Method for making creep resistant refractory metal structures

A metal structure and metal technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of overlapping and non-overlapping, and achieve the effect of improving mechanical properties and improving sag resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Unless otherwise indicated, it is to be understood that all numbers used in the specification and claims, such as those expressing weight percents of ingredients, dimensions, and values of certain physical properties, are in all instances modified by the term "about". It should also be understood that the precise numerical values used in the specification and claims form additional embodiments of the invention. Efforts have been made to ensure the accuracy of the numerical values disclosed in the examples. Any measured numerical value, however, may inherently contain errors resulting from the standard deviation found in their respective measurement techniques.

[0047] As used herein, in the description and claims of the present invention, the indefinite article "a" or "an" means "at least one", "at least one", and should not be limited to "only one" or "Only one" unless expressly stated to the contrary.

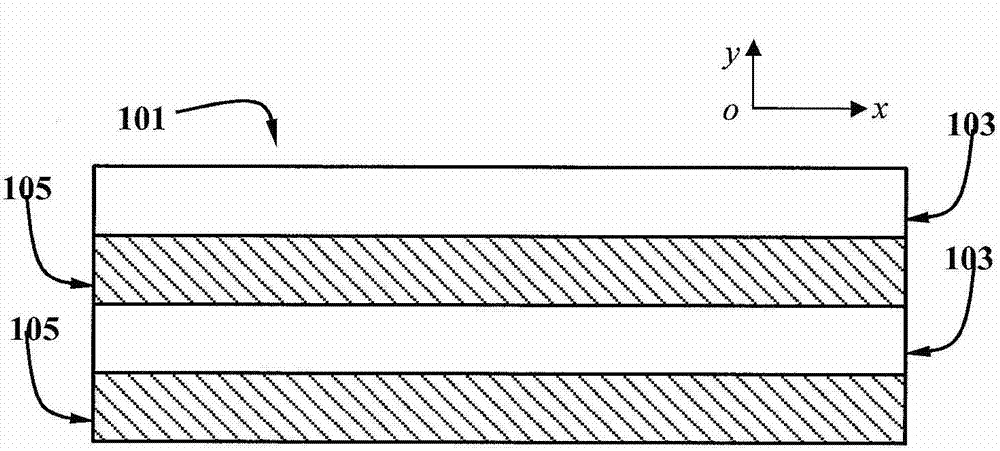

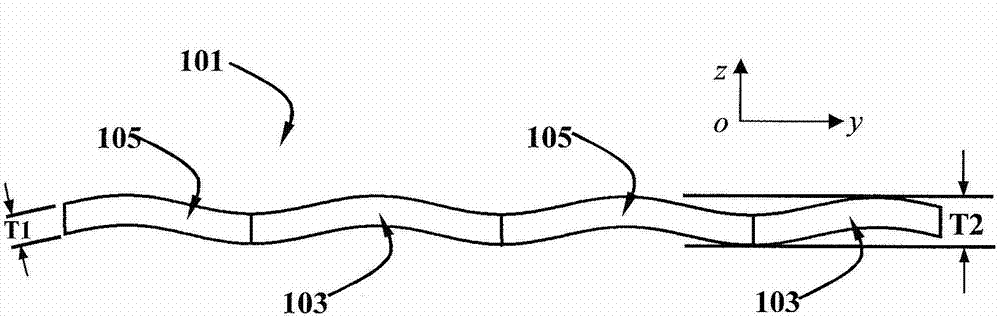

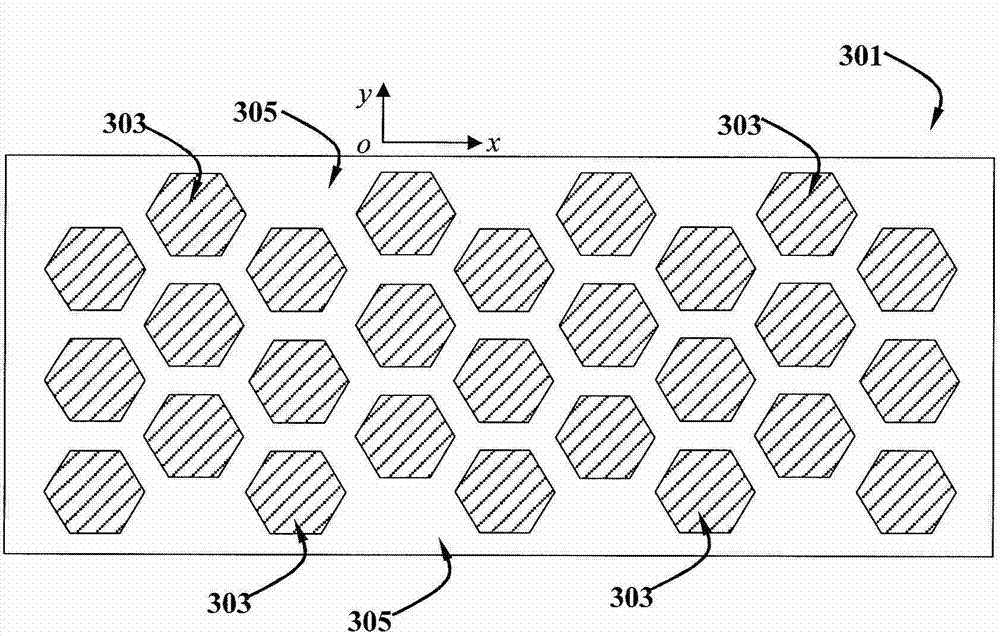

[0048] For the convenience of description, in this appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com