Waterproof paint for roads and bridges and preparation method thereof

A waterproof coating, road and bridge technology, applied in the field of building materials, can solve the problems of short service life, poor waterproof effect, acid and alkali resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

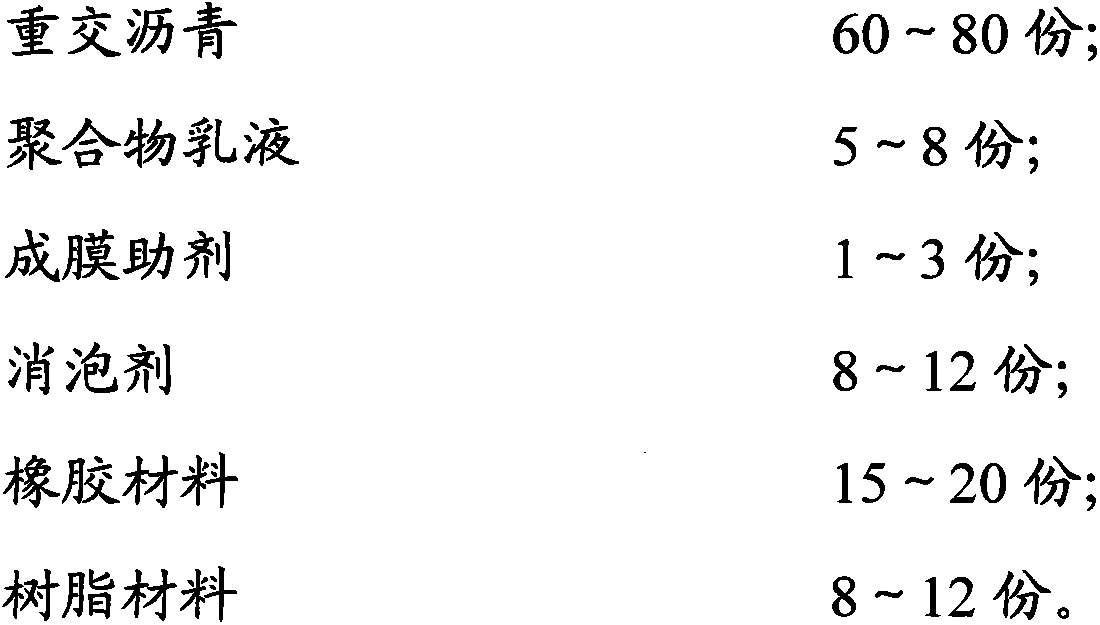

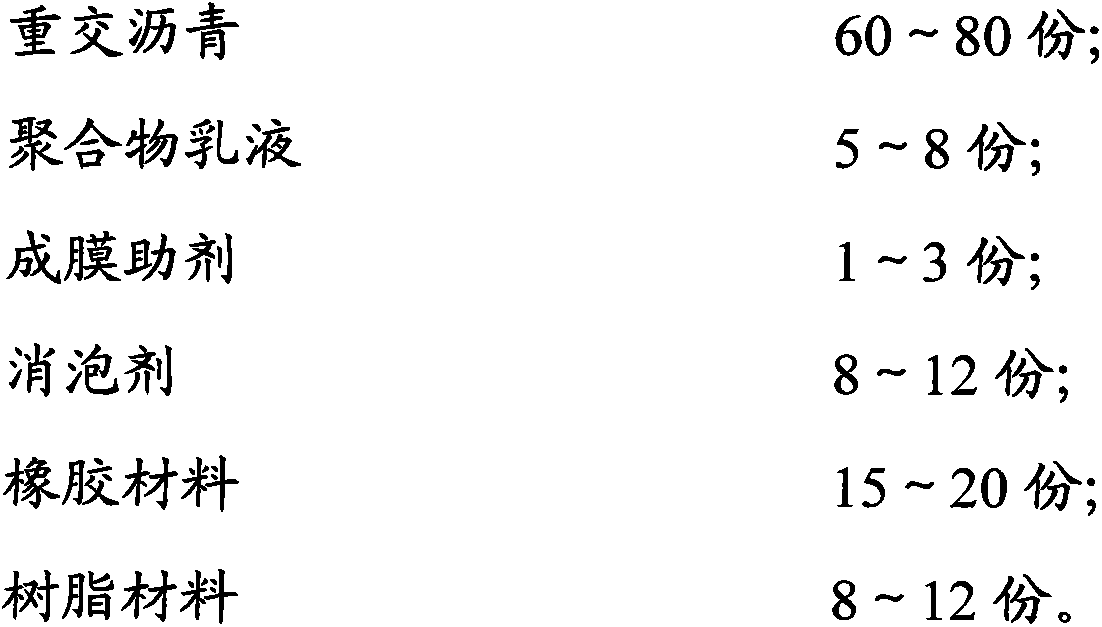

Method used

Image

Examples

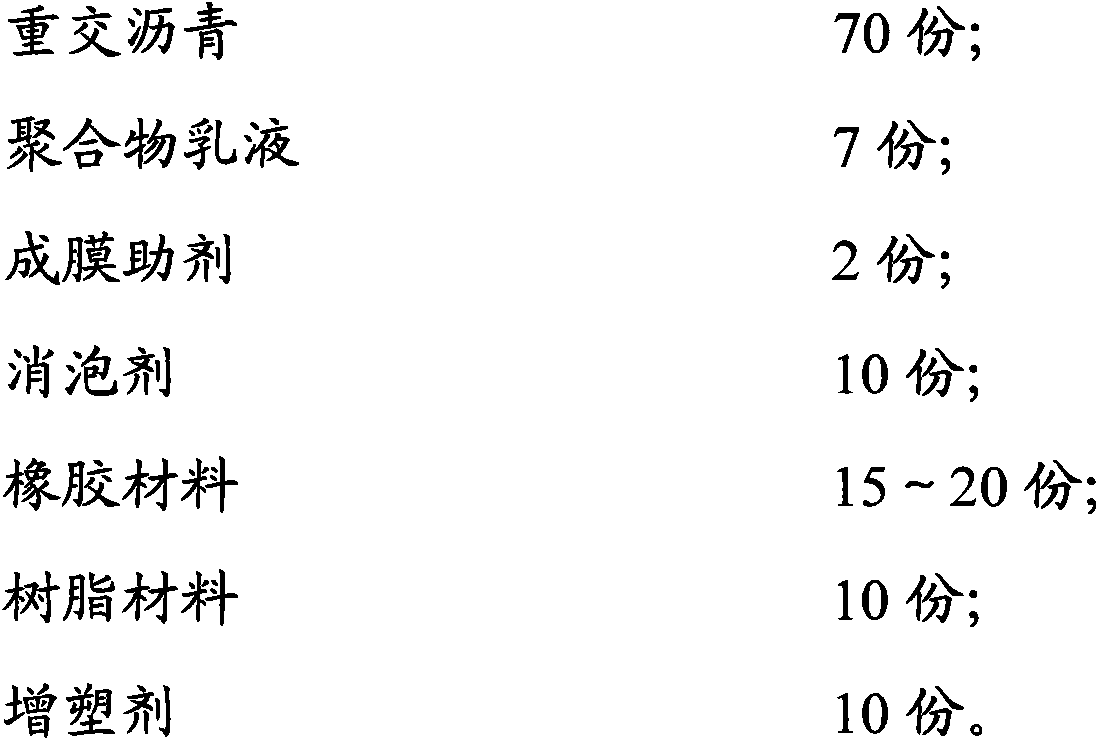

Embodiment 1

[0037] (1) 15kg neoprene latex, 8kg styrene-butadiene and 12kg acrylic acid are emulsified with an emulsifier at a temperature of 70°C to obtain a rubber latex emulsifier mixed solution;

[0038] (2) After mixing the rubber latex emulsifier mixed solution obtained in step (1) with 60kg of heavy traffic asphalt, 1kg of natural asphalt and 12kg of polyvinyl ether, emulsify with an emulsifier at a temperature of 130°C to obtain road and bridge waterproof coating 1.

Embodiment 2

[0040] (1) 20kg styrene-butadiene rubber latex, 5kg atactic polypropylene and 8kg phenolic resin are emulsified with an emulsifier at a temperature of 60° C. to obtain a rubber latex emulsifier mixed solution;

[0041] (2) After mixing the rubber latex emulsifier mixed solution obtained in step (1) with 80kg of heavy traffic asphalt, 3kg of synthetic rubber and 8kg of tributyl phosphate, emulsify with an emulsifier at a temperature of 120°C to obtain road and bridge waterproof coating 2 .

Embodiment 3

[0043] (1) 10kg neoprene rubber, 5kg styrene-butadiene rubber latex, 8kg dibutyl phthalate, 2kg styrene-butadiene rubber, 5kg neoprene rubber and 8kg polytetrafluoroethylene are emulsified with an emulsifier at a temperature of 70°C to obtain Rubber latex emulsifier mixture;

[0044] (2) After mixing the rubber latex emulsifier mixed solution obtained in step (1) with 60kg heavy traffic asphalt, 1kg acrylic acid copolymer and 12kg polypropylene glycol, emulsify with an emulsifier at a temperature of 130° C. to obtain road and bridge waterproof coating 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com