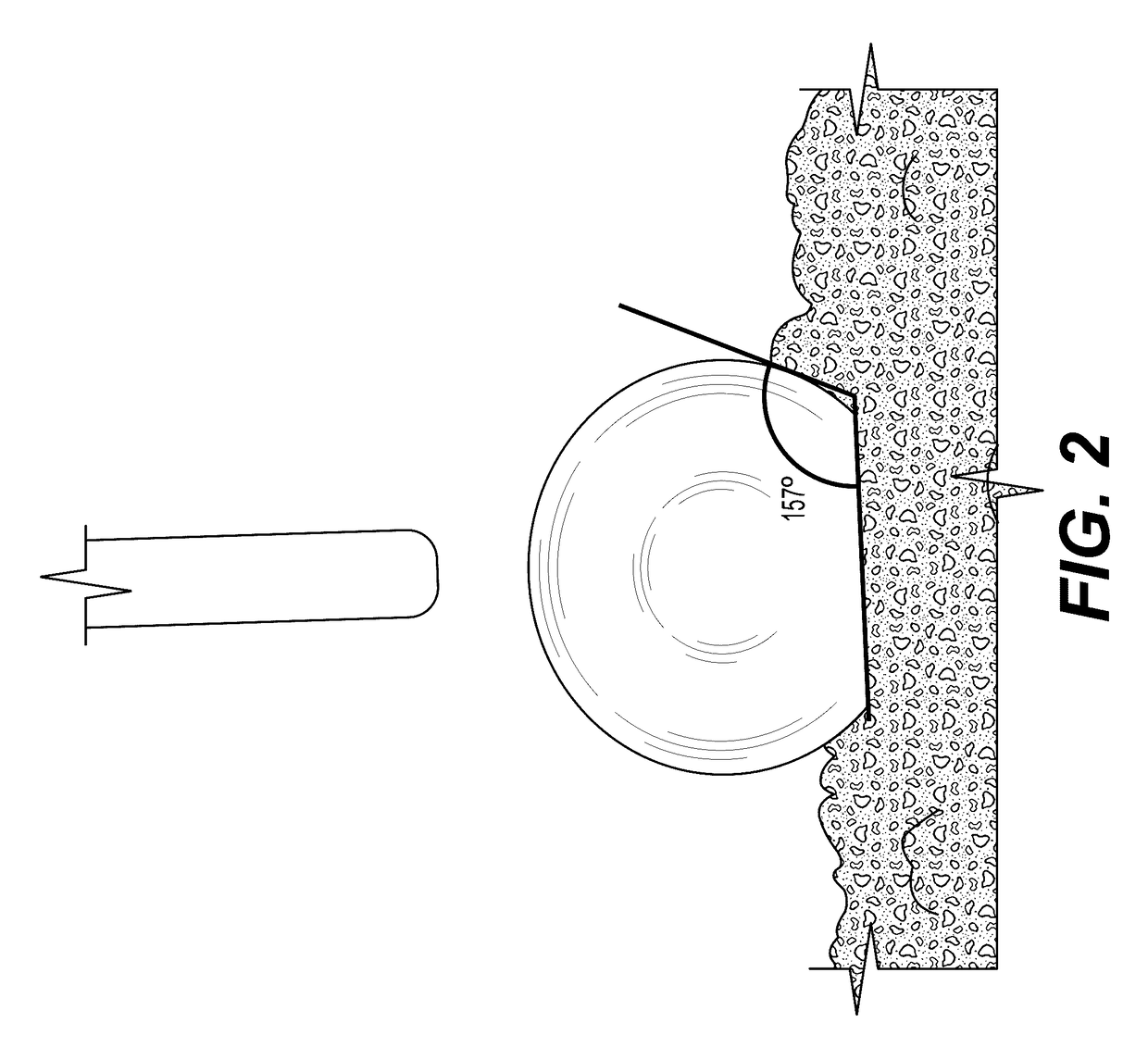

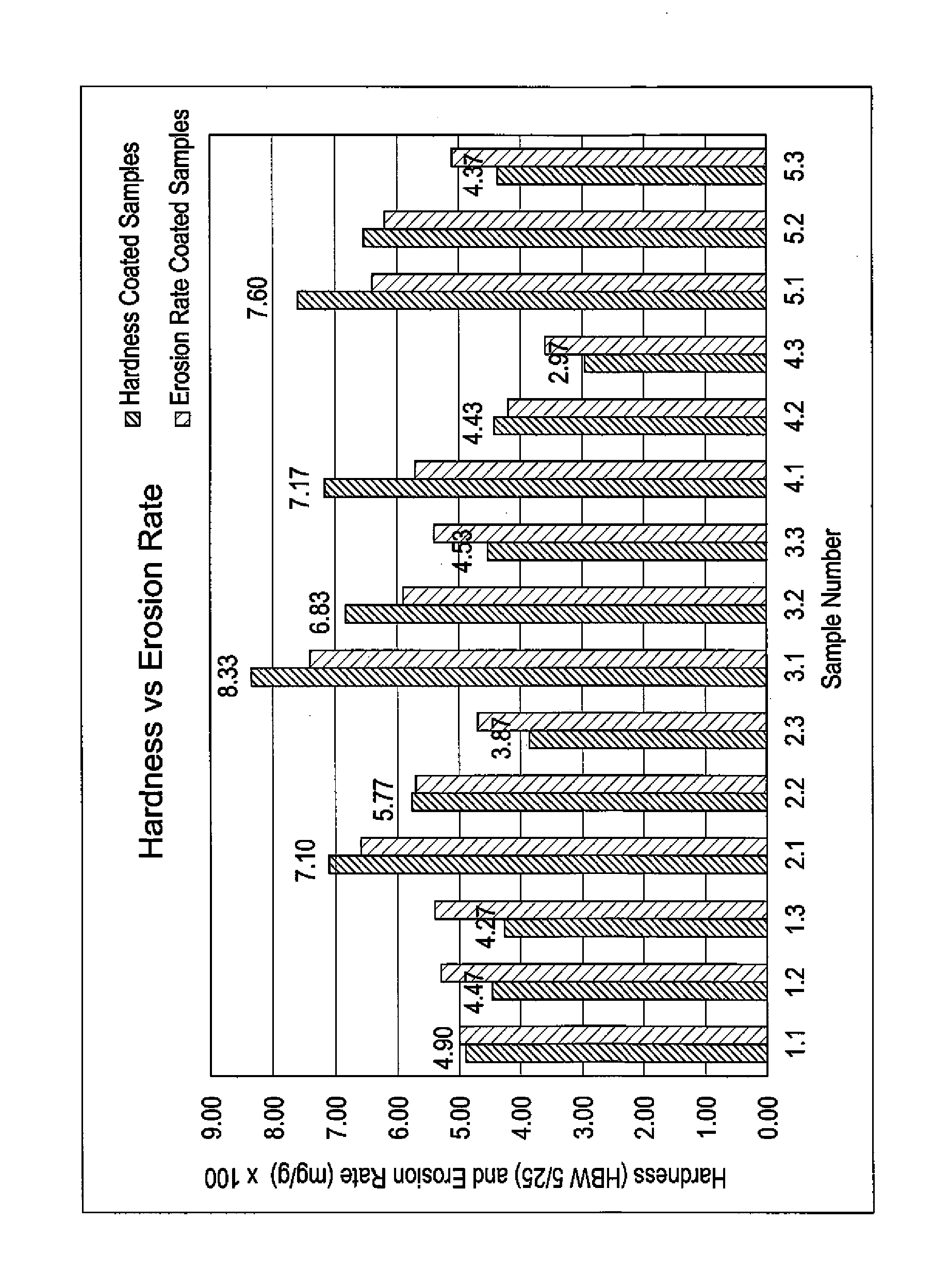

Crumb rubber coating composition and method for protecting a surface

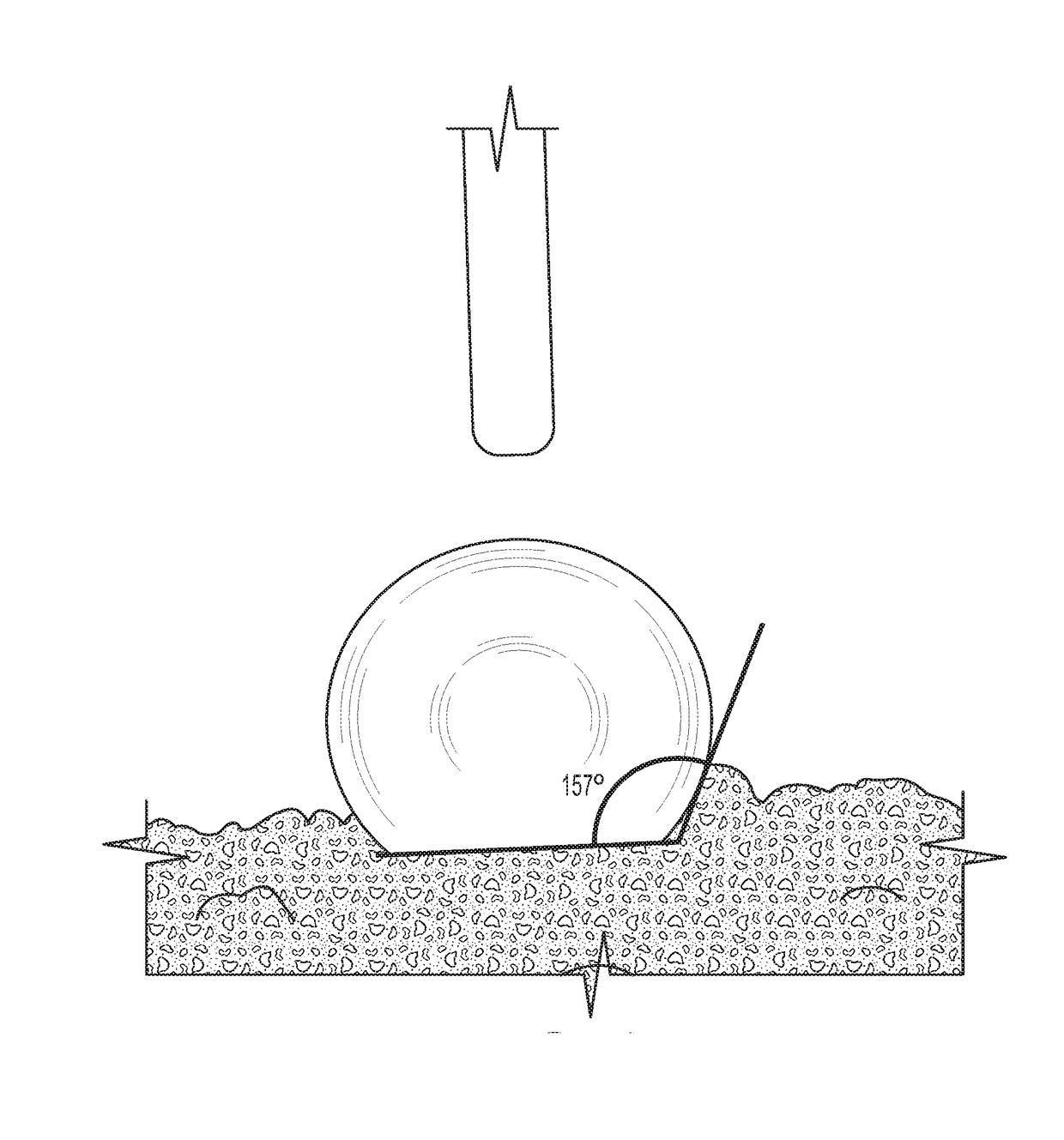

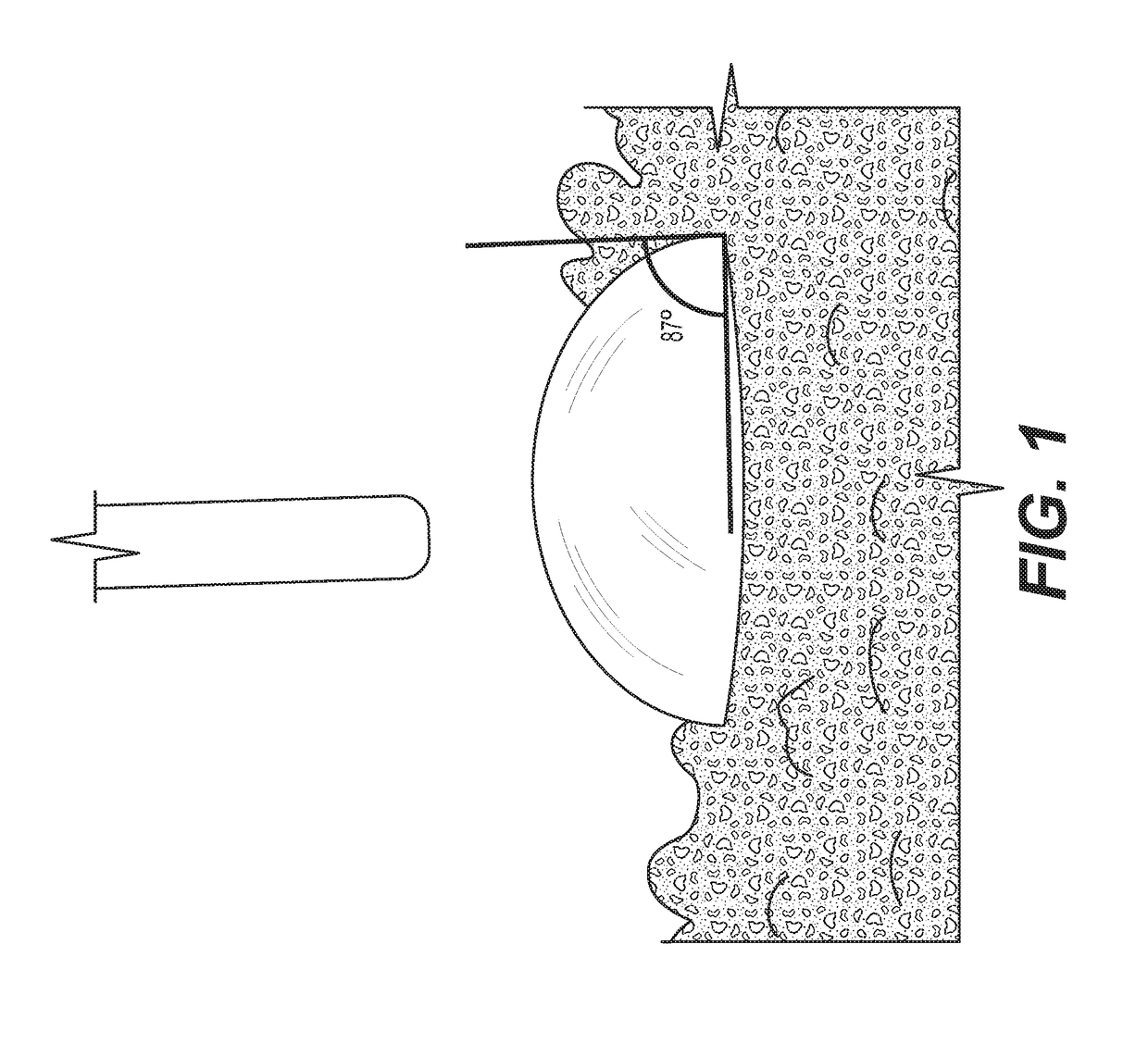

A recycled crumb rubber coating with a hydrophobic surface and a method for making the same. The coating with a hydrophobic surface includes a recycled crumb rubber coating layer comprising about 24-50 wt % of a crumb rubber, and about 25-75 wt % of an epoxy comprising a liquid epoxy resin and an epoxy hardener, and a first silane film comprising at least one silane and disposed on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface. The method includes (a) mixing a crumb rubber with a liquid epoxy resin to form a first mixture, (b) mixing the first mixture with an epoxy hardener to form a recycled crumb rubber coating layer, and (c) depositing a first silane film comprising at least one silane on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface of the recycled crumb rubber coating.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

