PVC anti-aging waterproof roll and preparation method thereof

A waterproofing membrane, anti-aging technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problem of impermeability, longitudinal tensile elongation at break, thermal aging and other properties that cannot be satisfied at the same time, restricting PVC waterproofing Coil application prospects, aging resistance and deformation resistance are difficult to achieve unity and other problems, to achieve the effect of strong adaptability to base shrinkage and cracking deformation, high deformation resistance, and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

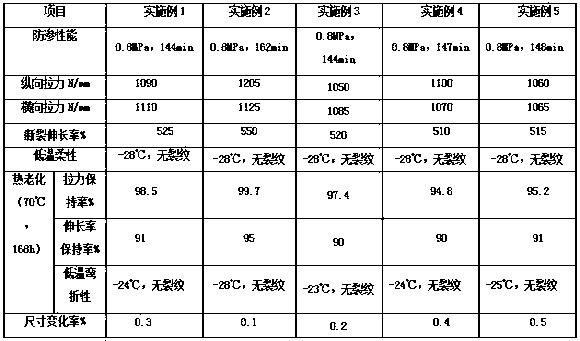

Embodiment 1

[0038] Embodiment 1 A kind of PVC aging-resistant waterproof coiled material

[0039] A PVC aging-resistant waterproof coiled material of the present invention is composed of a protective layer, a modified PVC layer and an adhesive layer, wherein the modified PVC layer includes the following raw materials: modified polyvinyl chloride, thermoplastic styrene-butadiene rubber, stabilized agent, epoxy resin, paraffin, sterol, anti-aging agent, pyrophyllite powder and isophorone diisocyanate, polyhexamethylene phosphate;

[0040] The raw materials include by weight: 25 parts of modified polyvinyl chloride, 10 parts of thermoplastic styrene-butadiene rubber, 5 parts of stabilizer, 7 parts of epoxy resin, 2 parts of paraffin, 1 part of sterol, 2 parts of antioxidant, leaf wax 1 part of stone powder, 5 parts of isophorone diisocyanate, 1 part of polyhexamethylene phosphate;

[0041] The modified polyvinyl chloride consists of 65 parts of polyvinyl chloride raw materials, 1.5 parts of...

Embodiment 2

[0047] Embodiment 2 A kind of PVC aging-resistant waterproof coiled material

[0048]A PVC aging-resistant waterproof coiled material of the present invention is formed by compounding a protective layer, a modified PVC layer and an adhesive layer, wherein the modified PVC layer comprises the following raw materials in parts by weight: 30 parts of modified polyvinyl chloride, 12 parts of thermoplastic styrene-butadiene rubber, 13 parts of stabilizer, 10 parts of epoxy resin, 6 parts of paraffin wax, 3 parts of sterol, 5 parts of antioxidant, 7 parts of pyrophyllite powder and 6 parts of isophorone diisocyanate, polyhexamethylene 3 parts of base phosphate;

[0049] The modified polyvinyl chloride consists of 65 parts of polyvinyl chloride raw materials, 1.5 parts of TAS-2A dispersion lubricant, 2.5 parts of compatibilizer, 6 parts of nano calcium carbonate, 21 parts of ethylene-octene copolymers, 3 parts of plant fibers Parts, 2 parts of diphenyl phosphate;

[0050] The epoxy ...

Embodiment 3

[0055] Embodiment 3 A kind of PVC aging-resistant waterproof coiled material

[0056] A PVC aging-resistant waterproof coiled material of the present invention is formed by compounding a protective layer, a modified PVC layer and an adhesive layer, wherein the modified PVC layer comprises the following raw materials in parts by weight: 35 parts of modified polyvinyl chloride, 15 parts of thermoplastic styrene-butadiene rubber, 15 parts of stabilizer, 12 parts of epoxy resin, 8 parts of paraffin wax, 5 parts of sterol, 8 parts of anti-aging agent, 15 parts of pyrophyllite powder and 15 parts of isophorone diisocyanate, polyhexamethylene 6 parts of base phosphate;

[0057] The modified polyvinyl chloride consists of 65 parts of polyvinyl chloride raw materials, 1.5 parts of TAS-2A dispersion lubricant, 2.5 parts of compatibilizer, 6 parts of nano calcium carbonate, 21 parts of ethylene-octene copolymers, 3 parts of plant fibers Parts, 2 parts of diphenyl phosphate;

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com