Polyamides semi-cristallins souples

A polyamide and impact modifier technology, applied in polyamide coatings, rigid containers, hoses, etc., can solve the problems of pure PA without flexibility, and achieve the effect of improving heat aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0210] For the preparation of the compositions of the invention, they can be prepared by melt blending the ingredients using standard techniques for thermoplastics.

[0211] The composition of the invention may additionally comprise at least one additive selected from the group consisting of:

[0212] dye;

[0213] pigment;

[0214] brightener;

[0215] Antioxidants;

[0216] flame retardant;

[0217] UV stabilizers;

[0218] nanofillers;

[0219] Nucleating agent.

[0220] As regards multilayer structures, the following structures may be mentioned:

[0221] Structure (a) contains:

[0222] a layer of the composition according to the invention and a further layer of polyamide, between which a coextruded link may be arranged;

[0223] Structure (b) contains:

[0224] A layer of the composition of the invention between two polyamide layers, a coextrusion linker can be arranged between two or more of these layers (for example it can be a layer of PA11 or PA12, a layer o...

Embodiment 1

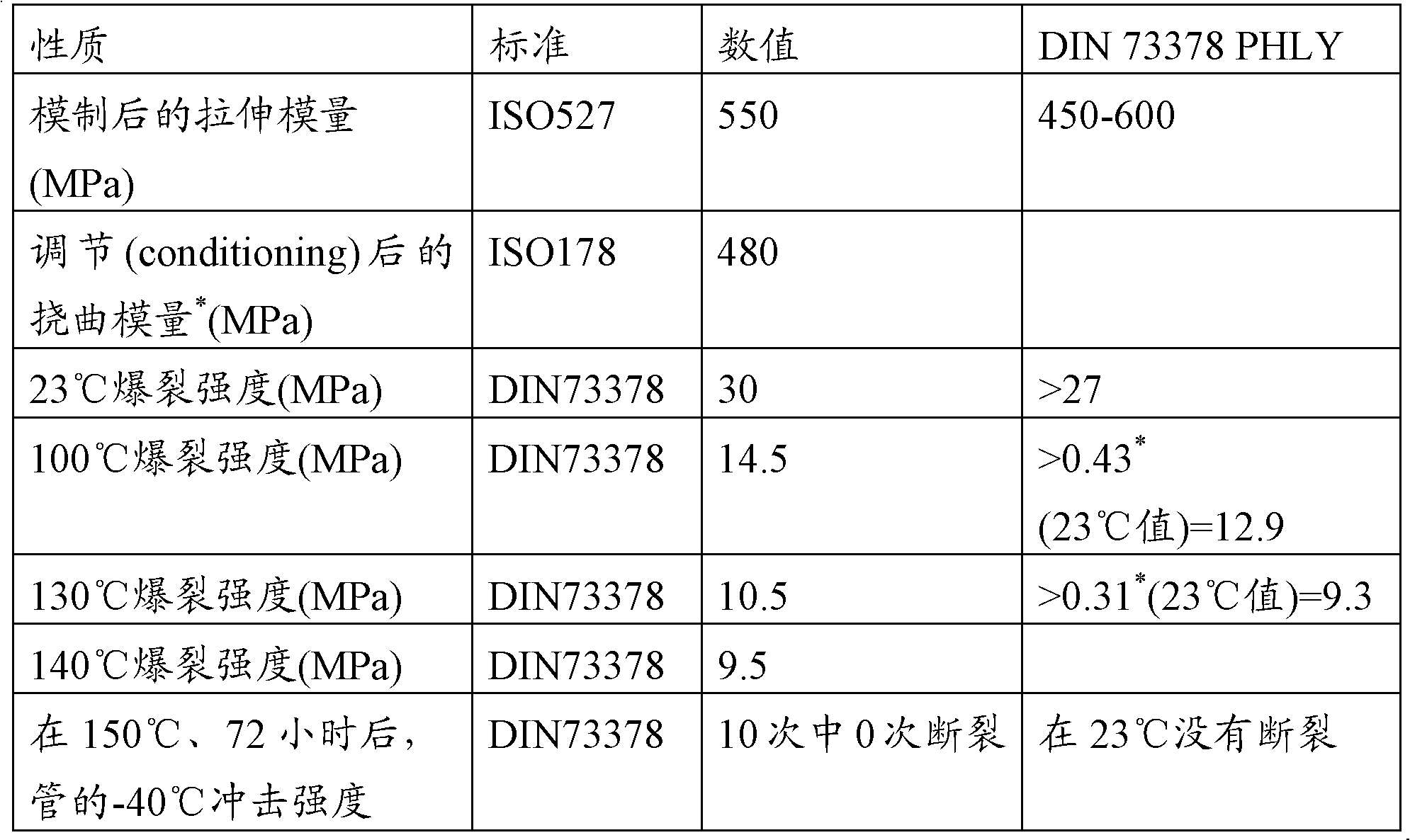

[0266] Example 1: Plasticized PA-10,10 for compressed air brake applications

[0267] Composition: PA-10, 10 (86.4%) + 13% BBSA + 0.6% Polyad PB201.