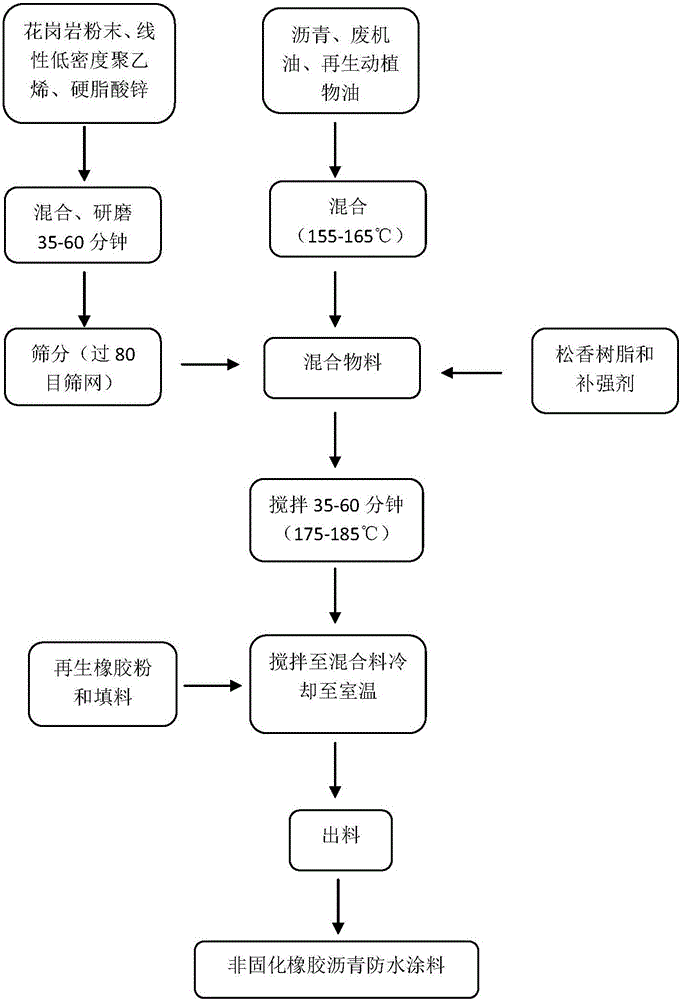

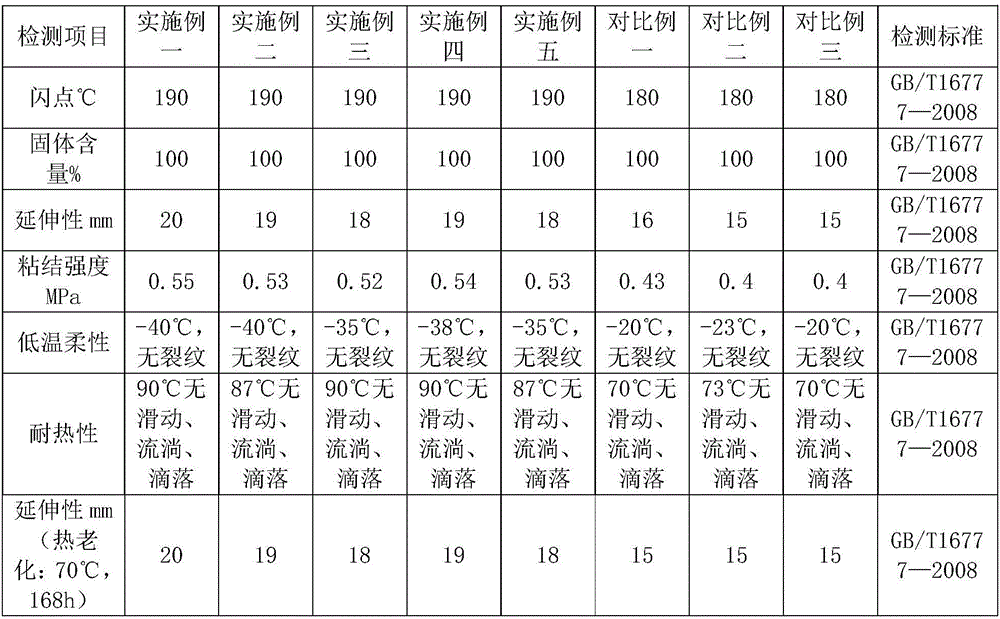

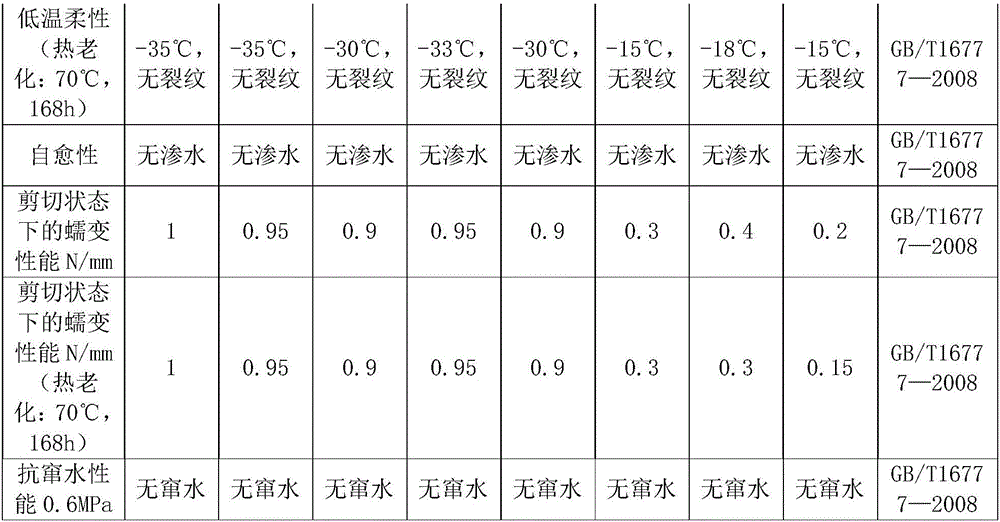

Non-curing rubber asphalt waterproof coating and preparation method thereof

ActiveCN106118473AFlexibleHas tensile strengthReclaimed rubber coatingsRosin coatingsLinear low-density polyethyleneBituminous waterproofing

The invention discloses a non-curing rubber asphalt waterproof coating. The non-curing rubber asphalt waterproof coating is prepared from, by weight, 20-60 parts of asphalt, 10-35 parts of reclaimed rubber powder, 2-20 parts of used oil, 2-10 parts of regenerated animal and vegetable oil, 5-10 parts of rosin resin, 10-25 parts of reinforcing agent, 5-15 parts of granite powder, 10-13 parts of linear low-density polyethylene, 2-8 parts of zinc stearate and 7-13 parts of packing. The problem that an existing non-curing rubber asphalt waterproof coating is low in tensile strength in a high-temperature or low-temperature environment is solved.

