Preparation method of conductive adhesive

A technology of adhesives and organic solvents, applied in the field of preparation of conductive adhesives, can solve problems such as limitations in the application of conductive adhesives, and achieve the effects of facilitating electron transfer, high conductivity, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

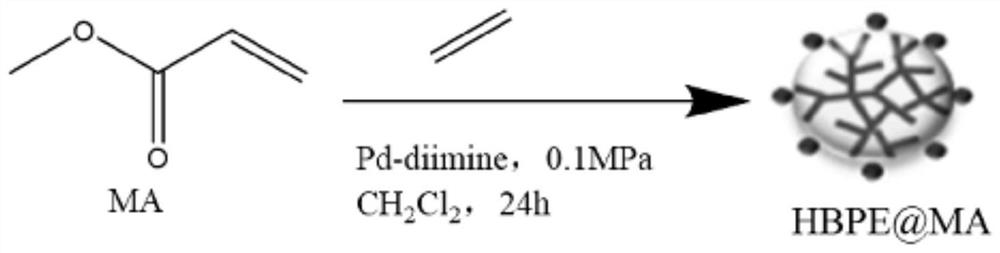

[0050] Example 0: Synthesis of HBPE@MA

[0051] In the present embodiment, there are many types of hyperbranched polyethylene. Exemplarily, hyperbranched polyethylene can be obtained by using a Pd-diimine catalyst to catalyze ethylene with a one-step "chain removal" copolymerization mechanism. The specific preparation process includes the following steps:

[0052] (1) Put a clean stirring magnet in a 250ml dry double-layer Schlenk bottle, plug it with a rubber stopper, evacuate for 3 minutes, pass ethylene for 3 minutes, repeat 3 times, and fill with ethylene, keep the temperature of the magnetic stirrer at a constant temperature Set at room temperature, and set the pressure of ethylene to 1.10 atmospheres (positive pressure protection). Bake the reaction flask at about 400 degrees for about 5 minutes with an electric heating gun, and then bake for a total of four times. (At the same time, vacuum and turn off the ethylene gas to ensure that the reaction flask is completely an...

Embodiment 1, Embodiment 2

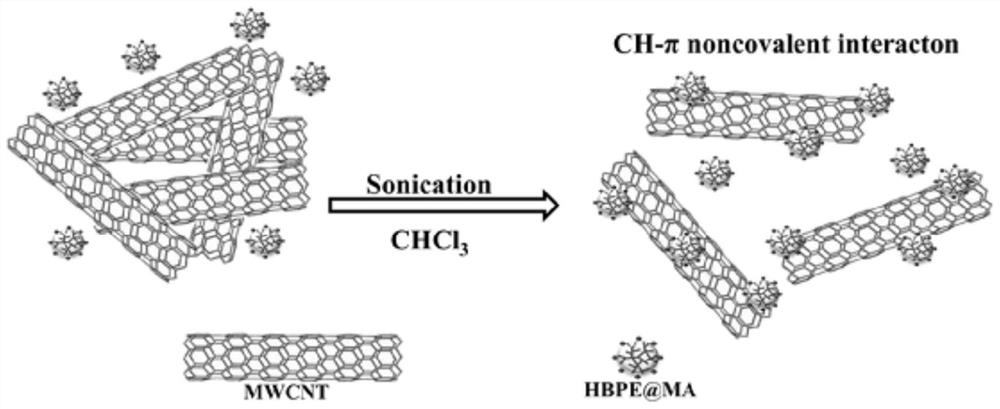

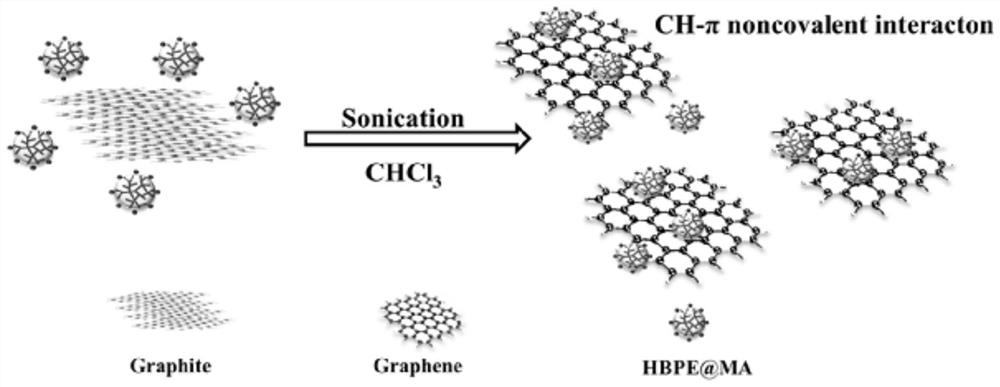

[0062] Example 1, Example 2, Comparative Example 1

[0063] 1. Preparation of Samples

[0064] (1) Embodiment 1 provides a kind of method for connecting methyl acrylate auxiliary dispersion carbon tube with hyperbranched polyethylene, peeling graphene and the method for preparing composite conductive adhesive, and the steps are as follows:

[0065] Step 1: Weigh 320 mg of natural flake graphite with a purity of 99.5% produced by SigmaAldrich in the United States into a 100 ml cylindrical glass bottle.

[0066] Step 2: Weigh 160mg HBPE@MA into a small glass bottle, add 10ml of chloroform (produced by Sinopharm Chemical Co., Ltd., its purity is greater than or equal to 99.0%, no other special instructions, also use the chloroform) rinse, then pour into In a cylindrical glass bottle, repeat 2 times (ensure that all hyperbranched polymer is completely carried out).

[0067] Step 3: Take 50ml of chloroform with a pipette and pour it into a 100ml cylindrical glass bottle, and seal...

Embodiment 2

[0075] Step 1: Weigh 0.8g of acrylic pressure-sensitive adhesive (produced by Anzo Chemical Company) into a small glass bottle, the solid content is 30.5±1.0%, and the solvents are toluene and ethyl acetate. Add 15 ml of chloroform to dissolve completely. Put into a stirring magnet and stir for 12h.

[0076] Step 2: Use an adjustable scraper to manually coat the adhesive layer (the thickness of the adhesive layer after drying is 20 μm) on the release film. It was dried in a forced air oven for 12 h and the solvent was removed. Finally, it was transferred to a 25 μm thick PET film with a roller. A pure glue layer was prepared.

[0077] (3) Comparative Example 1 has the same preparation steps as Example 1, except that the mass fraction of the total filler is 1%.

[0078] 2. Characterization and Testing

[0079] Test the electrical conductivity of composite materials.

[0080] (1) High resistance measuring instrument

[0081] The test instrument is a surface resistance tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com