High strength long-life aluminium tube material with high sagging resistance

A technology of aluminum plate and aluminum alloy, applied in the field of aluminum alloy, can solve problems such as difficulty in welding of alloy CAB, and achieve the effect of eliminating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Droop distance

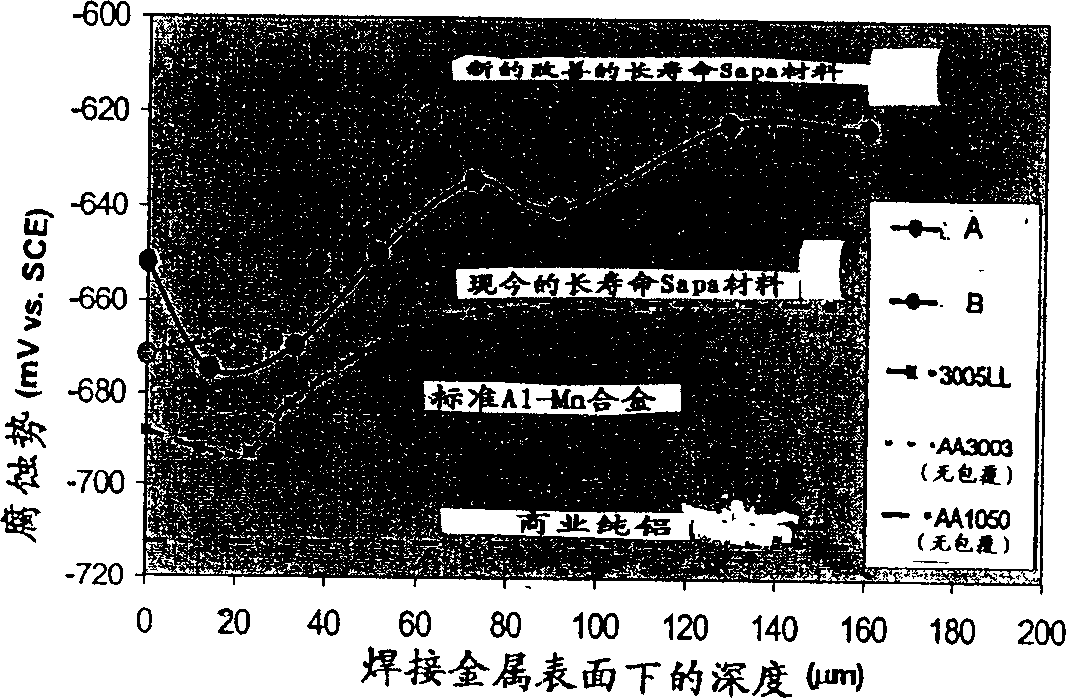

[0039] Four alloys designed with high Mn materials given in reference I US6019939. An alloy was prepared with the same composition as the reference except higher Cu (Reference II). Two different types of alloys according to the invention were prepared, Mg-free (A) and Mg-containing (B). The alloy composition is shown in Table 2.

[0040] Cut the test block into a rectangle and fix it with a free arm of 80mm as a cantilever beam. The free position of the end of the beam is measured before and after the simulated welding, and the distance between the two positions is used to define the sag distance below. The vacuum soldering process included heating from room temperature to 600°C in 45 minutes, holding at this temperature for 10 minutes, and natural cooling in air from ~550°C.

[0041] From the test results in Table 3, high Cu content in the alloy cannot substantially improve the sag resistance, as described in US6019939. Apparently, the p...

Embodiment 2

[0046] Example 2 Effect of Mn content on strength

[0047] Four alloys were designed using the high Mn material composition of US6019939 as reference. An alloy was prepared otherwise identical to the reference, but with high Zr (ref III). Alloys according to the present invention are prepared in two different types, Mg-free (A) and Mg-containing (B). The composition of the alloy is shown in Table 4. Samples are taken when the material has reached a suitable thickness for the pipe and is H24 tempered.

[0048] The material is subjected to welding simulations in a vacuum and cut to length suitable for tensile testing. The vacuum welding process consisted of heating from room temperature to 600°C in 45 minutes, holding at this temperature for 5 minutes, and natural cooling in air from ~550°C. Only air cooled samples (~1°C / s) were used.

[0049] The results of the tensile test are shown in Table 5. Mn increased from 1.5 to 1.7% by weight, and the strength increased. The str...

Embodiment 3

[0054] Example 3 Effect of Mg content on yield strength.

[0055] According to Table 6, two alloy compositions containing Mg (A) and Mg (B) in the present invention were compared. The plate of the material is subjected to a pressure of about 10 -4 Simulated welding was carried out in Torr's vacuum furnace according to the following welding procedure, heating from room temperature to 600°C in 45 minutes, followed by holding at this temperature for 5 minutes before the specimen was cooled to room temperature in air.

[0056] As shown in Table 7, Mg is beneficial to the strength and increases the yield strength by 7 MPa.

[0057] Table 6: Chemical composition (weight %), melt analysis

[0058] sample

Si

Fe

Cu

mn

Mg

Zr

A

0.06

0.16

0.79

1.72

<0.01

0.12

B

0.06

0.16

0.81

1.72

0.31

0.13

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com