Patents

Literature

40results about How to "Dispersion weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

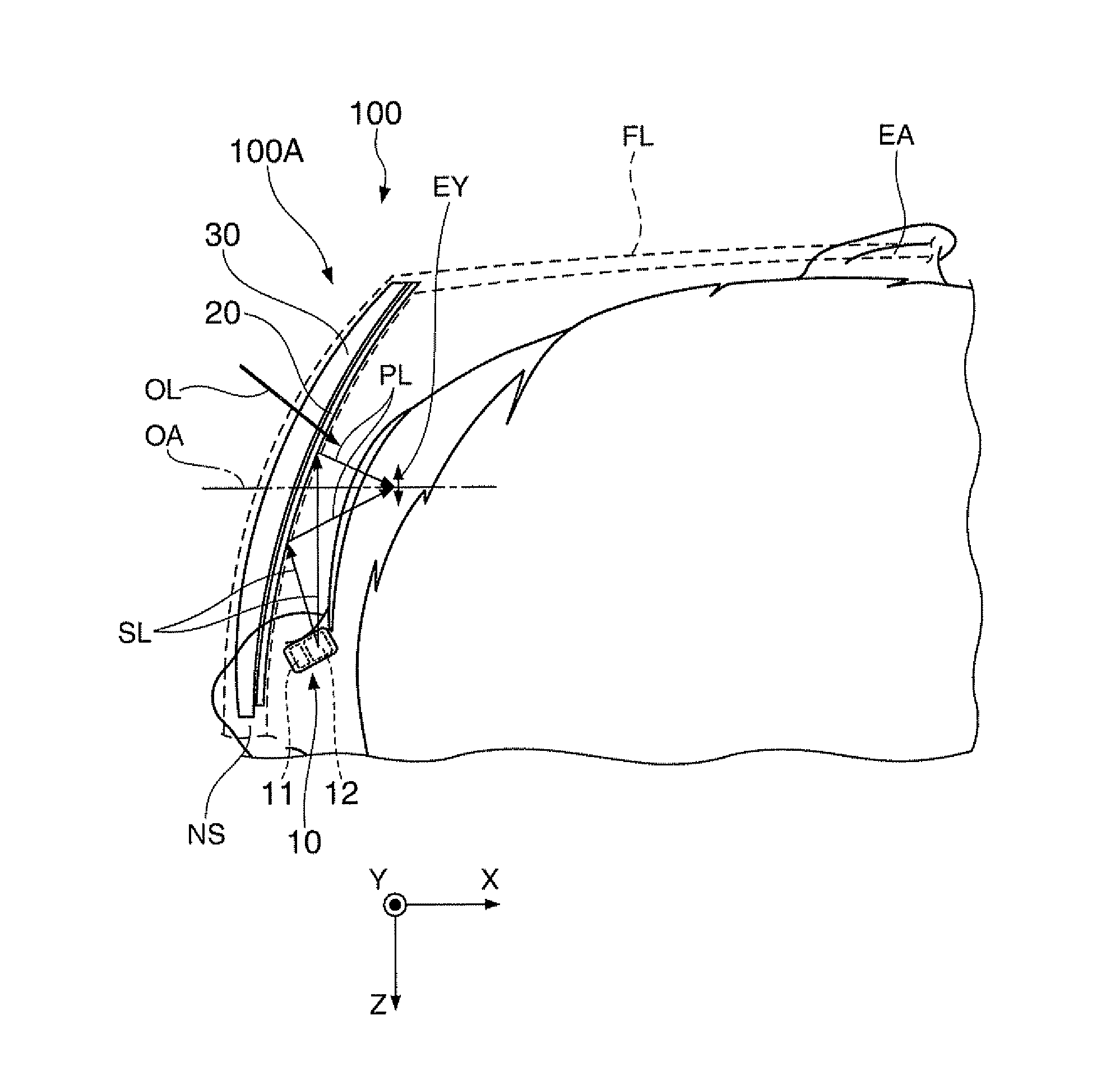

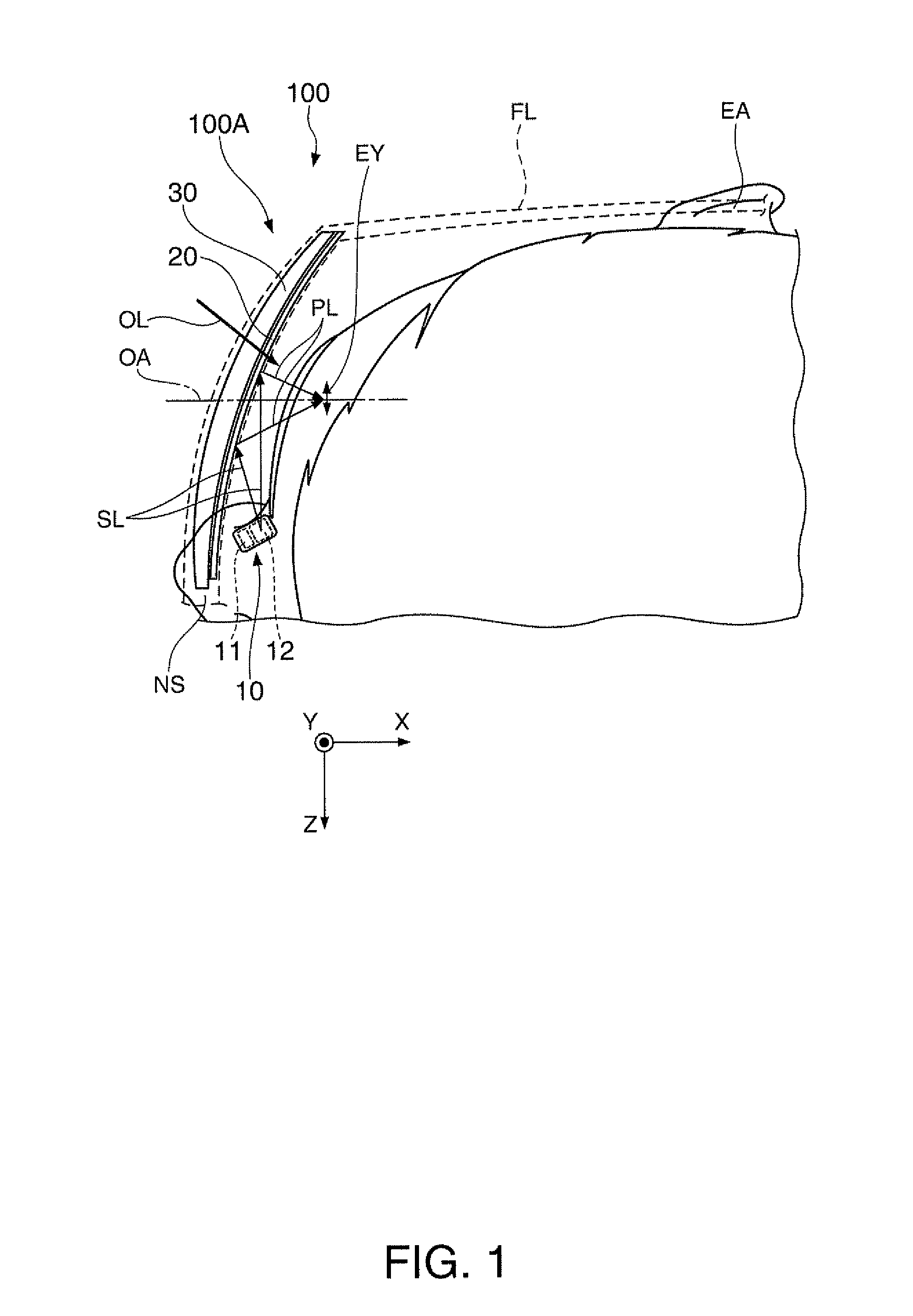

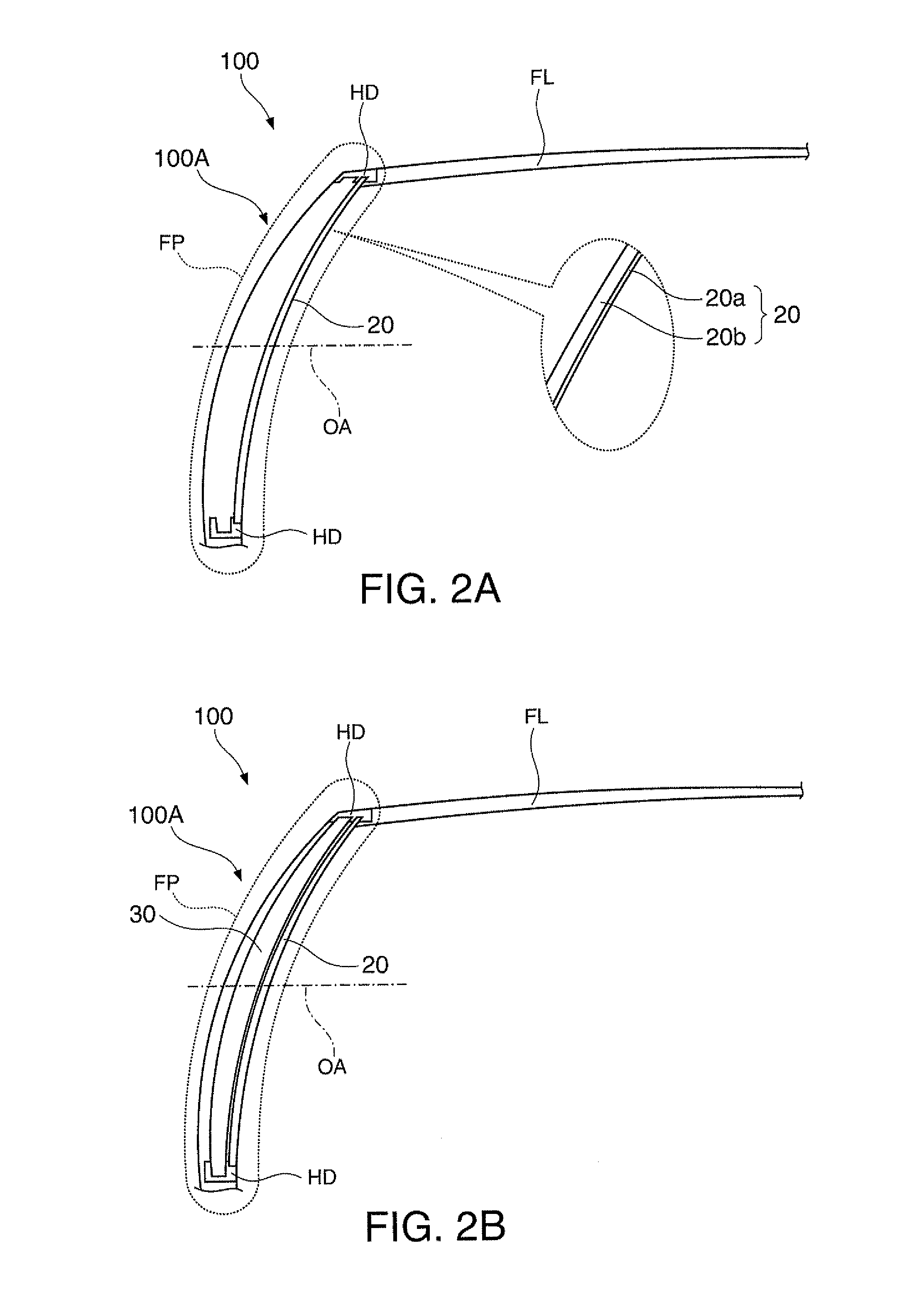

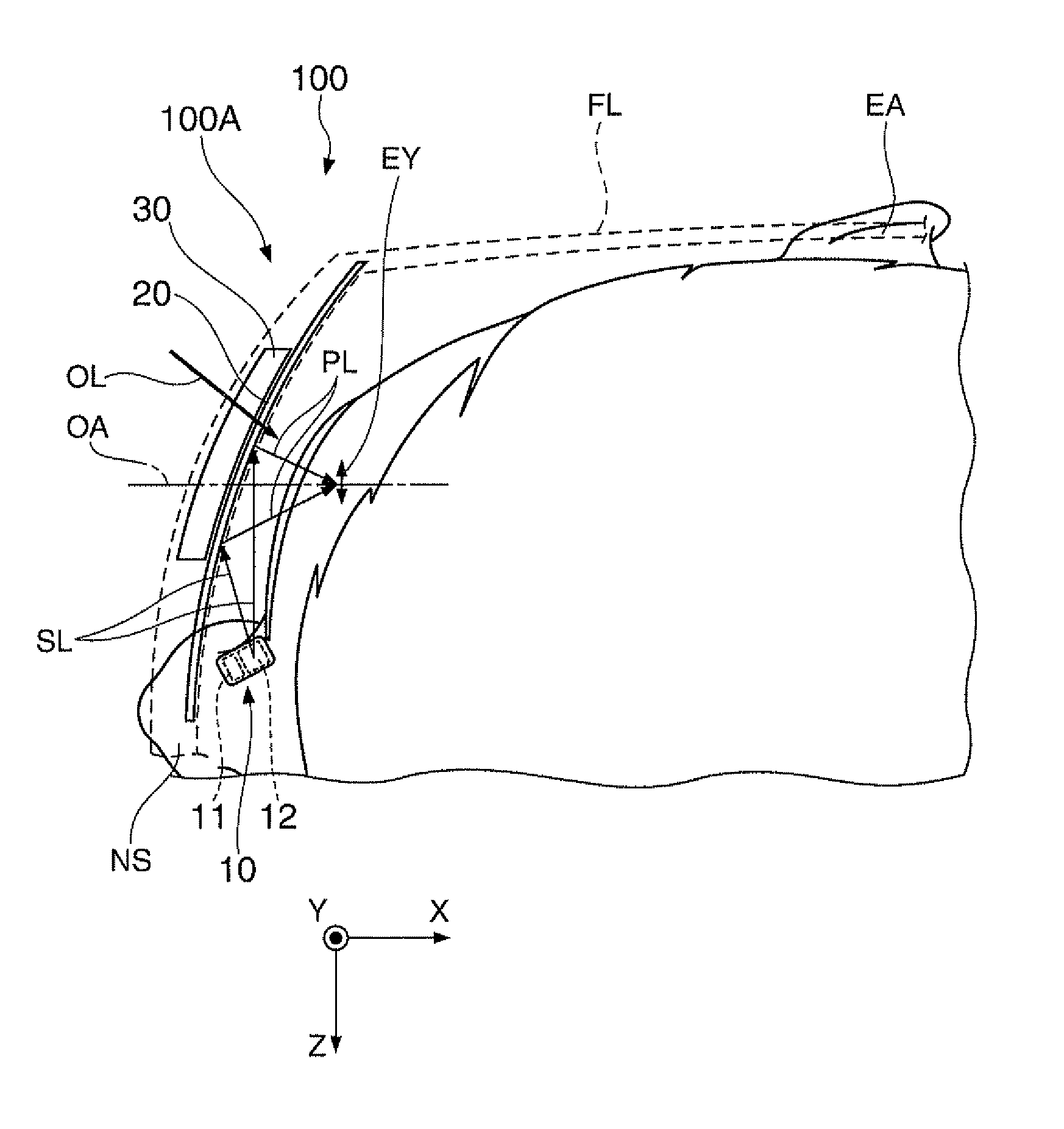

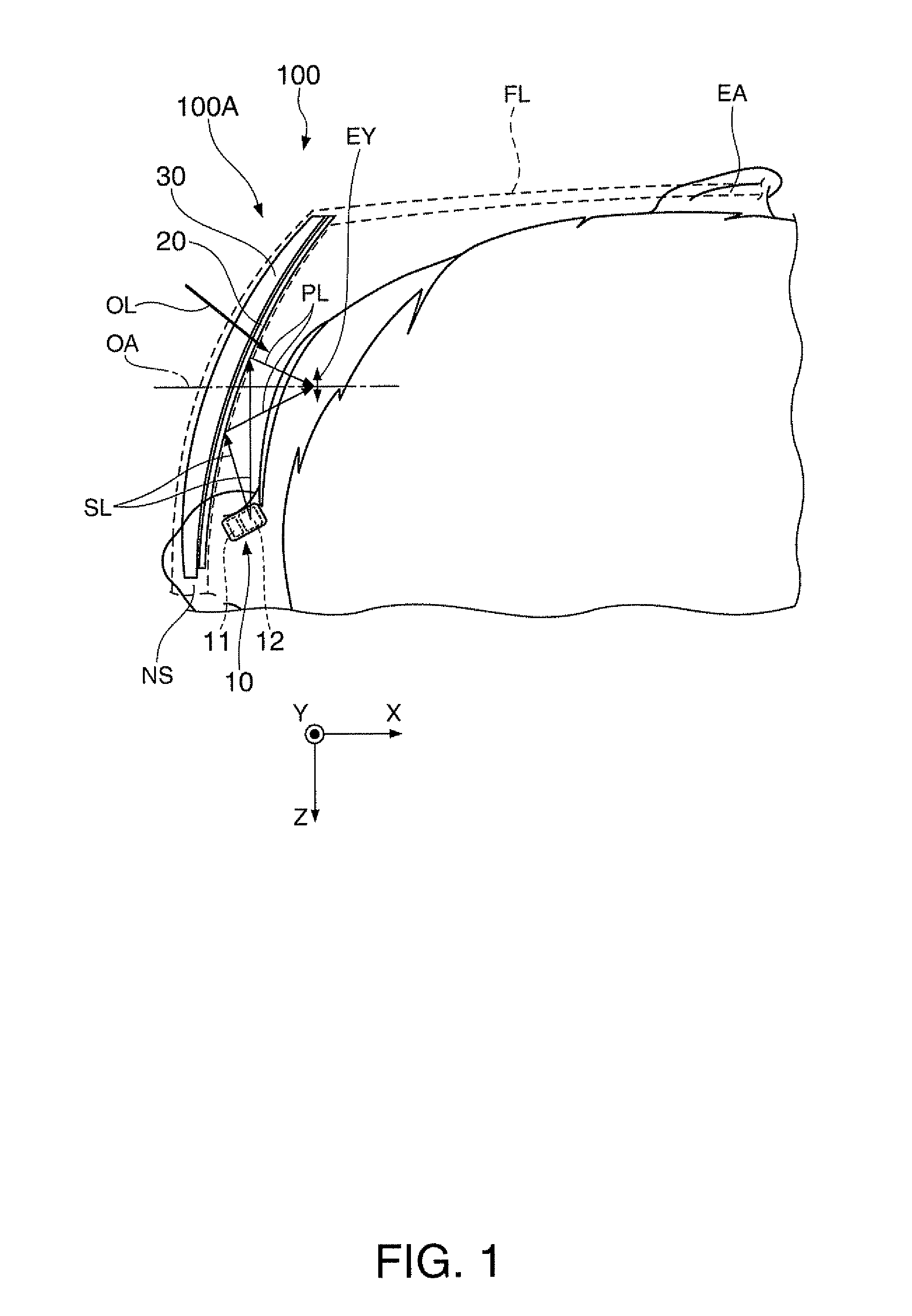

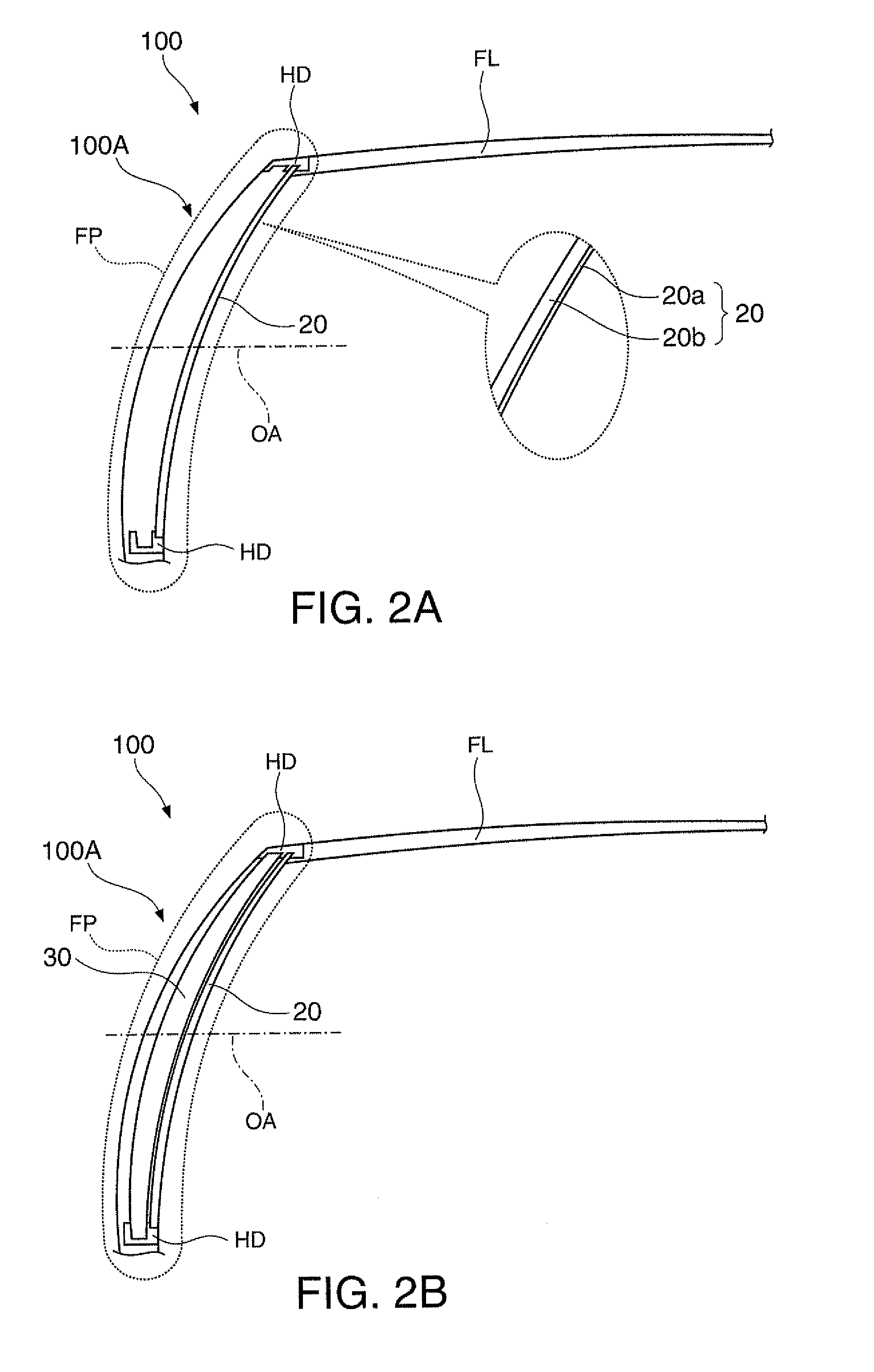

Virtual image display device

Image lights formed by a light emitting device and a virtual-image forming member and external light transmitted through a visibility adjusting member and the virtual-image forming member can be observed in parallel in a see-through manner. In the observation of the external light, the visibility adjusting member enables visibility adjustment corresponding to the eyesight of a wearer. Therefore, the wearer can observe the external light without wearing a device for visibility adjustment such as glasses. Therefore, it is possible to suppress an increase in the size of a virtual image display device.