Owner:北京洪雨建设工程有限公司

Crumb rubber coating composition and method for protecting a surface

A recycled crumb rubber coating with a hydrophobic surface and a method for making the same. The coating with a hydrophobic surface includes a recycled crumb rubber coating layer comprising about 24-50 wt % of a crumb rubber, and about 25-75 wt % of an epoxy comprising a liquid epoxy resin and an epoxy hardener, and a first silane film comprising at least one silane and disposed on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface. The method includes (a) mixing a crumb rubber with a liquid epoxy resin to form a first mixture, (b) mixing the first mixture with an epoxy hardener to form a recycled crumb rubber coating layer, and (c) depositing a first silane film comprising at least one silane on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface of the recycled crumb rubber coating.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Crumb rubber coating with a hydrophobic surface

A recycled crumb rubber coating with a hydrophobic surface and a method for making the same. The coating with a hydrophobic surface includes a recycled crumb rubber coating layer comprising about 24-50 wt % of a crumb rubber, and about 25-75 wt % of an epoxy comprising a liquid epoxy resin and an epoxy hardener, and a first silane film comprising at least one silane and disposed on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface. The method includes (a) mixing a crumb rubber with a liquid epoxy resin to form a first mixture, (b) mixing the first mixture with an epoxy hardener to form a recycled crumb rubber coating layer, and (c) depositing a first silane film comprising at least one silane on a surface of the recycled crumb rubber coating layer to form the hydrophobic surface of the recycled crumb rubber coating.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Liquid ethylene propylene diene monomer rubber asphalt waterproofing paint and preparation method thereof

InactiveCN104974666ASolve crackingImprove bindingReclaimed rubber coatingsBituminous coatingsButadiene-styrene rubberPetroleum

The invention discloses a liquid ethylene propylene diene monomer rubber asphalt waterproofing paint and a preparation method thereof. The used additives are long-chain low-molecular-weight additives, can enable the asphalt to be mixed and dissolved with various high-polymer materials to form a stable combination in the production process, and display the respective characteristics in the most stable state in the application process, thereby achieving the goal of never curing. The preparation method comprises the following steps: heating asphalt according to the formula weight to 130-180 DEG C, adding liquid ethylene propylene diene monomer rubber, SBS (styrene-butadiene-styrene), naphthenic oil and a petroleum resin into the asphalt according to the formula weight, stirring at 175-180 DEG C for 1-2 hours, cooling to 160 DEG C, adding regenerated rubber powder according to the formula weight, uniformly stirring for 1-1.5 hours to the granule-free molten state, and discharging. The liquid ethylene propylene diene monomer rubber asphalt waterproofing paint has favorable self-recovery property and creep property, and can effectively solve the problem of waterproofing layer cracking caused by deformation of the building basal plane.

Owner:阿尔法新材料江苏有限公司

Recycled crumb rubber coating

The recycled crumb rubber coating is a corrosion-proof coating for piping and the like. The coating is formed from recycled crumb rubber mixed with an epoxy resin and a hardener. Crumb rubber is first mixed with a liquid epoxy resin. An agent for reducing the viscosity of the liquid epoxy resin may also be added. A hardener is then added to this mixture. Finally, powdered crumb rubber is added and mixed to form the recycled crumb rubber coating. The total crumb rubber forms about 23-24 wt % of the coating, the balance being epoxy. The epoxy has liquid epoxy resin and a hardener in a ratio of about 2:1 by weight. The epoxy may also include a viscosity reducing agent of about 1% of the total weight of the liquid resin and the hardener. The crumb rubber may be a blend of powdered crumb rubber and mesh crumb rubber.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

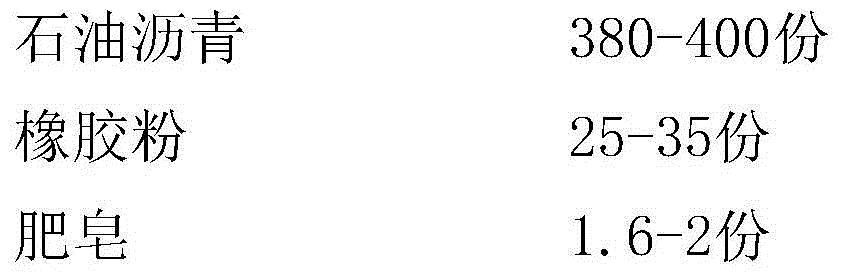

Preparation method for water-emulsion-type reclaimed-rubber-modified asphalt waterproof coating

