Manufacturing technology of molybdenum-based rare-earth alloy slab and equipment thereof

A rare earth alloy and manufacturing process technology, which is applied to the manufacturing process of molybdenum-based rare-earth alloy sheet and its equipment field, can solve the gap of sheet specifications and varieties, the rationality of molybdenum-based sheet alloy ratio, the sintering process arrangement for homogenization and purification of blanks, and the Problems such as temperature control, rolling process arrangement, sheet quality and specification and variety gaps, etc., to achieve the effect of fully stable mechanical properties and reduction of the number and size of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Manufacturing 0 XB--2×450×800 (mm) 100 pieces of molybdenum-based rare earth alloy plates.

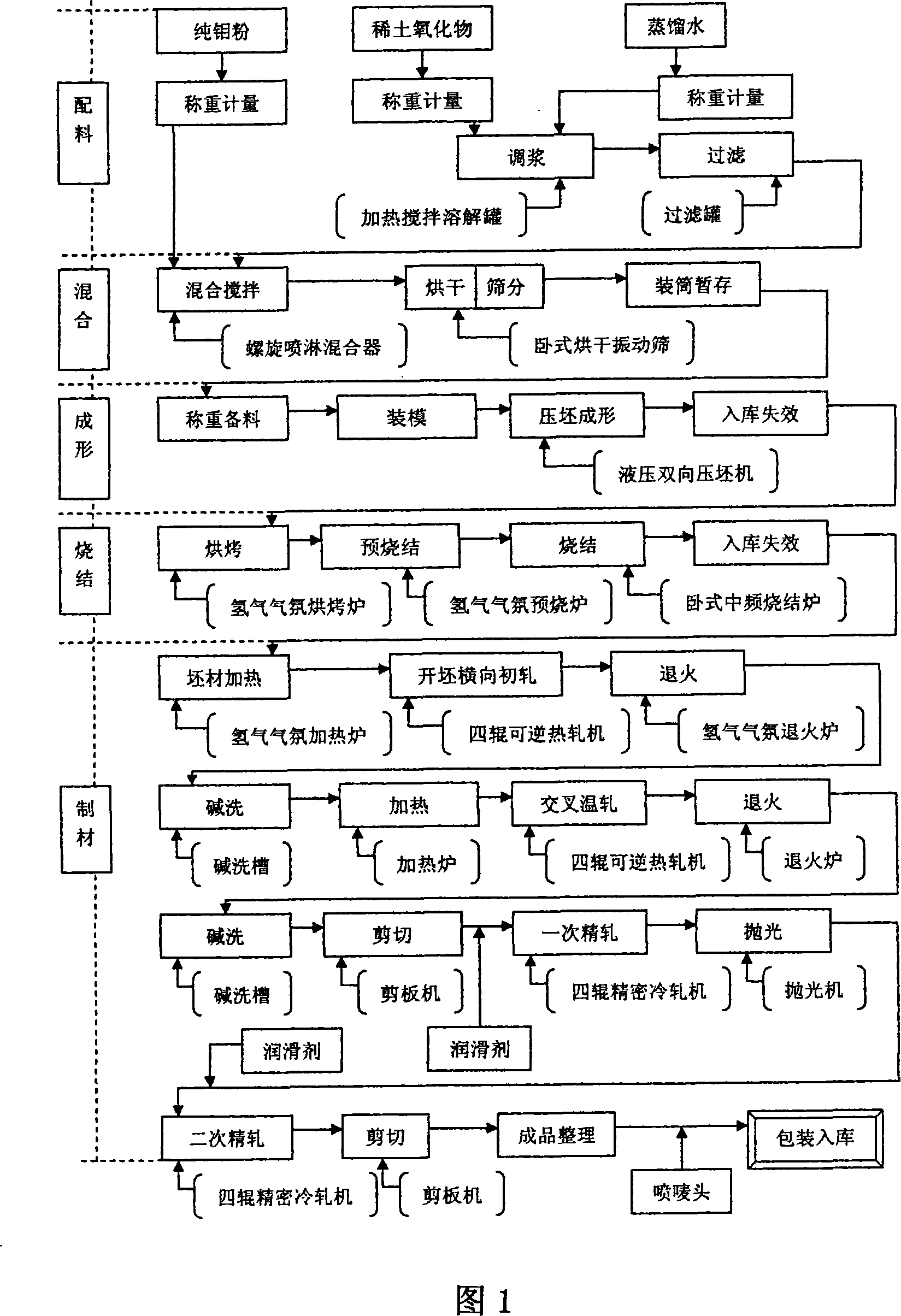

[0090] One, as attached figure 1 Shown: The first step is batching treatment: this treatment process is the basic treatment process for the preparation of component materials for the production and manufacture of molybdenum-based rare earth alloy plates.

[0091] The batching doping scheme of the present invention is: in pure molybdenum powder, ZrO 2 ;Y 2 o 3 ; La 2 o 3 ;Nd 2 o 3 and other 4 kinds of rare earth oxides.

[0092] The best batching doping ratio of the present invention is: 100 parts of pure molybdenum powder, ZrO 2 0.5 parts, Y 2 o 3 2 copies, La 2 o 3 : 2.5 parts, Nd 2 o 3 : 1 serving.

[0093] Manufactured according to M 0 XB--2×450×800(mm) molybdenum-based rare earth alloy plate finished volume and finished density 10.15g / cm 3 Standard calculation, the net weight of the finished product is 7.3kg.

[0094] According to the consumption of batc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com