Hollow porous spherical mixed oxide for lithium ion battery negative electrode and preparation method of hollow porous spherical mixed oxide

A technology of lithium-ion batteries and mixed oxides, applied in the field of nanomaterials and chemical power sources, can solve problems such as unsuitable for actual production, high cost, poor cycle stability, etc., to improve high-current discharge performance and cycle stability, and improve structural stability Sexuality, the effect of speeding up the transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

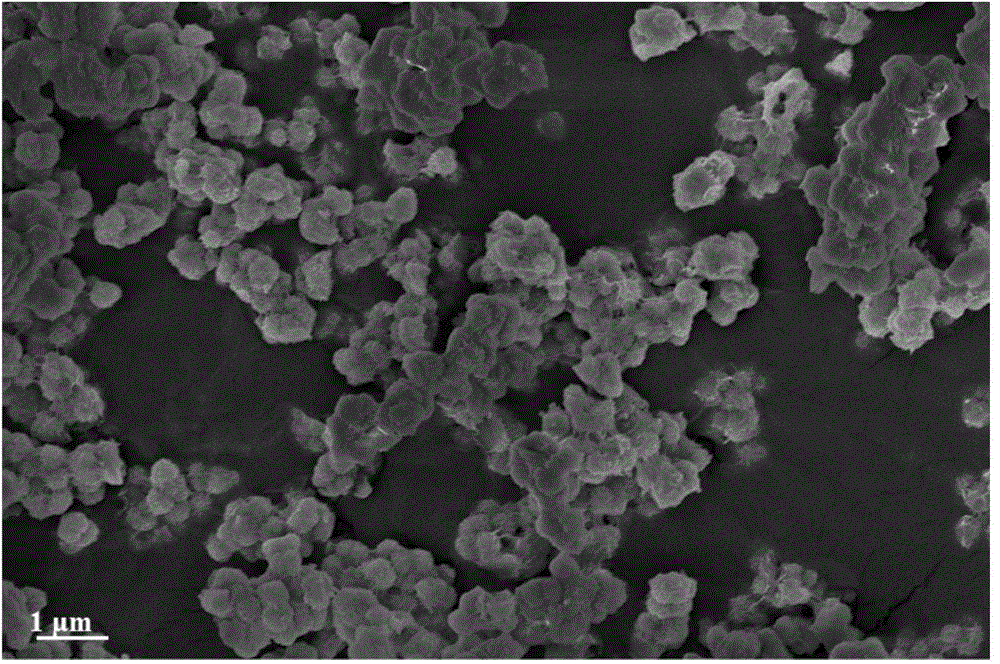

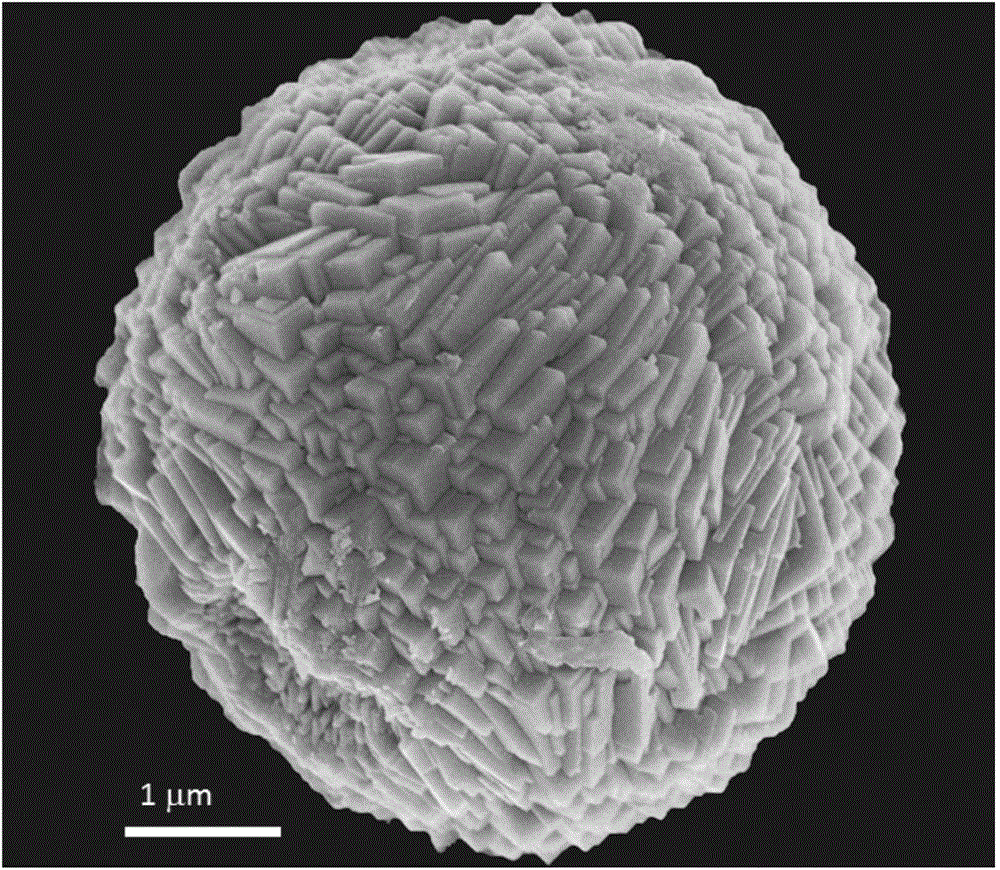

[0032] First weigh 1.67mmol of Ni(NO 3 ) 2 ·6H 2O and 3.33 mmol of MnSO 4 ·H 2 O, then measure 35mL of absolute ethanol and add it to 350mL of deionized water, stir vigorously, and obtain liquid A after the above-mentioned salts are completely dissolved; at the same time, add 50mmol of NH to another 350mL of deionized water 4 HCO 3 And after vigorous stirring, liquid B was obtained. Subsequently, liquid B was added to liquid A and stirred vigorously, and then the reaction liquid was heated to 45° C. for 9 h. After stopping the reaction, the reaction solution was filtered and washed with a large amount of deionized water, and then dried in vacuum at 60°C to obtain a light green solid (Ni 0.14 mn 0.86 CO 3 ). The obtained solid was placed in a muffle furnace and fired at 600°C at a heating rate of 2°C / min for 3 hours, and then continued to be fired at 900°C at a heating rate of 2°C / min for 2 hours to obtain the prepared porous hollow Ni 0.14 mn 0.86 o 1.43 Microspher...

Embodiment 2

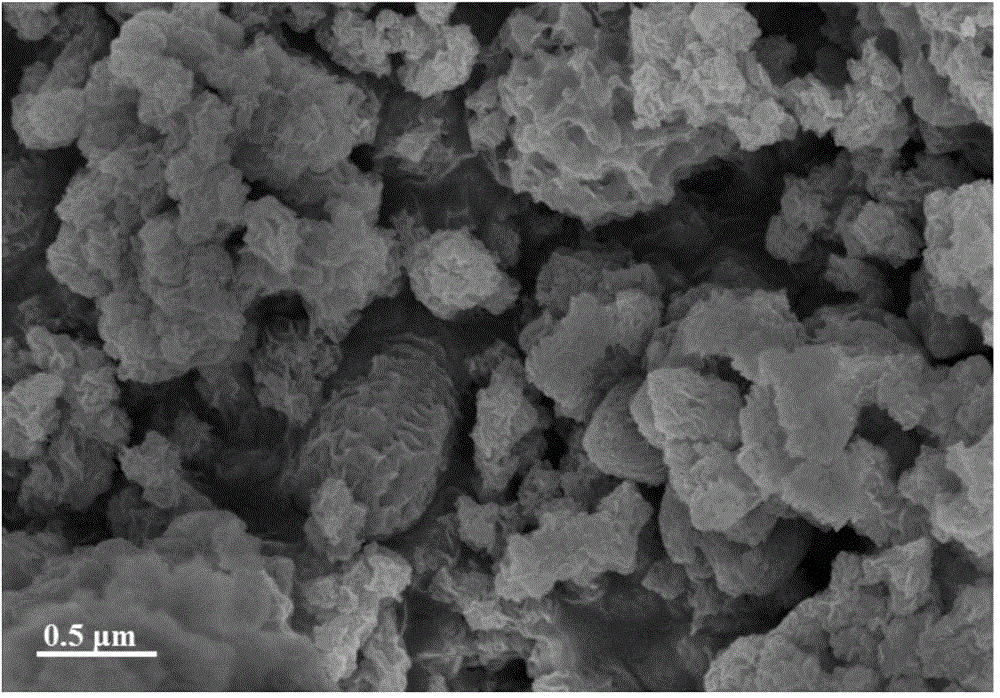

