Oxygen sensor

A technology of oxygen sensor and casing, which is applied in the improvement field of oxygen sensor, and can solve the problem of easy damage of sealing rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

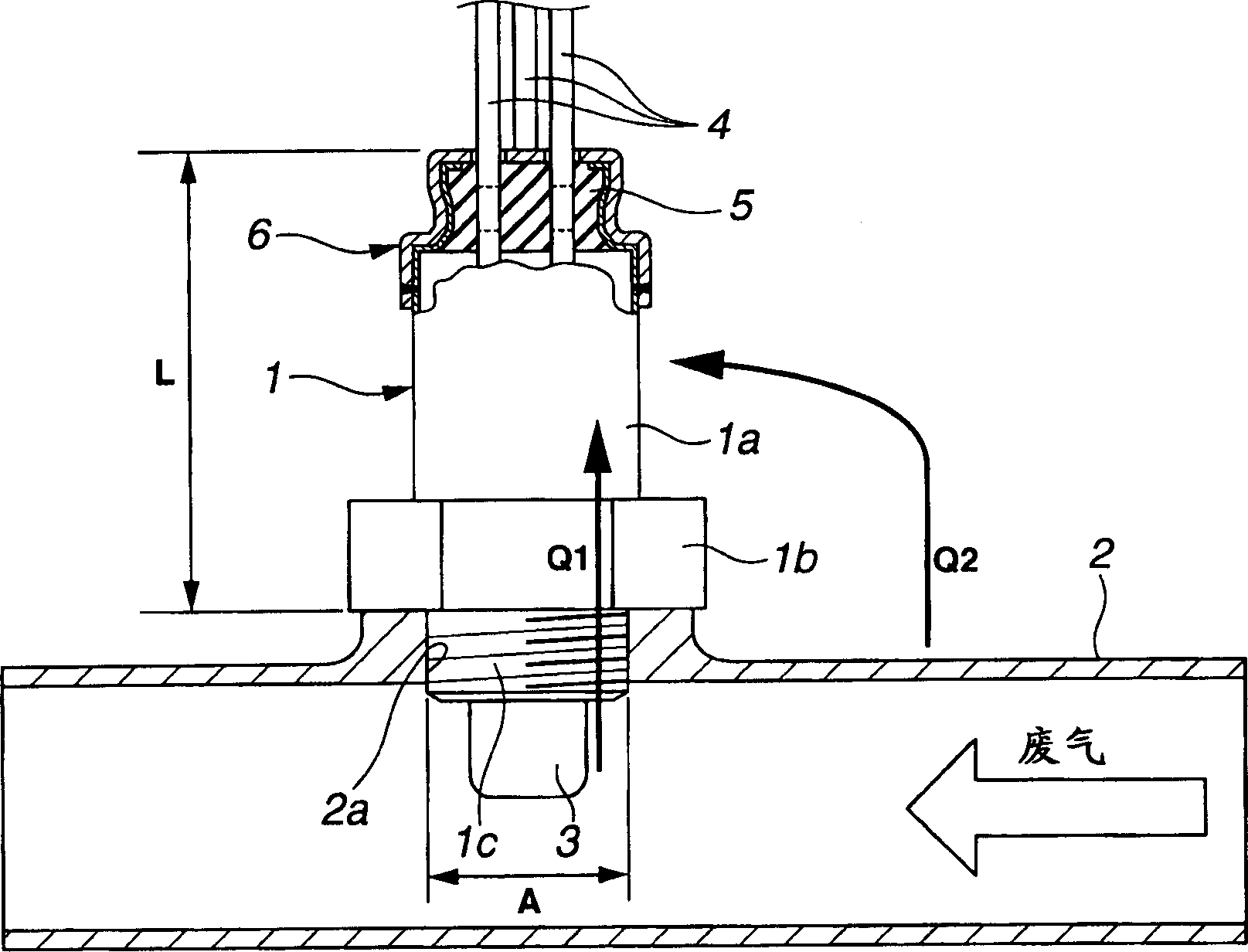

[0015] Referring to the accompanying drawings, an embodiment of the oxygen sensor of the present invention is illustrated in conjunction with an exhaust pipe installed on an automobile internal combustion engine, wherein the oxygen sensor is installed on the exhaust pipe for detecting the air-fuel ratio of the exhaust gas.