Owner:SEIKO EPSON CORP

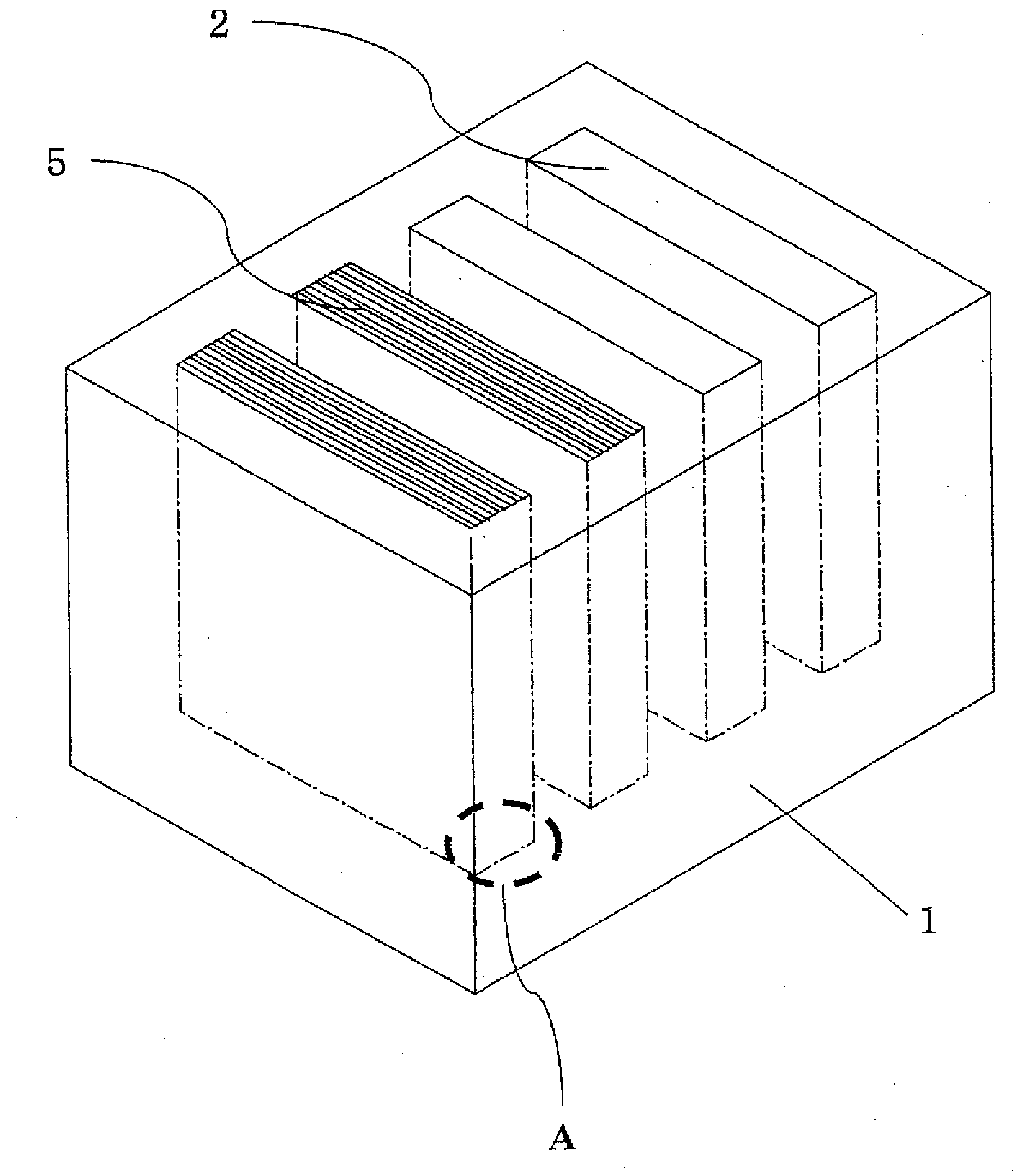

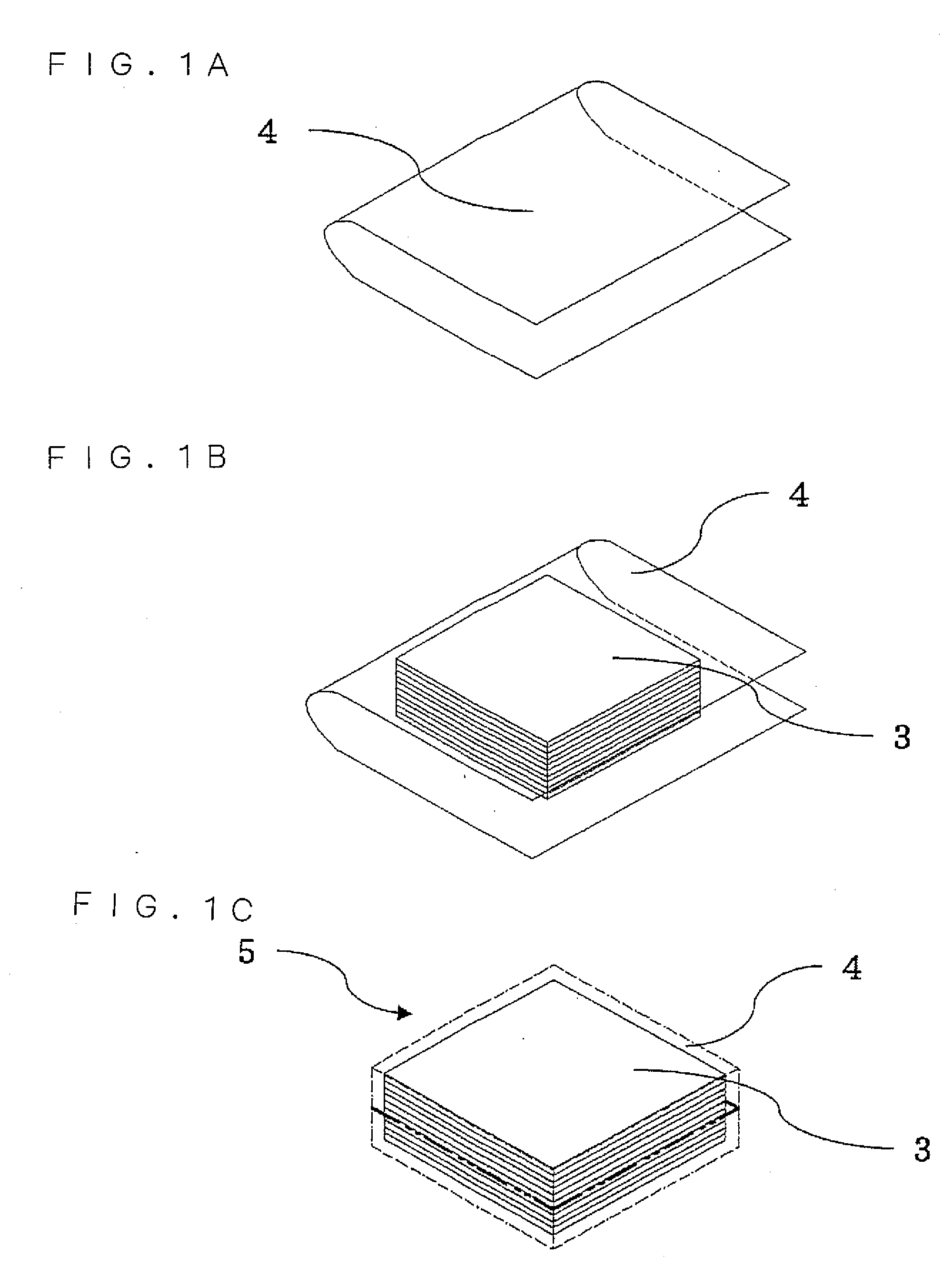

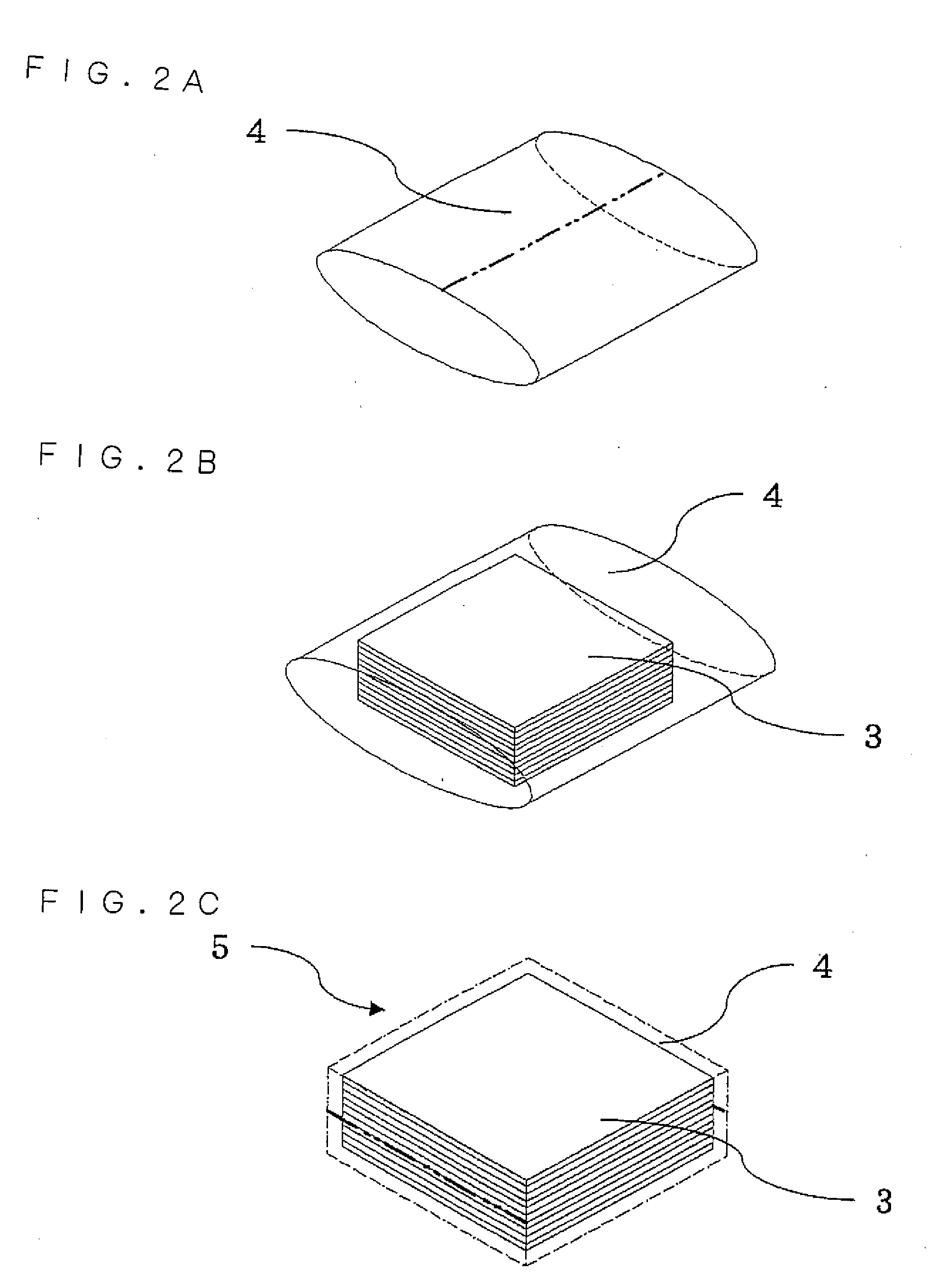

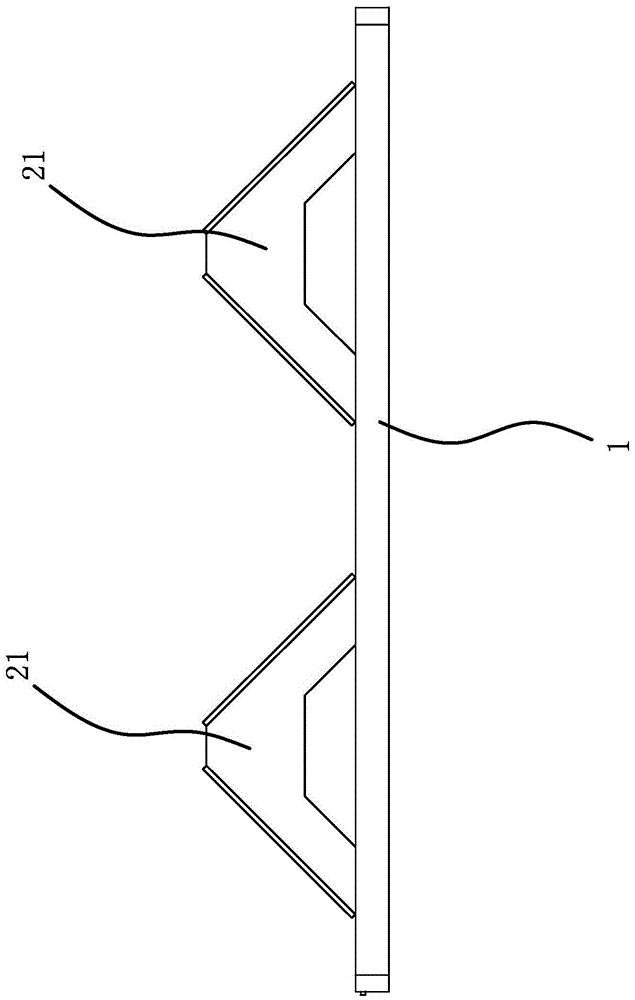

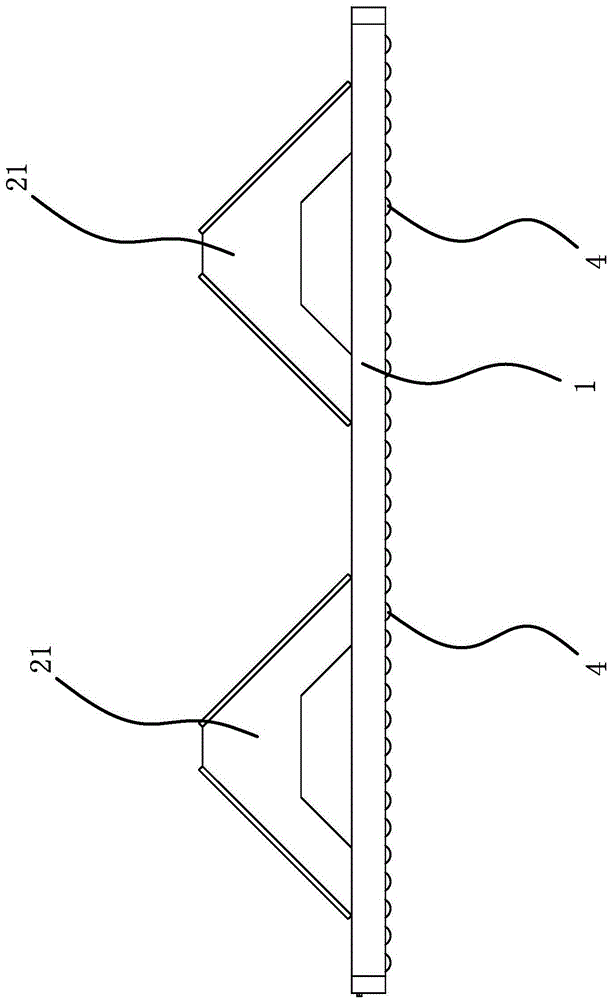

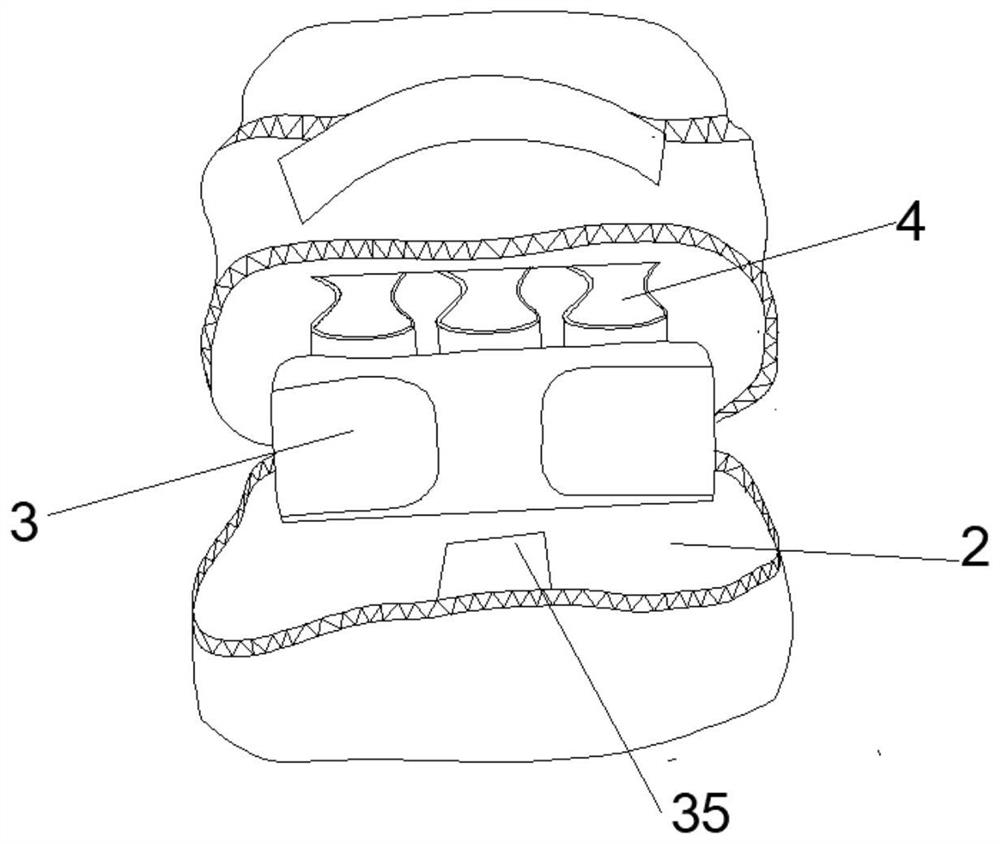

Method For Packing Solar Battery Elements and Package For Solar Battery Elements

InactiveUS20080251114A1High strengthAvoid crackingPV power plantsSemiconductor/solid-state device manufacturingSolar batteryPacking method

An object of the invention is to provide a method for packing solar battery elements where cracking or chipping does not occur during the packing work and transportation, and the solar battery elements can be easily packed. In addition, in order to achieve the above described object, the method includes: a first packing step of covering a plurality of layered solar battery elements (3) with a heat-shrinkable film (4); a first heating step of heating this heat-shrinkable film (4) so that the solar battery elements 3 are held as an assembly (5); and a second packing step of inserting the assembly (5) into an opening (2) of a container (1) having the opening (2) for holding this assembly (5).

Owner:KYOCERA CORP

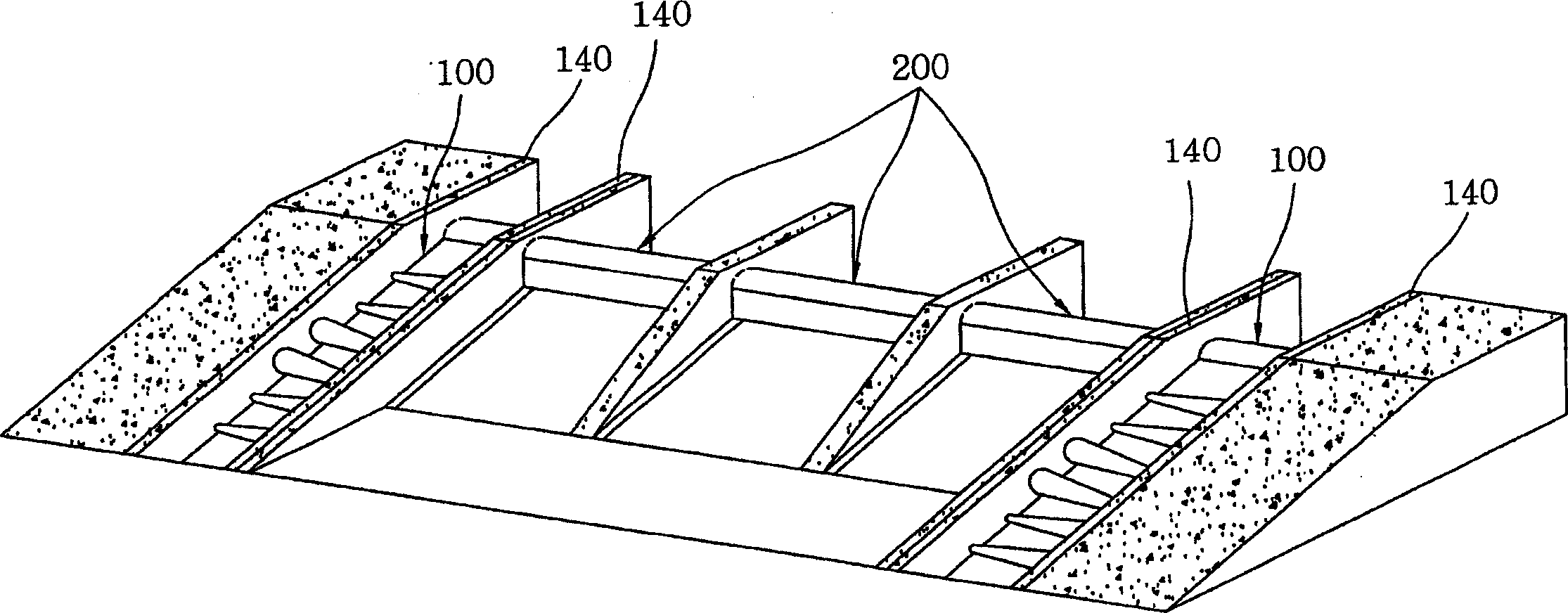

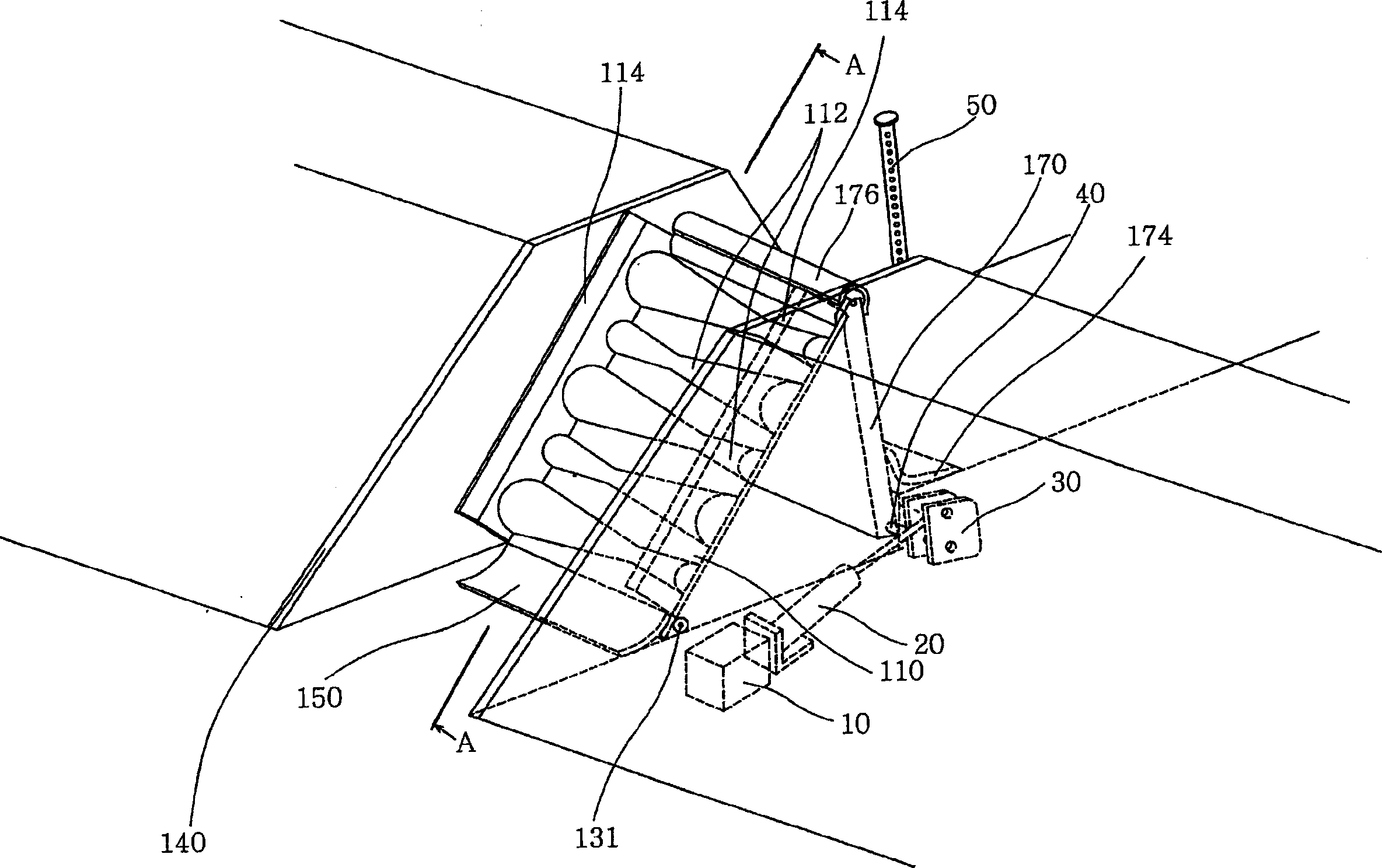

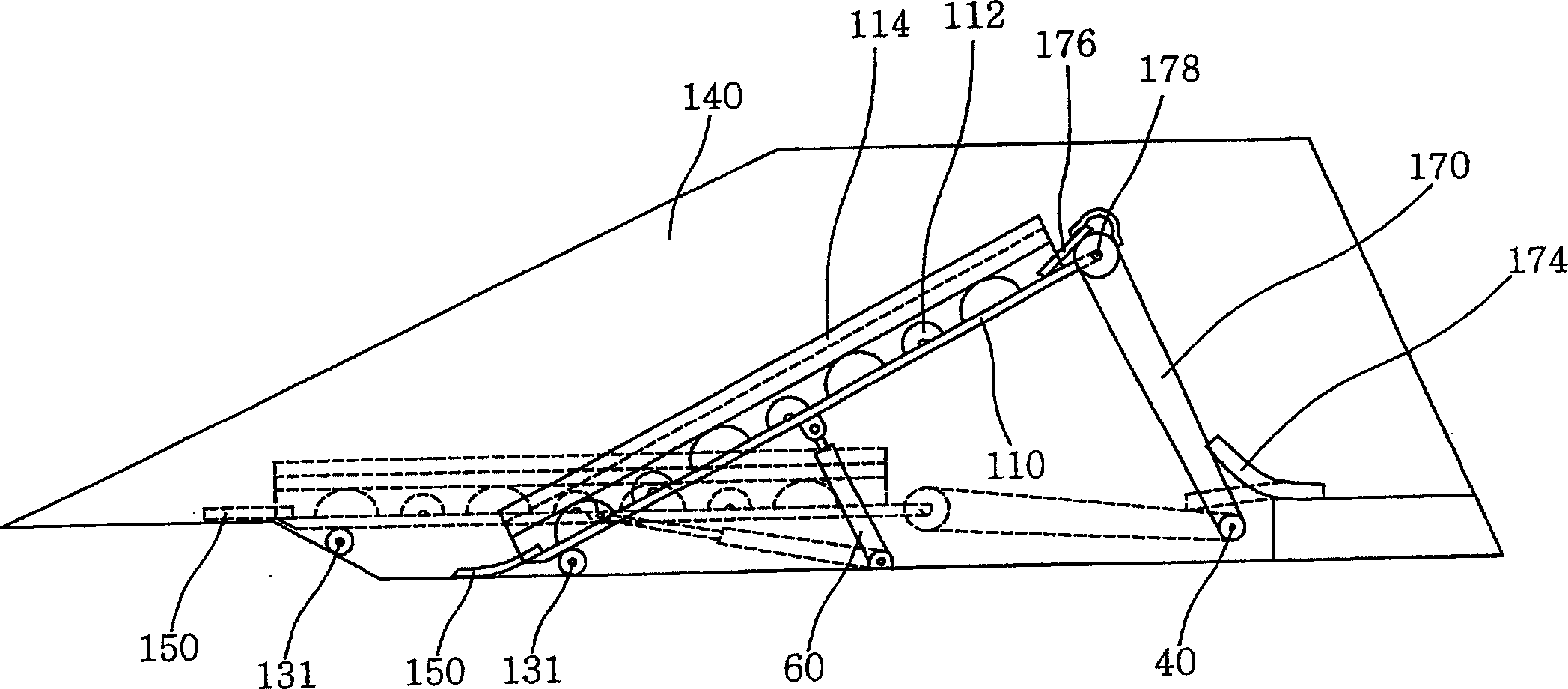

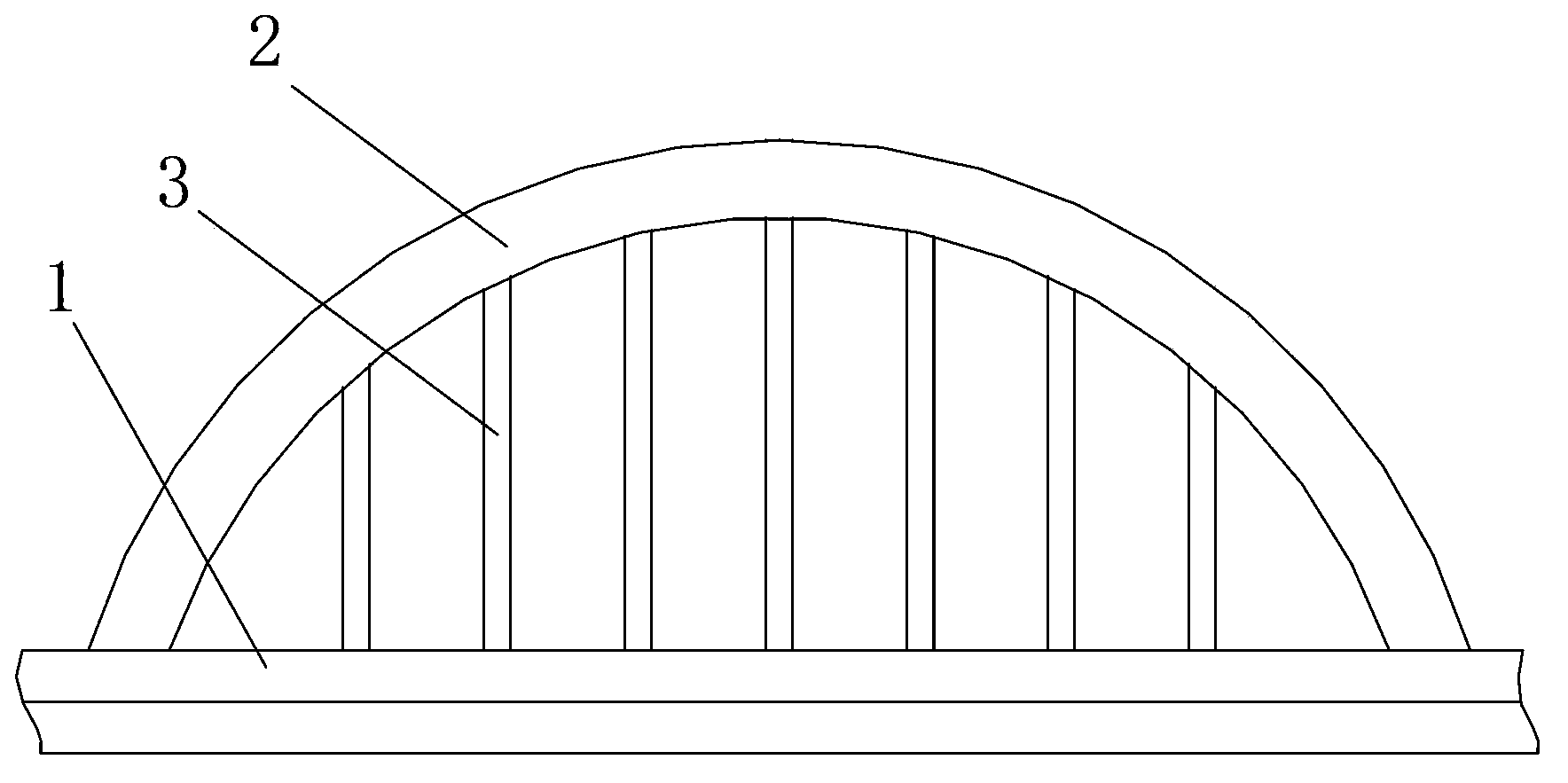

Automatic variable fishway by water level sensed

InactiveCN1863970AProtect the ecosystemGuaranteed normal displacementBarrages/weirsClimate change adaptationEngineeringWater level

The present invention relates to an automatic variable fishway. More particularly, an automatic variable fishway by water level sensed of the invention can automatically vary its height to uniformly maintain the quantity of water drained through the fishway so that migratory animals can freely move through the fishway to upstream or downstream of a dam regardless of the quantity of storage water. The automatic variable fishway by water level sensed of the invention is installed in a bank for storing a predetermined quantity of water to allow migration of fish, and comprises: an underwater gate 170 for being erected or laid by a drive means which is operative in response to a signal from a water level detecting sensor 50 for detecting the level of storage water; and a fishway plate 110 connected with a top of the underwater gate 170 to form a migration path for fish.

