Regenerated tissue matrix microparticles for micro-plastic surgery, preparation method and application

A technology for tissue regeneration and micro-shaping, applied in medical science, prostheses, etc., can solve the problems of increasing the economic pressure of users, the difficulty of operation by clinicians, the short duration of maintenance effect, and the tendency to appear uneven, so as to achieve easy cell adhesion and emigration, low usage, and the effect of avoiding burning damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

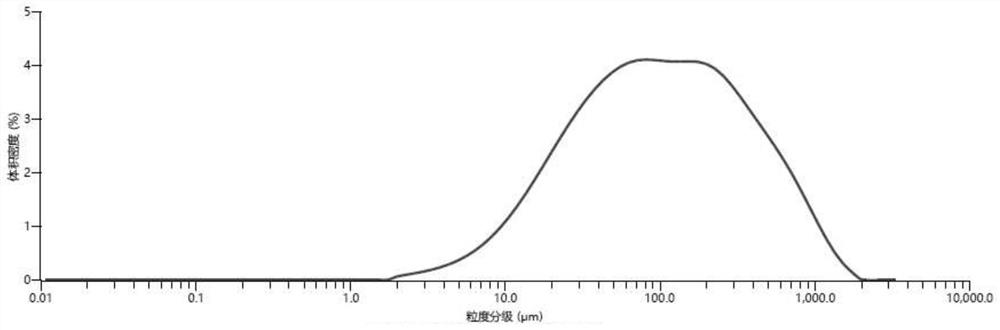

[0059] The preparation method of the regenerated tissue matrix microparticles proposed by the present invention comprises the steps of:

[0060] 1) Put the allograft skin raw material into the glycerin solution of alkali, soak and vibrate to obtain the semi-finished product A;

[0061] 2) Remove the epidermis of the semi-finished product A, put it into a surfactant solution, and perform ultrasonic soaking treatment to obtain the semi-finished product B;

[0062] 3) Cut the semi-finished product B into small skins, immerse it in liquid nitrogen for 3-10 minutes, and take it out as semi-finished product C;

[0063] 4) Under the action of high-speed rotating centrifugal force, the semi-finished product C is cut with a rotary knife to obtain the semi-finished product D;

[0064] 5) Soak the semi-finished product D in the D-amino acid solution, and separate the solid and liquid to obtain the semi-finished product E;

[0065] 6) The semi-finished product E is made into a prefilled...

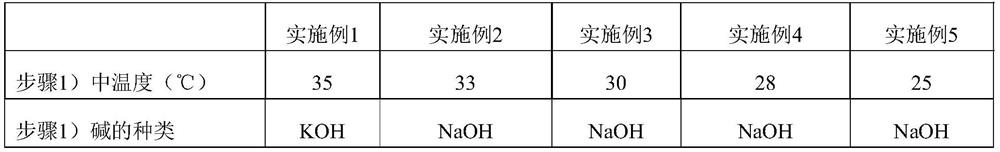

Embodiment 1-5

[0069] 1) Put the allograft skin raw material into the glycerol solution of alkali, soak it at 25-35°C for 1-10 hours and shake it to get the semi-finished product A;

[0070] 2) After removing the epidermis of the semi-finished product A, wash it with sterile pure water for 0.1-5.0 minutes, put it into the surfactant solution, and ultrasonicate it for 1-5 minutes at an ultrasonic frequency of 20-45KHz and an ultrasonic temperature of 1-20°C. Soak 1~4h, change the surfactant solution of new; Repeat the treatment of ultrasonic and immersion, get semi-finished product B (specifically, embodiment 1 is 2.5h four times. Embodiment 2 is 2h four times. Embodiment 3 is 2.5h Secondary. Embodiment 4 is 2h once. Embodiment 5 is 1h once).

[0071] 3) Optionally, the semi-finished product B is rinsed with sterile pure water for 0.1-5.0 min, and put into 0-0.6% genipin aqueous solution (the pH of the genipin solution at this concentration is 5-7) for cross-linking, Rinse with sterile pure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com