Epoxy resin system for wind blade hand lay-up repair and preparation method thereof

An epoxy resin system and wind blade technology, which is applied in the field of epoxy resin system and its preparation for hand paste repair of wind blades, can solve the problems of large fan blades, affecting safe production, economic losses, etc., and achieve anti-sagging Good, excellent toughness, low operating environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

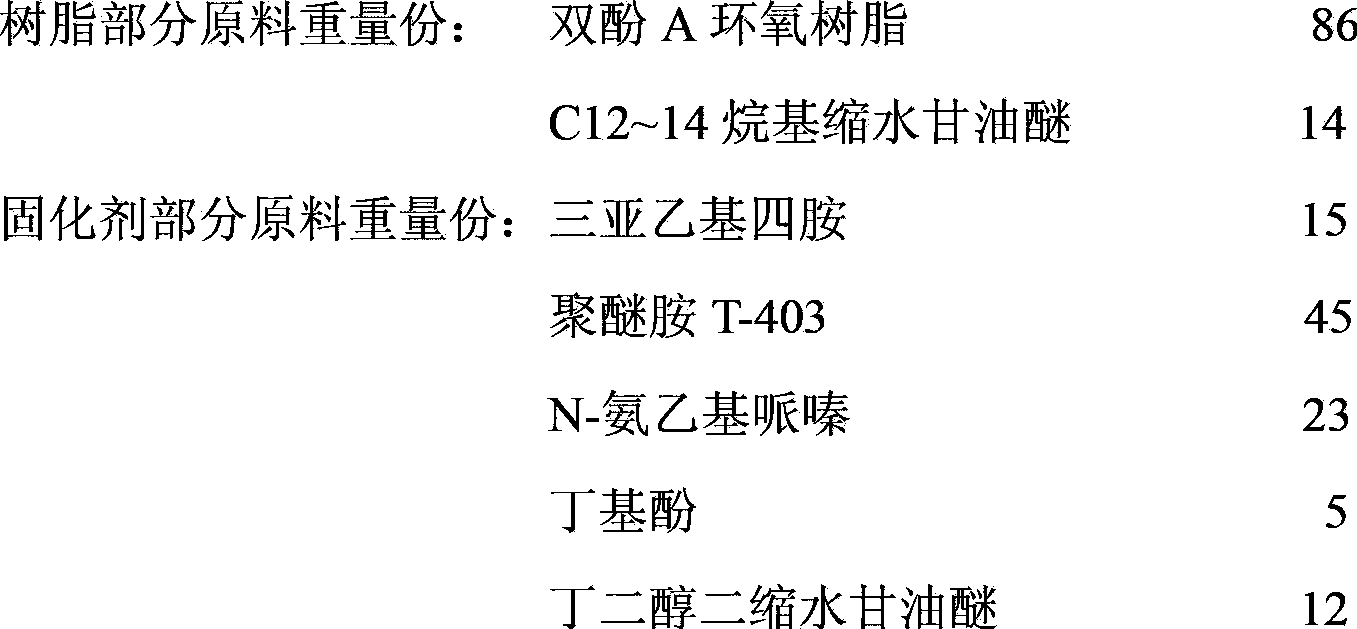

[0028]

[0029] Preparation:

[0030] 1) Add bisphenol A epoxy resin, the raw material of the resin, into the reaction kettle, raise the temperature to 60°C, and keep the temperature constant. Add C12~14 alkyl glycidyl ether, fully stir until uniform. Transfer the mixed resin into a sealed container and store at room temperature.

[0031] 2) Add all the raw materials of the curing agent into the reaction kettle, raise the temperature to 70°C, keep the temperature constant, and continue stirring at a speed of 300rpm / min for 5h. After cooling, transfer to a sealed container and store at room temperature.

[0032] 3) Preparation of epoxy resin system: Mix the resin part and curing agent part evenly at a weight ratio of 100:32.

[0033] 4) Curing: The mixed epoxy resin system was first cured at room temperature for 24 hours, and then cured at 70°C for 8 hours. The mechanical properties of the cured product are shown in Table 1.