Owner:寄寅舒

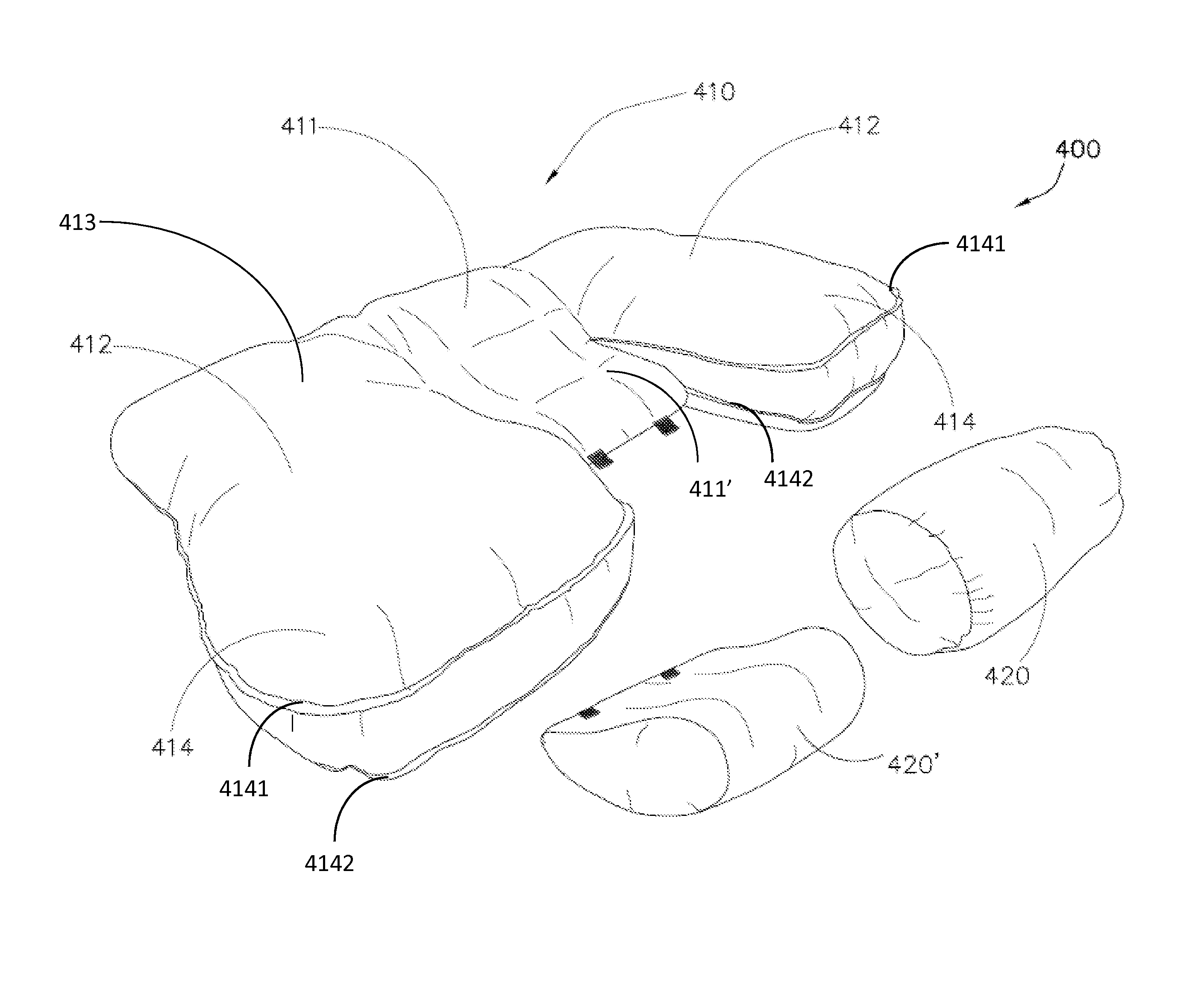

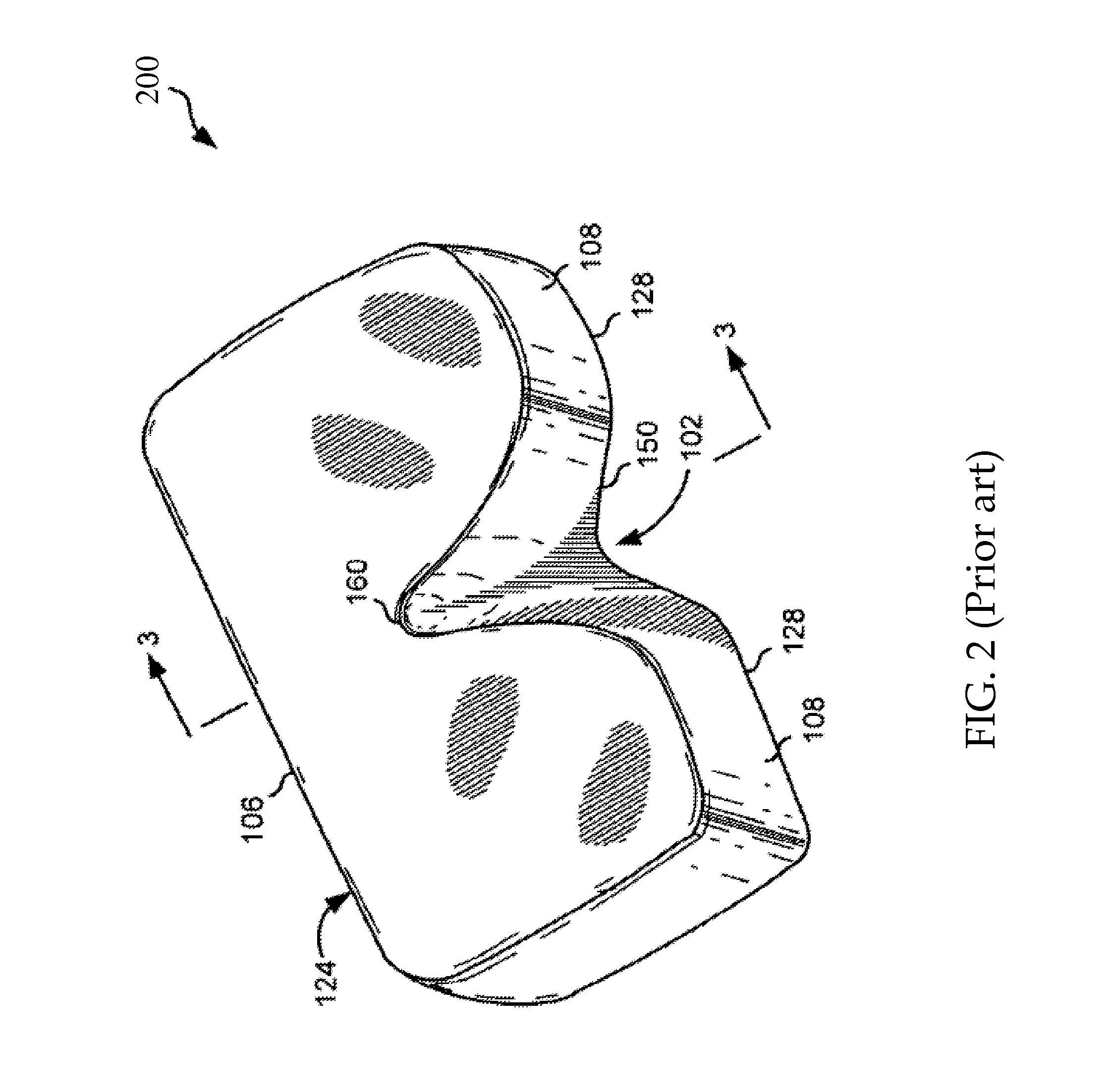

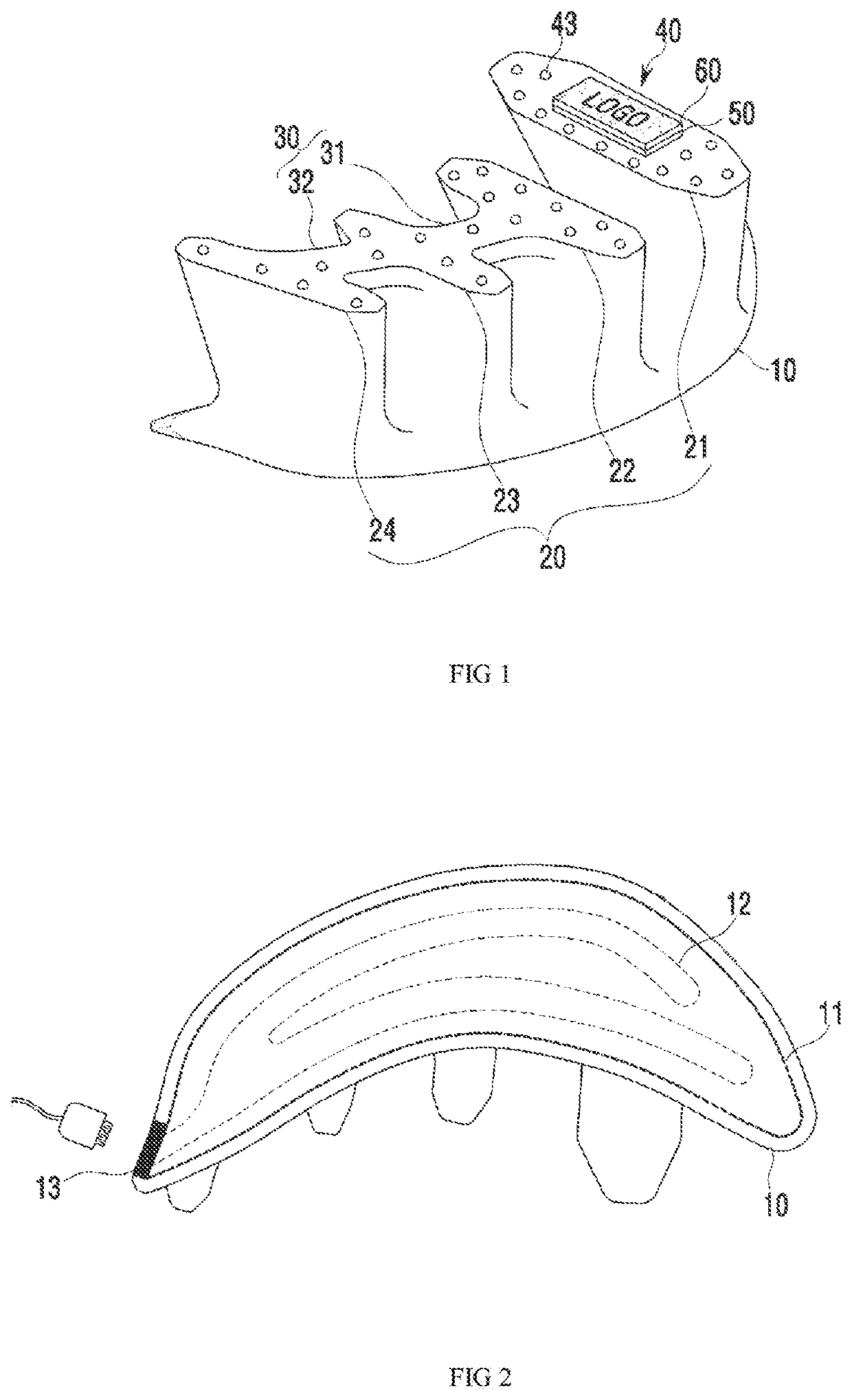

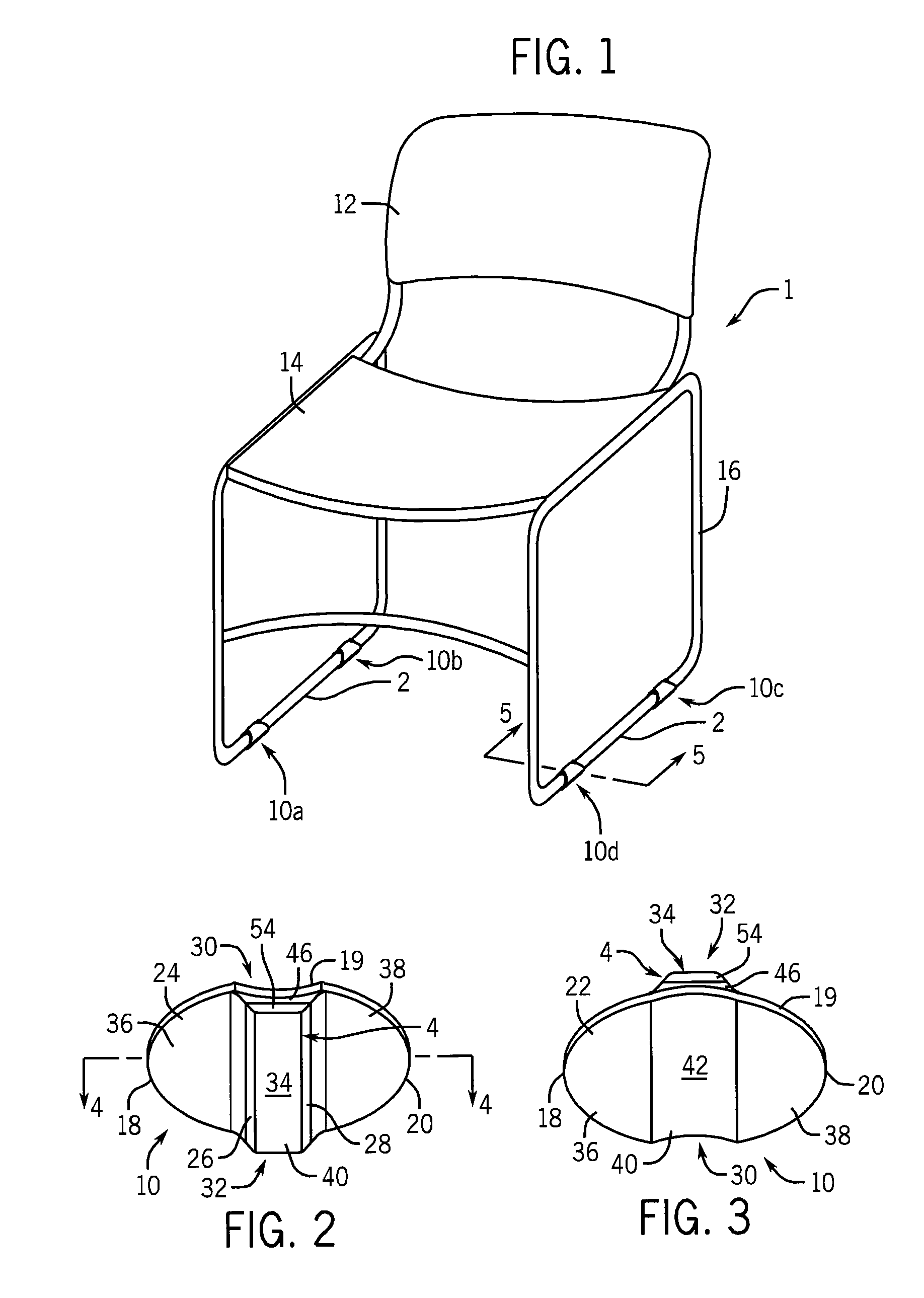

Orthopedic pillows

ActiveUS8893334B1Good lateral supportMaximizes comfort levelPillowsSofasRest positionOrthopedic pillow

A pillow in the present invention may include a main pillow body and a neck support. The main pillow body may include three sections: a head support section and a pair of lateral support sections; and the shape of the main pillow body resembles a reverse letter “U.” In an exemplary embodiment, each lateral support section extends from the main pillow body with an enlarging rear end, and the length of lateral support sections is designed to be slightly longer than conventional pillows, so that the pillow would be long and wide enough to support the user's shoulders, no matter which rest position the user adopts. Also, the rear ends of the lateral support sections are thicker by inserting more stuffing materials inside to provide better lateral support to the user when he / she rests on the side during sleep.

Owner:WONG DANNY C

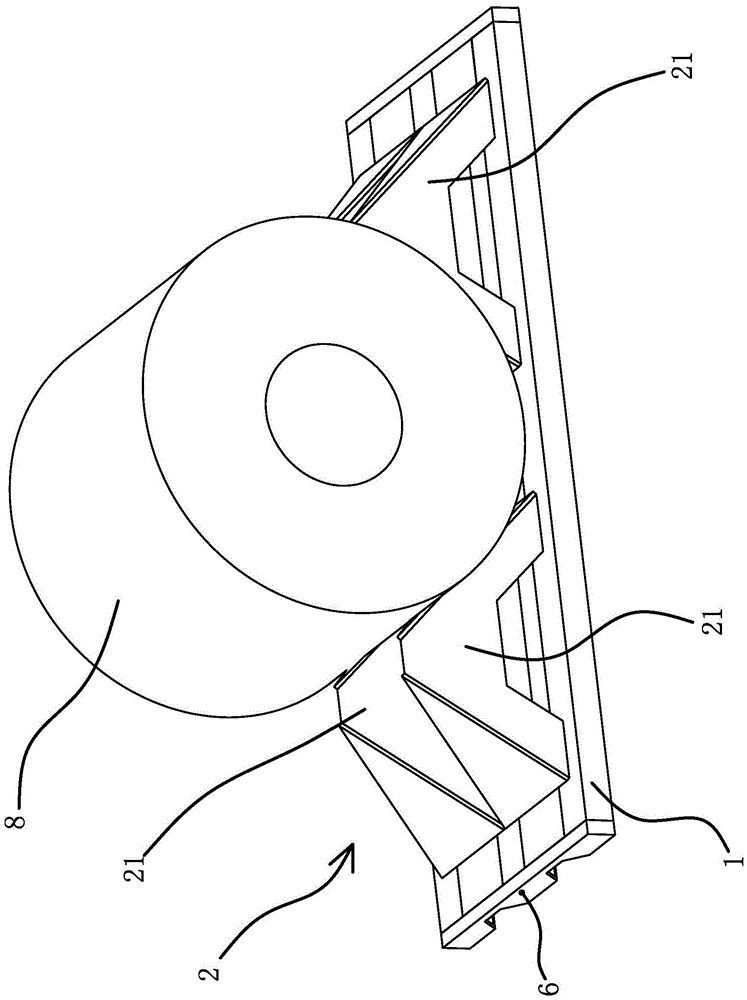

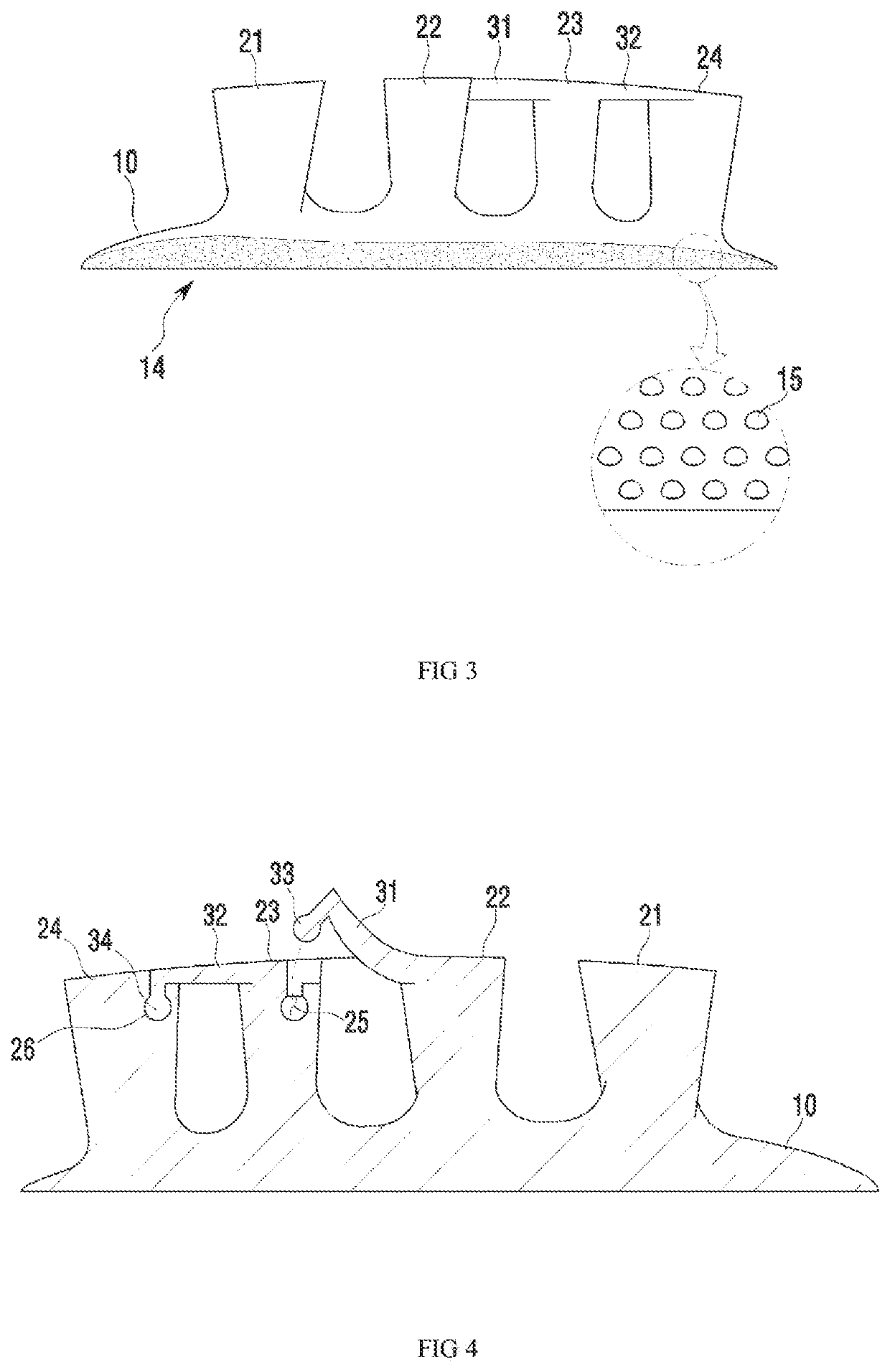

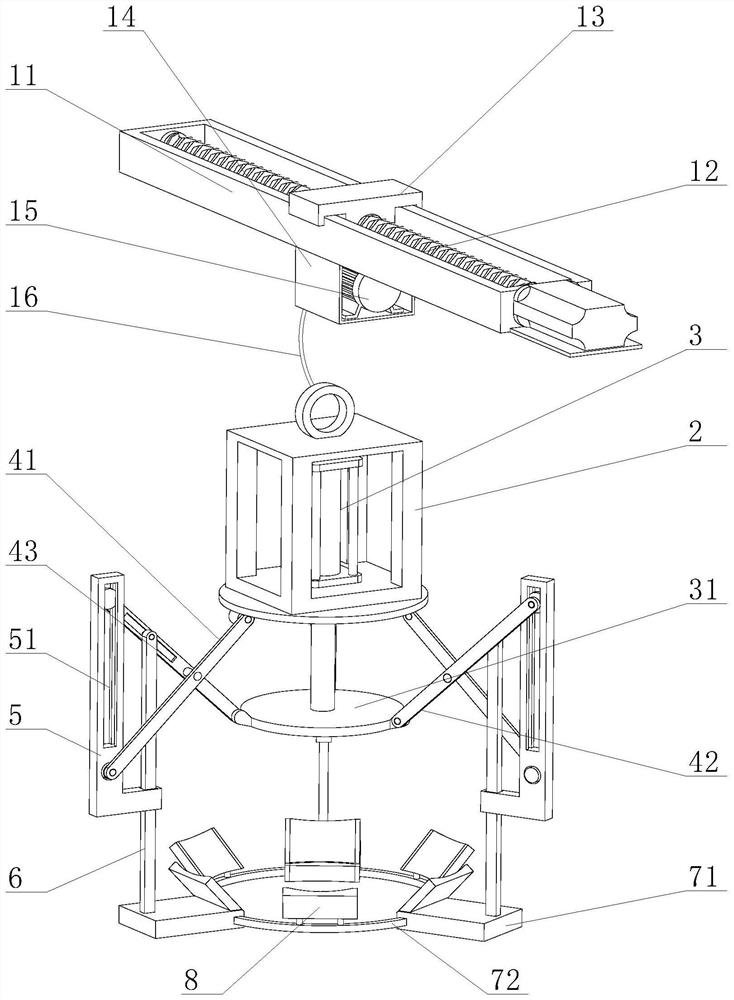

Tray used for steel coil transportation

ActiveCN105600134AEasy to transfer and transportEasy to transportExternal framesRigid containersEngineeringMechanical engineering

The invention provides a tray used for steel coil transportation, and belongs to the technical field of transportation. The tray solves the technical problem that an existing movable tray is not suitable for bearing steel coils. The tray comprises a tray frame and a limiting frame arranged on the tray frame and used for positioning a steel coil. At least two long-strip-shaped installation grooves are formed in the bottom of the tray frame. Long-strip-shaped rolling wheel frames are arranged in the installation grooves. A plurality of rolling wheels are connected to the rolling wheel frames in the length direction of the rolling wheel frame. Guide structures capable of guiding the rolling wheel frames to move up and down relative to the tray frame and limiting structures capable of preventing the rolling wheel frames from being disengaged from the installation grooves are arranged on the portions, located in the installation grooves, on the tray frame. Gas bags are arranged in the installation grooves and located above the rolling wheel frames. The whole rolling wheels can be located in the installation grooves when the gas bags are not inflated. The gas bags can act on the rolling wheel frames to make the rolling wheels stretch out of the installation grooves when the gas bags are inflated and expanded. The tray has the advantage that the steel coil can be stably transported.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

