Preparation method of flame-retardant halogen-free TPU sunscreen fabric

A technology of sunshine fabric and composite flame retardant, which is applied in the field of preparation of TPU sunshine fabric, can solve the problems of poor flame retardancy and limit the application of TPU materials, and achieve the effect of high flame retardancy, good application prospect and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dry the TPU and anti-adhesive masterbatch at 105°C for 3 hours for later use.

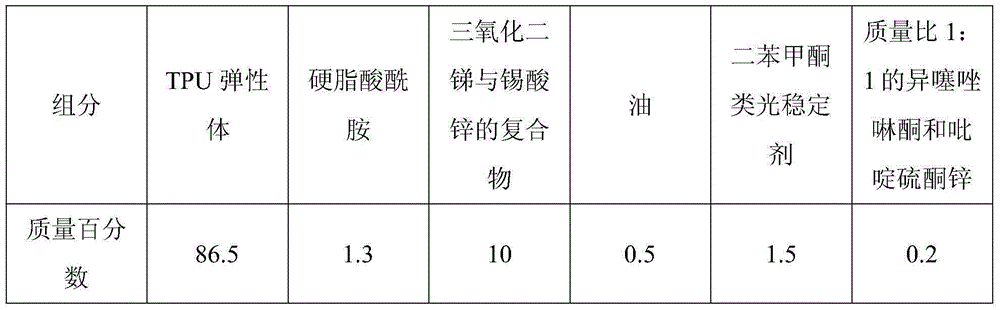

[0024] (2) According to the formula in Table 1, physically blend TPU with various fillers, mix well and set aside.

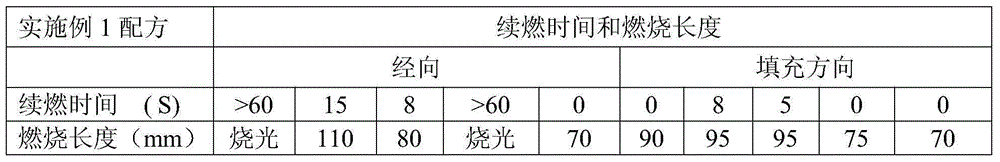

[0025] (3) The mixed TPU particles are melted in the extruder and coated with PET precursors to obtain coated yarns, and the yarns are woven and shaped into finished fabrics. Among them, the parameters of the extruder are set as follows: the temperature of the die head and the screw is set to 210°C, the temperature of the barrel outlet is set to 180°C, the screw speed is 50r / min, and the winding speed is set to 400m / min. min. The yarn obtained under this process condition is subjected to warping, weaving, heat setting and other processes to obtain a flame-retardant and halogen-free TPU sunshine fabric; among them, the temperature of heat setting is 160°C, the speed is 15m / min, and the quality of TPU / PET Ratio = 72%: 28%. The obtained TPU fabric was tested for performanc...

Embodiment 2

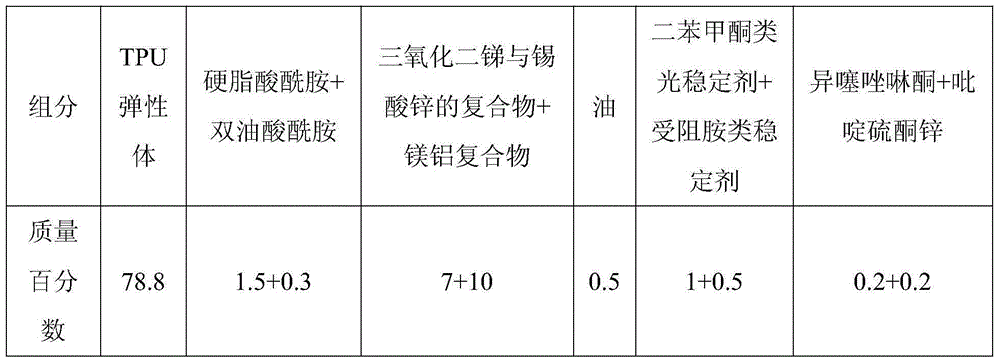

[0031] Concrete each production process is the same as implementing 1, just formula is different, and formula is as shown in table 3. The obtained TPU fabric was tested for performance, and the results are shown in Table 4.

[0032] The add-on of each component in the embodiment 2 of table 3

[0033]

[0034] The performance test result of the TPU fabric of table 4 embodiment 2

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com