Preparation method of anti-aging polyester film material

A polyester material, anti-aging technology, applied in the analysis of materials, material thermal analysis, computer parts, etc., to avoid the difficulty of detection, improve accuracy, and facilitate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Step 4: Extrude the masterbatch obtained in the above steps to blow the film, the blown film temperature is controlled at 180°C, and the anti-aging polyester film is obtained after further stretching.

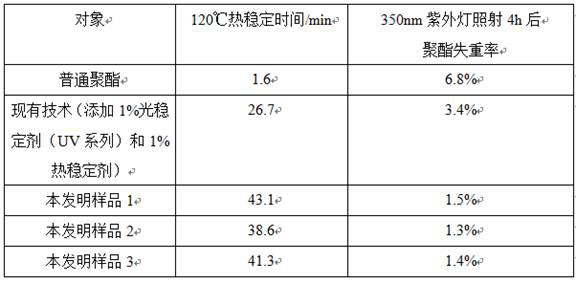

[0039] The above samples were tested to obtain

[0040] The detection device includes a light source, a heat source, a camera, and a processor.

[0041] The light source is used to irradiate the anti-aging film, thereby causing the photo-instability of the anti-aging film, thereby causing discoloration.

[0042] The heat source is used to apply heat to the anti-aging film, thereby causing thermal instability of the anti-aging film, and thus discoloration.

[0043] The camera is used to take the image of the anti-aging film before discoloration and the image after discoloration after a period of time.

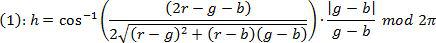

[0044] The processor is used to control the opening and closing of the light source and the camera, and is used to record time stamps when the camera takes pictures. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com