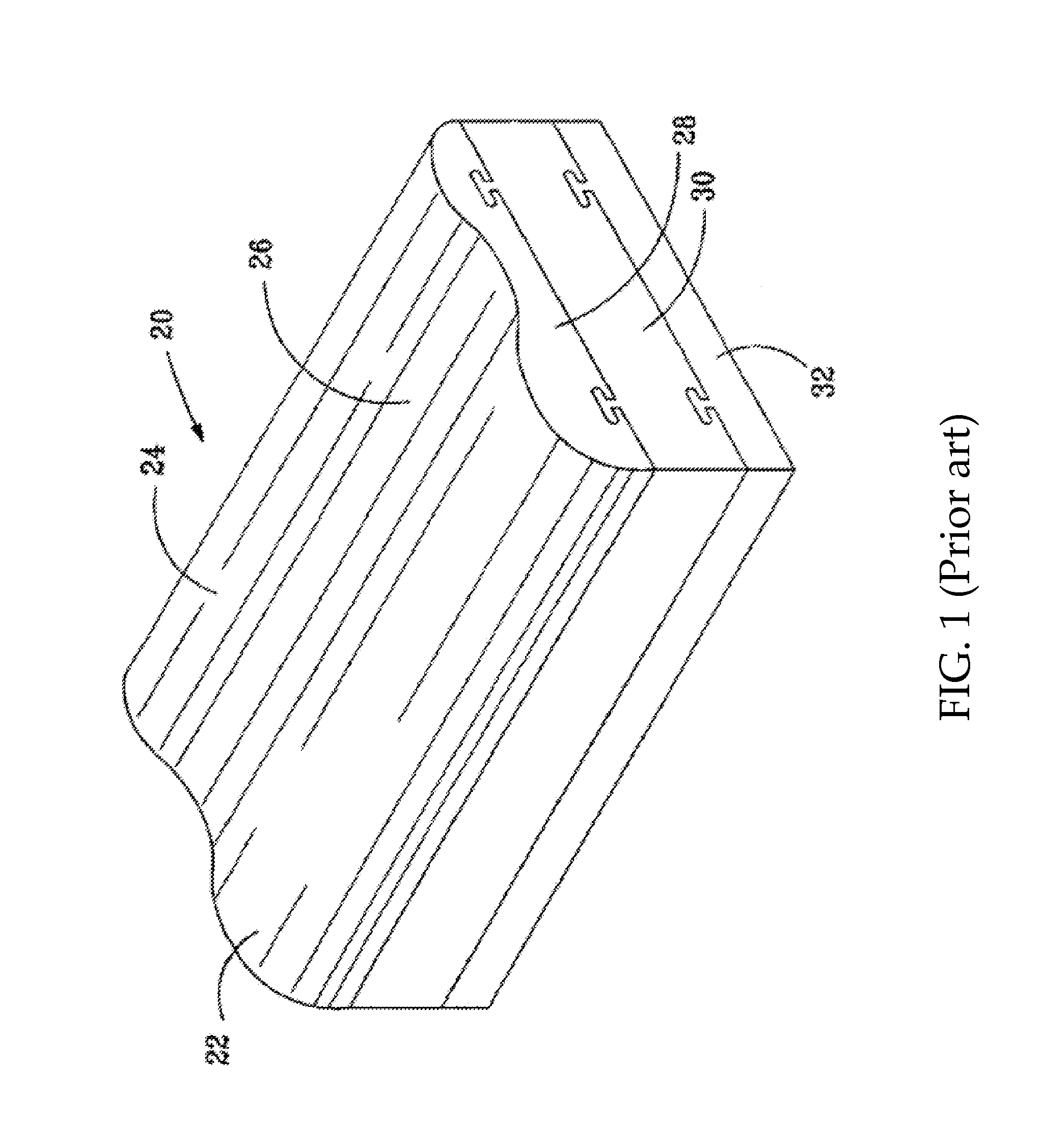

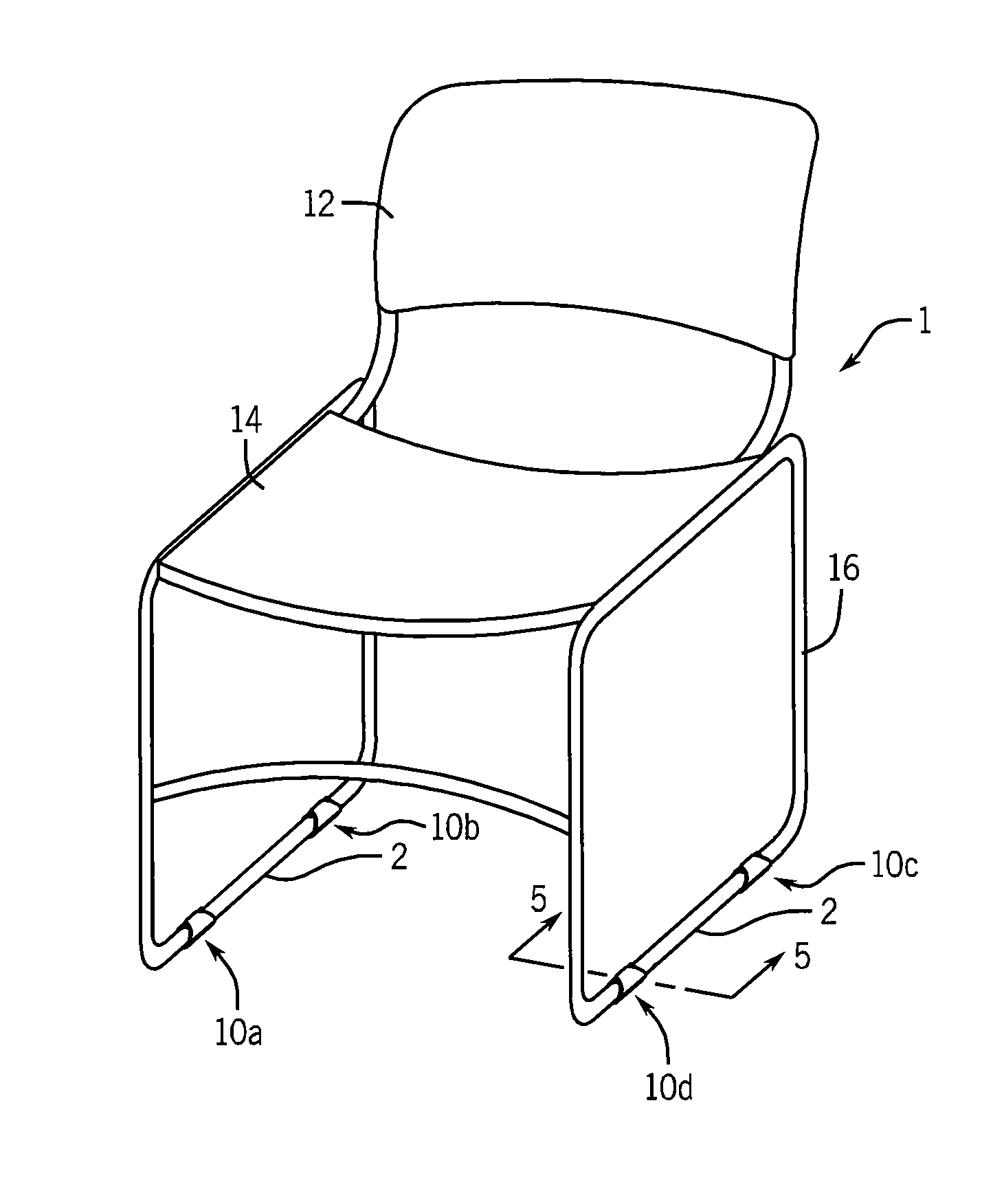

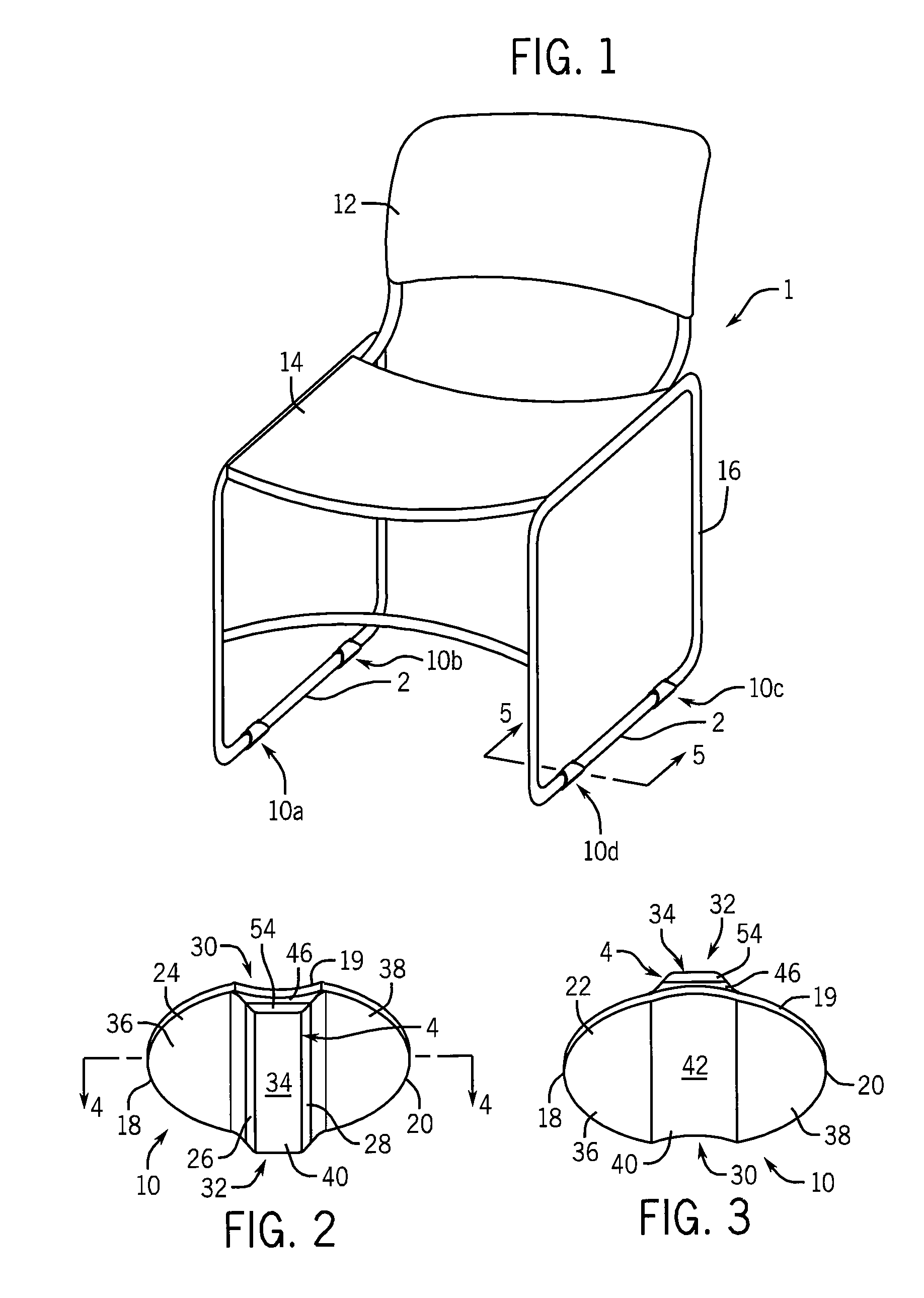

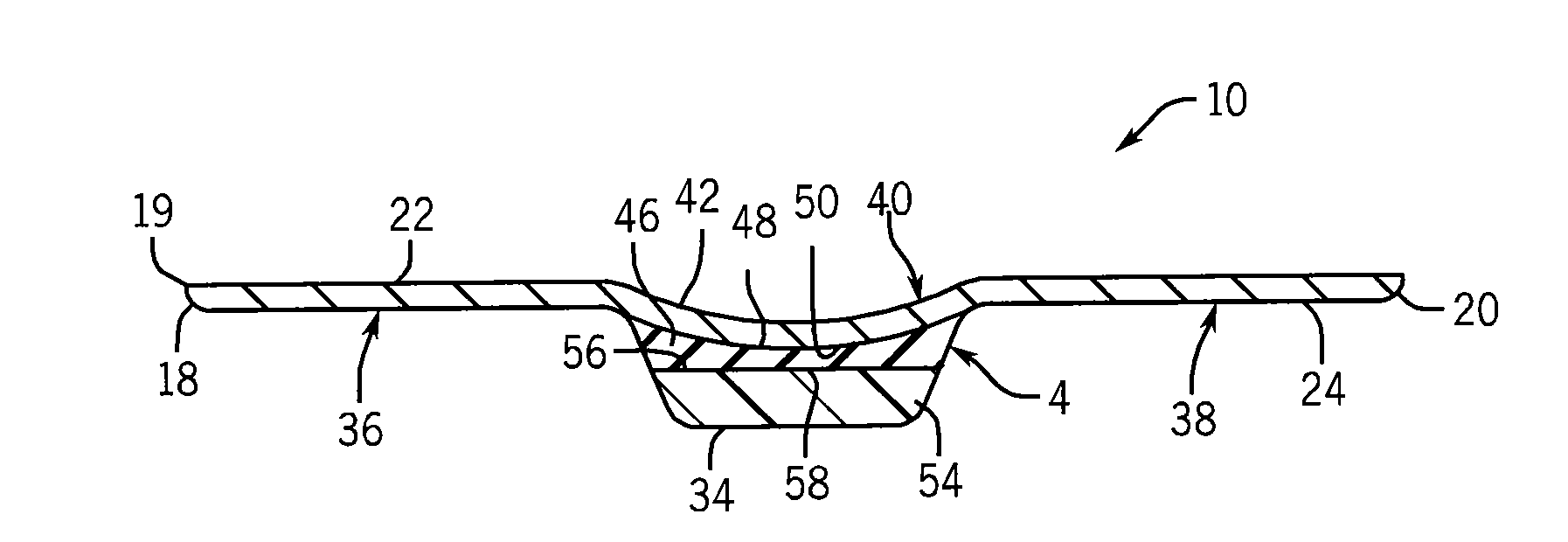

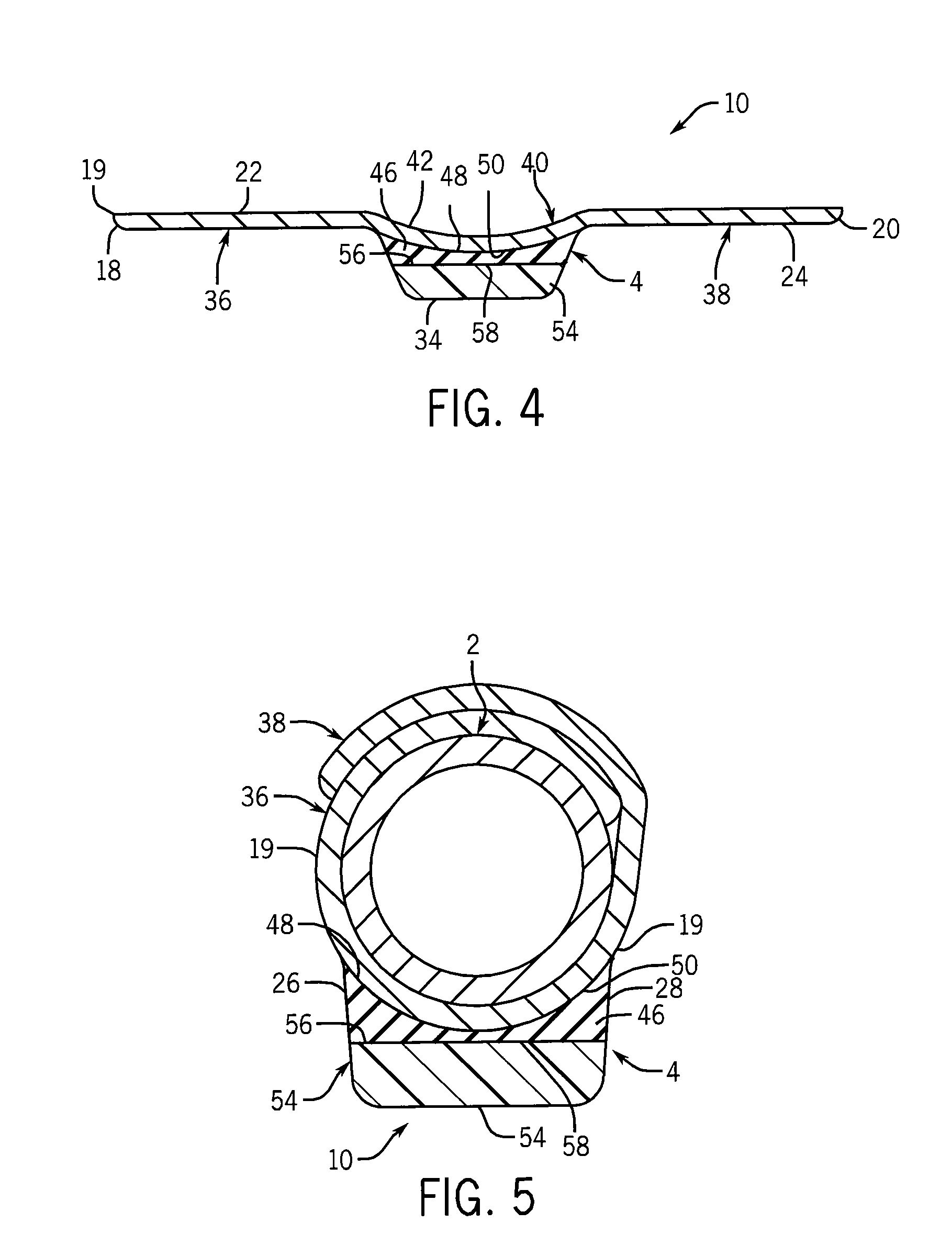

Wrap around furniture glide

A furniture glide configured to wrap around a base portion of a chair frame is disclosed. The furniture glide is of multi-layer construction. A first layer is flexible and configured to engage the chair frame. A second layer, bonded to the first layer, is cushioned. A third layer is configured too engage the floor and is made of a durable material to handle the wear associated with engaging the floor. Side portions of the first layer wrap around the base portion of the chair to easily attach the furniture glide to the chair.