Embodiment 2

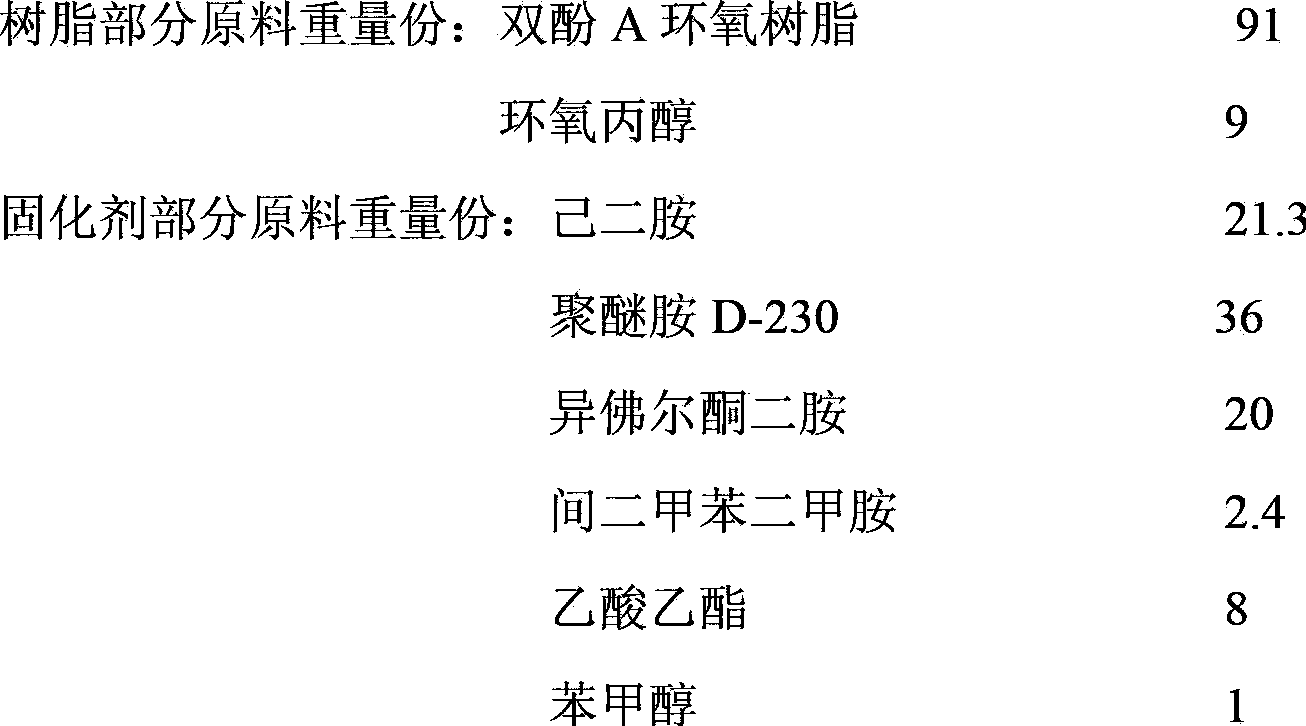

[0035]

[0036]

[0037] Preparation:

[0038] 1) Add bisphenol A epoxy resin, the raw material of the resin, into the reaction kettle, raise the temperature to 70°C, and keep the temperature constant. Add glycidyl alcohol and stir well until uniform. Transfer the mixed resin into a sealed container and store at room temperature.

[0039]2) Add all the raw materials of the curing agent into the reaction kettle, raise the temperature to 90°C, keep the temperature constant, and continue stirring at a speed of 320rpm / min for 3h. After cooling, transfer to a sealed container and store at room temperature.

[0040] 3) Preparation of epoxy resin system: Mix the resin part and curing agent part evenly at a weight ratio of 100:30.

[0041] 4) Curing: The mixed epoxy resin system was first cured at room temperature for 24 hours, and then cured at 70°C for 8 hours. The mechanical properties of the cured product are shown in Table 1.

Embodiment 3

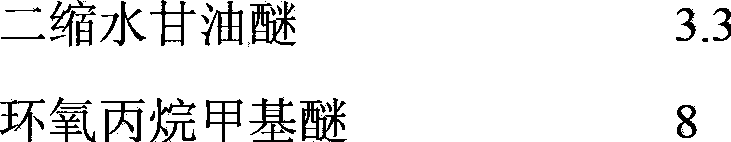

[0043]

[0044] Preparation:

[0045] 1) Add bisphenol A epoxy resin, the raw material of the resin, into the reaction kettle, raise the temperature to 65°C, and keep the temperature constant. Add hexanediol diglycidyl ether and stir well until uniform. Transfer the mixed resin into a sealed container and store at room temperature.

[0046] 2) Add all the raw materials of the curing agent into the reaction kettle, raise the temperature to 95°C, keep the temperature constant, and continue stirring at a speed of 360rpm / min for 2h. After cooling, transfer to a sealed container and store at room temperature.

[0047] 3) Preparation of epoxy resin system: Mix the resin part and curing agent part evenly at a weight ratio of 100:28.

[0048] 4) Curing: The mixed epoxy resin system was first cured at room temperature for 24 hours, and then cured at 70°C for 8 hours. The mechanical properties of the cured product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com