Carrier film for transparent conductive films and laminate

A technology of transparent conductive film and transparent conductive layer, which is applied to the conductive layer, application, coating and other directions on the insulating carrier to achieve the effect of softening the adhesive layer, inhibiting the zipper phenomenon, and reducing the crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

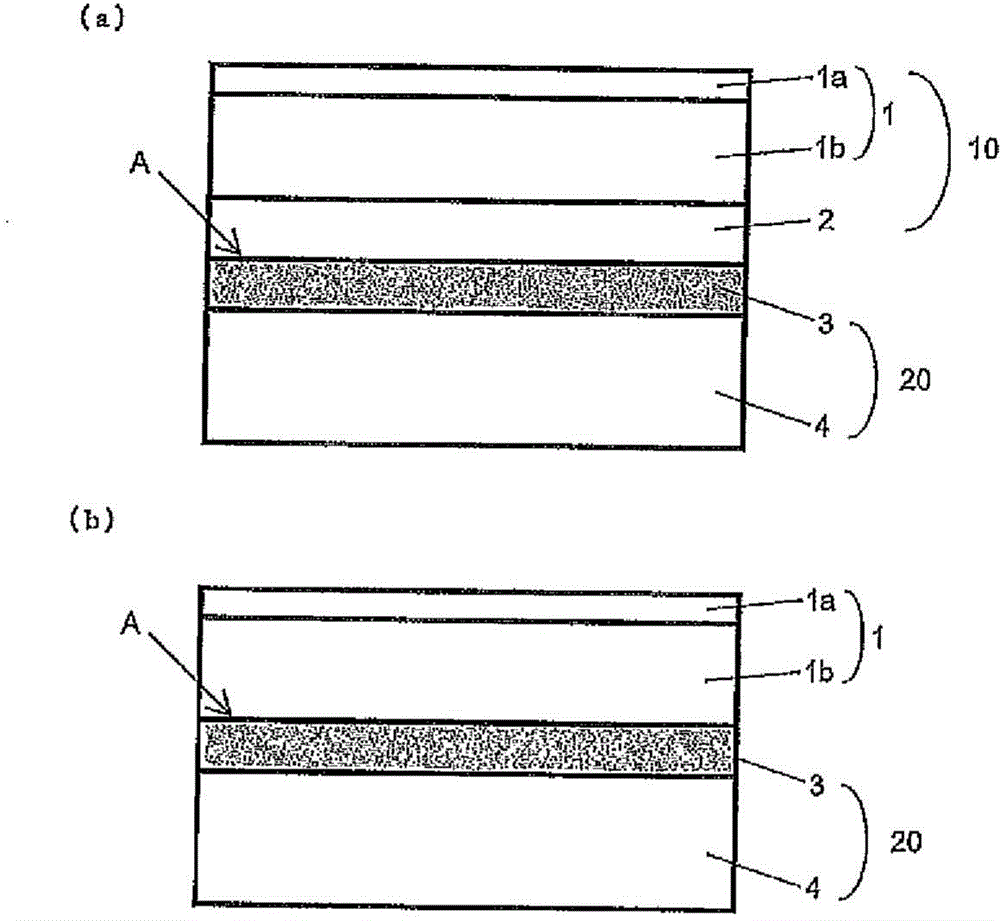

Image

Examples

Embodiment 1

[0168]

[0169] In a four-necked flask with a stirring blade, a thermometer, a nitrogen inlet tube and a condenser, 100 parts by weight of 2-ethylhexyl acrylate (2EHA), 10 parts by weight of 4-hydroxybutyl acrylate (HBA), 0.2 parts by weight 2,2'-Azobisisobutyronitrile and 205 parts by weight of ethyl acetate as a polymerization initiator, nitrogen gas was introduced while stirring slowly, and the liquid temperature in the flask was kept at about 63°C for about 4 hours. Polymerization reaction, Thus, an acrylic polymer (A1) solution (about 35% by weight) was prepared. The acrylic polymer (A1) had a weight average molecular weight of 600,000 and a Tg of -67°C.

[0170]

[0171] The above-mentioned acrylic polymer (A1) solution (about 35% by weight) was diluted to 29% by weight with ethyl acetate, and 4 parts by weight of trimethylol was added to 100 parts by weight (solid content) of the acrylic polymer in the solution. Propane / toluene diisocyanate trimer adduct (manufactu...

Embodiment 2~20、 comparative example 1~2

[0175] As shown in Table 1 and Table 2, the types or compounding amounts of the monomer components constituting the acrylic polymer, the crosslinking agent constituting the adhesive composition, the catalyst, and the keto-enol tautomeric compound were changed. Except that, the carrier film for transparent conductive films was produced by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com