Owner:BUSHEY RICHARD D +1

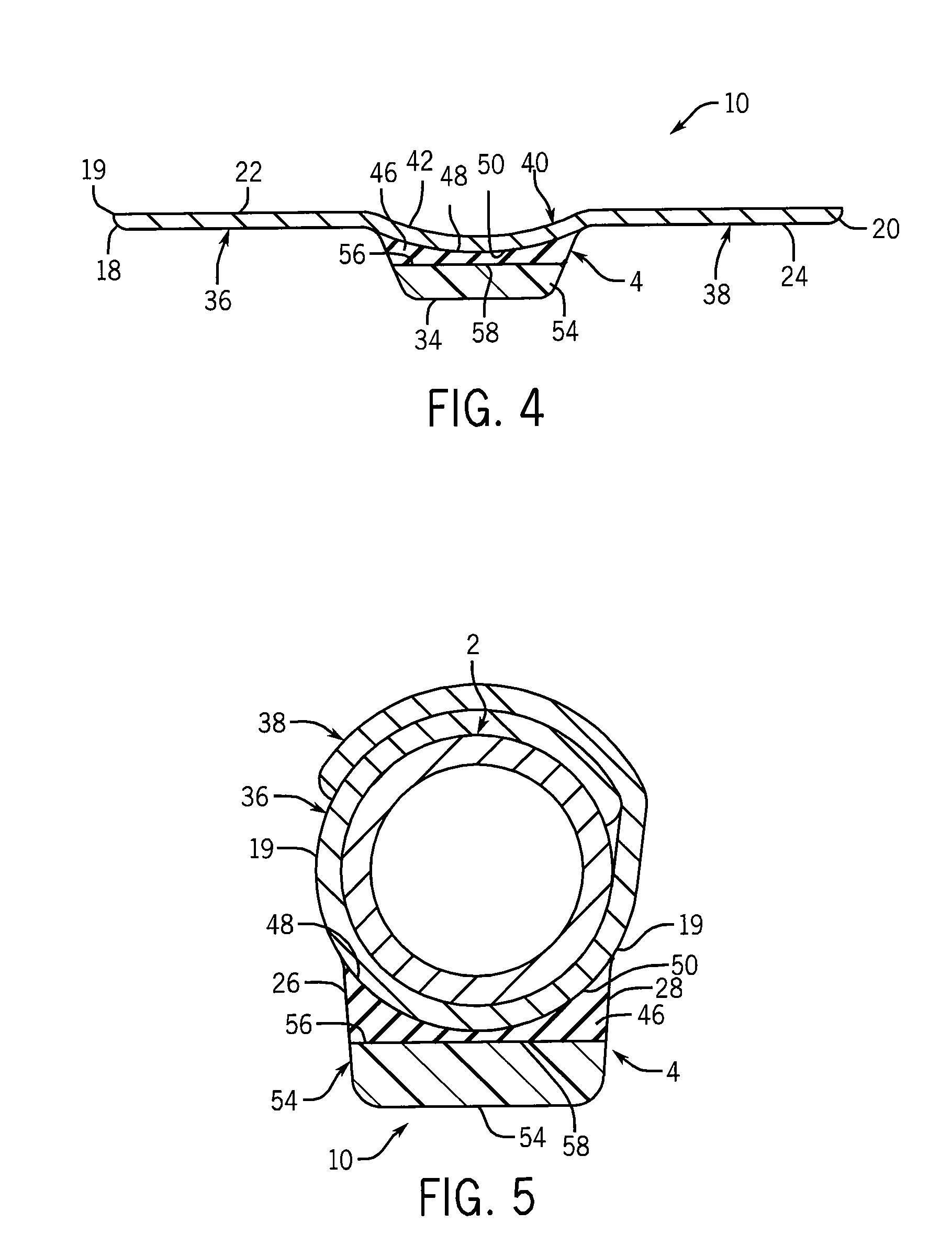

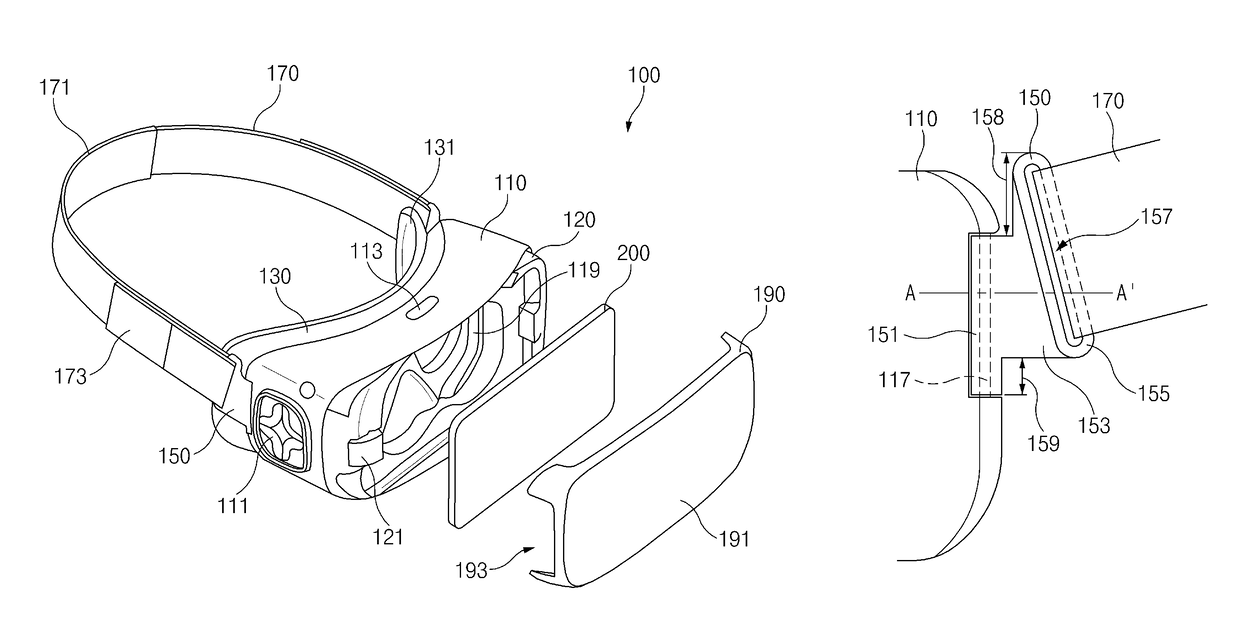

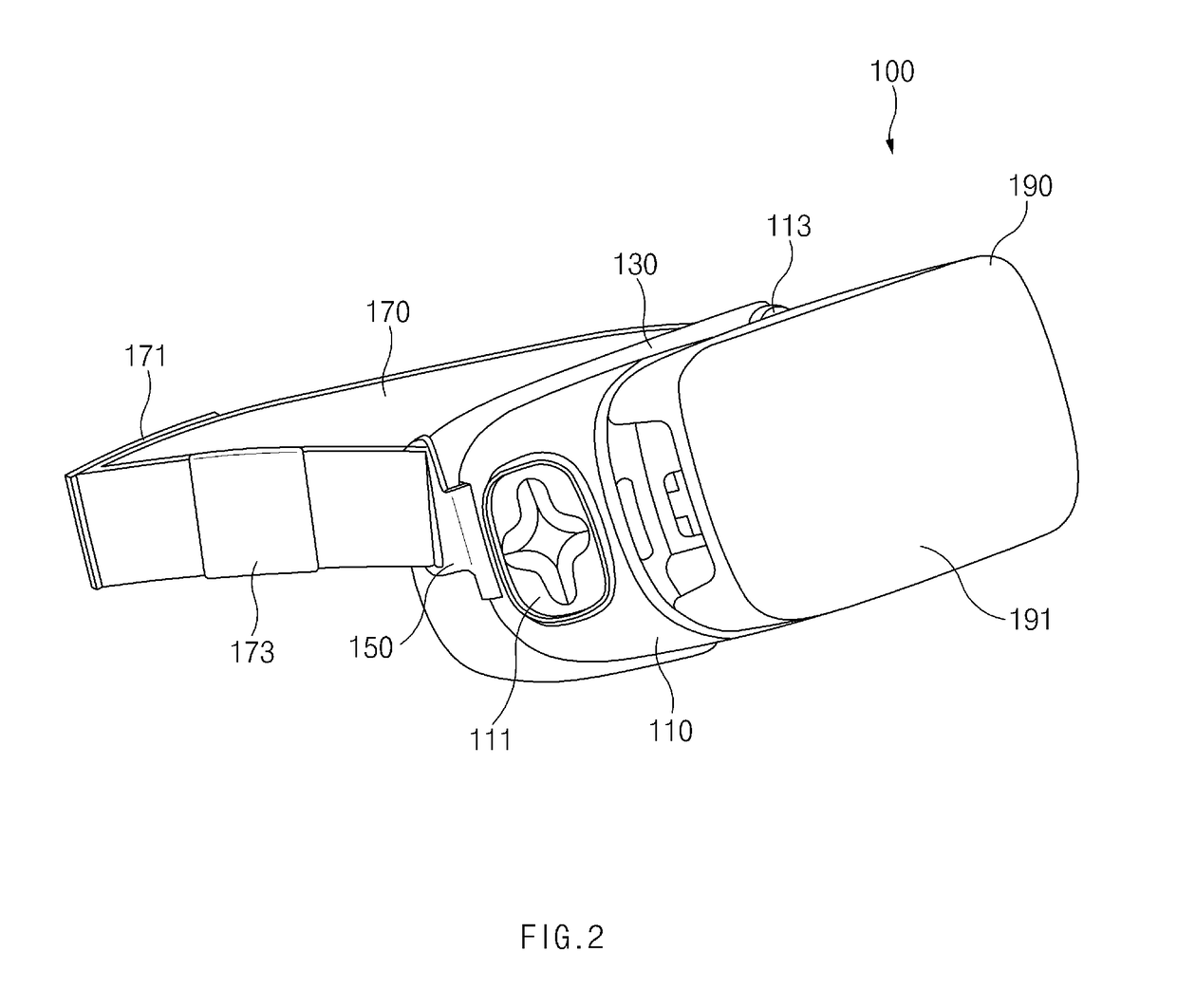

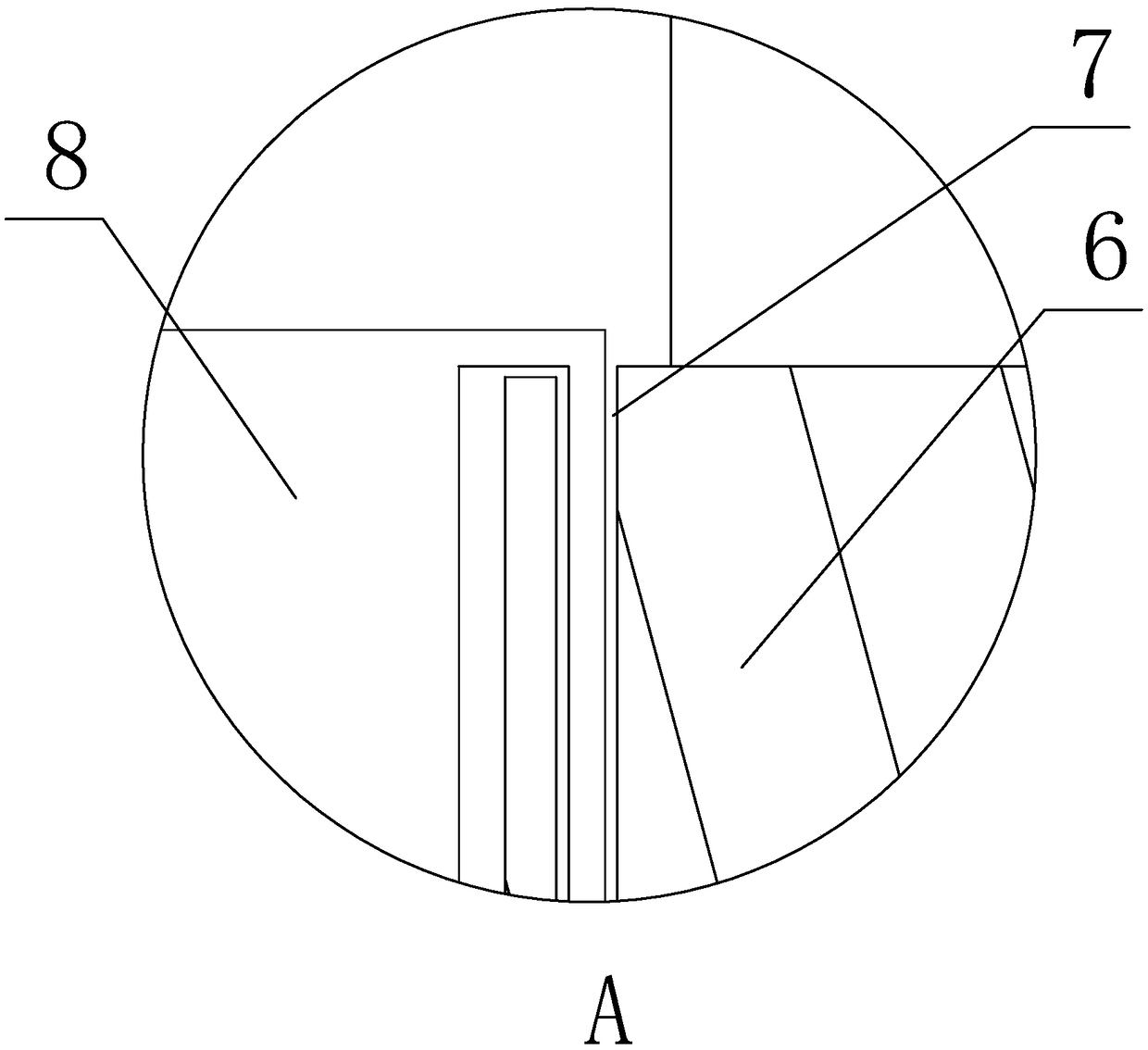

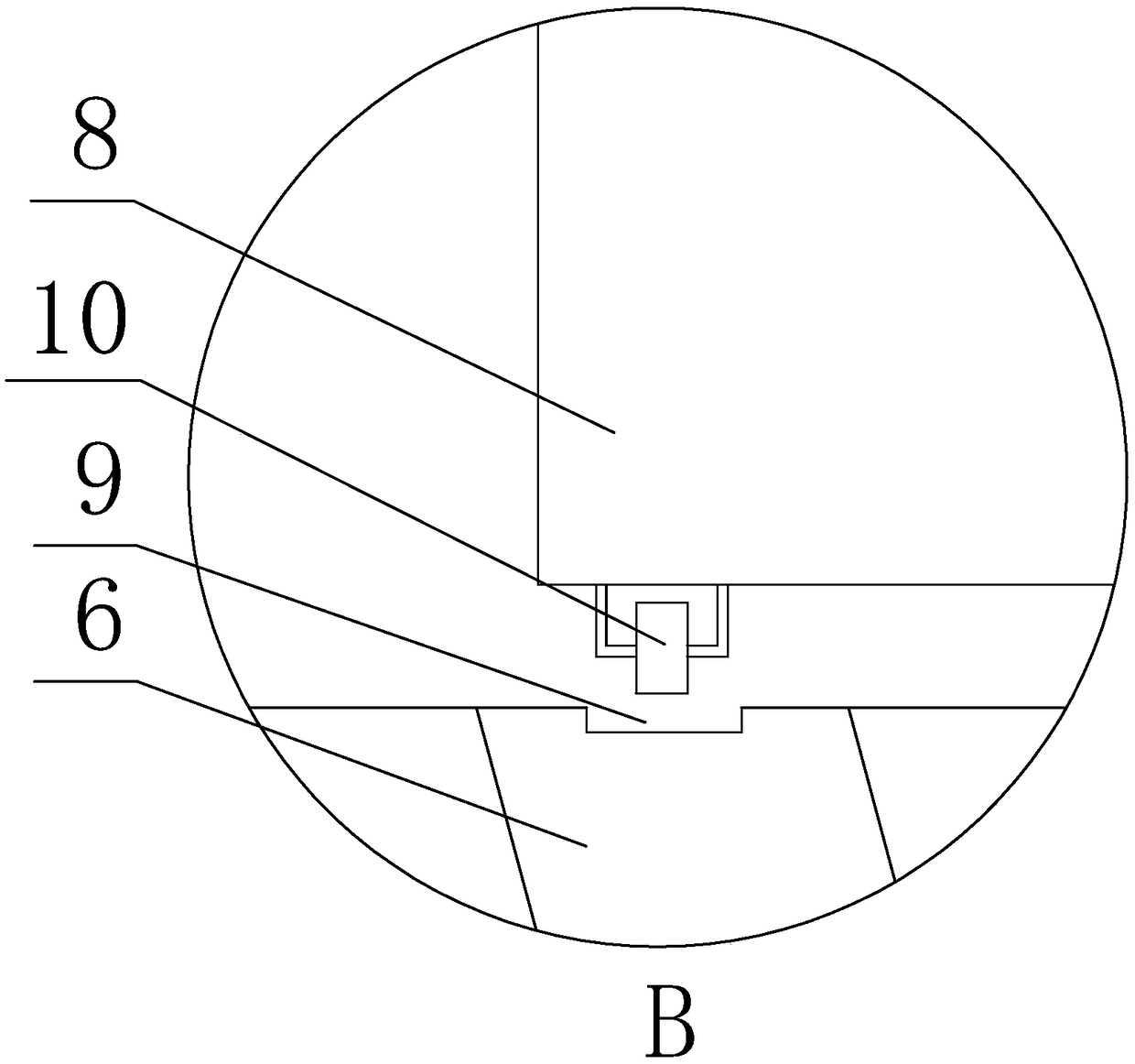

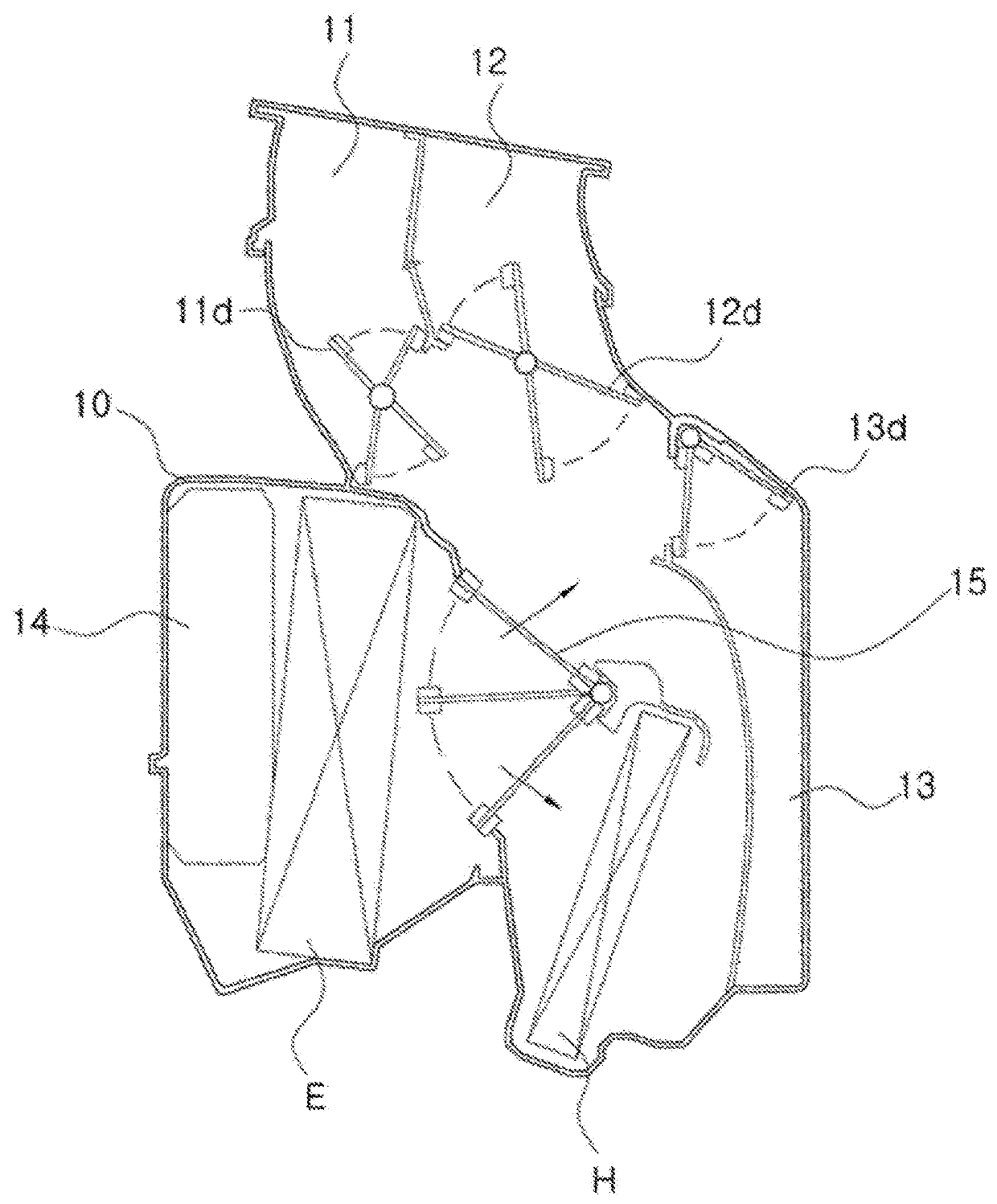

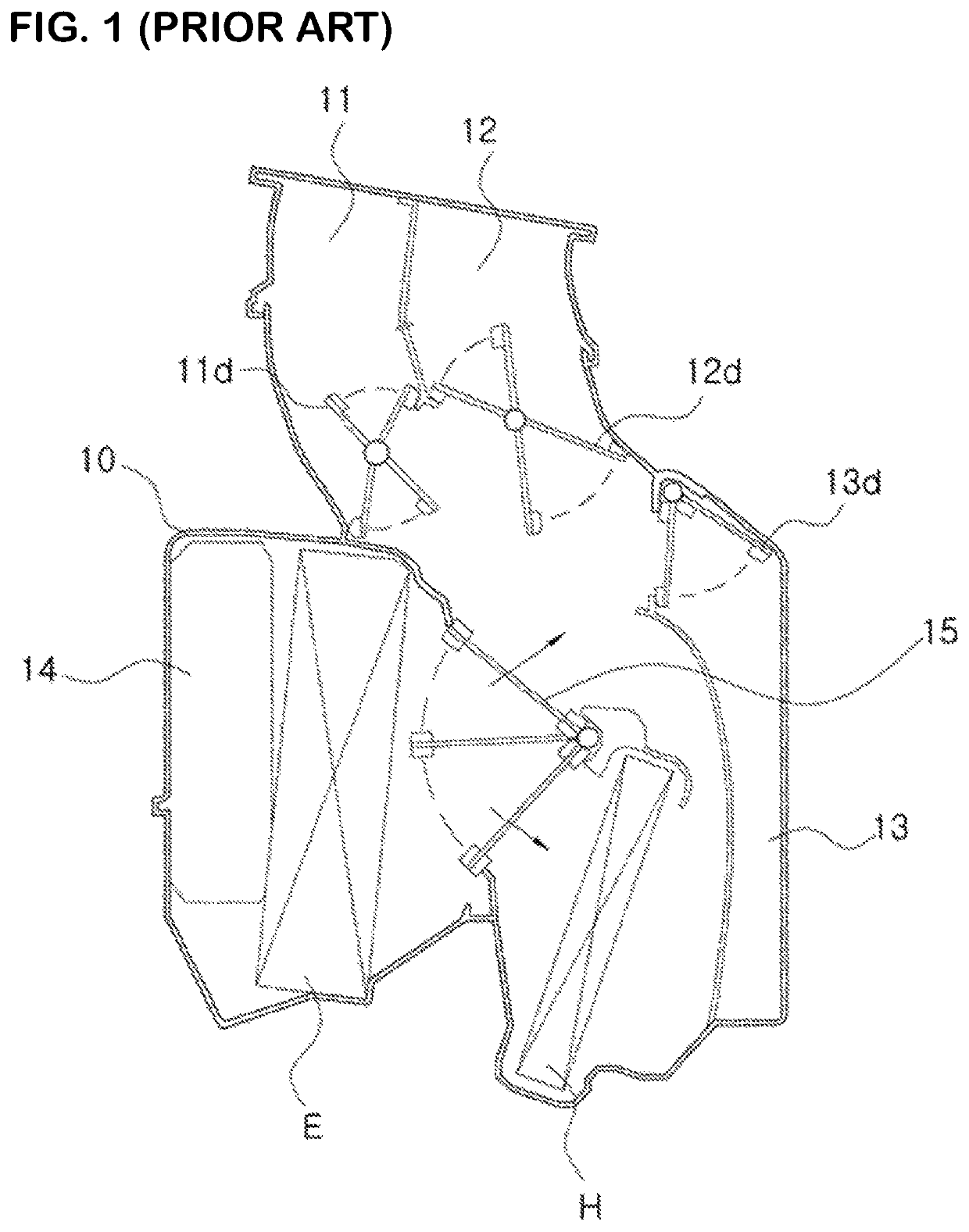

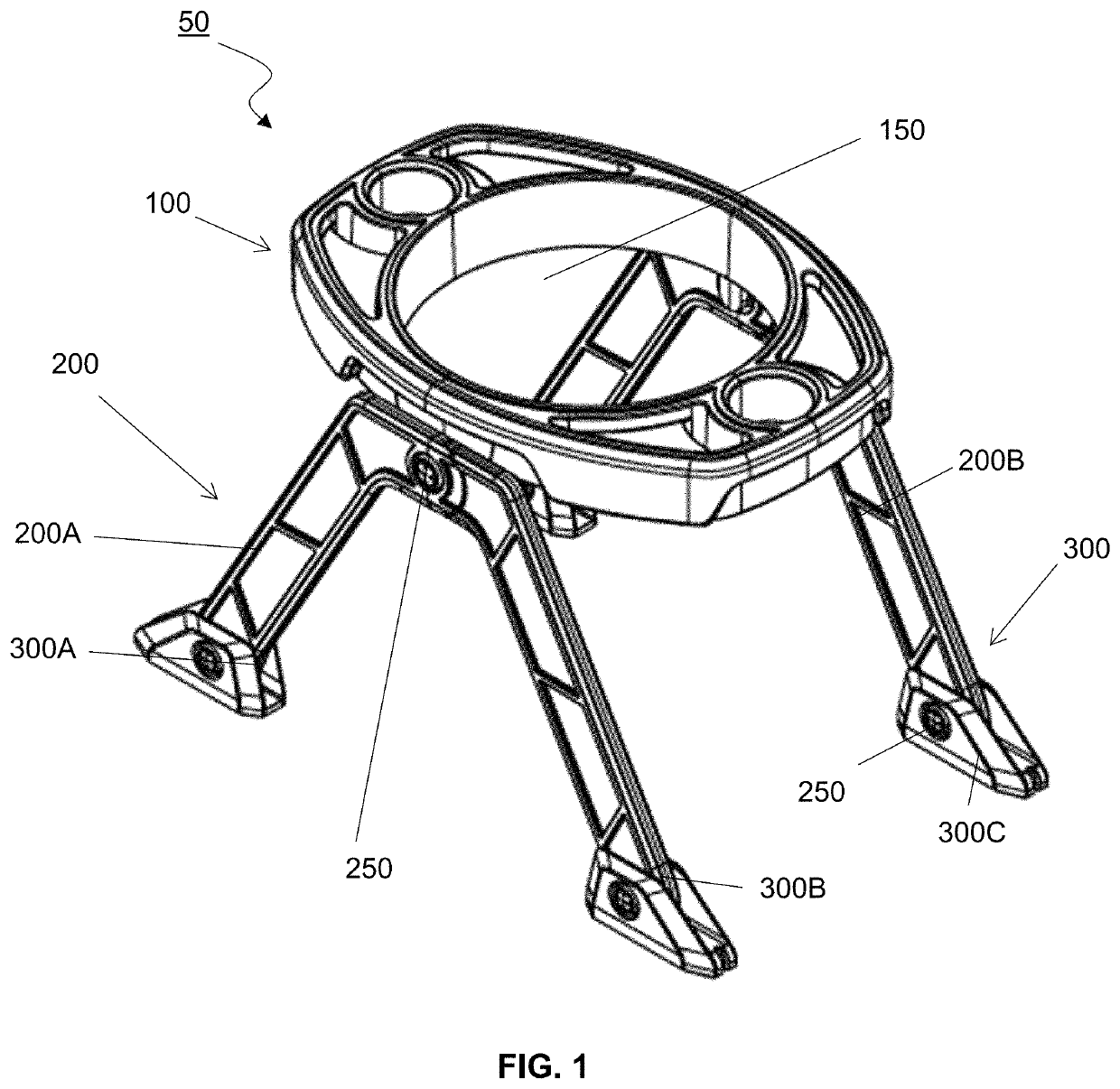

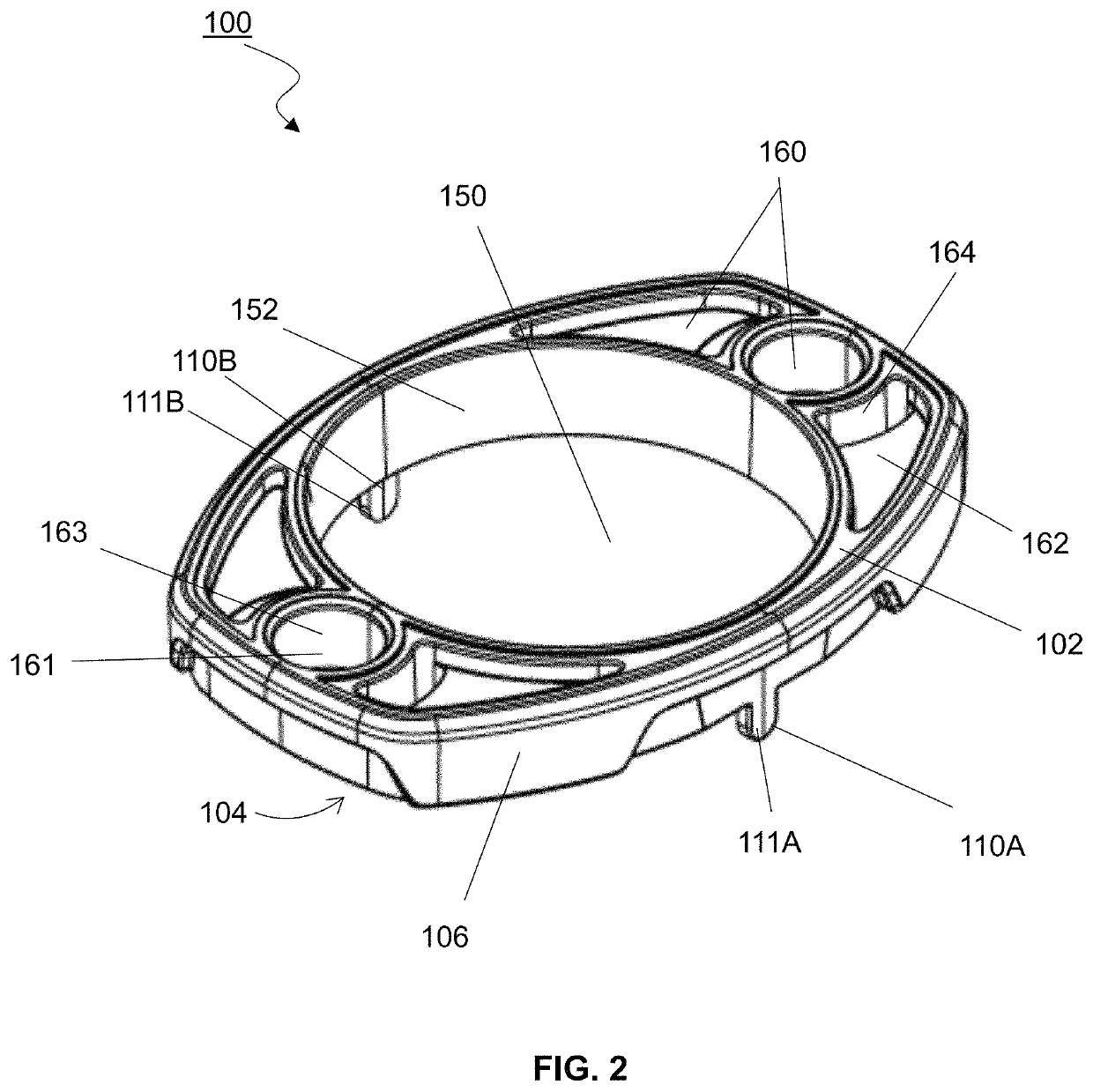

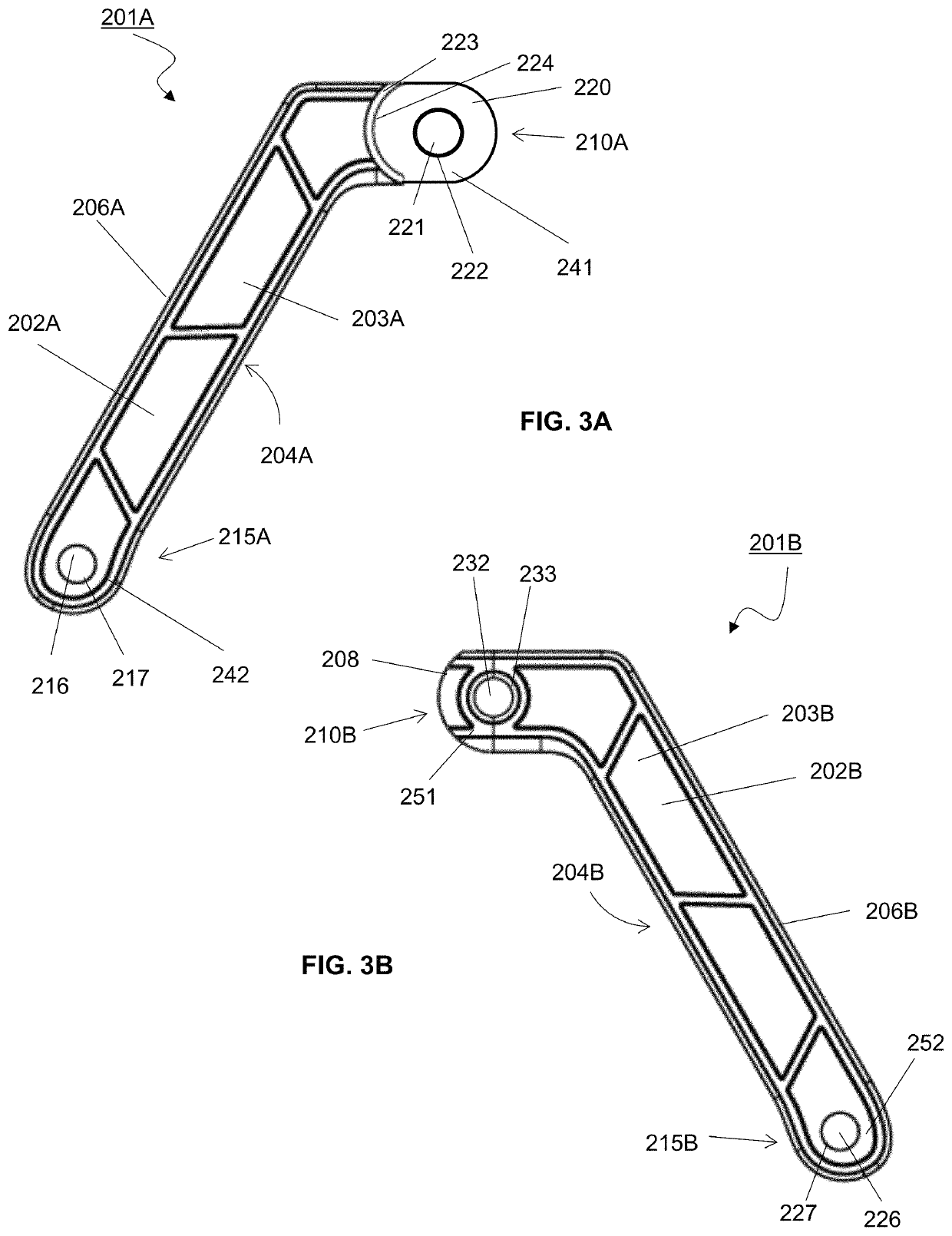

Band connecting device and head mounted display including the same

ActiveUS10095275B2Dispersion weightCathode-ray tube indicatorsDetails for portable computersDisplay deviceBiomedical engineering

A head mounted display device is provided. A head mounted display device includes a main frame including surface formed to face a facial side of a user and an opposite surface on which an external electronic device is mounted; a connecting device connected to the main frame; and a support part connected to the connecting device that fixes the head mounted display device to the facial side of the user. At least a portion of a surface of the connecting device, which is connected to the support part, forms an angle with a direction in which the main frame faces the facial side of the user.

Owner:SAMSUNG ELECTRONICS CO LTD

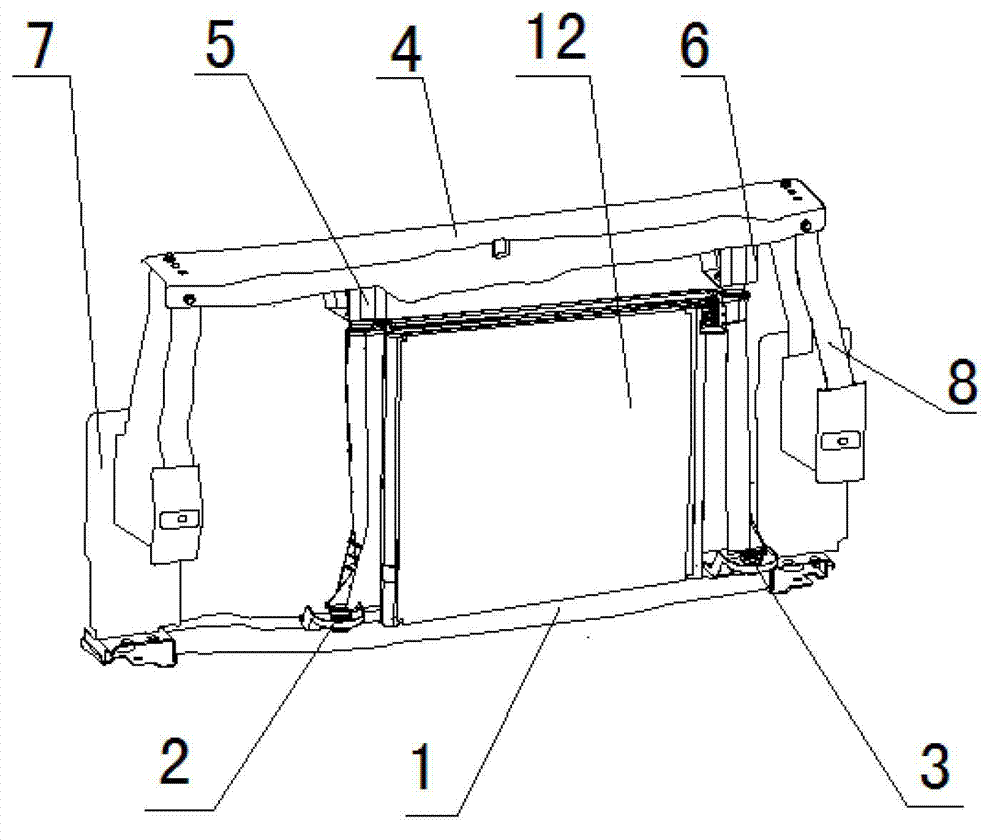

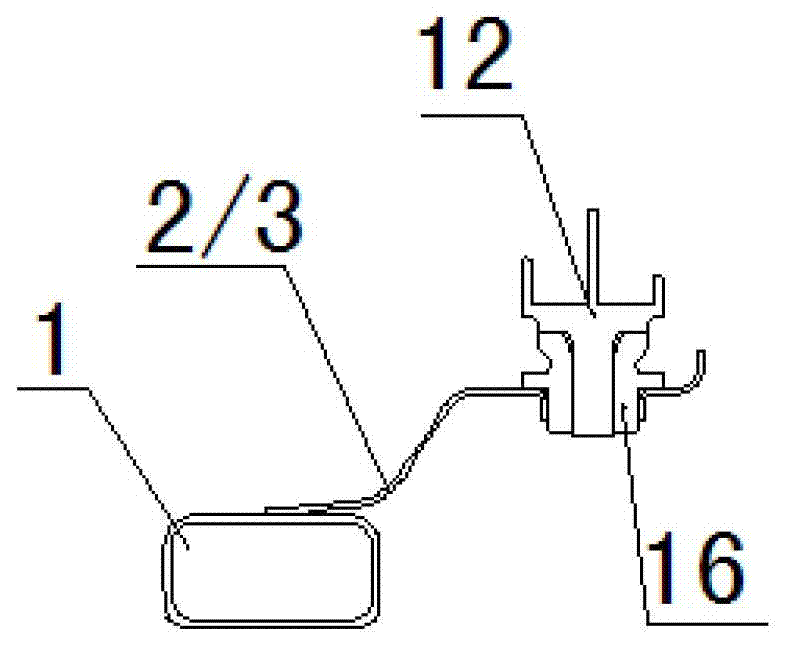

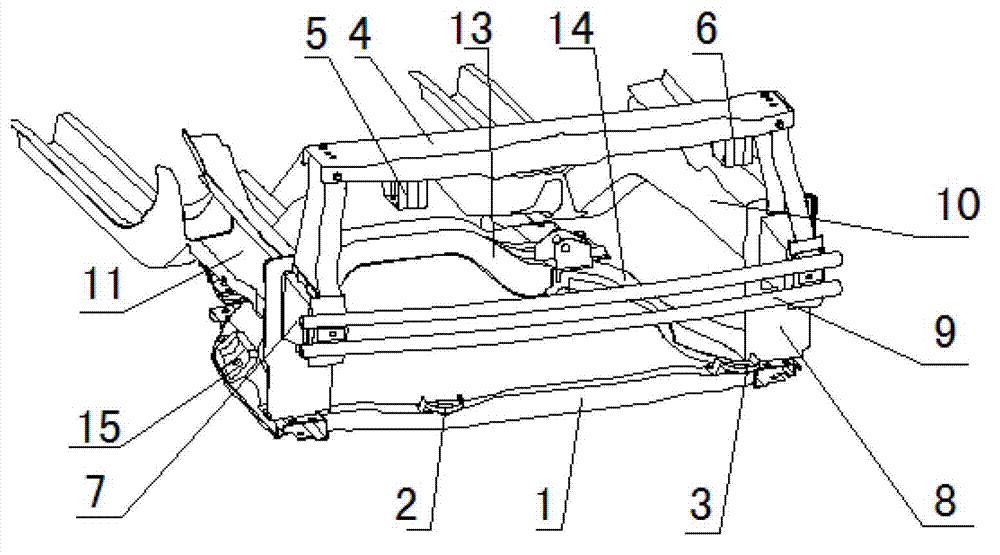

Automobile radiator installation frame and radiator assembly installation structure

ActiveCN103029570AImprove limitationsImprove crash performancePropulsion coolingTransverse beamAerospace engineering

The invention discloses an automobile radiator assembly installation frame, which comprises an upper radiator transverse beam, a left upper radiator bracket, a right upper radiator bracket, a left radiator upright post, a right radiator upright post, a front engine carriage transverse beam, a left lower radiator bracket and a right lower radiator bracket, wherein the left upper radiator bracket and the right upper radiator bracket are welded on the upper radiator transverse beam; the left lower radiator bracket and the right lower radiator bracket are welded on the front engine carriage transverse beam; the left upper radiator bracket and the right upper radiator bracket are arranged oppositely one above the other; the four brackets are taken as four installation points of a radiator; the left radiator upright post and the right radiator upright post are connected to the two ends of the upper radiator transverse beam; the lower ends of the left radiator upright post and the right radiator upright post are connected to the two ends of the front engine carriage transverse beam through bolts; and the front engine carriage transverse beam is a part of an engine bracket assembly. Due to the adoption of the automobile radiator assembly installation frame, the installation requirements of a radiator assembly can be met, the strength and rigidity of the radiator installation frame are optimized, and the weight of the radiator on the front part of an automobile is scattered; and the automobile radiator assembly installation frame has high generality, can be general for derivative automobiles of the same style, has high assembly manufacturability, is installed on the premise of not influencing the original structure of the radiator, and is convenient to detach.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