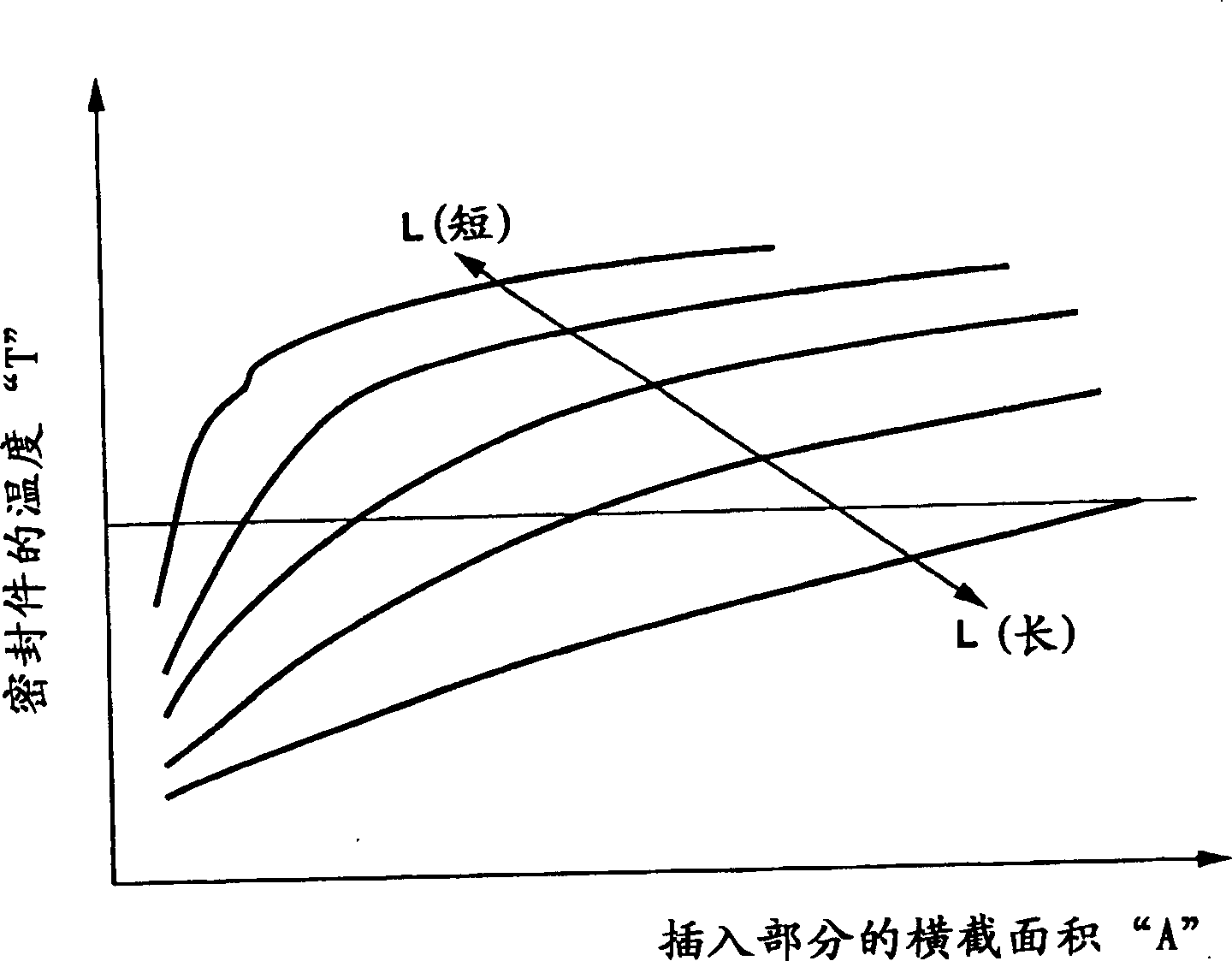

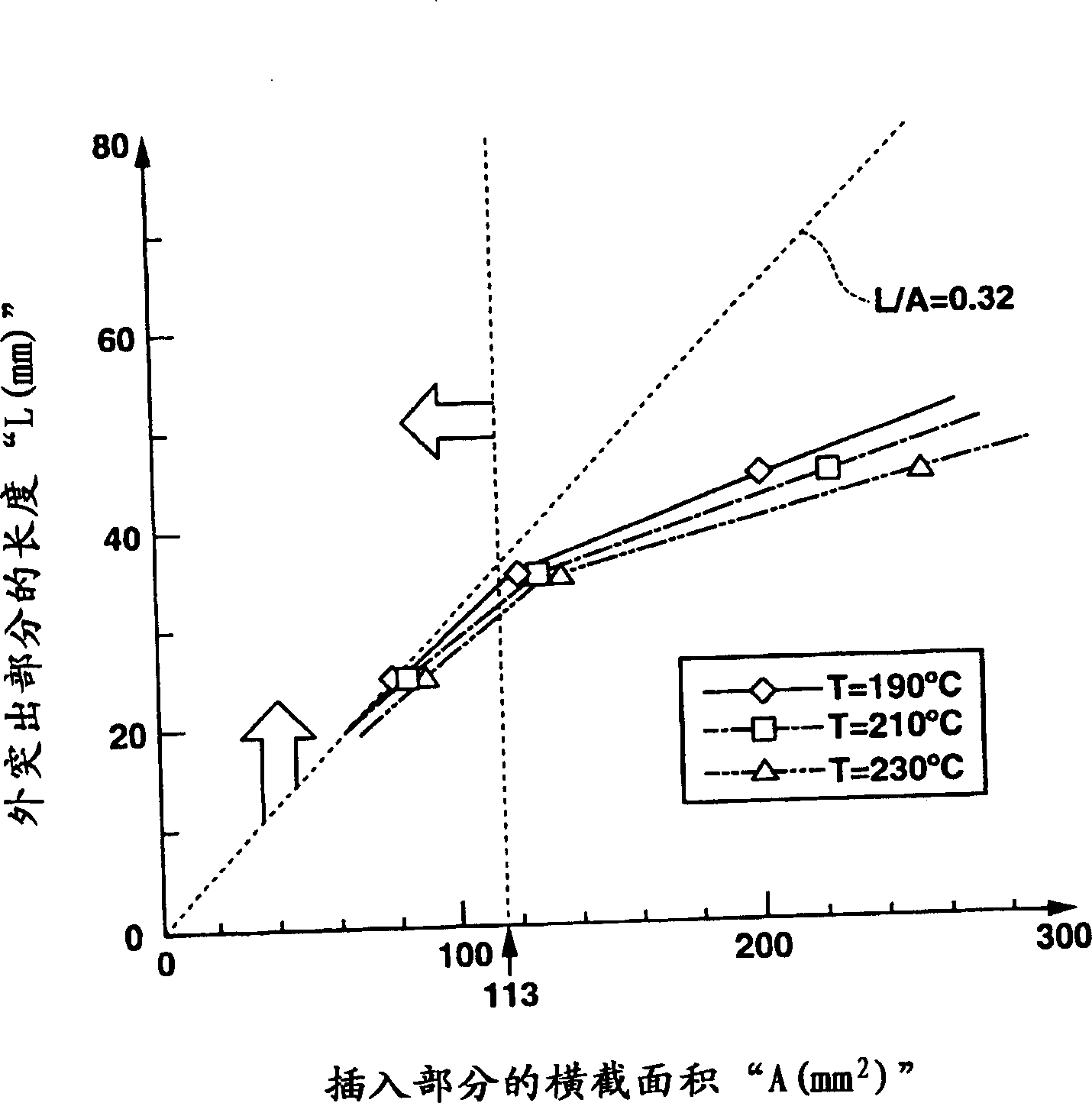

[0016] figure 1 is a side view of an embodiment of the oxygen sensor of the present invention, partially cut away, and the oxygen sensor is installed on the exhaust pipe; figure 2 yes means figure 1 A curve of the relationship between the cross-sectional area of the inserted part of the oxygen sensor and the temperature of the seal; and image 3 yes means figure 1 The curve of the relationship between the cross-sectional area of the insertion part of the oxygen sensor and the length of the outer protrusion.

[0017] Such as figure 1 As shown, the exhaust pipe 2 has an internally threaded hole 2a as a through hole on its side wall, and the external...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com