[0035] First weigh 1.67mmol of NiSO 4 ·6H 2 O and 3.33mmol of Mn(NO 3 ) 2 , then measure 70mL of absolute ethanol and add it to 350mL of deionized water, stir vigorously, and obtain liquid A after the above salts are completely dissolved; at the same time, add 75mmol of NH to another 350mL of deionized water 4 HCO 3 And after vigorous stirring, liquid B was obtained. Subsequently, liquid B was added to liquid A and stirred vigorously, and then the reaction liquid was heated to 45° C. for 9 h. After stopping the reaction, the reaction solution was filtered and washed with a large amount of deionized water, and then dried in vacuum at 60° C. to obtain a light green solid. The obtained solid was placed in a muffle furnace and calcined at a rate of 2 °C / min to 600 °C for 3 h, and then continued to be calcined at a rate of 2 °C / min to 900 °C for 2 h to obtain the prepared porous hollow mixed oxide.

Embodiment 3

[0037] First weigh 1.67 mmol of C 4 h 6 o 4 Ni·4H 2 O and 3.33 mmol of C 4 h 6 MnO 4 , then measure 25mL of absolute ethanol and add it to 375mL of deionized water, stir vigorously, and obtain liquid A after the above salts are completely dissolved; at the same time, add 25mmol of NH to another 350mL of deionized water 4 HCO 3 And after vigorous stirring, liquid B was obtained. Subsequently, liquid B was added to liquid A and stirred vigorously, and then the reaction liquid was heated to 45° C. for 9 h. After stopping the reaction, the reaction solution was filtered and washed with a large amount of deionized water, and then dried in vacuum at 60° C. to obtain a light green solid. The obtained solid was placed in a muffle furnace and calcined at a rate of 2 °C / min to 600 °C for 3 h, and then continued to be calcined at a rate of 2 °C / min to 900 °C for 2 h to obtain the prepared porous hollow mixed oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com