Rare earth, molybdenum and tungsten alloy used for cutting wires and preparing method thereof

A molybdenum-tungsten alloy and cutting wire technology, applied in the field of alloy research, can solve the problems of negative impact on electrical conductivity and mechanical properties, poor processing performance, high brittleness, etc., and achieve excellent electrical and thermal conductivity, low tensile strength, and resistivity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of rare earth molybdenum tungsten alloy comprises the following steps:

[0038] 1) Powder mixing: according to the weight ratio of 74.4% molybdenum, 25% tungsten and 0.6% rare earth, put 37.2kg molybdenum powder, 12.5kg tungsten powder, 0.176kg lanthanum oxide, and 0.8kg cerium oxide into the "V" type mixing In the feeder, mix for 0.5h to obtain synthetic powder;

[0039] 2) Powder filling: Take 920 grams of synthetic powder and put it into the rubber sleeve on the vibration platform, vibrate for 0.5h, vibrate until it is uniform and dense, and then seal it with a plug;

[0040] 3) Forming: Place the sealed rubber sleeve on the rubber sleeve frame, then put the rubber sleeve frame into the barrel of the cold isostatic press, increase the pressure from 0MPa to 145-165MPa within 5-6min, The duration of the pressure holding process under 165MPa is 1-5min, and then the pressure relief is completed within 3-5min. After the cool pressing is completed, the mater...

Embodiment 2-4

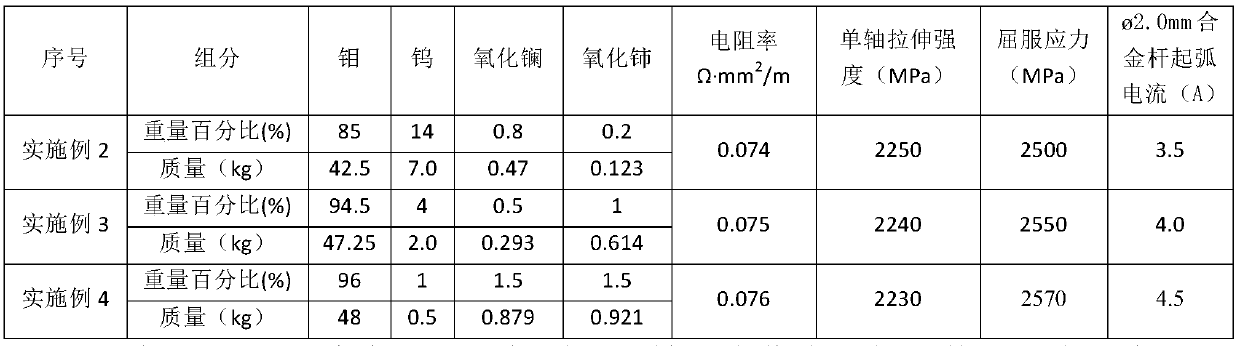

[0049] In Examples 2-4, the preparation process of the alloys is exactly the same as in Example 1, except that the ratio of the components is changed, as shown in Table 1 below.

[0050] Composition and performance parameters of rare earth molybdenum-tungsten alloy in the embodiment 2-4 of table 1

[0051]

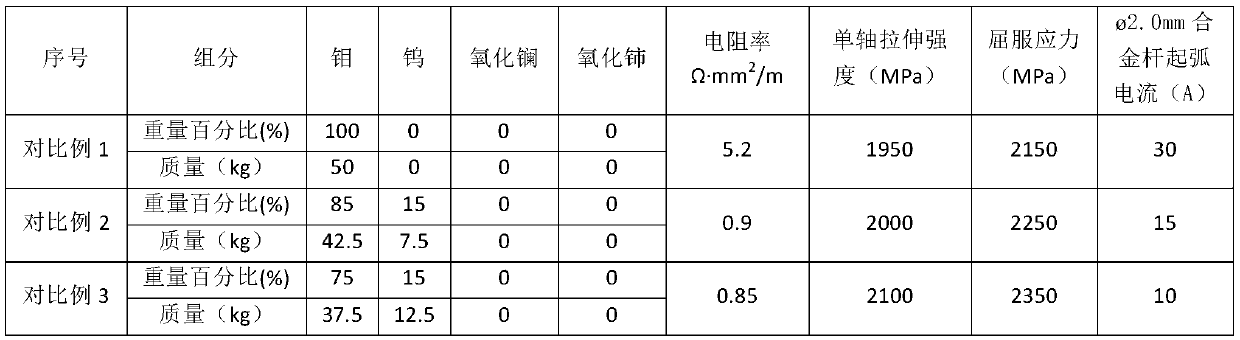

[0052] It can be seen from Table 1 that the rare earth molybdenum-tungsten alloy provided by the present invention is used as a cutting wire, and the resistivity is all less than 0.080Ω·mm 2 / m, the uniaxial tensile strength is greater than 2200MPa, the yield stress is greater than 2500MPa, the diameter The minimum arcing current of the alloy rods is not more than 4.5A, which shows that the rare earth molybdenum-tungsten alloy provided by the present invention has excellent electrical and thermal conductivity and tensile strength as a cutting wire, as well as a small arcing current, so that it can be obtained Larger cutting current and discharge spark greatly improve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com