Process for the manufacture of an ophthalmic lens

A technology of ophthalmic lenses and raw materials, applied in applications, household appliances, and other household appliances, can solve problems such as complex systems, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

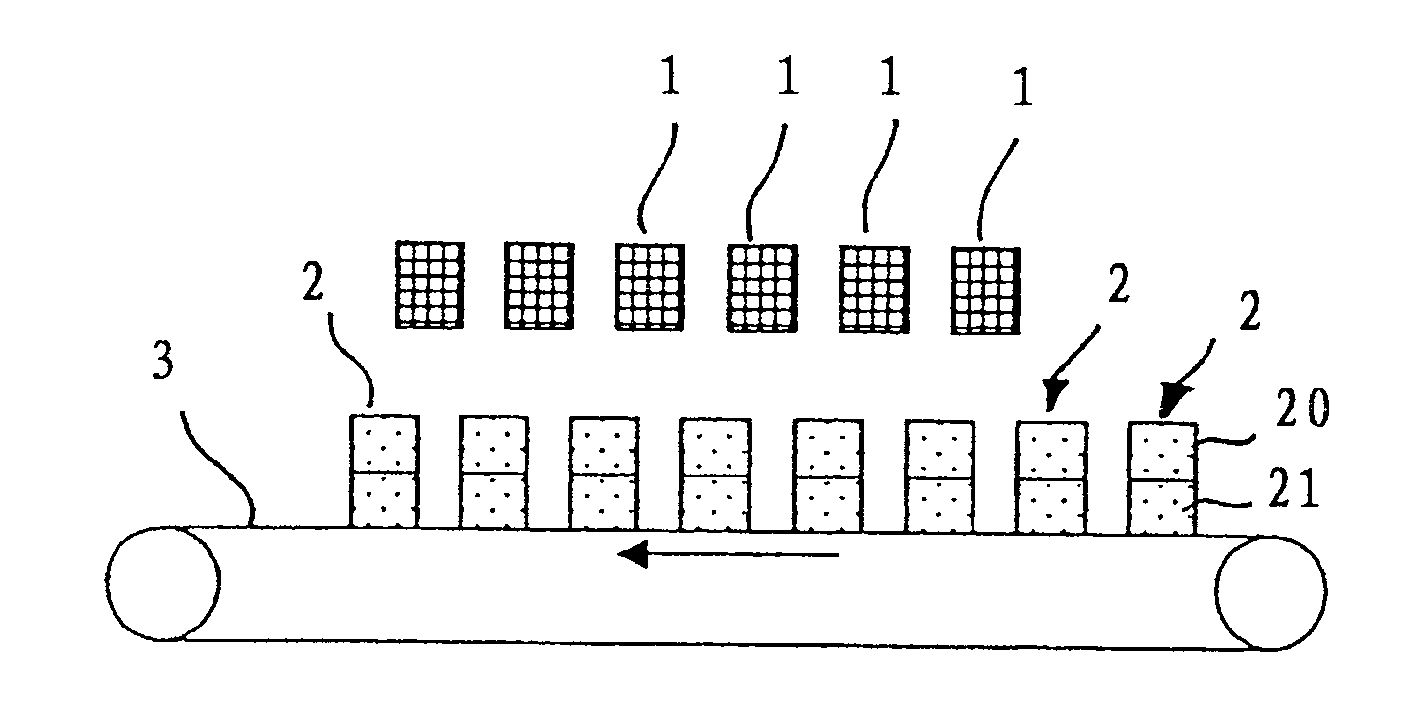

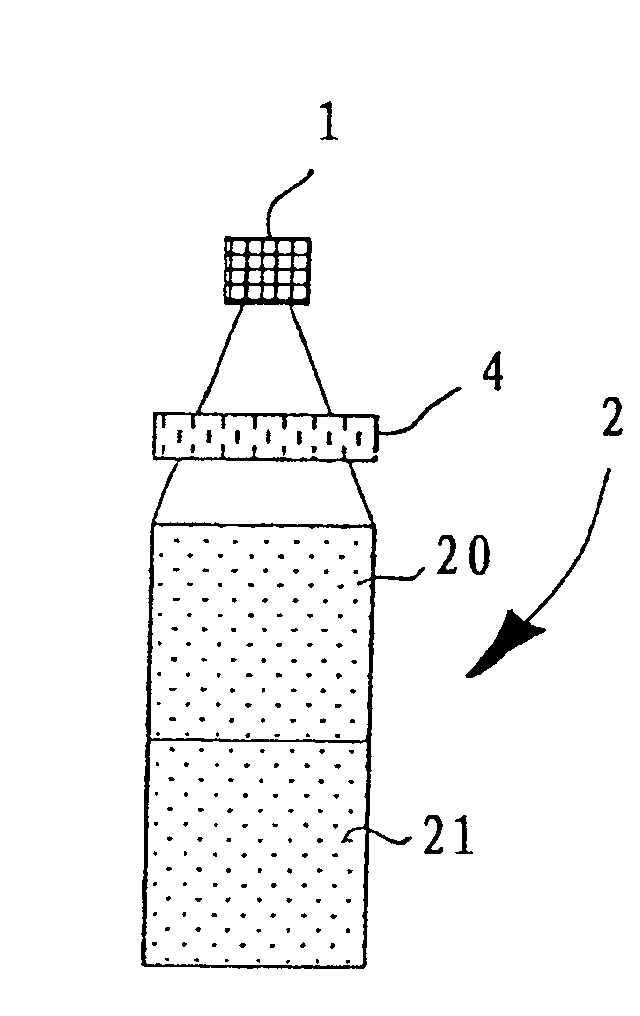

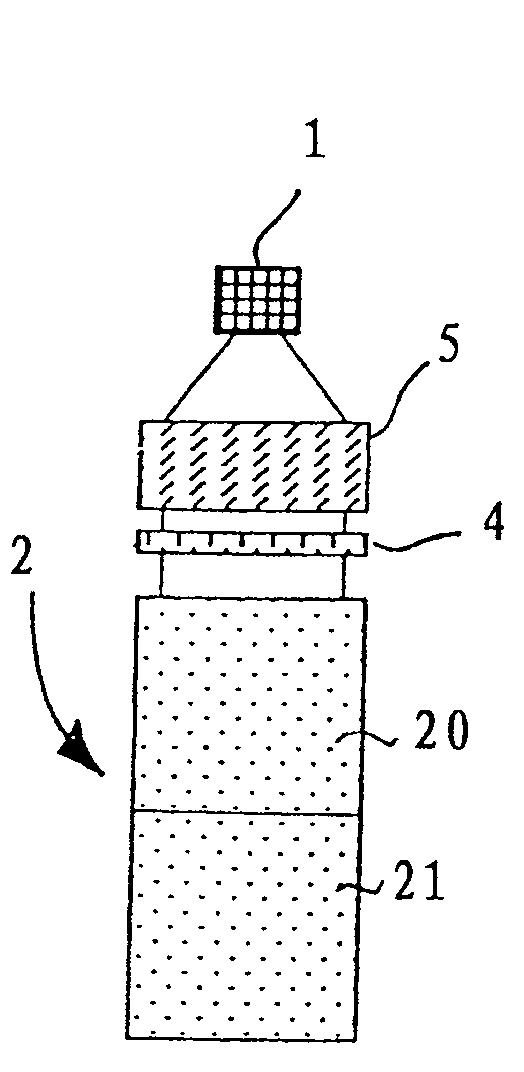

[0025] A first variant of the method according to the invention consists in figure 1 shown in . A plurality of UV-LEDs 1 are arranged on a conveyor belt 3 on which a plurality of molds 2 are arranged. Each mold 2 comprises a male mold half 20 and a female mold half 21 forming a mold cavity between their respective lens forming surfaces. Typically, by assembling the male mold half 20 and the female mold half 21 , the raw material comprising a photoinitiator can be filled into the female mold half 21 before closing the mold 2 . The mold 2 is made of a translucent light scattering material, such as polypropylene.

[0026] figure 1 The embodiment shown in is a so-called double-sided molding (DSM) process. The raw materials used have a relatively low polymerization and / or crosslinking rate, that is to say the polymerization and / or crosslinking process lasts for a longer period of time, for example in the range of one to several minutes. The moving mold 2 passes through the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com