Preparation method for water-emulsion-type reclaimed-rubber-modified asphalt waterproof coating

A technology of modified asphalt and waterproof coating, applied in the chemical industry, can solve the problems of high toxicity of tar gas, containing toxicity, short construction period, etc., and achieve the effects of convenient and simple preparation, strong high temperature resistance, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

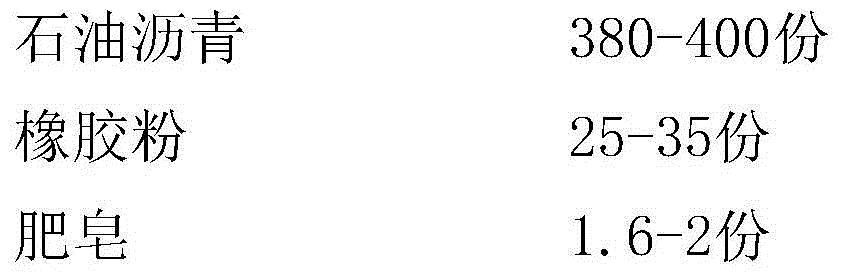

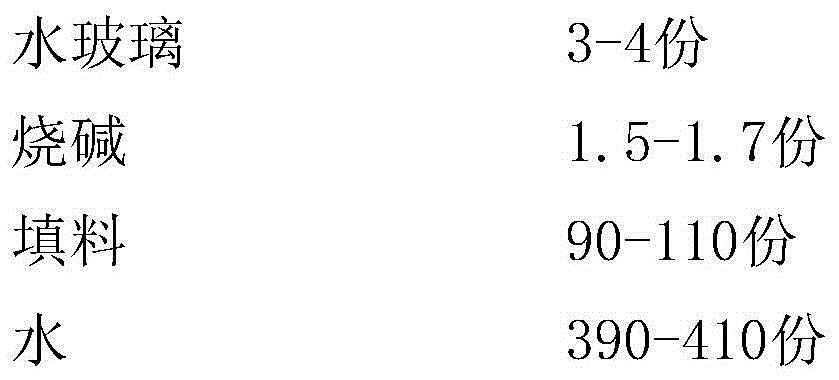

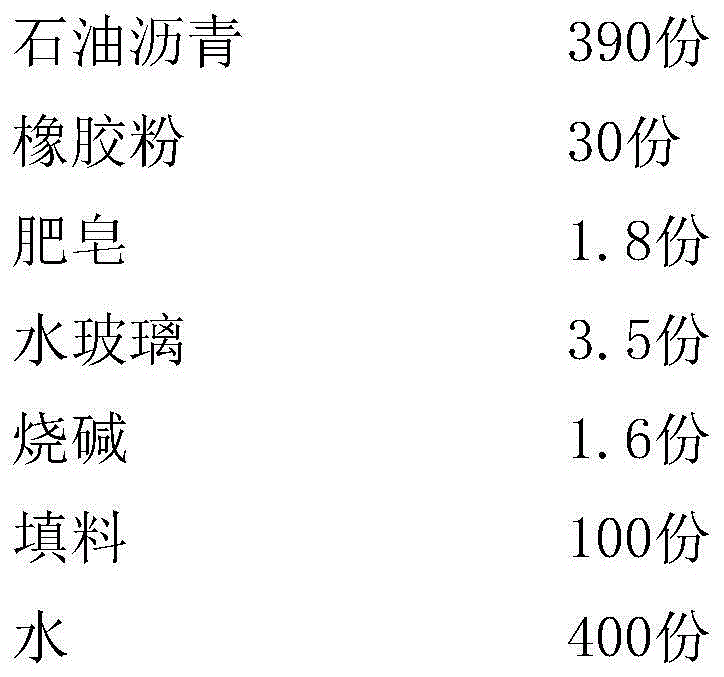

[0028] A water-emulsion type reclaimed rubber modified asphalt waterproof coating is composed of the following raw materials:

[0029]

[0030] The method for preparing the water-emulsion type reclaimed rubber modified asphalt waterproof coating of the present invention comprises the following process steps:

[0031] a. Add the water in the raw material into the mixing mixer according to 50% of the formula amount, then heat it to boiling, then add the caustic soda in the raw material, and stir until it dissolves.

[0032] b. After the caustic soda in step a is dissolved, continue to stir, put the soap box water glass in the raw material into the mixing mixer according to the formula amount, then raise the temperature to 40-50°C, and stir well to obtain A clear anionic emulsifier, stored at a temperature between 60-80°C for future use.

[0033] c. Select a melting tank, add the petroleum pitch in the raw material into the melting tank according to the formula amount, heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com