Fat-soluble vitamin microcapsule continuous cross-linking method and device

A technology of fat-soluble vitamins and cross-linking method, which is applied in the field of continuous cross-linking of fat-soluble vitamin microcapsules, which can solve the problems of loss and deterioration of effective components, differences in particle cross-linking degree, and lower heat utilization rate, and achieve short cross-linking time , Uniform cross-linking degree of particles, long product shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

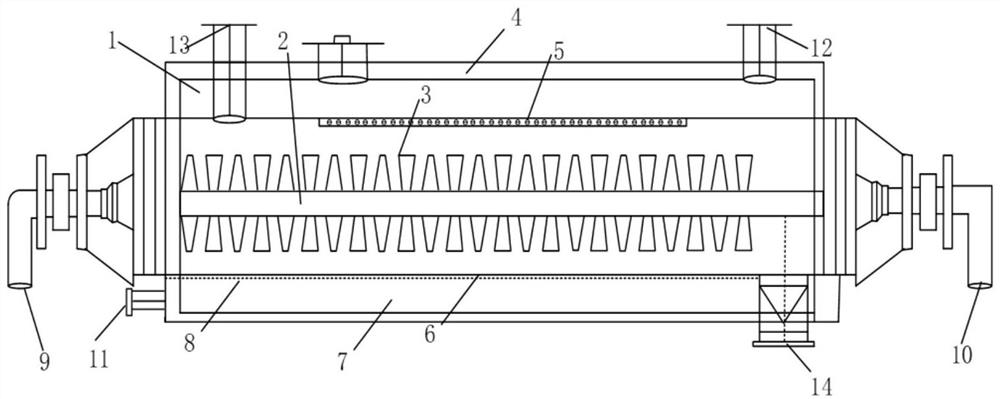

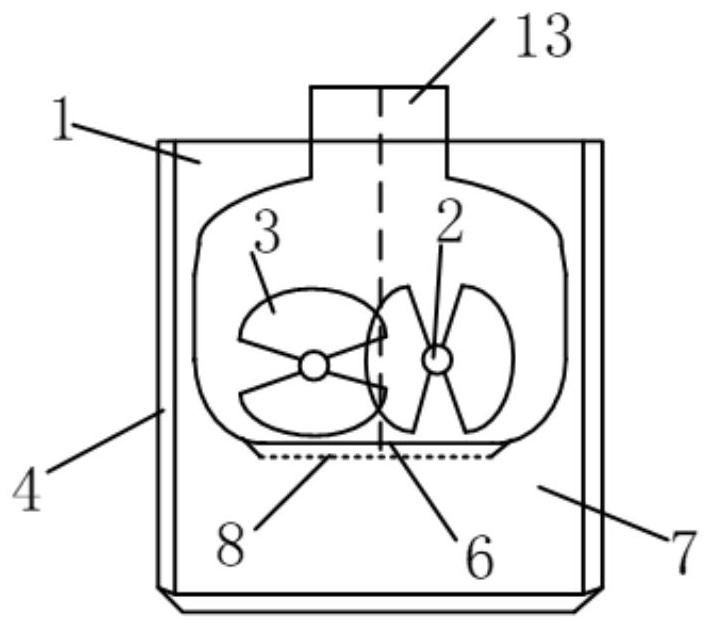

[0061] A horizontal twin-shaft hollow paddle dryer (structure such as figure 1 , 2 shown), the housing 1 contains double screw shafts 2, paddles 3 added on the screw shafts 2, and shell jacket layer 4, the double screw shafts 2 and paddles 3 are hollow, and the paddles 3 The shape is wedge-shaped, and the dryer with this structure (ordinary horizontal double-shaft hollow paddle dryer, excluding the following special structures such as mesh plates and screens) can be purchased from the market. In this embodiment, Changzhou Youbo KJG- 120 dryer. On the basis of the dryer structure, the following improvements are made:

[0062] An ultraviolet light irradiation device 5 is arranged on the top of the inner cavity of the dryer.

[0063] The bottom of the horizontal cavity of the above-mentioned dryer is designed as a mesh plate 6, and a layer of carrier gas passage 7 is arranged between the mesh plate 6 and the shell jacket layer 4; the hole type of the mesh plate 6 is a nail hol...

Embodiment 2

[0067] Adopt the horizontal twin-shaft hollow paddle drier of embodiment 1, vitamin A acetate microcapsules (moisture content 9wt%) carry out cross-linking reaction, and step is:

[0068] 1) Pass hot water (75-90°C) into the shaft, paddle, and shell jacket layer of the horizontal double-shaft hollow blade to preheat the horizontal double-shaft hollow blade until the double-shaft The initial temperature is 45°C, and there is no condensed water on the inner wall of the dryer; at the same time, a mixed gas of nitrogen and water vapor is introduced into the cavity of the dryer as a carrier gas (the temperature of the carrier gas is 45°C, and the humidity of the carrier gas is 65%);

[0069] 2) Turn on the drying machine and the ultraviolet light irradiation device, the ultraviolet light wavelength is 300nm, and the light intensity is 180Lux. Add vitamin A acetate microcapsules to be cross-linked into the cavity of the dryer, so that the fat-soluble vitamin microcapsules to be cros...

Embodiment 3

[0075] Using the horizontal twin-shaft hollow paddle dryer of Embodiment 1, vitamin A acetate microcapsules (moisture content 10wt%) carry out cross-linking reaction, and the steps are:

[0076] 1) Introduce steam (105-115°C) into the shaft of the horizontal twin-shaft hollow blade, the blade, and the jacket layer of the shell to preheat the horizontal twin-shaft hollow blade until the initial The temperature is 50°C, and there is no condensed water on the inner wall of the dryer; at the same time, a mixed gas of air and water vapor is introduced into the cavity of the dryer as a carrier gas (the temperature of the carrier gas is 50°C, and the humidity of the carrier gas is 70%);

[0077] 2) Turn on the drying machine and the ultraviolet light irradiation device, the ultraviolet light wavelength is 350nm, and the light intensity is 200Lux. Add vitamin A acetate microcapsules to be cross-linked into the cavity of the dryer, so that the fat-soluble vitamin microcapsules to be cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com