[0268] Polyad PB201 represents an inorganic antioxidant based on copper iodide.

[0269] The formulation was tested and compared with the DIN 73378PHLY standard value. The modulus was evaluated for the injection molded material, and the burst strength and impact strength values were evaluated for the extruded tubes with ID / OD of 6 and 8 mm. The table below shows that plasticized PA-10,10 meets this criterion for modulus after aging, burst strength and impact strength. The burst strength value at 140°C is greater than the requirement at 130°C.

[0270]

[0271] * Conditioned for 15 days at 23°C / 50%RH.

Embodiment 2

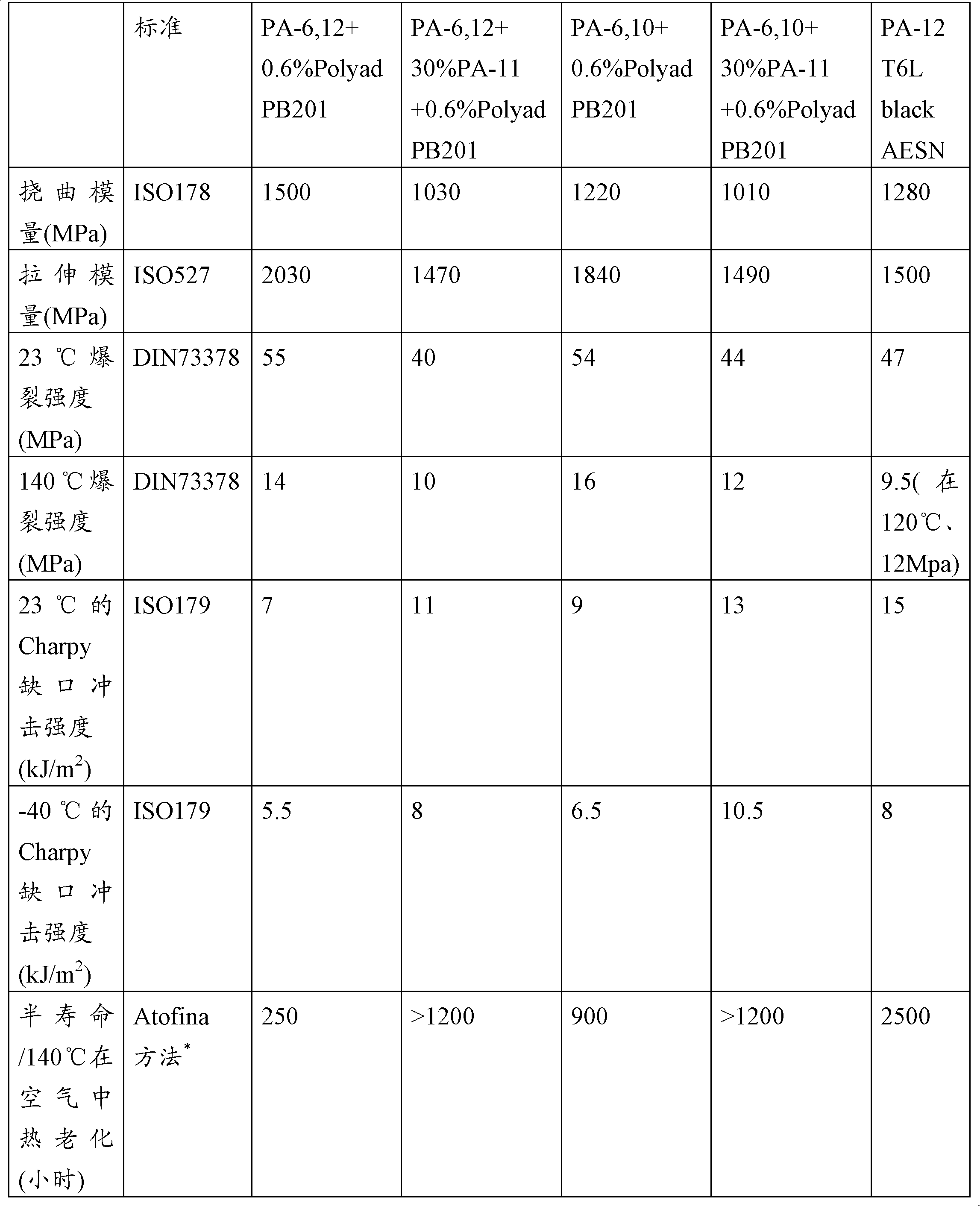

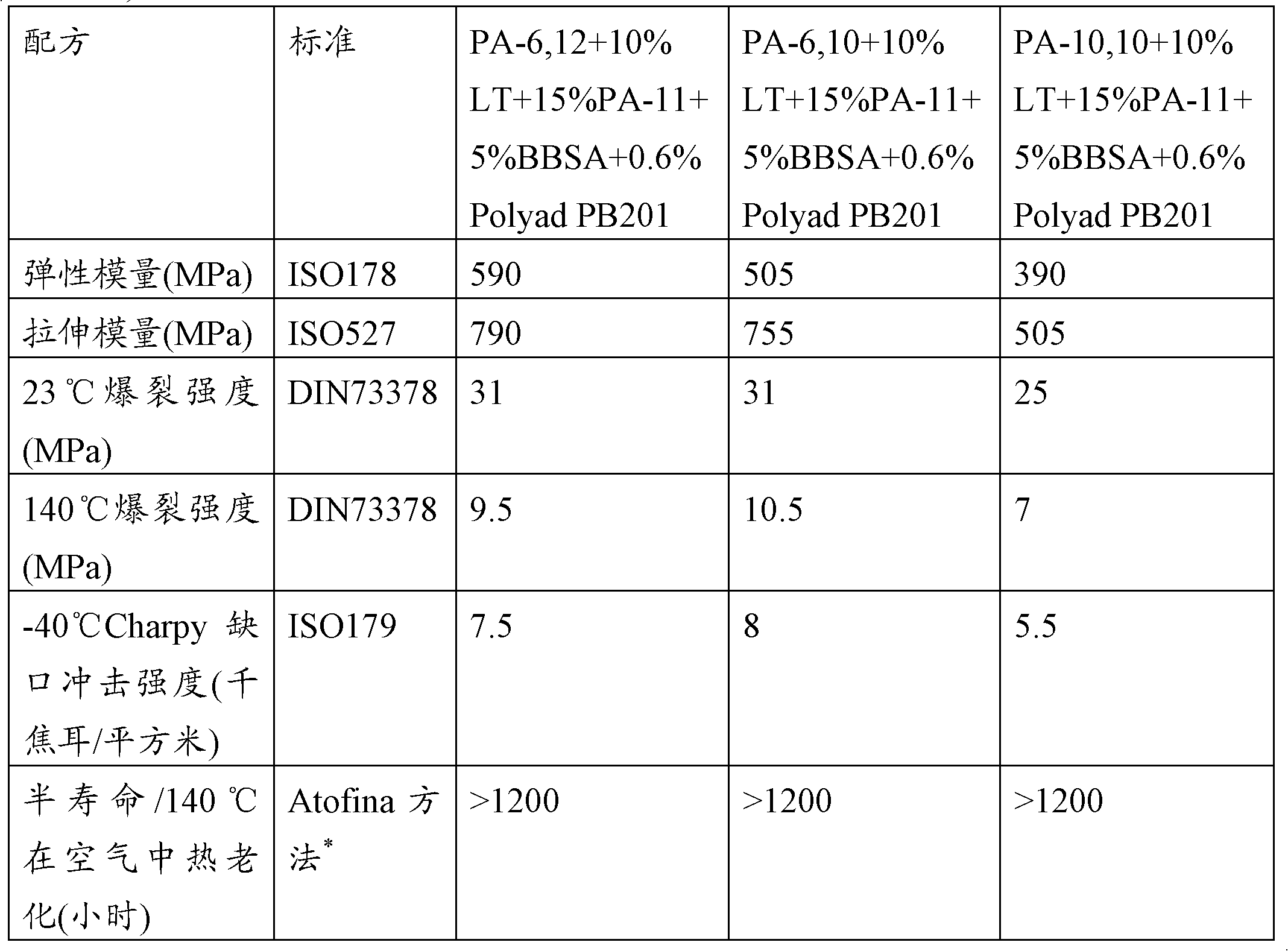

[0273] PA-6,10 and PA-6,12 for hydraulic (clutch) tube applications. The ratio of polyamide in the table below represents the balance relative to 100%. PA-11 represents catalytic PA-11 containing 600 ppm phosphoric acid.

[0274]

[0275] * After this time, the elongation of the specimen is reduced by a factor of 2 relative to the initial value (injection molded specimen)

[0276] The above table shows that PA-6,10 and PA-6,12 can be advantageously used instead of PA-12 for hydraulic applications such as for clutch fluid pipes, which require high pressure resistance. Compared with PA-6,12, PA-6,10 has advantages in thermal burst strength, impact strength and high temperature aging. Addition of PA-11 increases rigidity and life, but impairs burst strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com