Flame-retardant and smoke-inhibition type non-cured rubber asphalt waterproof coating material

A technology of asphalt waterproof coating and non-curing rubber, which is applied in the direction of asphalt coating, recycled rubber coating, fireproof coating, etc., and can solve the problems of releasing a large amount, affecting human health, melting at high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

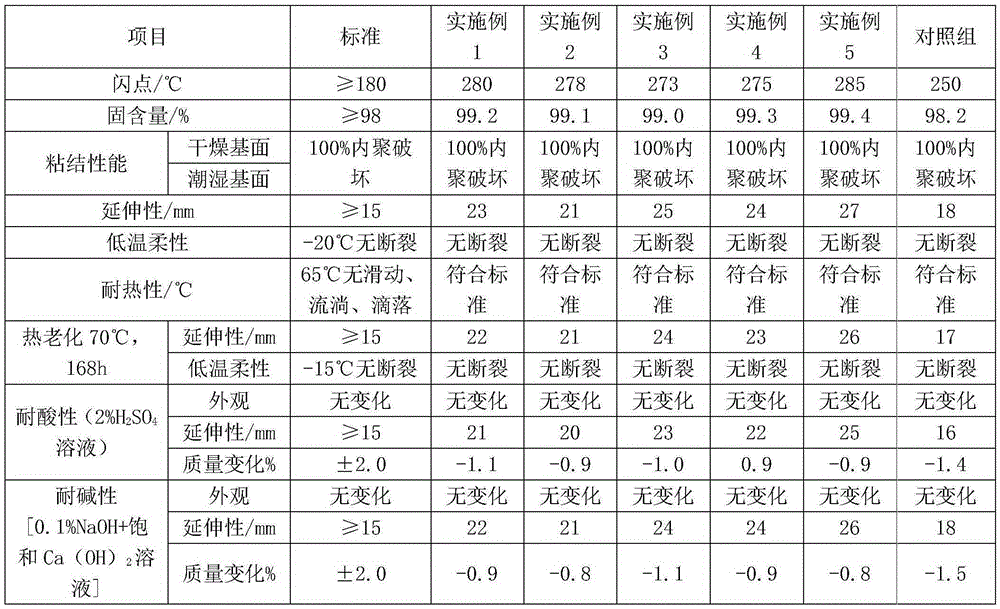

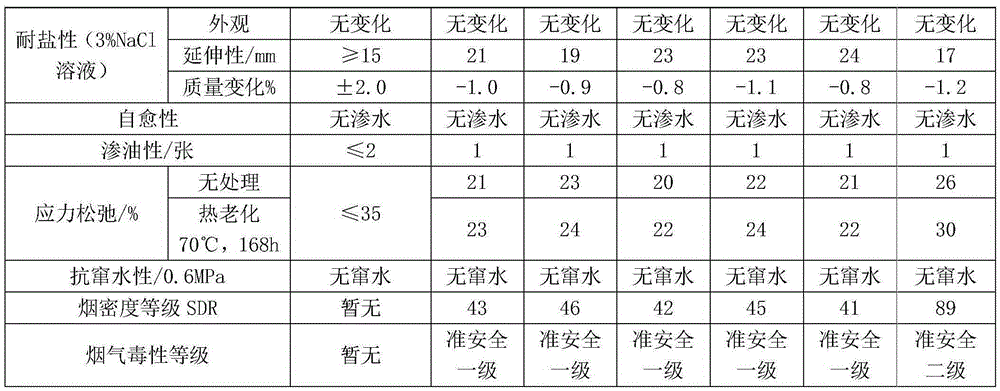

Examples

Embodiment 1

[0021] A flame-retardant and smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include: 25 parts of No. 90 road asphalt, styrene-butadiene- 7 parts of styrene block copolymer, 12 parts of octane oil, 7 parts of paraffin oil, 16 parts of 40 mesh reclaimed rubber powder, 28 parts of 200 mesh talcum powder, 5 parts of 100 mesh limestone powder, 5 parts of rosin resin, C5 petroleum resin 3 parts, 2 parts of paraffin, 2 parts of p-diphenylamine, 6220.2 parts of light stabilizer, 0.7 parts of 2-hydroxy-4-methoxybenzophenone, 1 part of PP-g-MAH, 0.8 parts of dicumyl peroxide , 0.2 parts of stearic acid, 0.2 parts of zinc oxide, 1 part of 3-aminopropyltriethoxysilane, 4 parts of microencapsulated red phosphorus, 3 parts of ammonium polyphosphate, 3 parts of modified smoke suppressant, coumarone 0.8 parts of resin;

[0022] Among them, the preparation method of the modified smoke suppressant is: adding 1000 mesh expandable graphite into isopropanol, hea...

Embodiment 2

[0024] A flame-retardant and smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include: 30 parts of No. 90 road asphalt, styrene-butadiene- 3 parts of styrene block copolymer, 16 parts of octane oil, 4 parts of paraffin oil, 10 parts of 70 mesh reclaimed rubber powder, 22 parts of 300 mesh talcum powder, 3 parts of 200 mesh limestone powder, 8 parts of rosin resin, C5 petroleum resin 1 part, 4 parts of paraffin, 1 part of p-diphenylamine, 6220.6 parts of light stabilizer, 0.4 part of 2-hydroxy-4-methoxybenzophenone, 2 parts of PP-g-MAH, 0.4 part of dicumyl peroxide , 0.4 parts of stearic acid, 0.1 parts of zinc oxide, 2 parts of 3-aminopropyltriethoxysilane, 2 parts of microencapsulated red phosphorus, 5 parts of ammonium polyphosphate, 1 part of modified smoke suppressant, coumarone 1.2 parts of resin;

[0025] Among them, the preparation method of the modified smoke suppressant is: adding 1200 mesh expandable graphite to isopropanol, heating ...

Embodiment 3

[0027]A flame-retardant and smoke-suppressing non-curing rubber asphalt waterproof coating, its raw materials include: 29 parts of No. 90 road asphalt, styrene-butadiene-butadiene with a block ratio of styrene and butadiene of 32:68 4 parts of styrene block copolymer, 15 parts of octane oil, 5 parts of paraffin oil, 12 parts of 65 mesh reclaimed rubber powder, 24 parts of 270 mesh talcum powder, 3.5 parts of 180 mesh limestone powder, 7 parts of rosin resin, C5 petroleum resin 1.5 parts, 3.5 parts of paraffin, 1.3 parts of p-diphenylamine, 6220.5 parts of light stabilizer, 0.5 parts of 2-hydroxy-4-methoxybenzophenone, 1.8 parts of PP-g-MAH, dicumyl peroxide 0.5 parts, 0.35 parts of stearic acid, 0.12 parts of zinc oxide, 1.8 parts of 3-aminopropyltriethoxysilane, 2.5 parts of microencapsulated red phosphorus, 4.5 parts of ammonium polyphosphate, 1.5 parts of modified smoke suppressant, ancient Malone resin 1.1 parts;

[0028] Among them, the preparation method of the modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com