Zinc oxide nanowire array photocatalytic material based on cuprous oxide quantum dot modification and its preparation method and application

A zinc oxide nanowire, photocatalytic material technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, botanical equipment and methods, etc., to achieve good killing effect, firm connection, high effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

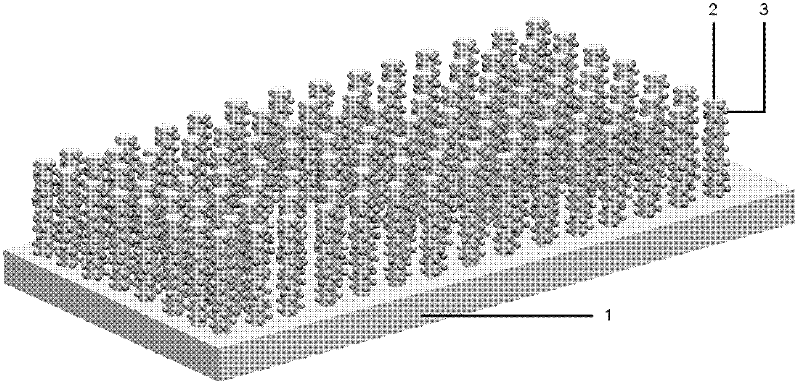

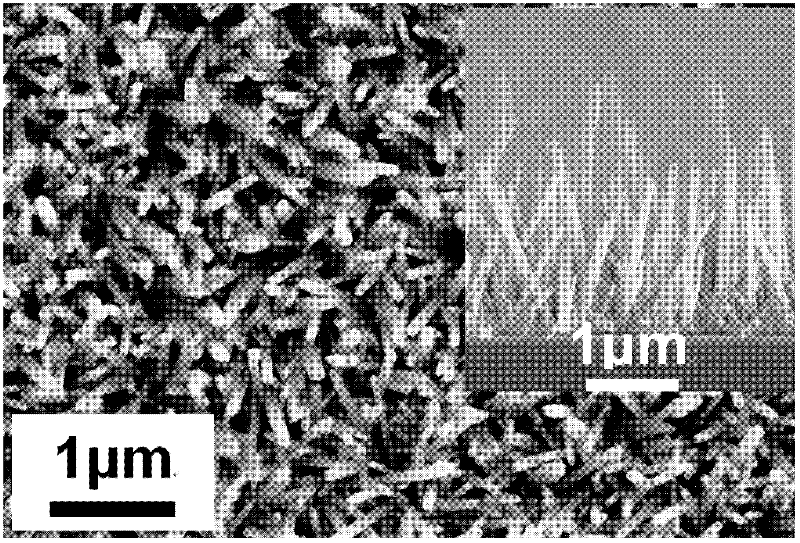

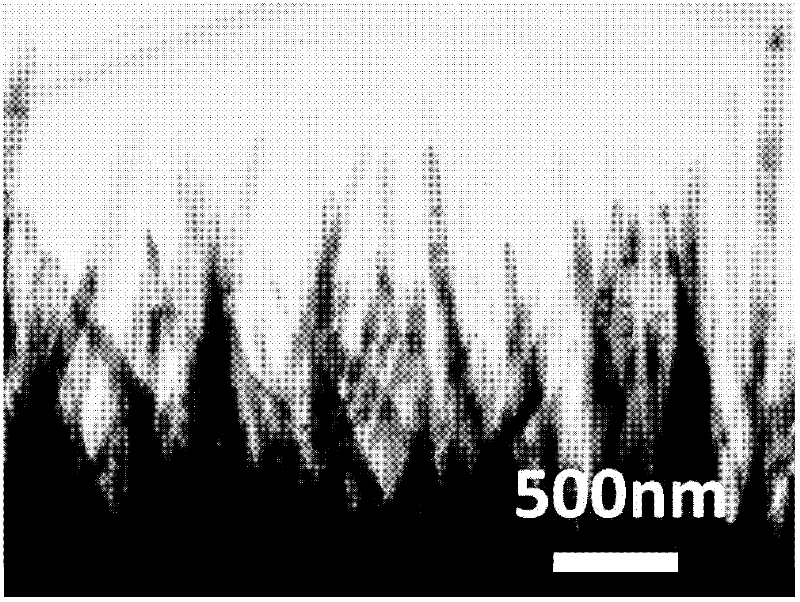

[0035] 1) Preparation of zinc oxide nanowire array: prepare a zinc acetate aqueous solution with a concentration of 0.05mM as electrolyte, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, and ITO conductive glass as working electrode; At 75°C, oxygen was blown into the zinc acetate aqueous solution, and a voltage of -0.8V was applied to the working electrode for 1 hour to obtain an array of zinc oxide nanowires grown on ITO conductive glass; the morphology of the sample Perform SEM and TEM characterization respectively, and the results obtained are as follows figure 2 , image 3 Shown.

[0036] 2) Deposit cuprous oxide quantum dots on the surface of zinc oxide nanowires: prepare a 5mM copper nitrate dimethyl sulfoxide solution as electrolyte, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, Take the ITO conductive glass grown with zinc oxide nanowire arrays obtained in step 1) as the working ...

Embodiment 2

[0042] 1) Preparation of zinc oxide nanowire array: prepare 0.5mM zinc acetate aqueous solution as electrolyte, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, and FTO conductive glass as working electrode; At 85° C., oxygen gas was blown into the zinc acetate aqueous solution, and a voltage of -1V was applied to the working electrode for 2 hours to obtain an array of zinc oxide nanowires grown on the FTO conductive glass.

[0043] 2) Deposit cuprous oxide quantum dots on the surface of zinc oxide nanowires: prepare a 10 mM copper nitrate dimethyl sulfoxide solution as an electrolyte, a platinum electrode as a counter electrode, and a saturated calomel electrode as a reference electrode. Take the FTO conductive glass grown with zinc oxide nanowire arrays obtained in step 1) as the working electrode; at a temperature of 60°C, electrochemical cyclic voltammetry is used to apply a voltage range of -0.2V to -0.6V ( Compared with the cyclic...

Embodiment 3

[0049] 1) Preparation of zinc oxide nanowire array: prepare 1 mM zinc acetate aqueous solution as electrolyte, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, and ITO conductive glass as working electrode; At 95° C., oxygen was blown into the zinc acetate aqueous solution, and a voltage of -1.1V was applied to the working electrode for 3 hours to obtain an array of zinc oxide nanowires grown on the ITO conductive glass.

[0050] 2) Depositing cuprous oxide quantum dots on the surface of zinc oxide nanowires: prepare a 15 mM copper nitrate dimethyl sulfoxide solution as electrolyte, platinum electrode as counter electrode, and saturated calomel electrode as reference electrode. Take the ITO conductive glass grown with zinc oxide nanowire arrays obtained in step 1) as the working electrode; at a temperature of 75°C, electrochemical cyclic voltammetry is used to apply a voltage range of -0.2V to -0.6V ( Compared with the cycle scanning vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com