Tray used for steel coil transportation

A technology of steel coils and pallets, applied in the field of transportation, can solve the problems of lack of shock absorption effect, limited force, and inappropriateness of hydraulic cylinders, and achieve the effects of convenient transportation and transfer, improved stability, and easy support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

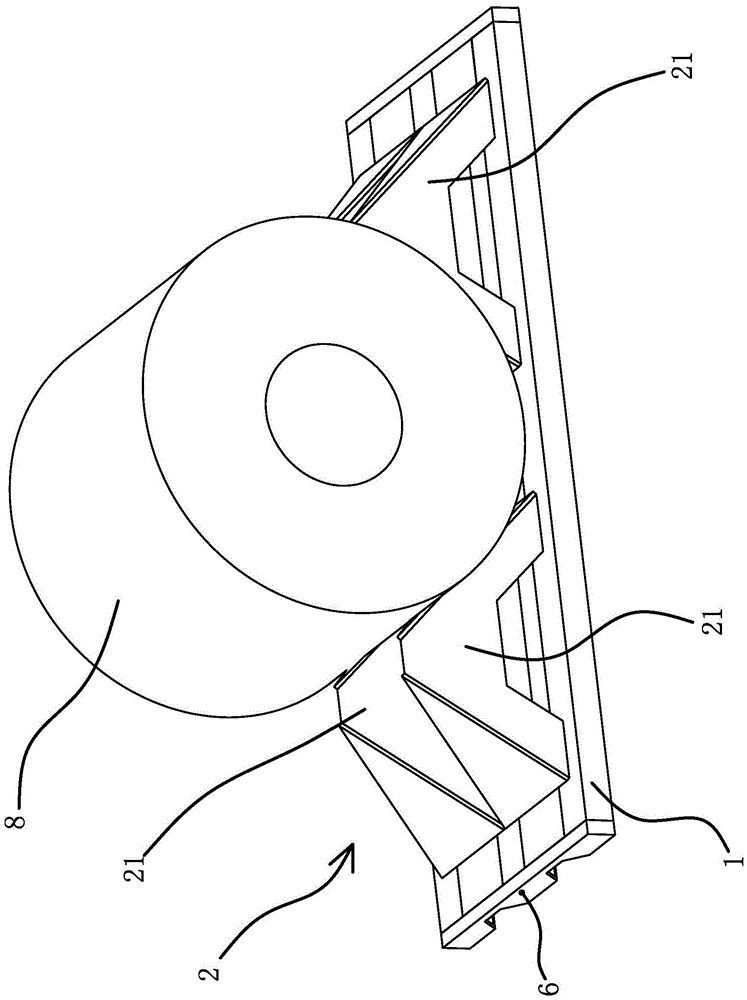

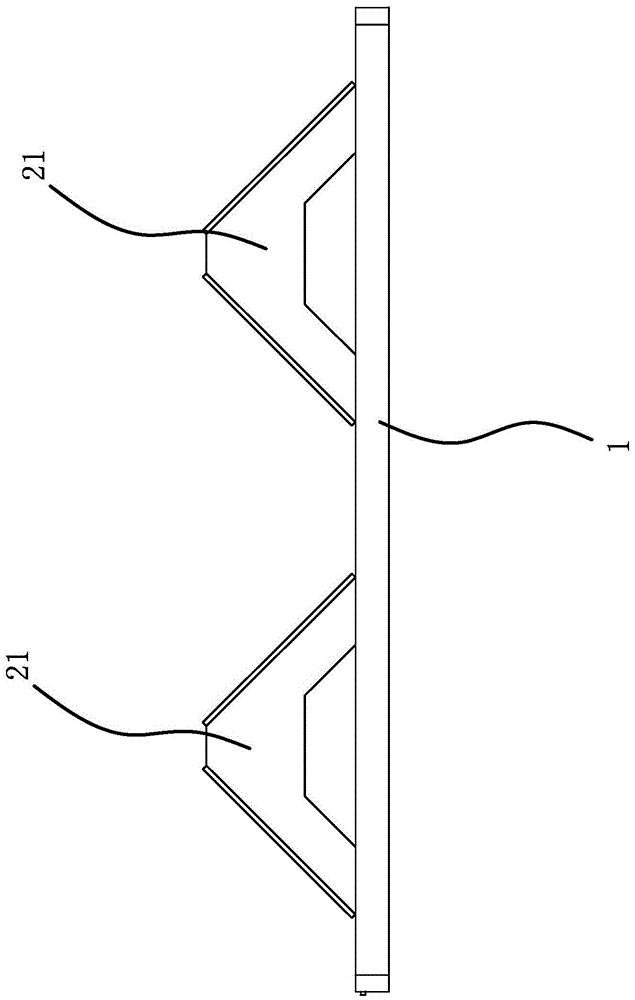

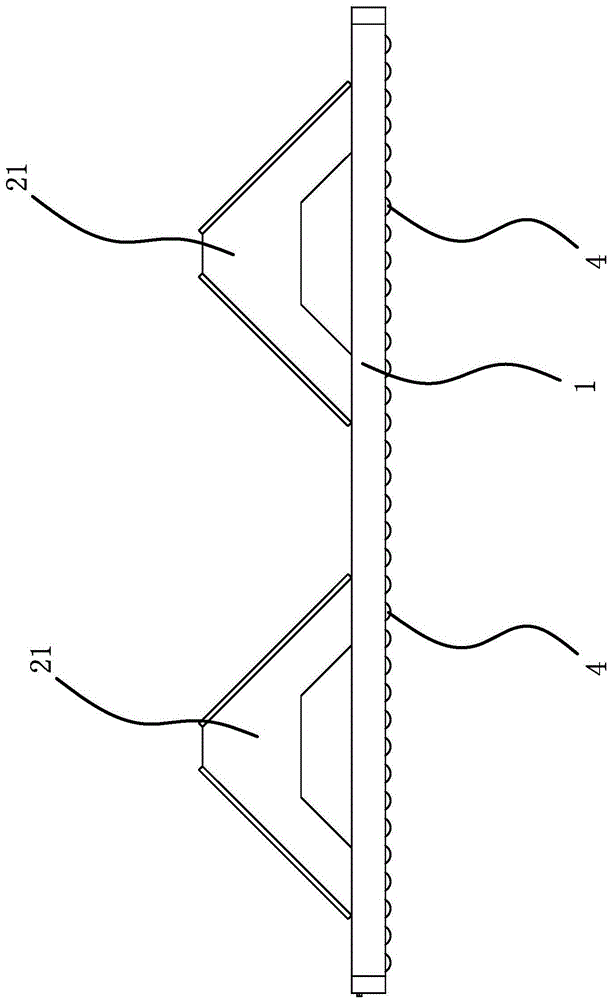

[0036] Such as figure 1 As shown, the pallet used for steel coil transportation includes a pallet frame 1 and a limit frame 2 arranged on the pallet frame 1 for positioning the steel coil 8. The limit frame 2 includes at least two stoppers 21, and the two stoppers 21 A notch for placing the steel coil 8 is formed between them, and the stopper 21 can be in the shape of a triangular platform or a quadrangular platform. In this embodiment, the limit frame 2 has four stoppers 21, and two stoppers 21 form Arranged side by side, the stopper 21 is a hollow structure, and a through hole aligned with the stopper 21 is opened on the pallet rack 1. When transporting the pallet, the pallets can be stacked, and the stopper 21 of the lower pallet can pass through the upper pallet. Through holes for positioning and stacking, reducing the space occupied during transportation.

[0037] Such as Figure 4 to Figure 8 As shown, the bottom of the pallet rack 1 has at least two elongated installa...

Embodiment 2

[0044] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that at least two airbags are arranged in each installation groove, and the airbags are arranged along the length direction of the installation groove. Justify. When the pallet needs to be moved, the airbags are inflated at the same time, and multiple airbags are inflated at the same time to make the rollers contact the ground and lift the pallet frame off the ground, thereby realizing the movement of the pallet; corresponding airbags are provided at both ends of the roller frame to ensure the stability of the roller frame. The distance between the two ends and the pallet frame remains the same, so that the pallet frame can be kept horizontal when the pallet frame is lifted, so that the steel coil can be stably positioned on the pallet frame.

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the guide structure includes several guide rods, which are vertically fixed in the installation groove, and there are a number of guide rods corresponding to the guide rods on the roller frame. hole through which the guide rod passes. The roller frame can only move up and down relative to the pallet frame through the guide rod, so that the pallet frame remains stable when it is lifted off the ground or lowered to the ground, so that the steel coil can be stably positioned on the pallet frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com