InactiveCN104087168AHigh purityEasy to useReclaimed rubber coatingsBituminous coatingsBituminous waterproofingEmulsion

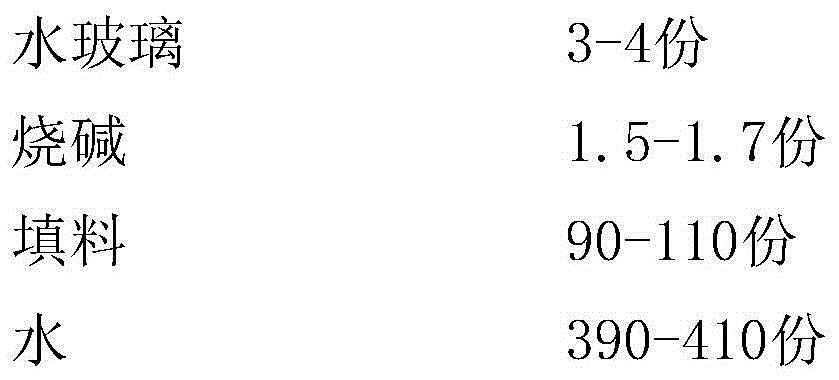

A preparation method for water-emulsion-type reclaimed-rubber-modified asphalt waterproof coating relates to the technical field of chemical engineering. The coating is composed of the following compositions: 380-400 parts of petroleum asphalt, 25-35 parts of rubber powder, 1.6-2 parts of soap, 3-4 parts of water glass, 1.5-1.7 parts of sodium hydroxide, 90-110 parts of a filling material and 390-410 parts of water. The beneficial effects comprise that the preparation is convenient and simple, easily available in raw materials, less in equipment investment and convenient to operate, and the prepared water-emulsion-type reclaimed-rubber-modified asphalt waterproof coating is environment-friendly, free of pollution, high in purity, good in usage effect, strong in high-temperature resistance, safe and reliable.

Owner:BENGBU GUANGHUA METAL PROD

EPDM waterproof coating and its preparation process

InactiveCN101113262BImprove waterproof performanceImprove anti-agingReclaimed rubber coatingsAntifouling/underwater paintsWater basedEPDM rubber

Owner:北京立高科技股份有限公司

A kind of non-oil-seepage creep rubber waterproof coating and preparation method thereof

ActiveCN106566324BHas never solidified and become brittleLow VOCReclaimed rubber coatingsConjugated diene hydrocarbon coatingsPolymer sciencePolystyrene

The invention relates to non-oil-penetrating type creep rubber waterproof coating. The coating is characterized in that the coating includes, by mass, 3-20% of butyl rubber, 5-10% of styrene-butadiene rubber, 35-60% of rubber powder, 5-20% of a polymer modifying agent, 5-25% of asphalt and 5-15% of an inorganic modifying material; the polymer modifying agent is one of or a mixture of materials selected from a group consisting of polypropylene, polystyrene, bis(triethoxysilylpropyl) tetrasulfide, bis(triethoxysilylpropyl) disulfide, gamma-mercaptopropyl trimethoxysilane, oxidized polyethylene wax and ethylene-vinyl acetate copolymer wax; and the inorganic modifying material is glass microbeads, precipitated calcium carbonate powder, talcum powder, ground calcium carbonate powder or a mixture thereof. The actually measured VOC content of the coating is less than 10, and no oil is penetrated at 60 DEG C.

Owner:明象新型建材科技(上海)有限公司

Non-solidifying rubber asphalt building waterproof coating

InactiveCN102925058BReduce pollutionImprove stabilityReclaimed rubber coatingsPolyamide coatingsDistilled oilPolyamide

Owner:刘力

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com