A kind of brazing aluminum plate for sound insulation honeycomb panel and its manufacturing method

A technology for brazing aluminum plates and a manufacturing method, which is applied in the field of aluminum foil rolling and manufacturing, can solve the problems of poor impact resistance and low fire rating, and achieve the effects of high production efficiency, good welding quality and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

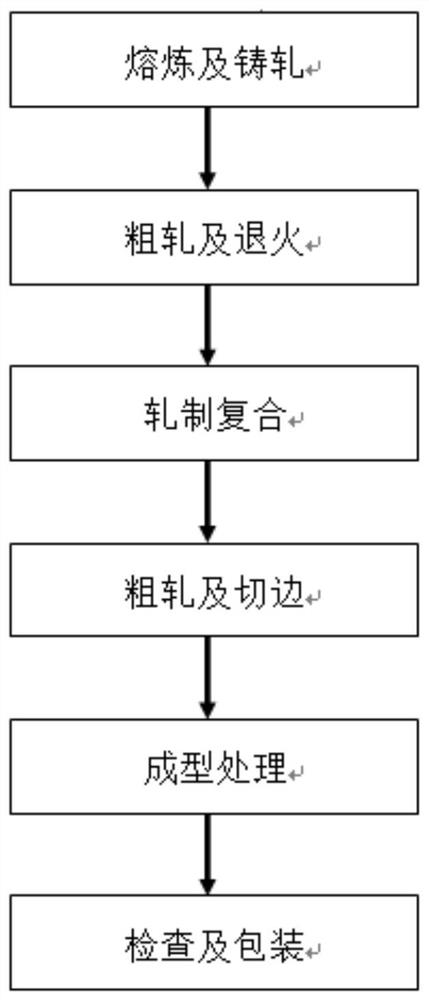

Method used

Image

Examples

Embodiment 1

[0079] 1) According to the weight percentage of Si: 0.12%, Fe: 0.41%, Cu: 0.08%, Mn: 1.1%, Ti: 0.03%, and the balance is Al as the basic component, prepare alloy raw materials for core layer billet melting and casting Rolled to obtain 7.0mm cast-rolled coil, alloy "AA3003";

[0080] According to the weight percentage of Si: 7.6%, Fe: 0.20%, Ti: 0.02%, and the balance is the ratio of Al as the basic component, the alloy raw materials are prepared and the brazing layer blank is smelted and rolled to obtain a 6.8mm cast-rolled coil. The alloy "4343" ";

[0081] 2) Preparation of core layer: the AA3003 cast-rolled parent coil is roughly rolled to a thickness of 7.0-5.1 to 5.1mm for homogenization annealing, and then heated to 570°C for 8h and cooled for 8 hours;

[0082] 3) Preparation of brazing layer: According to the design of the theoretical recombination rate of 12%, the 4343 cast-rolled parent coil is subjected to billet annealing for 18 hours, heated to 450 °C for 6 hours,...

Embodiment 2

[0090] a) According to the weight percentage of Si: 0.15%, Fe: 0.44%, Cu: 0.55%, Mn: 1.18%, Ti: 0.03%, and the balance is Al as the basic component, prepare alloy raw materials for core layer billet melting and casting Rolled to obtain a 7.2mm cast-rolled coil, and the internal alloy was named "DS302";

[0091] According to the weight percentage of Si: 7.6%, Fe: 0.20%, Ti: 0.02%, and the balance is the ratio of Al as the basic component, the alloy raw materials are prepared and the brazing layer blank is smelted and rolled to obtain a 6.8mm cast-rolled coil. The alloy "4343" ";

[0092] b) Core layer preparation: The DS302 cast-rolled parent coil is roughly rolled to a thickness of 7.2 mm-5.1 mm to a thickness of 5.1 mm for homogenization annealing, and then heated to 580 °C for 10 h, cooled and released;

[0093] c) Preparation of brazing layer: According to the design of the theoretical recombination rate of 15%, the 4343 cast-rolled parent coil is subjected to billet annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com