Non-solidifying rubber asphalt building waterproof coating

A non-curing rubber and building waterproof technology, which is applied in the field of chemical building materials, can solve problems such as coating film cracking, base cracks, loss of waterproof function, etc., and achieve the effects of reducing pollution, improving stability and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment further illustrate method and effect of the present invention.

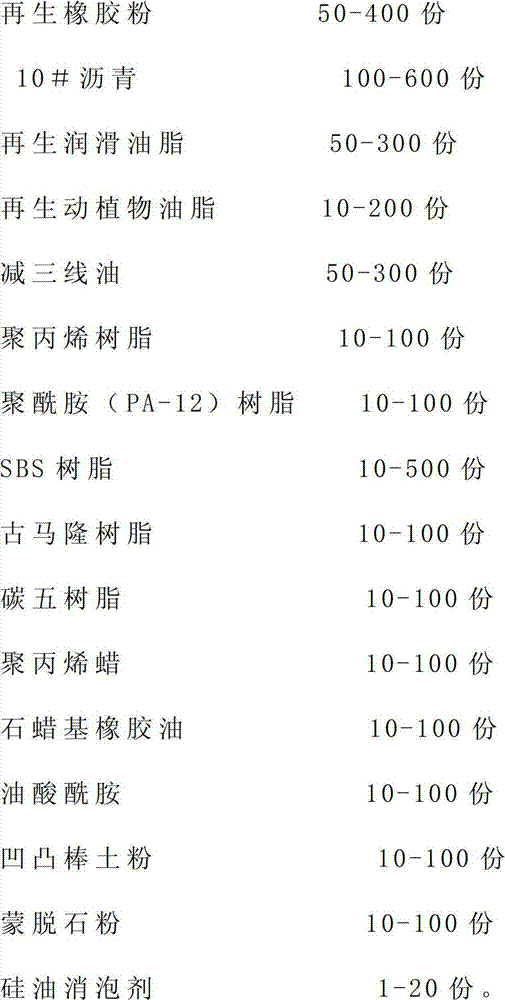

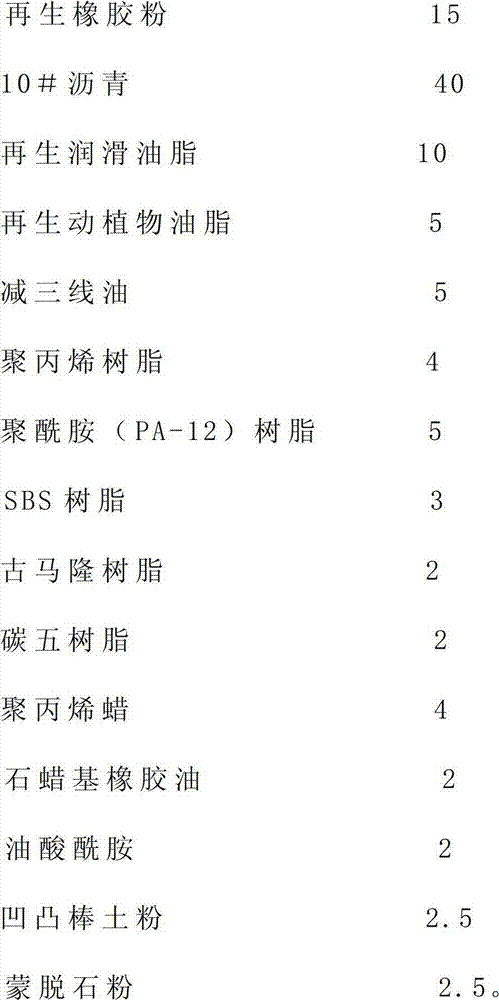

[0019] Various raw materials and proportioning (parts by weight)

[0020]

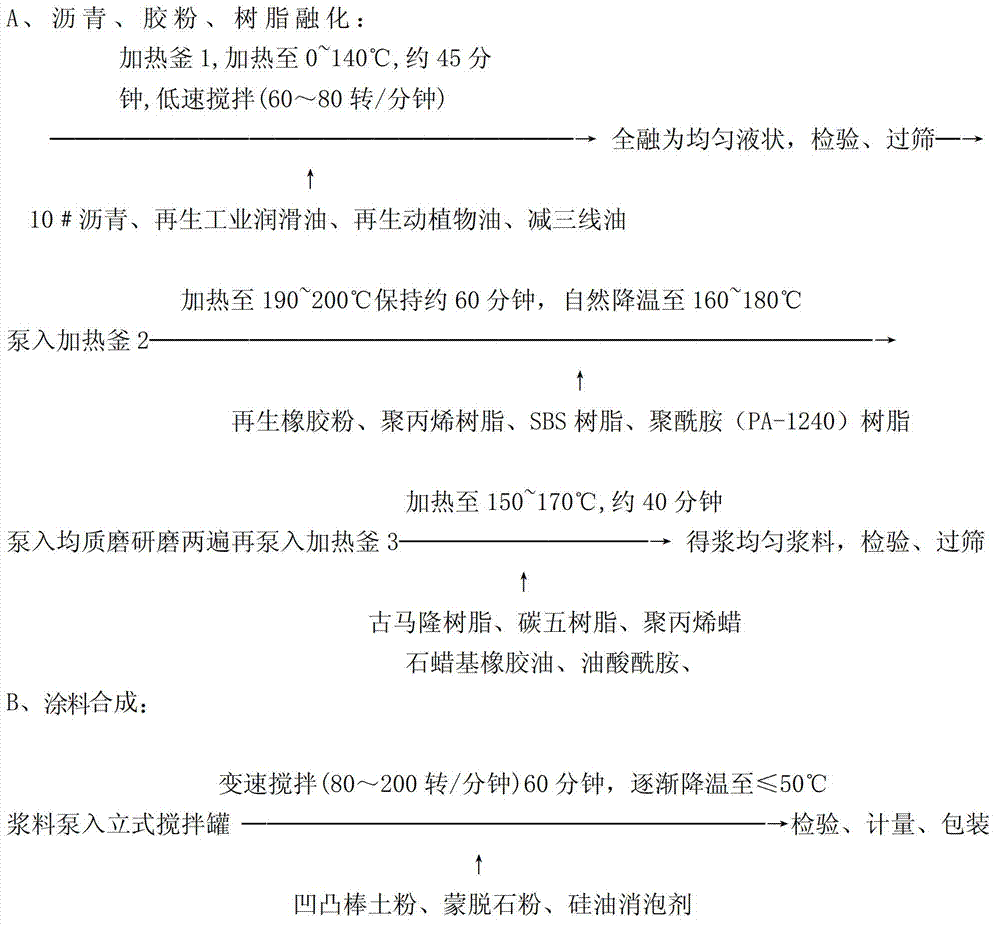

[0021] Preparation method: proceed as the process flow diagram shown in the accompanying drawing.

[0022] 1) Put asphalt, regenerated lubricating oil, regenerated animal and vegetable oil, reduced third-line oil, and 10# asphalt into the heating kettle Ⅰ, heat to 140°C, make the asphalt melt into a uniform asphalt liquid, keep it warm at 140°C and stir at 60 rpm About 45 minutes. Inspection, 50-mesh stainless steel sieve, pumped into heating kettle II.

[0023] 2) Put regenerated rubber powder, polypropylene resin, SBS resin, polyamide (PA-1240) resin into the asphalt liquid in heating kettle II while stirring at 60 rpm, heat to 190°C and keep for 60 minutes to make the rubber powder and The resin is melted into the asphalt liquid to form a uniform slurry, inspected, pumped into the homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com