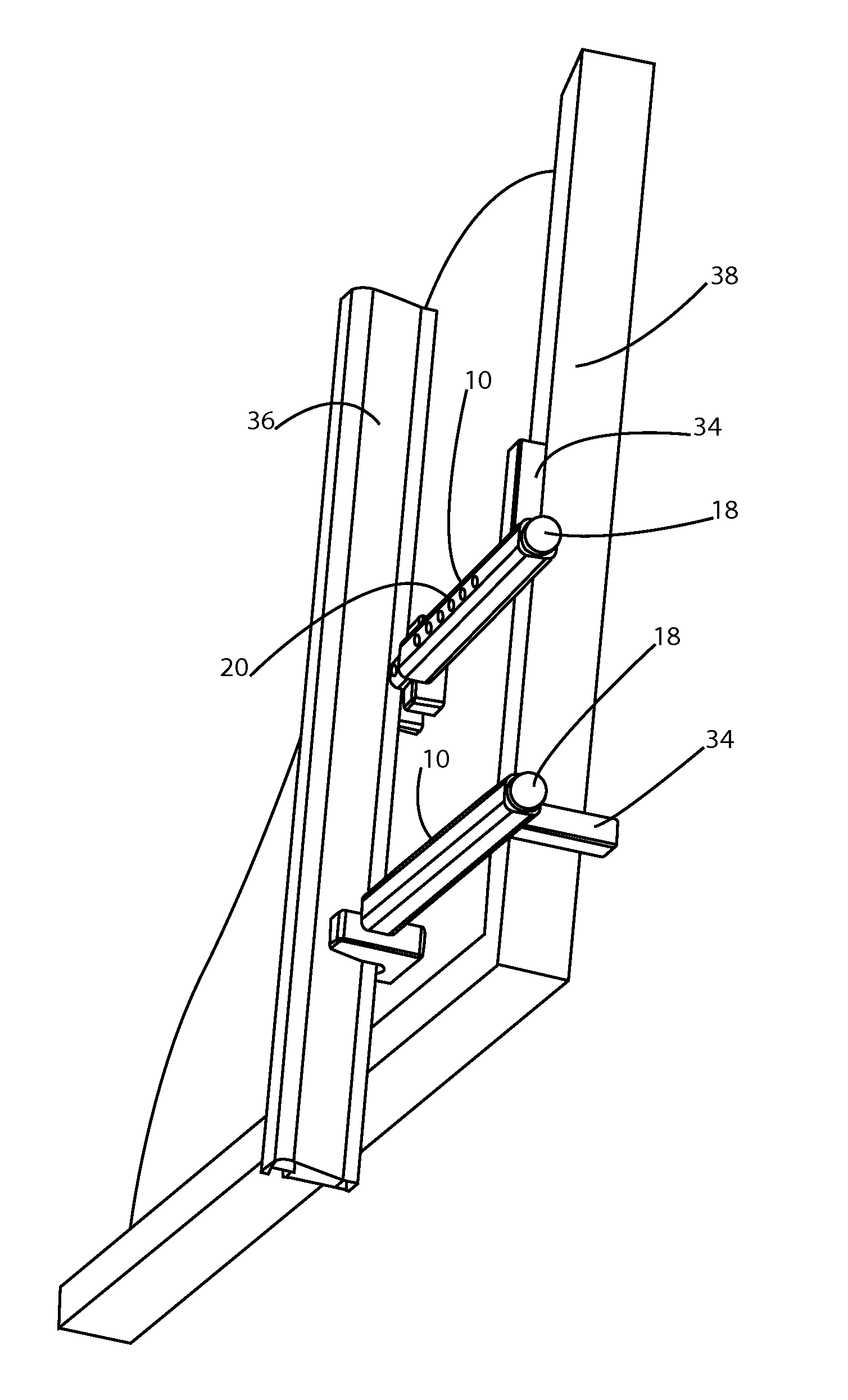

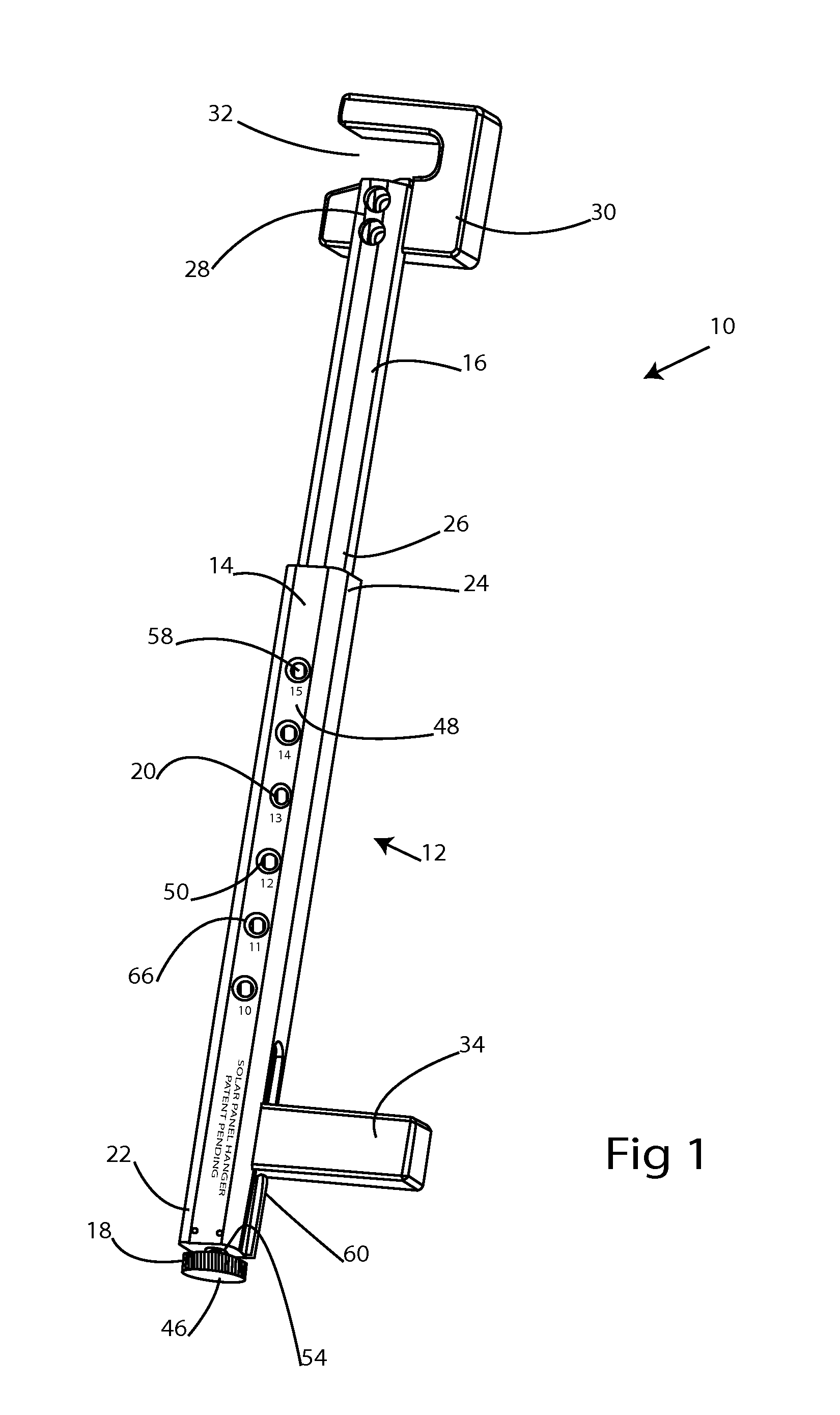

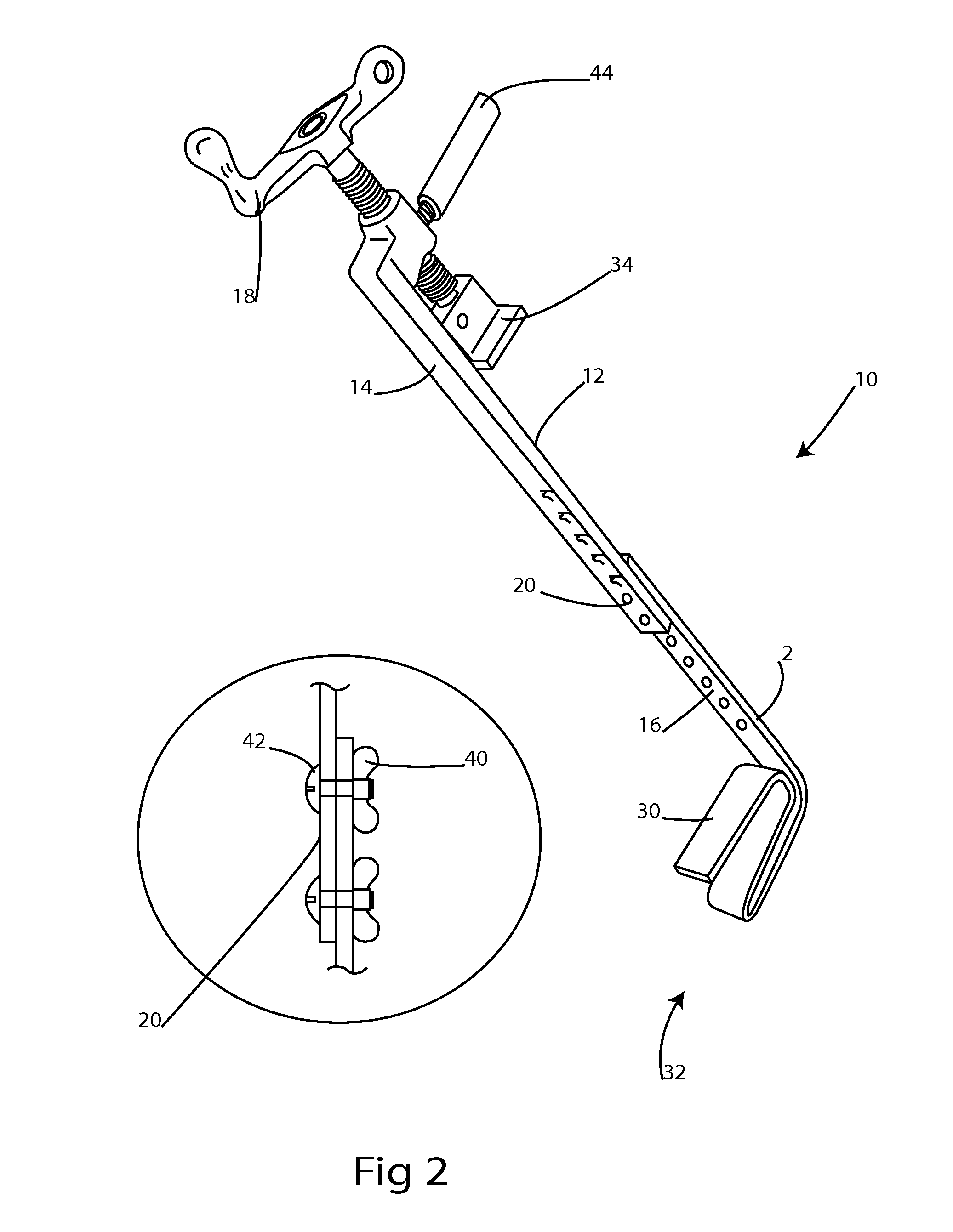

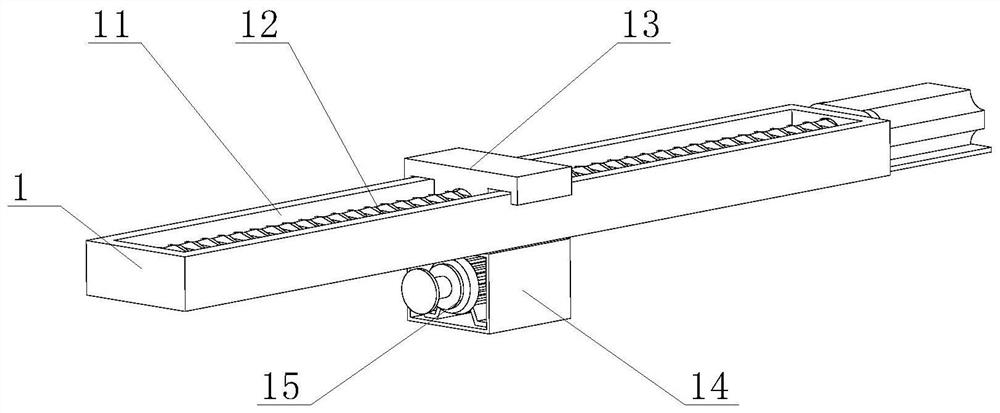

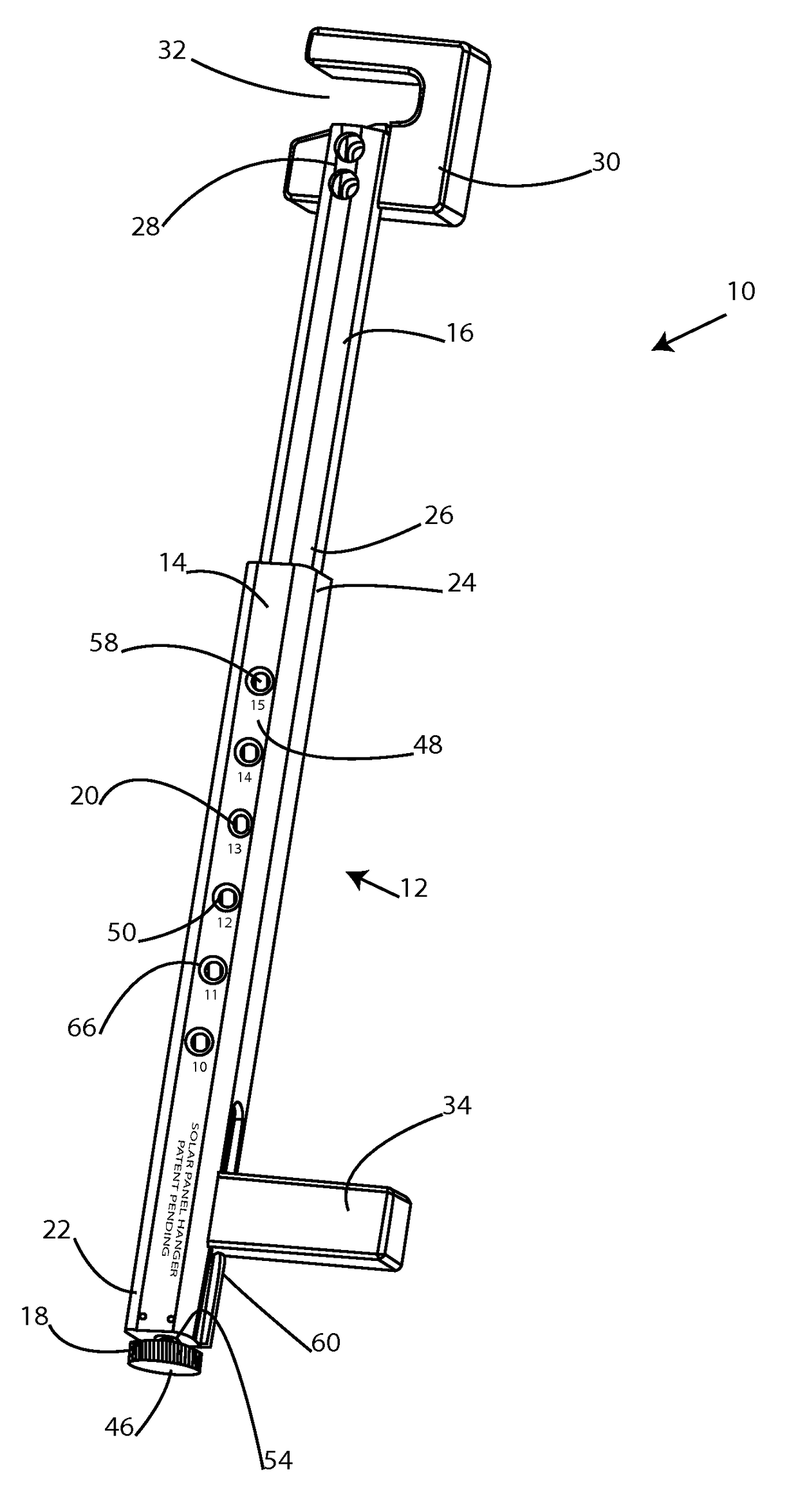

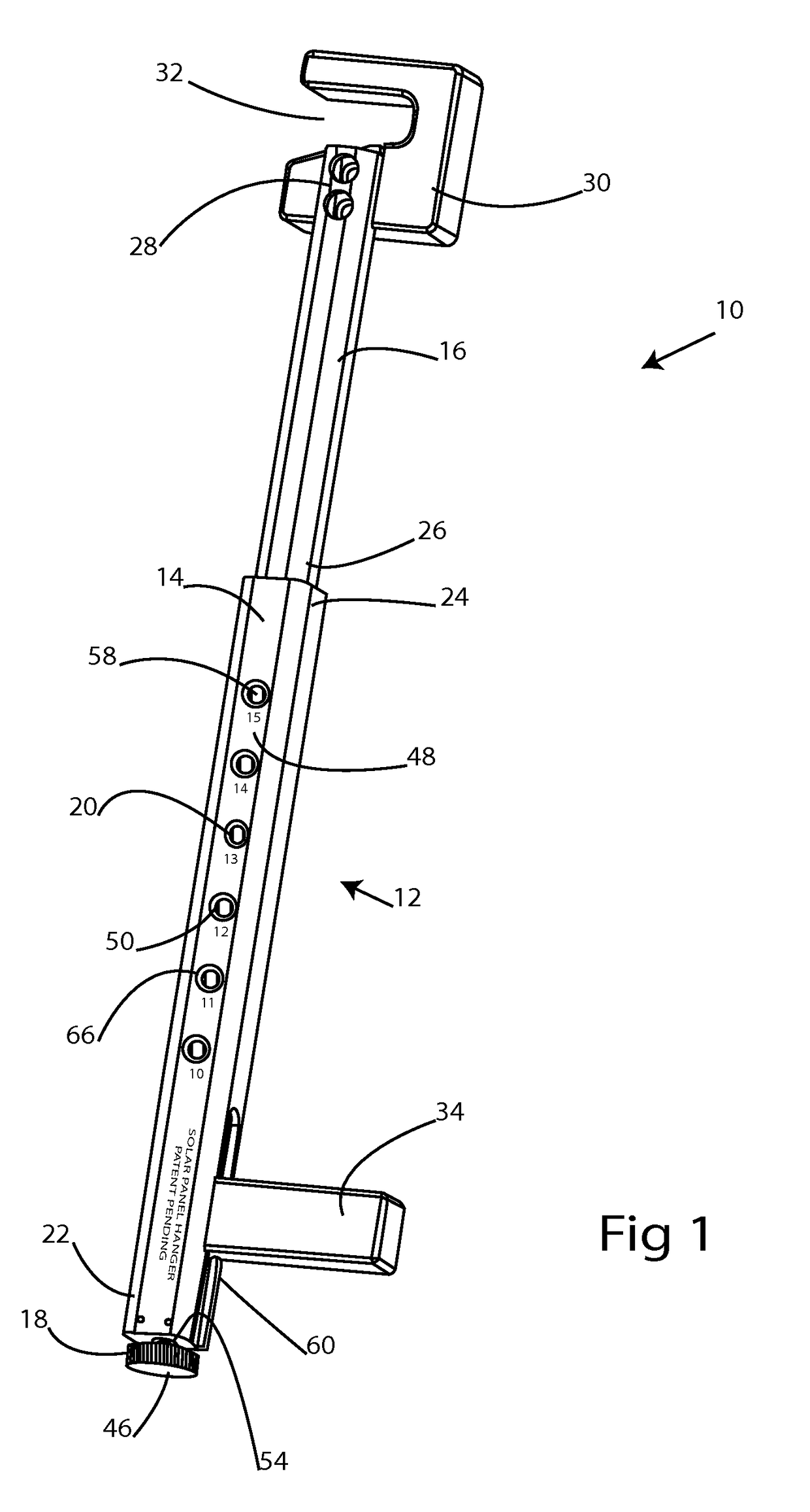

Solar panel installation tool

ActiveUS20160097565A1Easy to slideEasily offSolar heating energyAutomatic control devicesAerospace engineering

Owner:KING KEVIN

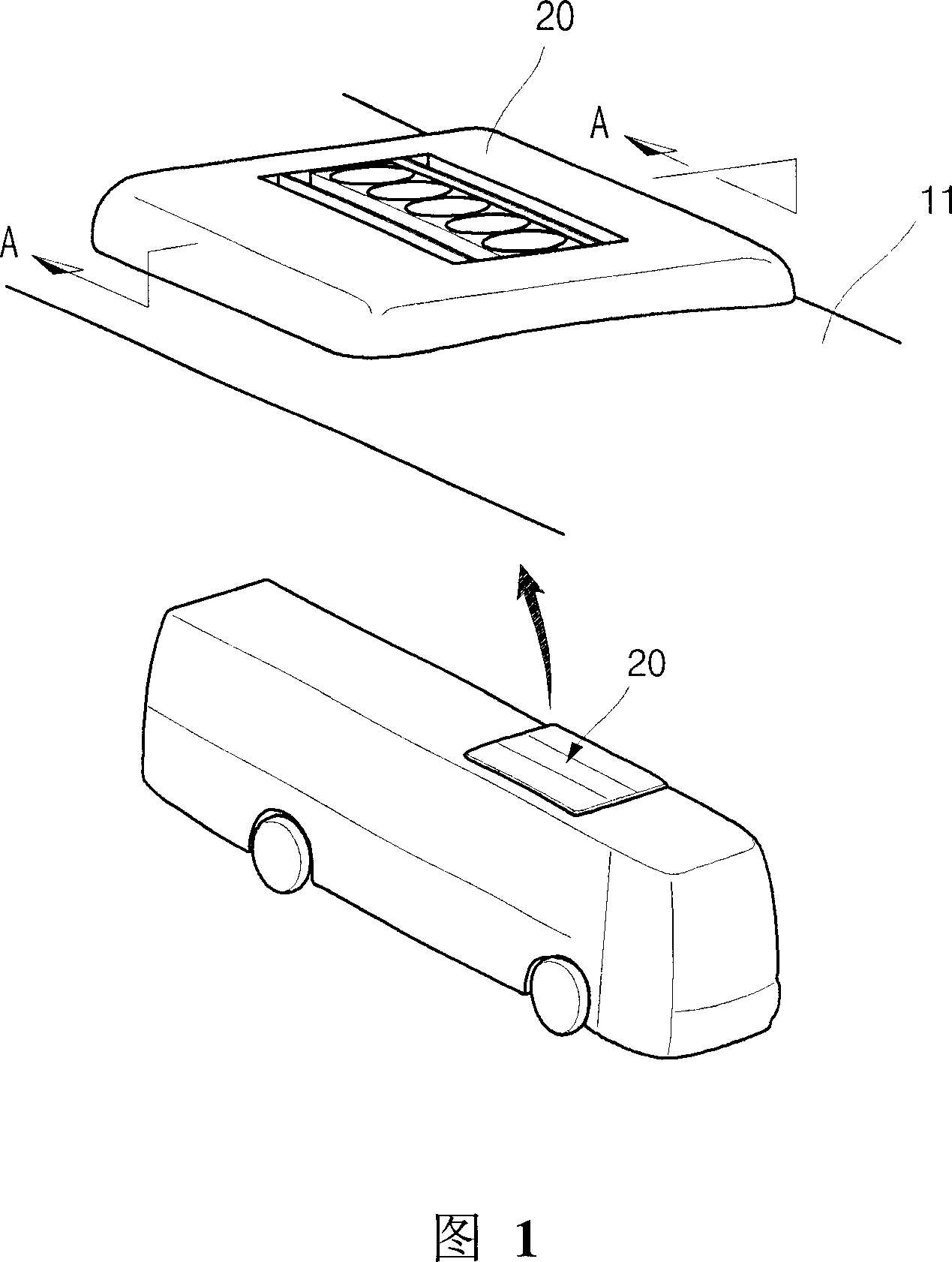

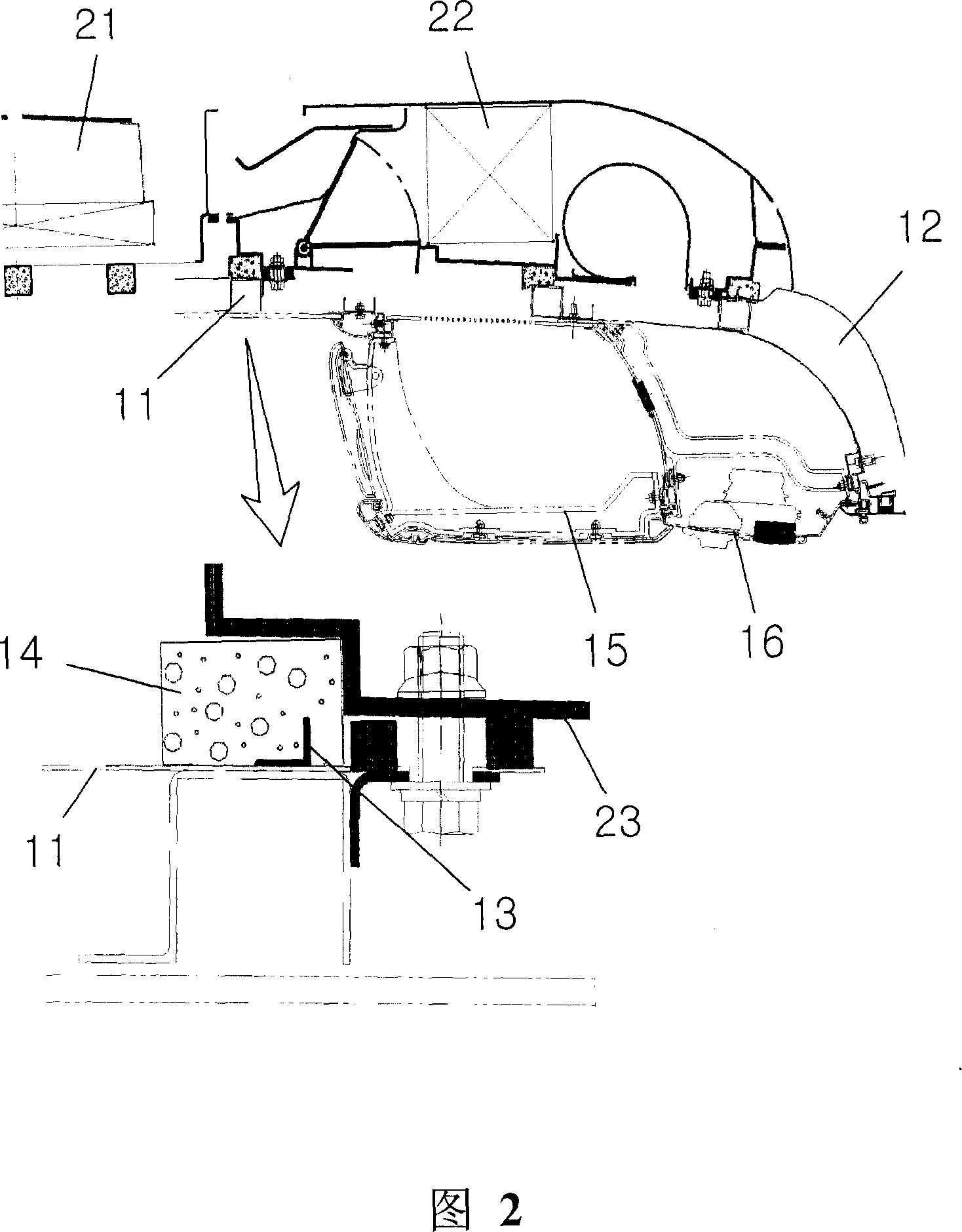

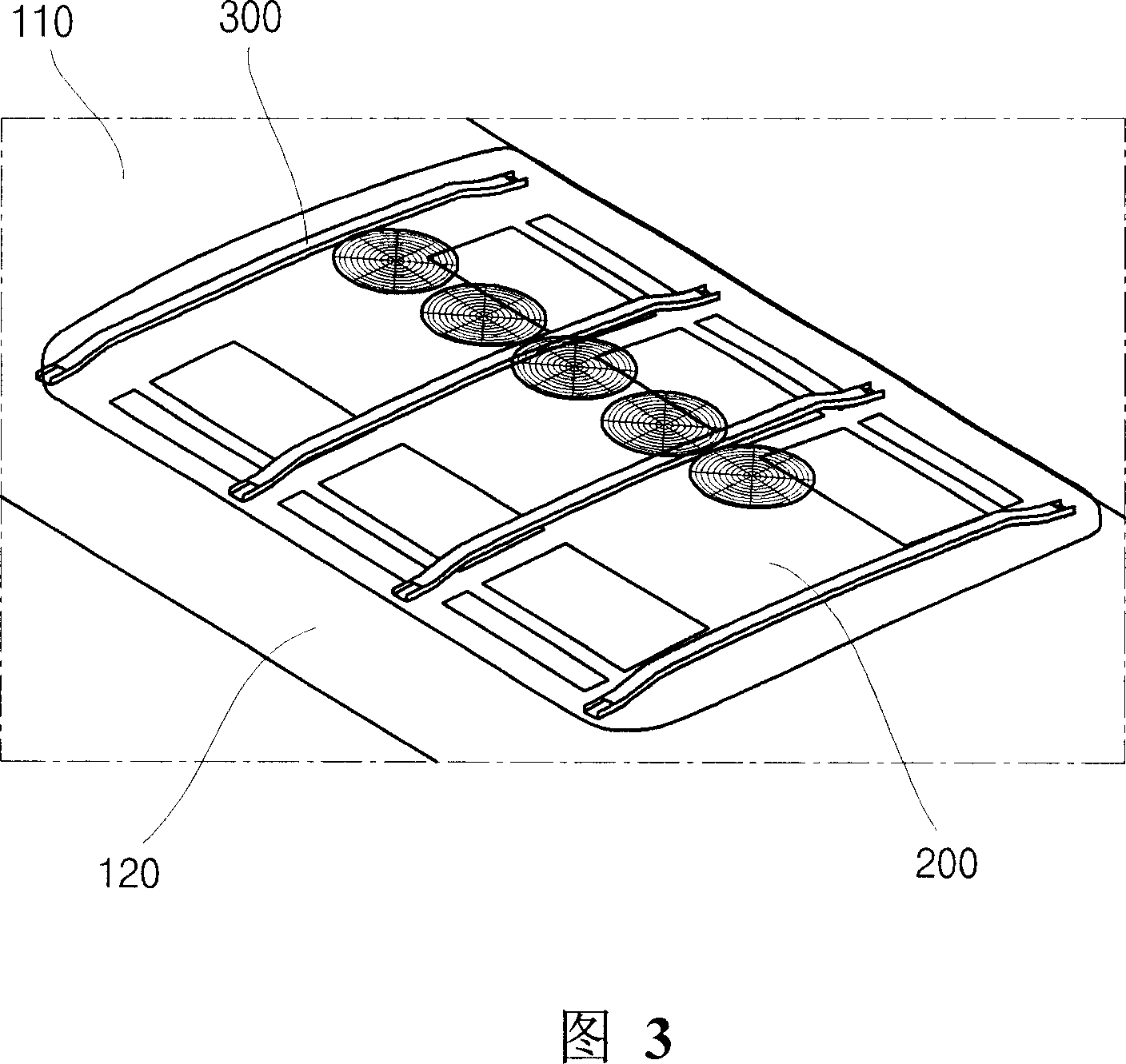

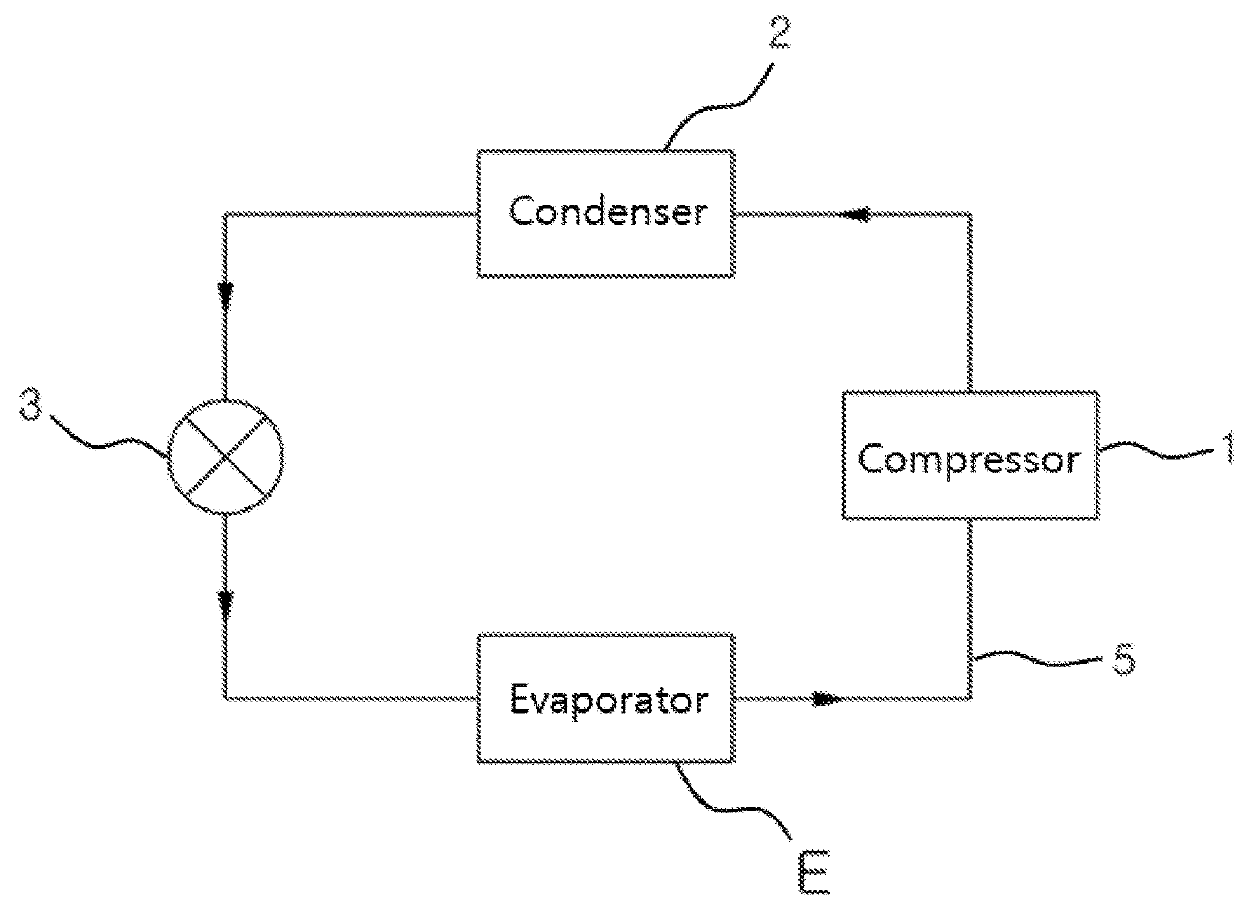

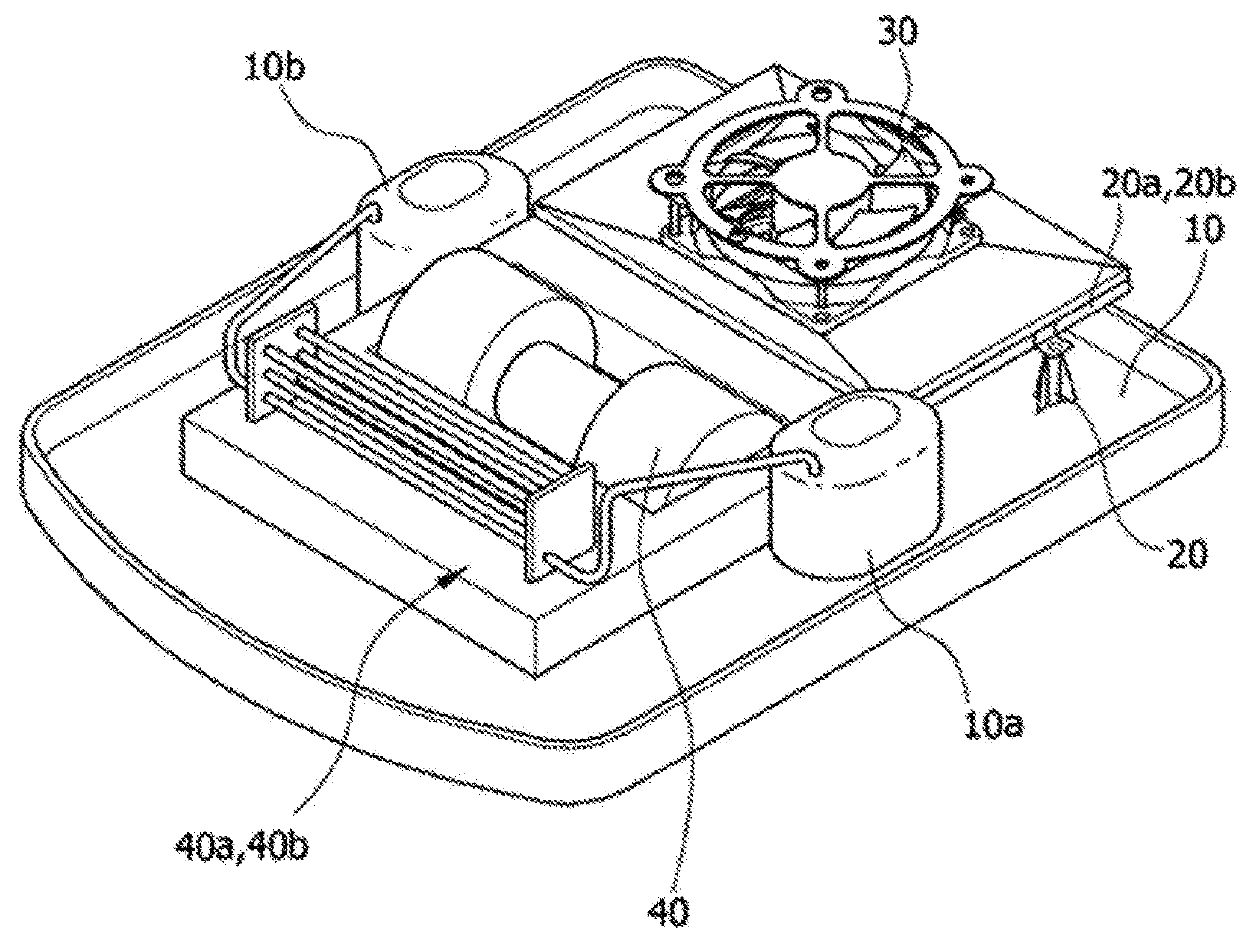

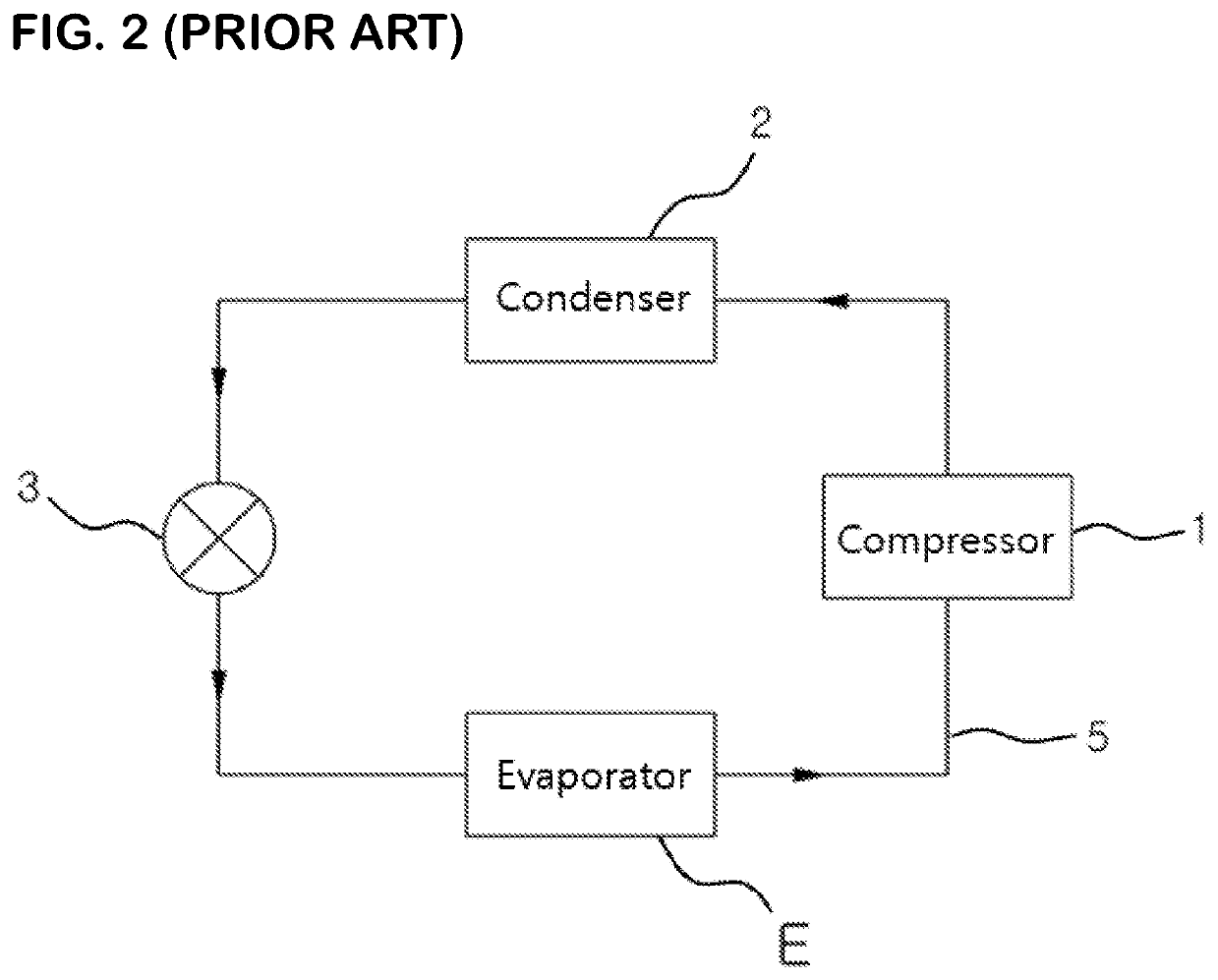

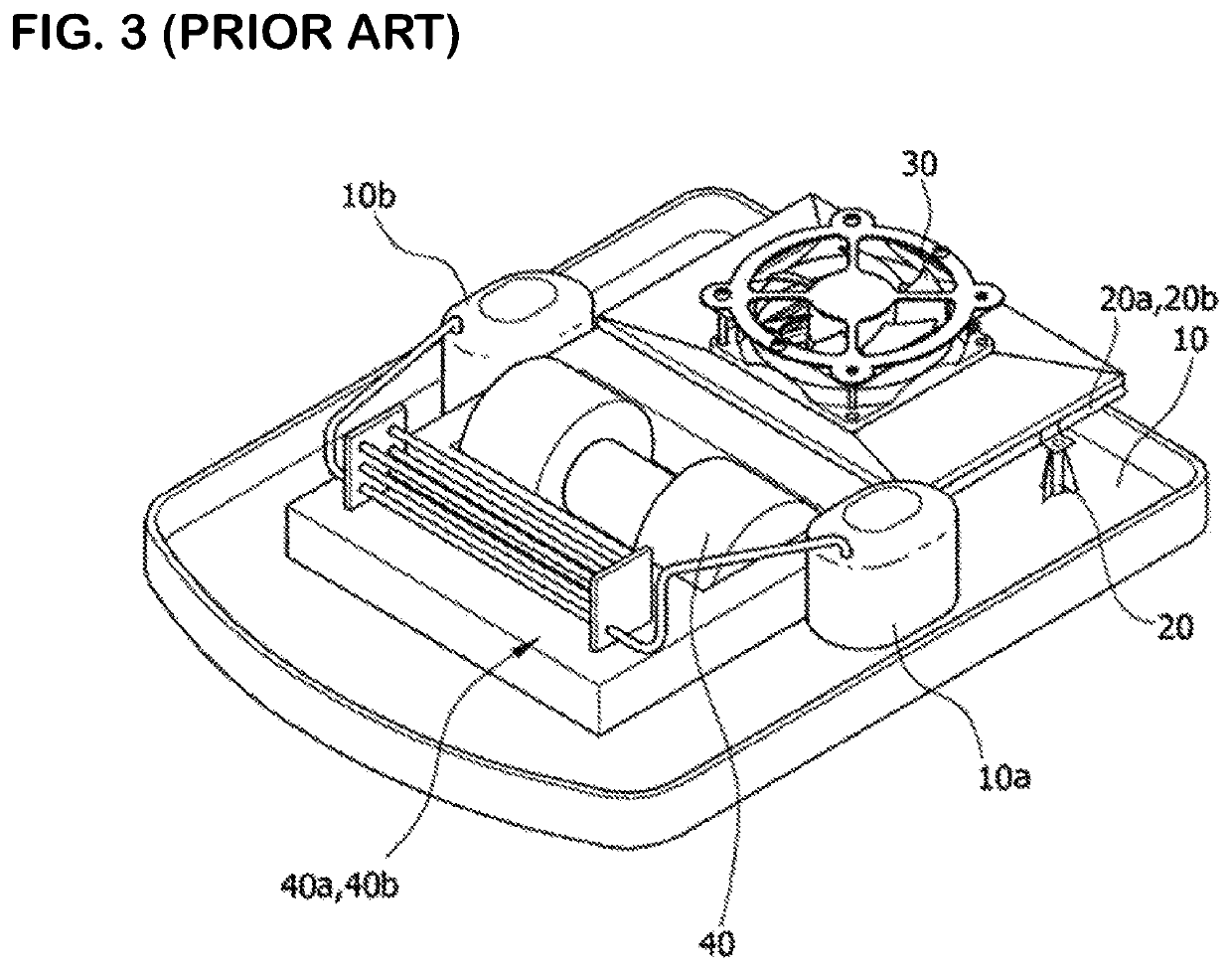

A fabricating structure of a roof-type airconditioner for a vehicle being unified condenser and evaporater

