Insulator and transmission line

A technology of insulators and insulating surfaces, applied in the field of power transmission and transformation, can solve problems affecting the safe and stable operation of power systems, and achieve the effects of increasing temperature, accelerating thermal aging, and preventing ice formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

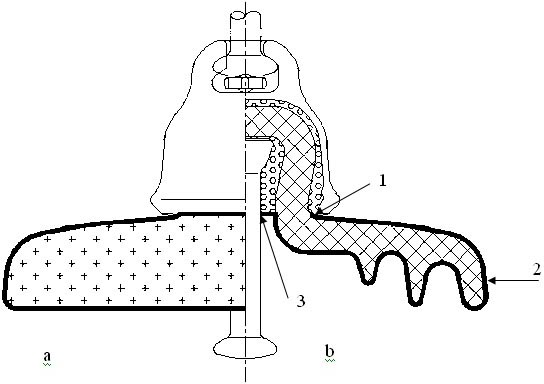

[0023] In one embodiment, the insulator includes an insulating surface, a portion of which is coated with a conductive paint of a specific resistivity. see figure 1 , the insulator of one embodiment is divided by the center line, the left half a of the center line is the view of the outer surface of the insulator, the right half part b is the cross-sectional view of the insulator, and the specific resistivity conductive paint area on the insulating surface is figure 1 For surfaces between midpoint 2 and point 3, the specific resistivity conductive coating preferably has a volume resistivity of 10 5 Ohm centimeters, forming a low-temperature hydrophobic surface, the coating thickness is preferably 0.3mm-0.4mm. figure 1 The area between midpoint 1 and point 2 is not coated with conductive paint, which is a non-conductive paint area. Areas of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com