Technique for manufacturing natural crosslinking polyethylene-insulated cable material

A technology of natural cross-linking and manufacturing process, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of large equipment occupancy rate, slow cross-linking speed, and long time required to shorten the production cycle and exchange The effect of short connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

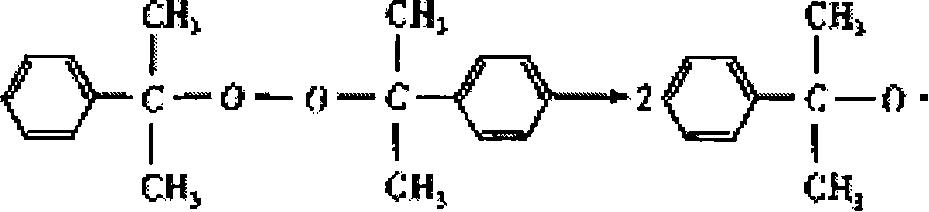

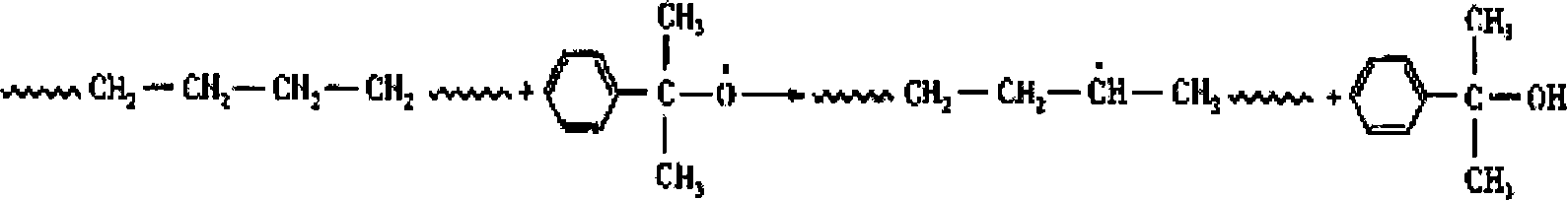

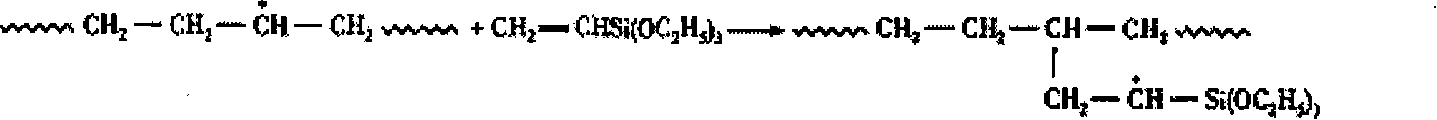

Method used

Image

Examples

Embodiment 1

[0102] 1), making A material:

[0103] (name and parts by weight of raw materials included):

[0104] LDPE, 90; linear low density polyethylene LLDPE, 10; vinyltriethoxysilane (silane coupling agent) 1.5; dicumyl peroxide (DCP) initiator, 0..5; sodium bicarbonate ( anti-precrosslinking agent), 0.03.

[0105] After the above raw materials are blended, reaction grafting occurs through a twin-screw extruder, melted and granulated, and A material is obtained.

[0106] 2), making B material:

[0107] (name and parts by weight of raw materials included):

[0108] LDPE, 10; linear low density polyethylene LLDPE, 90; benzenesulfonic acid (catalyst), 0.5; amine bicarbonate (anti-precrosslinking agent), 0.5; 3114 (antioxidant) 10; oleic acid amide (processing aid agent) 1.

[0109] The above raw materials are mixed, melted and granulated by a twin-screw extruder to obtain material B.

[0110] 3), mixing and melting

[0111] When the cable factory is producing, mix A material and ...

Embodiment 2

[0113] 1), making A material:

[0114] (name and parts by weight of raw materials included):

[0115] Ultra-low density polyethylene, 100; vinyldiethoxysilane (silane coupling agent) 1.5; TBPB (initiator), 0.1; aniline (anti-precrosslinking agent), 0.01; EVA (water diffusing agent), 1 .

[0116] After the above raw materials are blended, reaction grafting occurs through a twin-screw extruder, melted and granulated, and A material is obtained.

[0117] 2), making B material:

[0118] (name and parts by weight of raw materials included):

[0119] High-density polyethylene, 100; sulfuric acid (catalyst), 5; bicarbodiimide (anti-crosslinking agent), 5; DLTP (antioxidant) 1, polypropylene wax (processing aid) 5.

[0120] The above raw materials are mixed, melted and granulated by a twin-screw extruder to obtain material B.

[0121] 3), mixing and melting

[0122] When the cable factory is producing, mix A material and B material, the mixing weight ratio of A material and B ma...

Embodiment 3

[0124] 1), making A material:

[0125] (name and parts by weight of raw materials included):

[0126] Medium density polyethylene, 100; vinyl dimethoxysilane (silane coupling agent) 1.5; BPO (initiator), 0.2; isopropylamine (anti-precrosslinking agent), 0.05; EVA-g-MA (water diffusion agent) 10.

[0127] After the above raw materials are blended, reaction grafting occurs through a twin-screw extruder, melted and granulated, and A material is obtained.

[0128] 2), making B material:

[0129] (name and parts by weight of raw materials included):

[0130] Low-density polyethylene, 100; Alkylbenzenesulfonic acid (catalyst), 3; L-pyroglutamic acid (anti-precrosslinking agent), 3; Bisphenol A (antioxidant) 5, PPA (processing aid) 10.

[0131] The above raw materials are blended, melted by a twin-screw extruder, blended and granulated to obtain material B.

[0132] 3), mixing and melting

[0133] When the cable factory is producing, mix A material and B material, the mixing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com