InactiveCN101112860ADispersion weightIncreased durabilityAir-treating devicesVehicle heating/cooling devicesEvaporatorEngineering

Owner:HYUNDAI MOTOR CO LTD

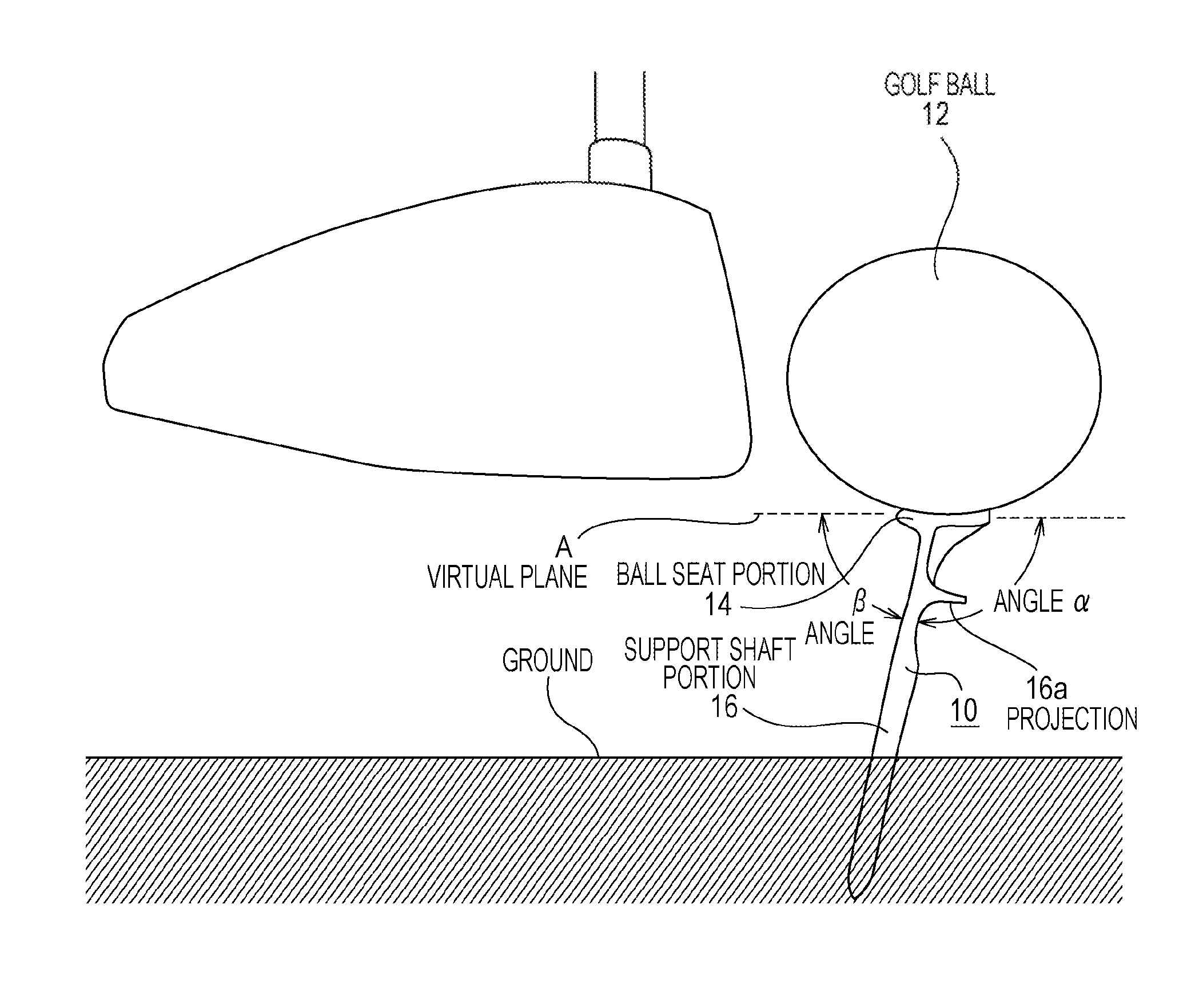

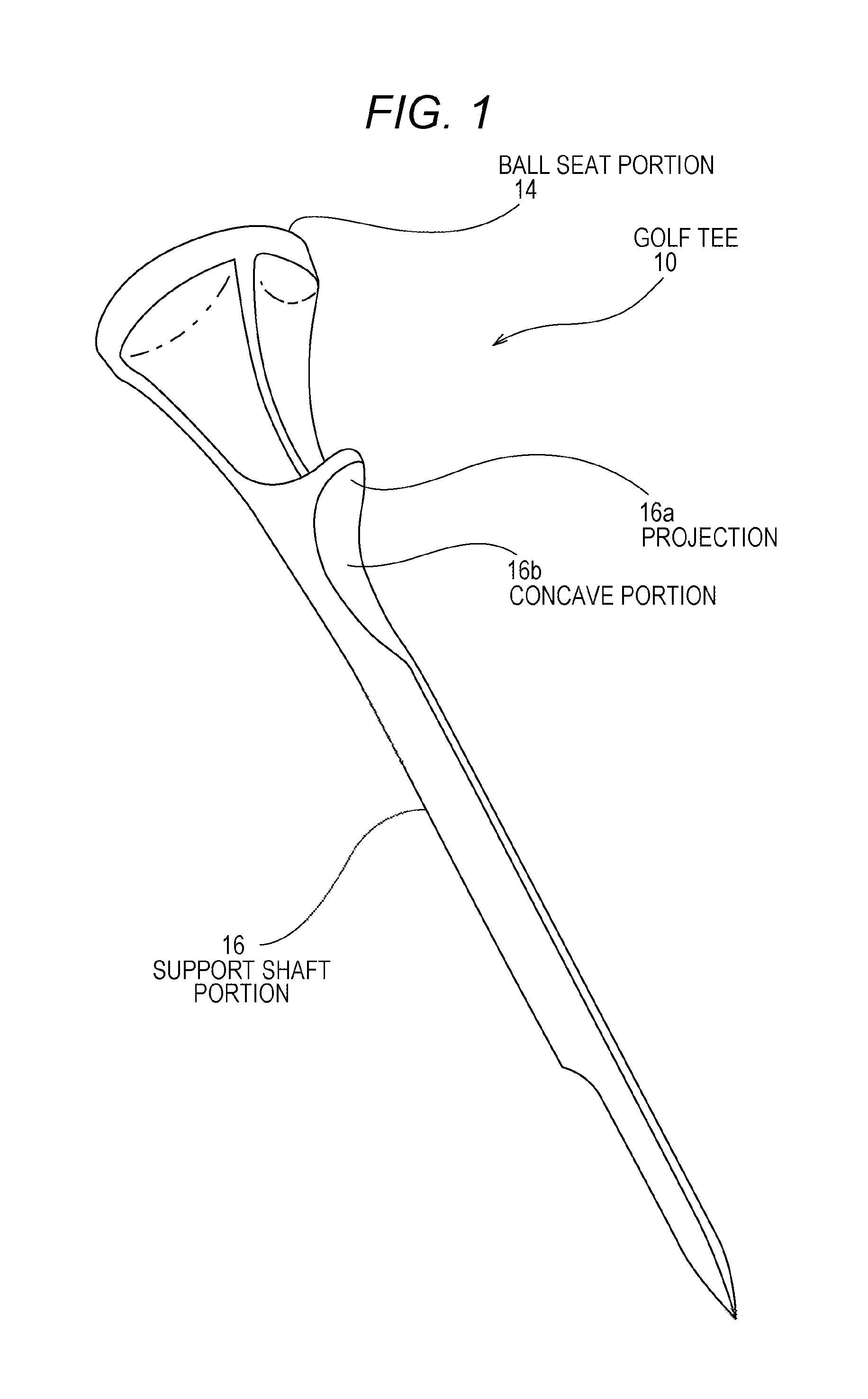

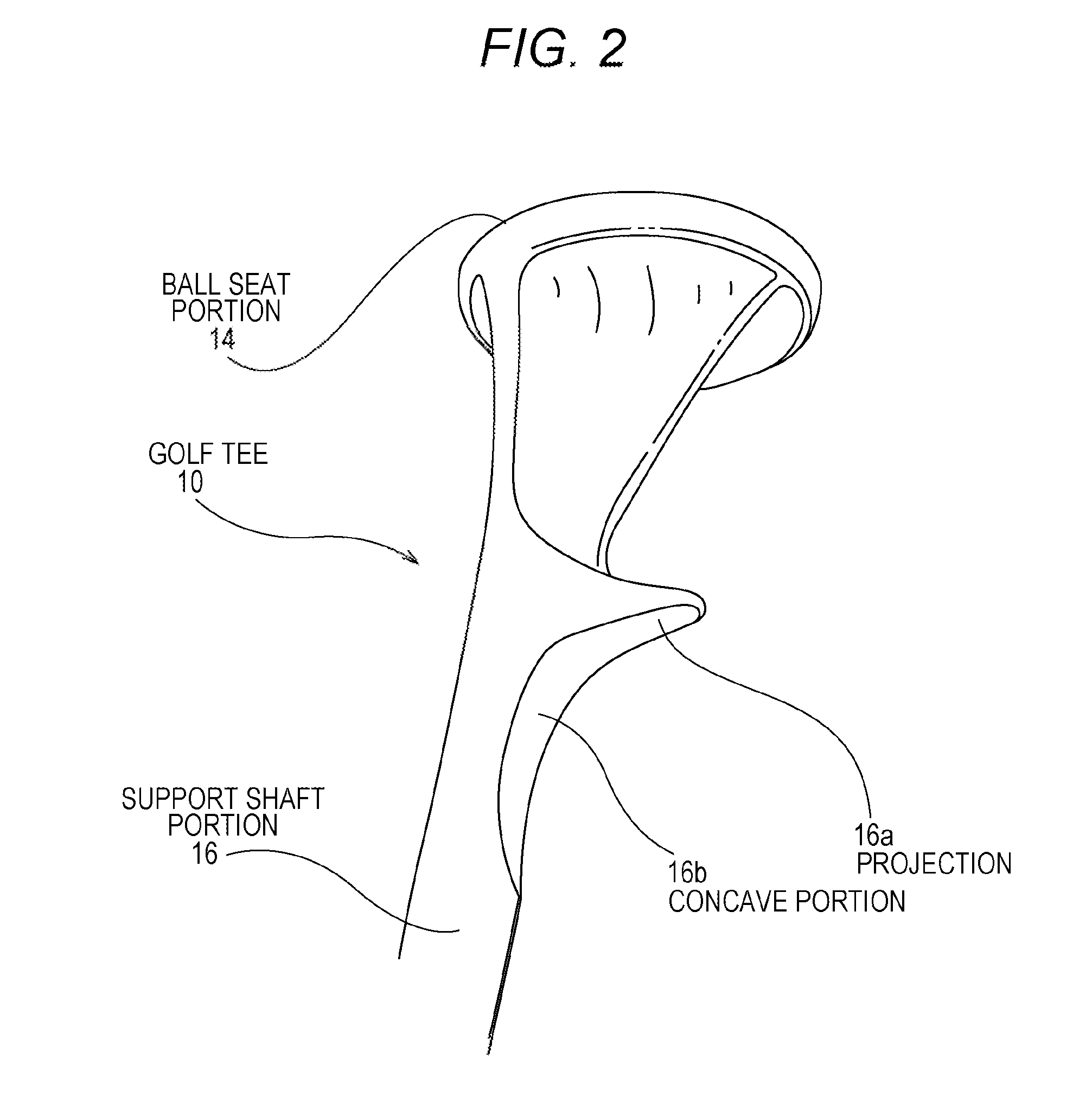

Golf tee

InactiveUS20140128180A1Reduce gapWeighing be so dispersedGolf teesRacket sportsAcute angleEngineering

A golf tee includes a ball seat portion on which a golf ball is placed; and a rod-shaped support shaft portion formed downward from the ball seat portion. The support shaft portion has a projection that is laterally formed on and projected from the support shaft portion. The ball seat portion and the support shaft portion are formed plane-symmetrically on a single plane including a central axis line of the support shaft portion and a point of the projection. In the single plane, a virtual plane including contact portion that contacts with a golf ball when the golf ball is placed on the ball seat portion and a central axis line of the support shaft portion form an obtuse angle on one side of the axis line and form an acute angle on the other side of the axis line.

Owner:IMAI TAKEO

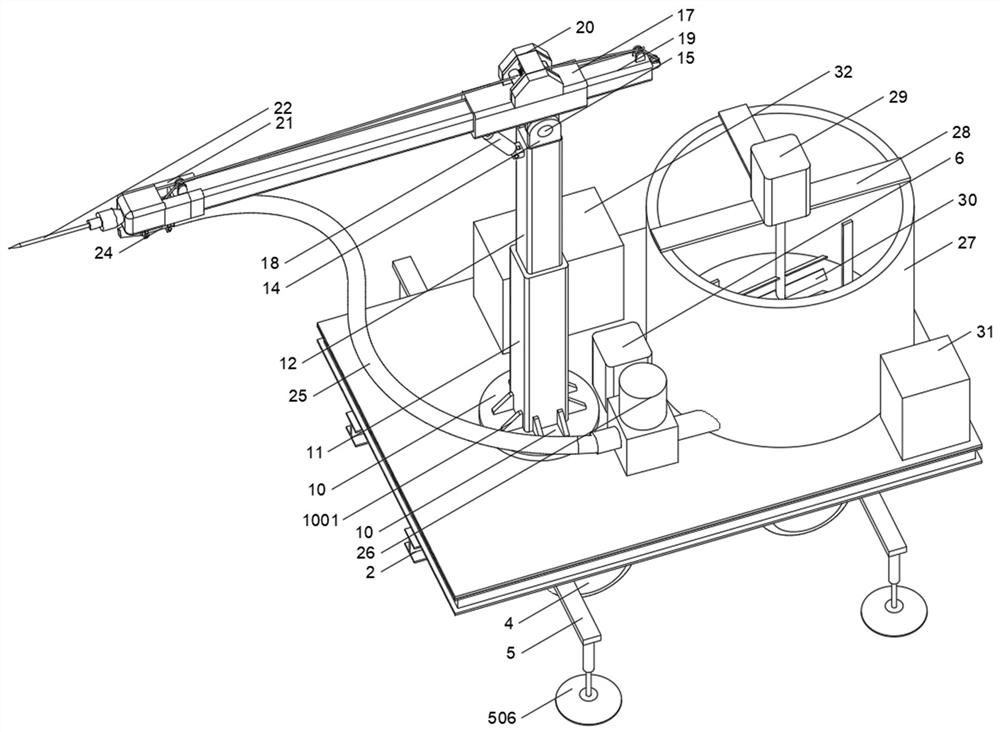

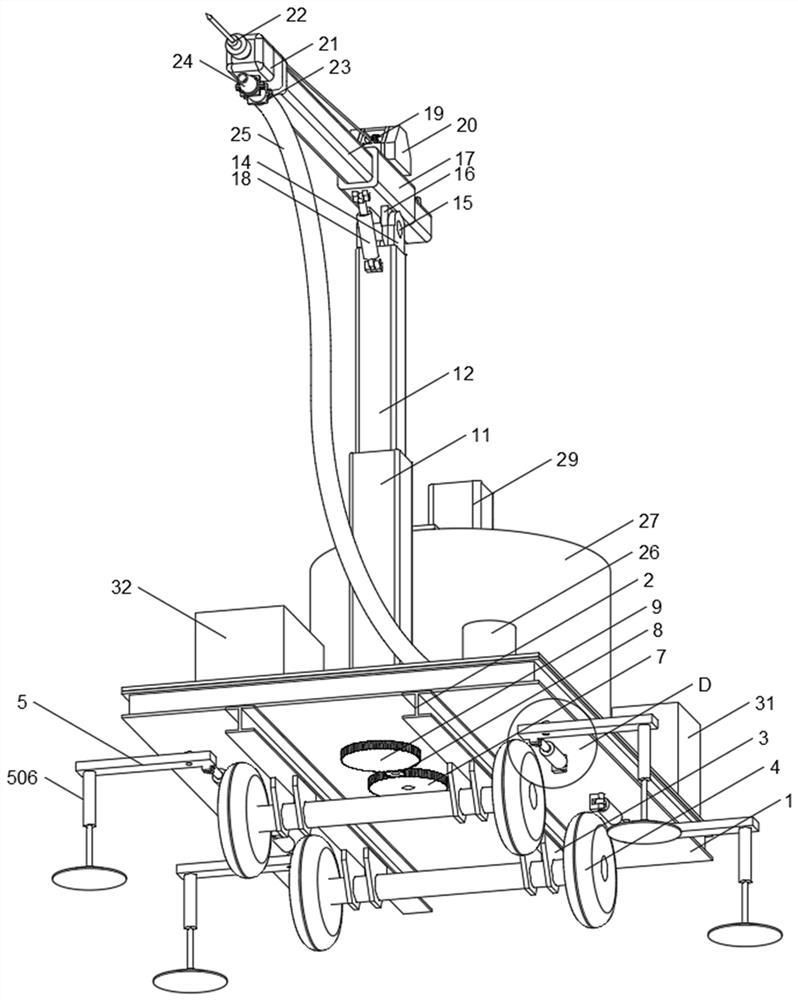

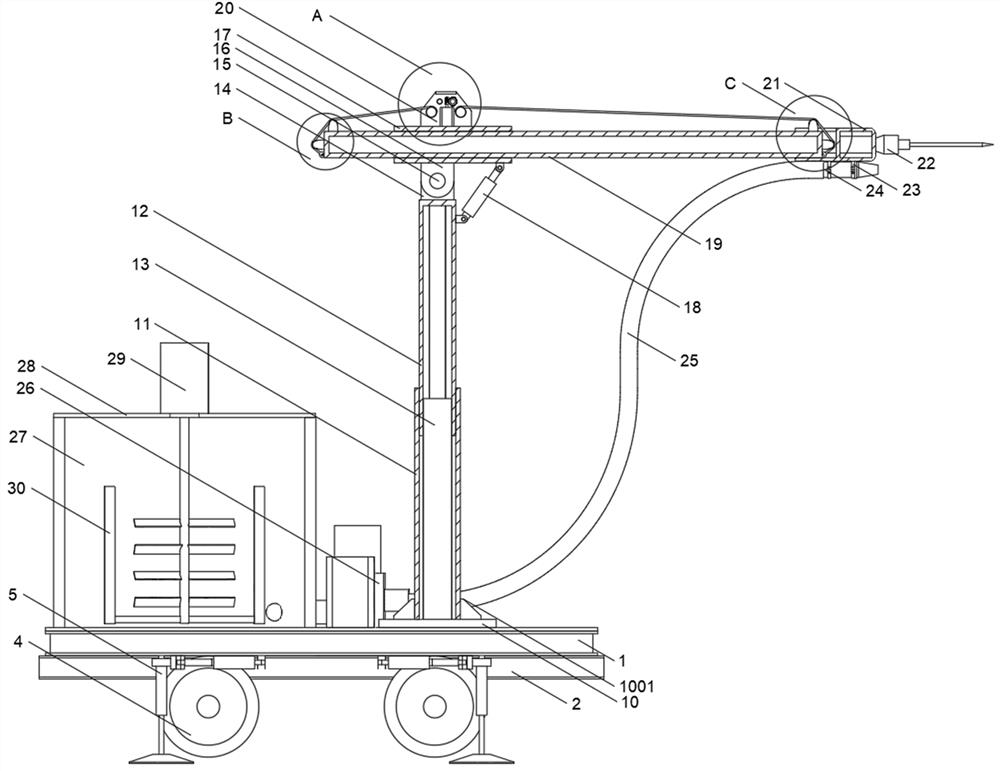

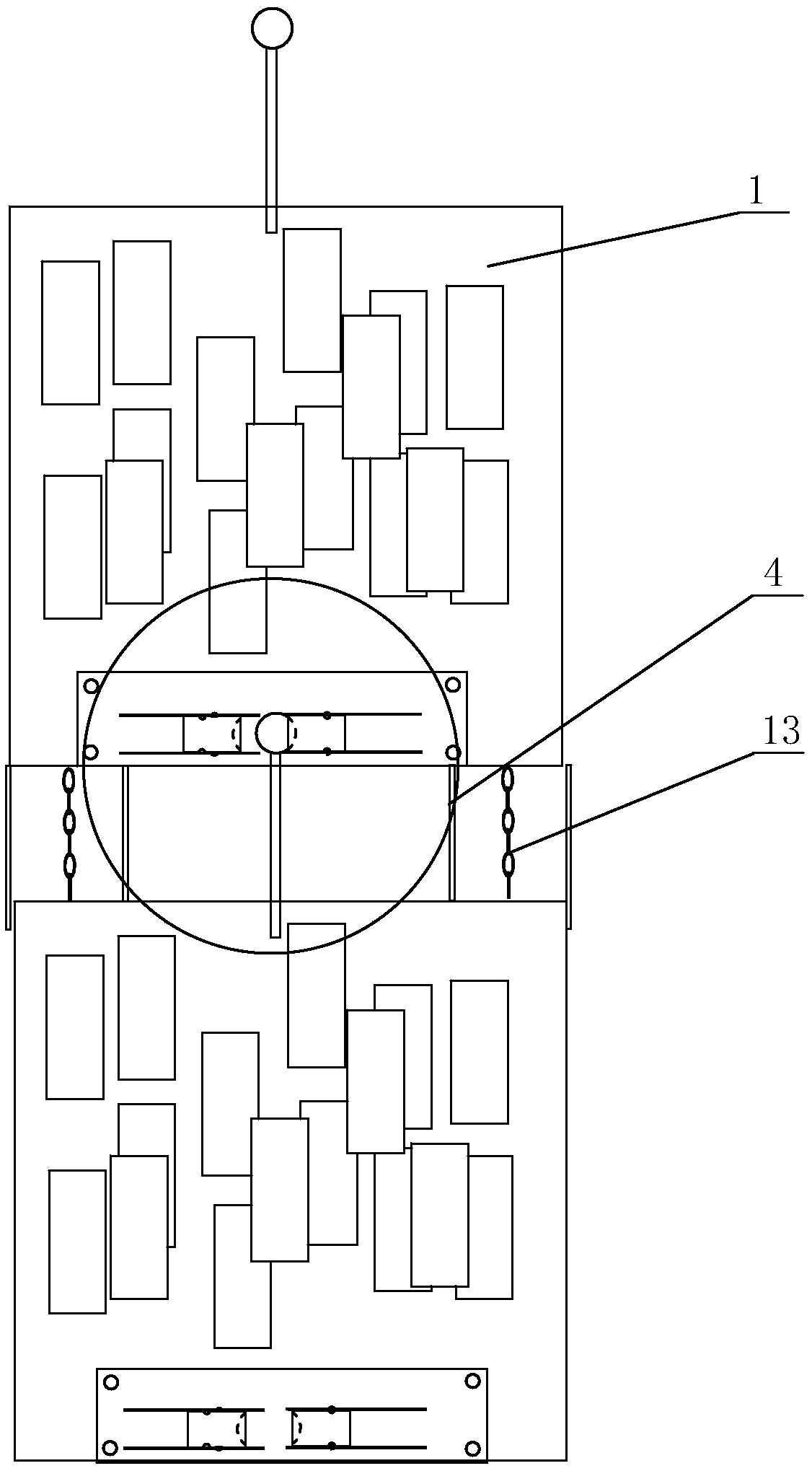

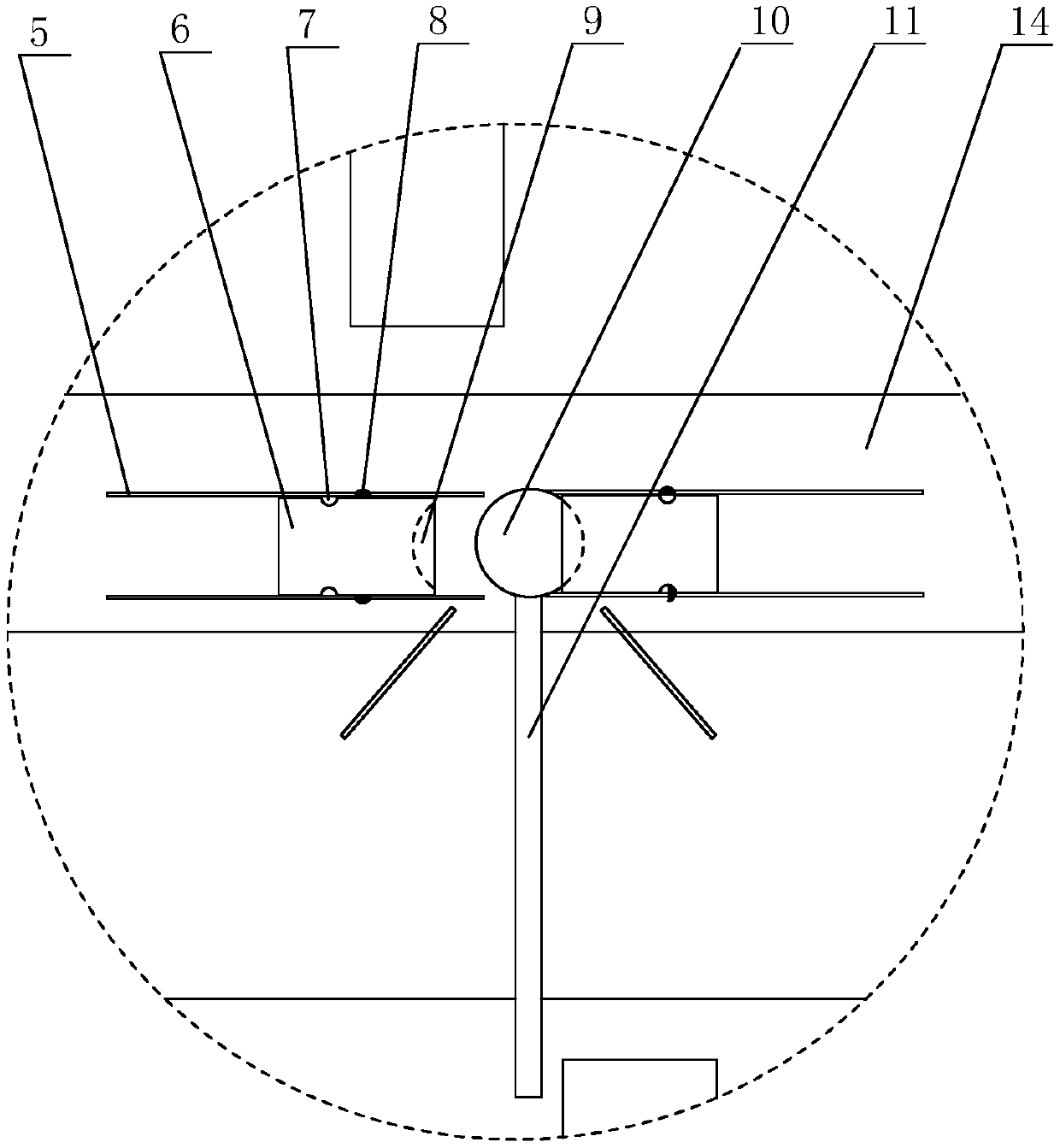

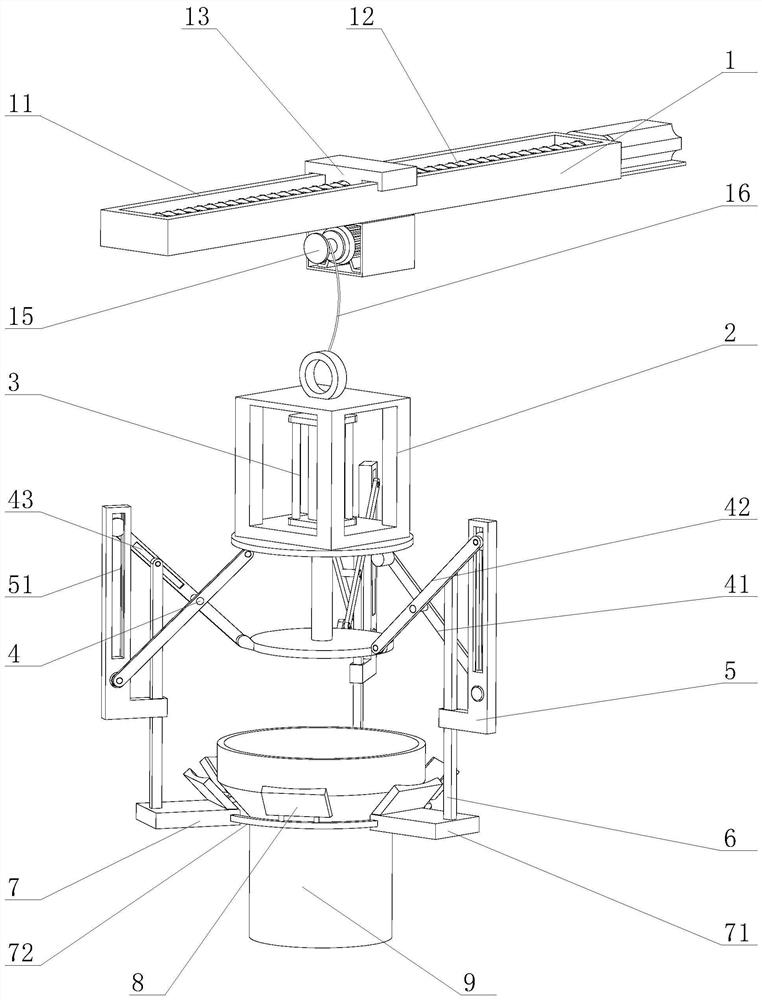

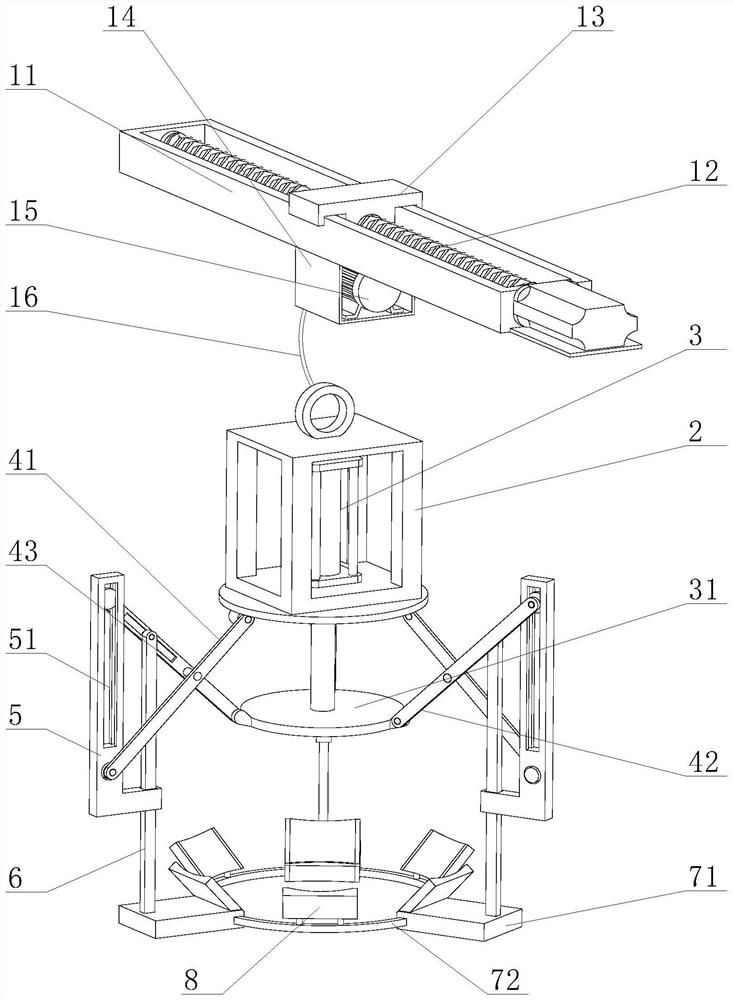

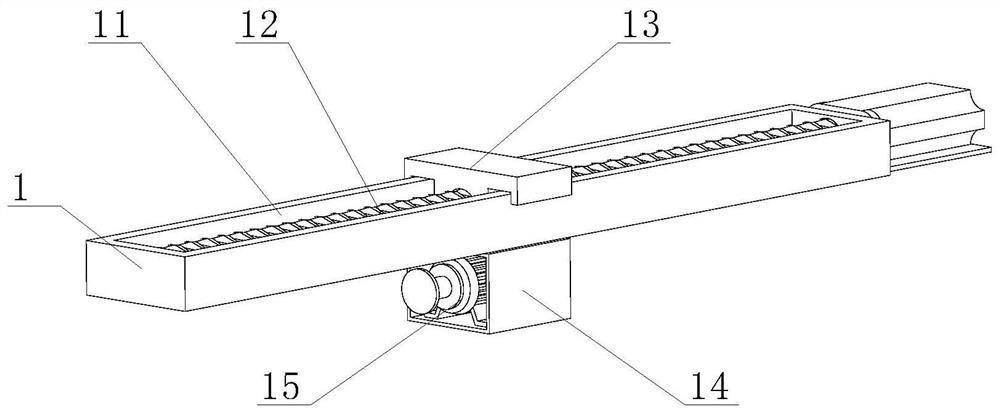

Distributed anchoring and grouting support device for deep mine fault fracture zone

