Direct-lit backlight module

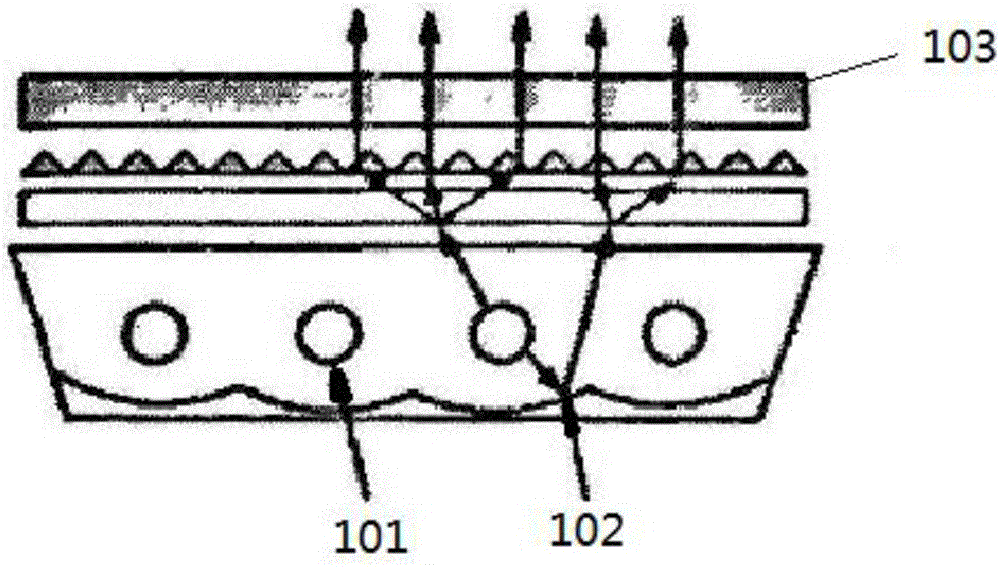

A backlight module, direct type technology, used in optics, nonlinear optics, instruments, etc., can solve problems such as light leakage, structural damage, and whitening of the picture, and achieve the effect of improving heat dissipation performance, prolonging life, and improving thermal aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In order to solve the problem that after the direct-type backlight module is used for a period of time, the backlight heats up seriously, causing the overall deformation of the polarizer and reducing the service life of the display. This embodiment proposes a direct-type backlight module.

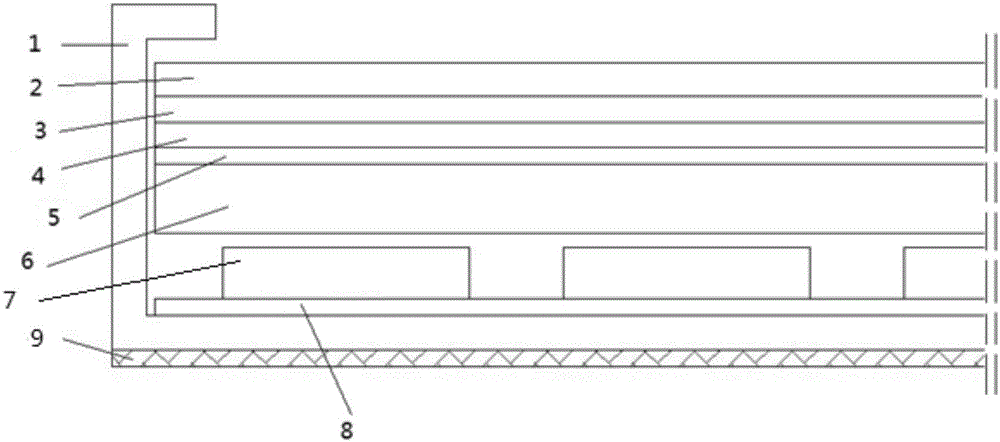

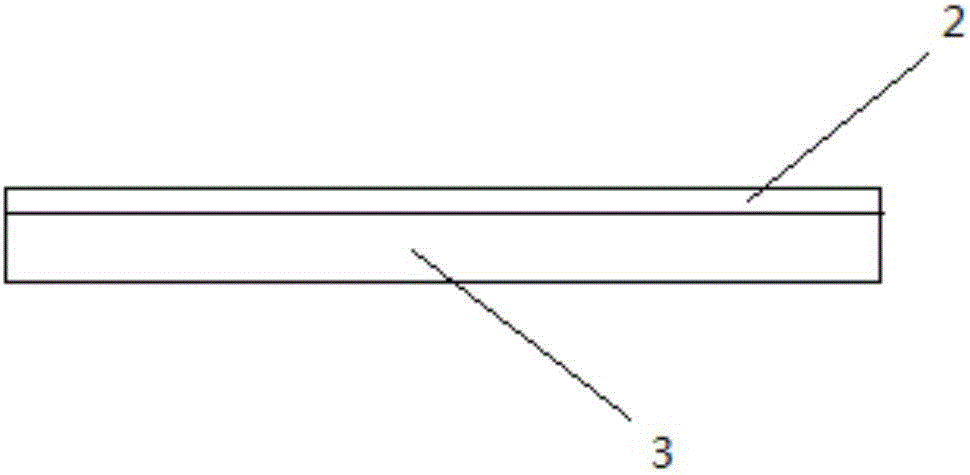

[0047] see figure 2 . like figure 2 As shown, from top to bottom are: SiOx layer 2, upper prism sheet 3, lower prism sheet 4, diffusion plate 5, light guide plate 6, light source 7, flexible circuit board 8, bottom plate of backplane 1 and heat dissipation film 9. A light source 7 is set above the bottom plate of the back plate 1, a light guide plate 6 is set above the light source 7, a diffusion plate 5 is set above the light guide plate 6, and a lower prism sheet 4 and an upper prism are sequentially set above the diffusion plate 5 Sheet 3; flexible circuit board 8 is arranged between the light source 7 and the bottom plate of the backplane 1 and supplies power to the light sou...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is only: it is about the optimized arrangement mode of the SiOx layer on the upper surface of the upper prism sheet 3, and the thickness of the SiOx layer is The thickness of the heat dissipation film is 0.05mm, while other technical features and technical problems to be solved are the same as those in Embodiment 1.

[0054] The scheme of this embodiment is: the outer edge of the thermal insulation layer is flush with the outer edge of the upper surface of the upper prism sheet, the inner edge of the thermal insulation layer is rectangular, and the four corners of the rectangle are chamfered. The advantage of this solution is that stress concentrations at the four corners of the rectangle are avoided. See Figure 7 .

Embodiment 3

[0056] The only difference between this embodiment and embodiment 1 is that it is about the optimized arrangement of the SiO layer on the upper surface of the upper prism sheet 3 , while other technical features and technical problems to be solved are the same as those of embodiment 1.

[0057] The outer edge of the thermal insulation layer is flush with the outer edge of the upper surface of the upper prism sheet, and the inner edge of the thermal insulation layer is oval. See Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com