ActiveCN112761691AImprove support strengthImprove connection strengthUnderground chambersTunnel liningGear wheelFracture zone

The invention belongs to the technical field of mining equipment, and particularly relates to a distributed anchoring and grouting support device for a deep mine fault fracture zone. The distributed anchoring and grouting support device comprises a working platform, wherein a first motor installed on the top face of the working platform is in driving connection with a base through a driving gear, an idle wheel and a driven gear; an outer sleeve and a second hydraulic rod are fixedly installed on the top face of the base; the top face of an inner sliding rod connected to the top end of the second hydraulic rod is rotationally connected with a fixing base; the front side face of the inner sliding rod is rotationally connected with the fixing base through the second hydraulic rod; a translation arm is installed on the inner side of the fixing base in a sliding mode; a translation mechanism is installed on the top face of the fixing base; an electric pick and a grouting spray head are installed at the front end of the translation arm through a connecting sleeve; and the grouting spray head is connected with a stirring tank through a hose and a cement pump. Cement can be used immediately after being adjusted through the stirring tank and a stirring anchor, then the positions of the movable electric pick and the grouting spray head are adjusted, so that the operation of distributed anchoring and grouting support in a roadway and a shaft is completed, and the support level and the support efficiency are effectively improved.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

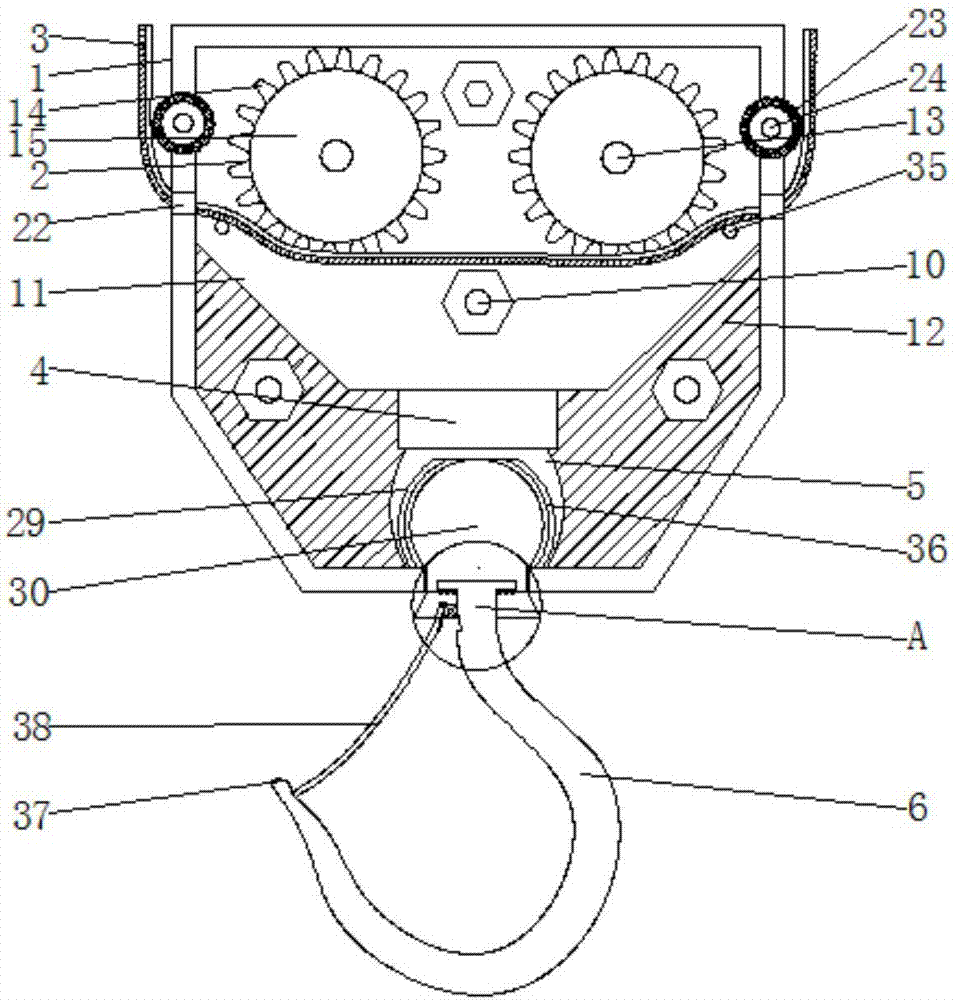

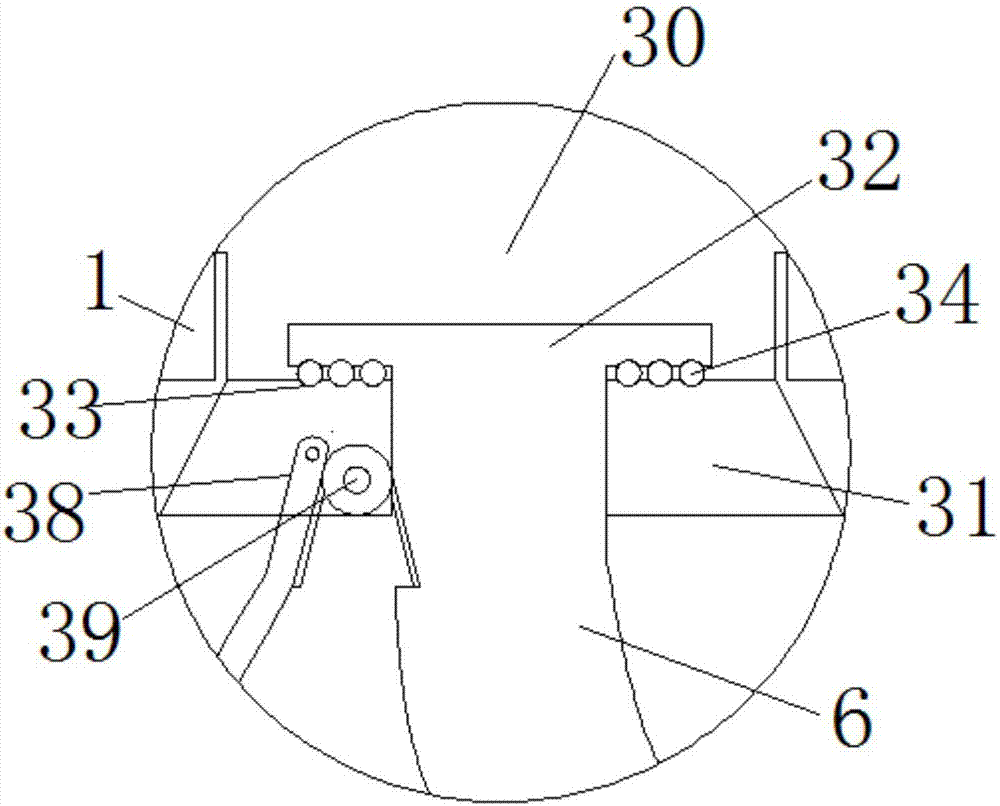

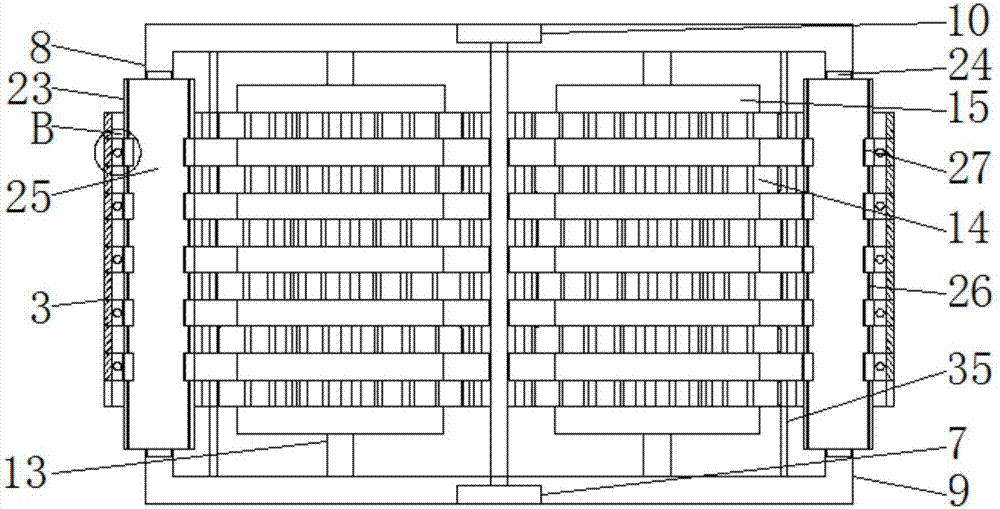

Electric hoist lifting hook device

InactiveCN107473113AImprove securityReduce wearWinding mechanismsLoad-engaging elementsEngineeringWire rope

The invention discloses an electric hoist hook device, which comprises a shell, a multi-layer gear, a chain, an overweight alarm device, a universal bearing, a hook and a hexagonal bolt, and the shell includes a first shell and a second shell , the first housing and the second housing are provided with a number of hexagonal screw holes, the hexagonal bolts connect the first housing and the second housing through the hexagonal screw holes, so The cavity formed by the first casing and the second casing is divided into cavity one and cavity two. Beneficial effects: the invention reduces the friction on the steel wire rope by setting the gear to rotate, and at the same time, adding a protective cover greatly reduces the loss of the steel wire rope, and at the same time strengthens the weighing weight of the chain through multiple steel wire ropes, so that the steel wire rope in use can disperse the weight, effectively The burden of a single wire rope is reduced, and the service life is greatly improved, and the hook can be rotated universally, which makes it more convenient to use, and a baffle is added to prevent the goods from falling, which increases safety.

Owner:池州市知识产权服务中心有限公司

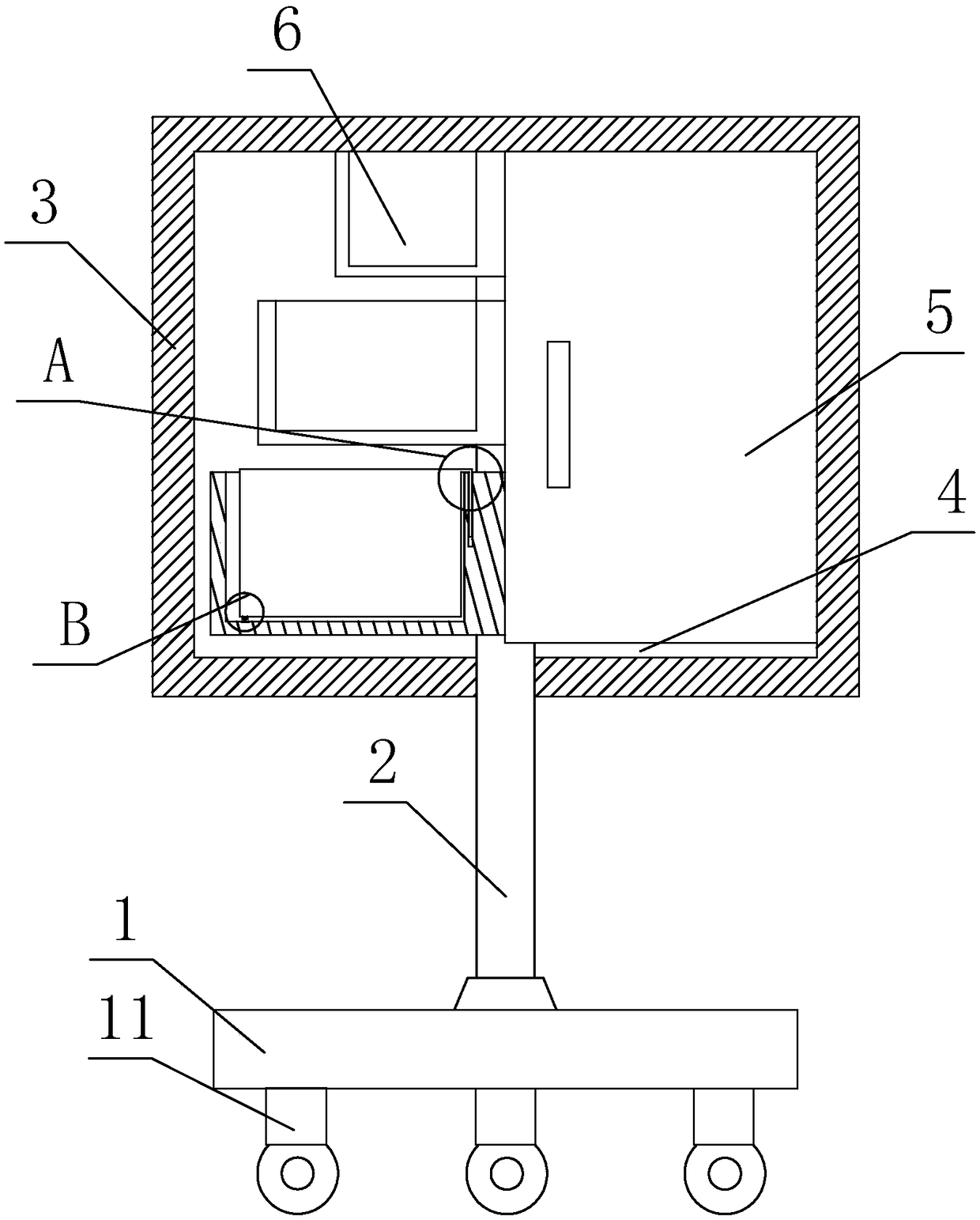

Educational data placing cabinet

The invention discloses an educational data placing cabinet, and relates to the technical field of education teaching technology. The educational data placing cabinet is characterized by comprising abase and supporting columns fixedly connected with the base, wherein the supporting columns are fixedly connected with a cabinet body, the cabinet body is a cylinder, the cabinet body is provided witha cavity, the inner side wall of the cabinet body is provided with a first sliding rail, the first sliding rail is slidably connected with a cabinet door, the supporting columns are inserted into thecabinet body, the supporting columns are rotationally connected with a plurality of data placing tables, the data placing tables are provided with grooves, partition plates are detachably connected in the grooves, the inner side walls of the data placing tables are provided with second sliding rails, the lower sides of the ends, away from the supporting columns, of the partition plates are fixedly connected with rollers, the rollers are in rolling cooperation with the second sliding rails. The educational data placing cabinet has the advantages that an automatic management mechanism is added,so that the data placing cabinet can quickly arrange educational data neatly, thereby being convenient and quick and improving the work efficiency.

Owner:江苏天泽教育咨询有限公司

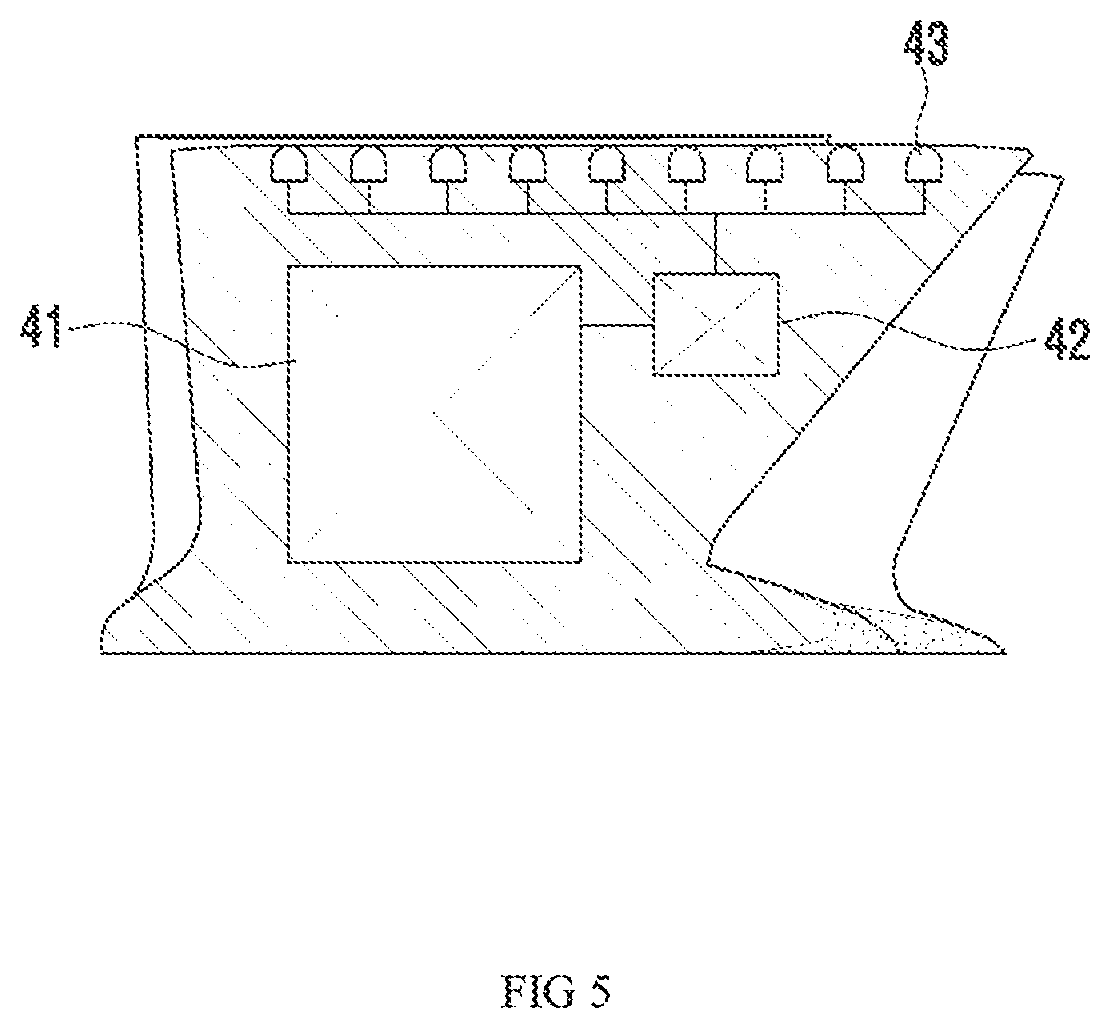

Air conditioning module

ActiveUS20180264911A1Easy to installSmall sizeAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

An air conditioning module, which can perform cooling and heating through a single module, which is capable of being compact-sized, which can easily control a flow of heated or cooled air, which can disperse weight because a compressor is mounted in a first space and the other components are mounted in a second space, and which is easy in carrying due to a handle.

Owner:HANON SYST

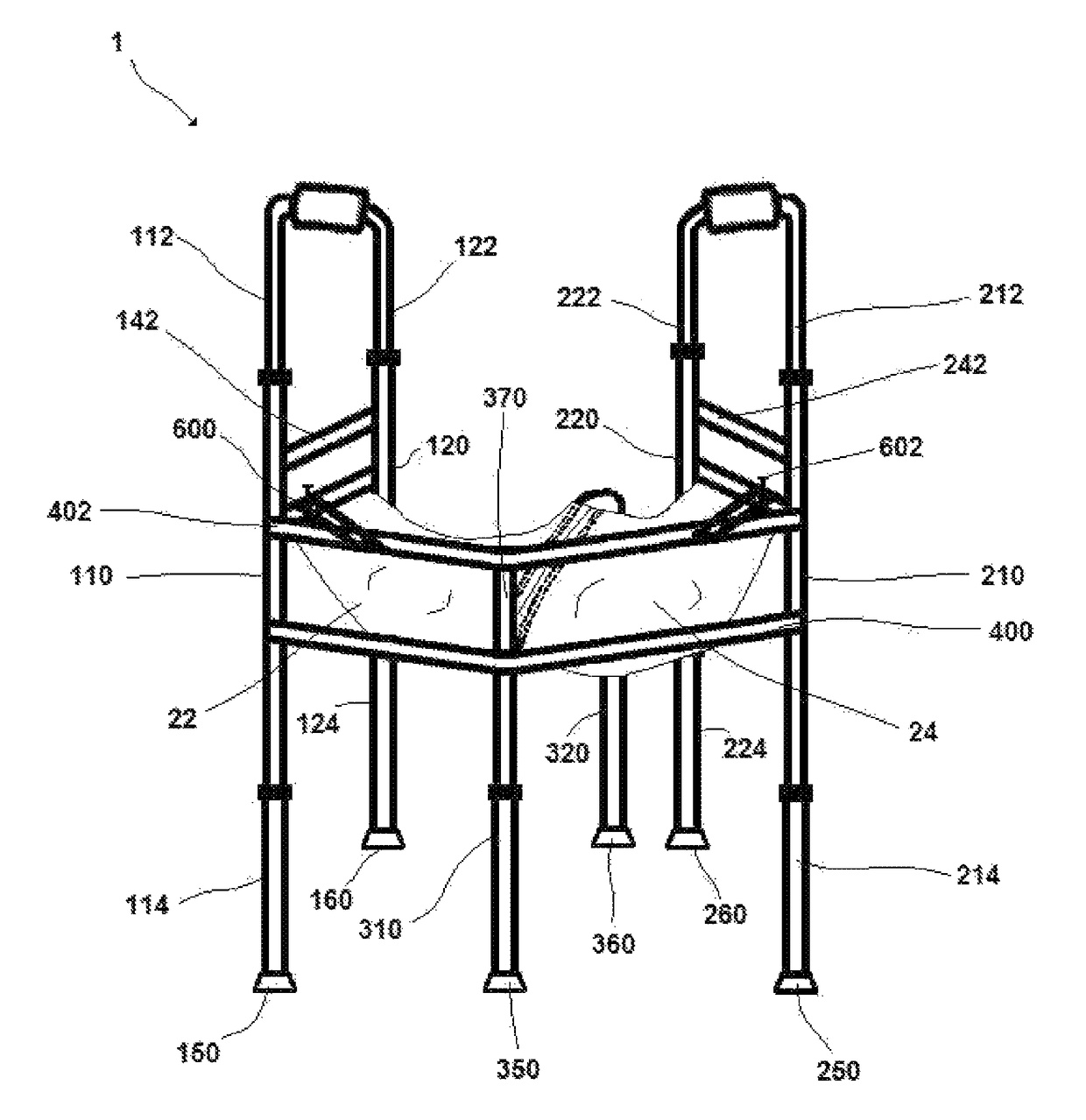

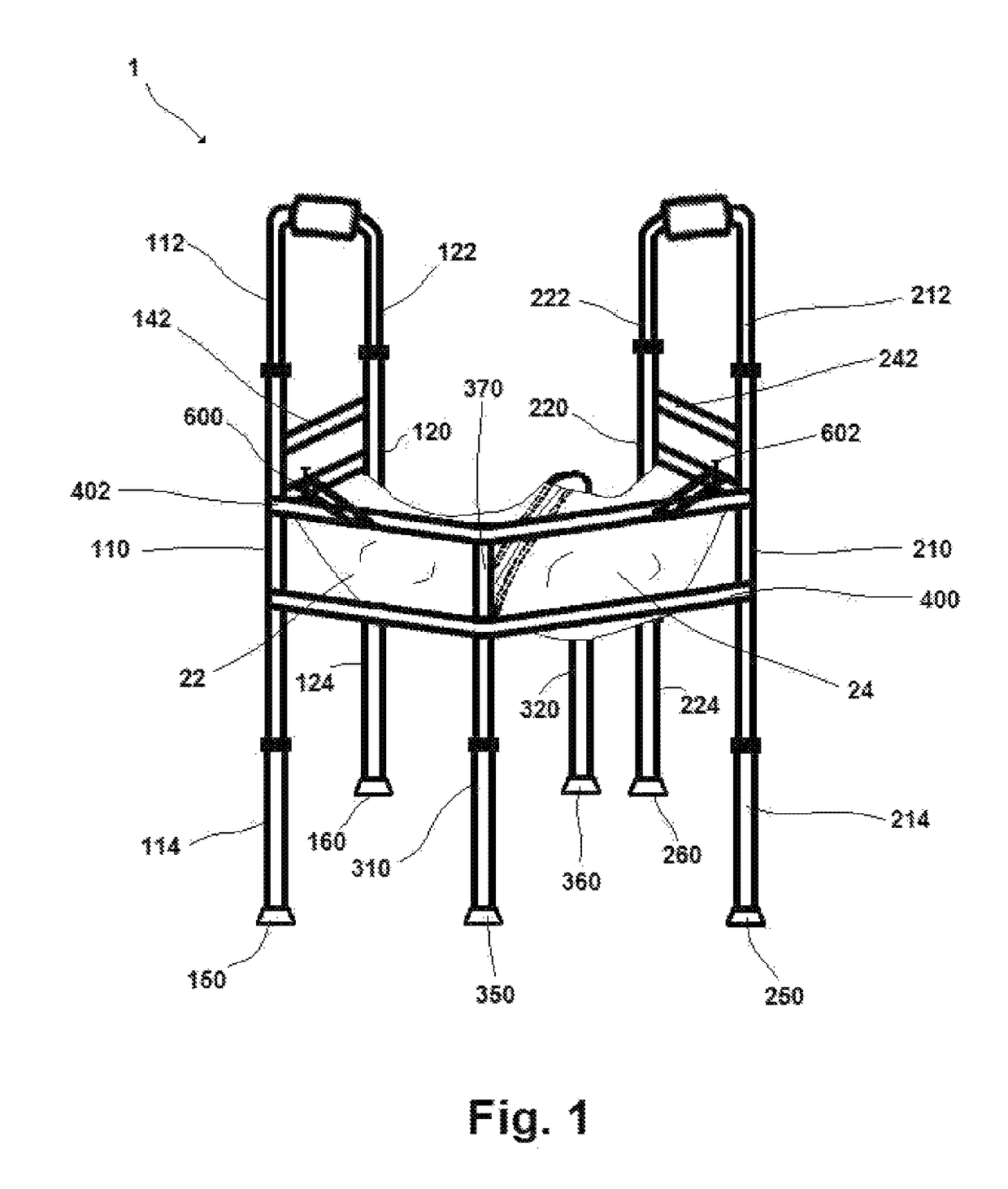

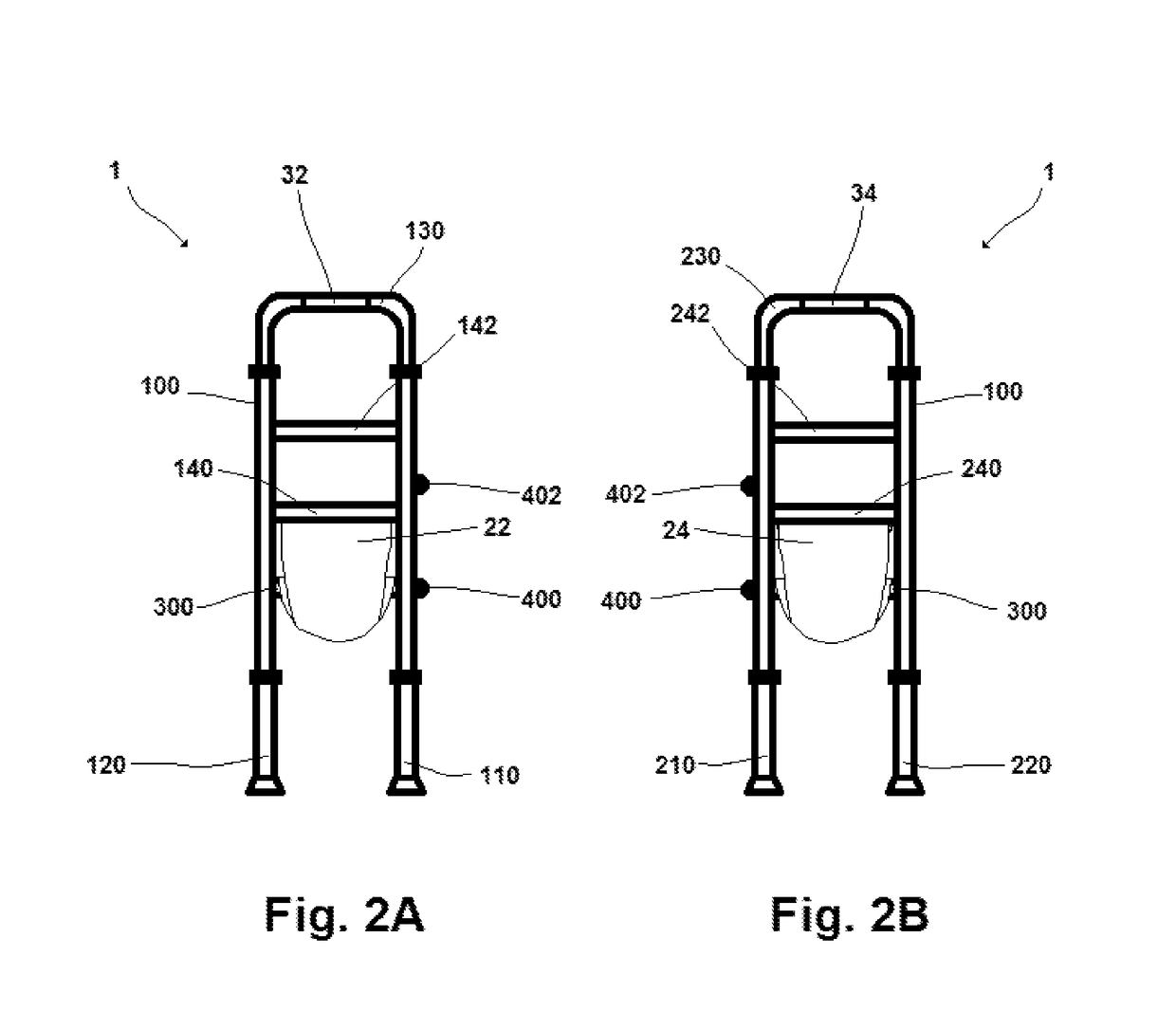

Kneeler

ActiveUS10104976B1Simple interfaceDiscomfort while kneeling is minimized or even eliminatedPrayer-stoolsPhysical medicine and rehabilitationKnee support

A kneeler to support a person in the kneeling position, having a frame configured to support a pair of flexible knee support pouches, each knee support pouch configured to retain and support a human knee above the ground, and further having a pair of laterally disposed handles to assist the person with moving into and out of a kneeling position.

Owner:SPRAGUE FREDERICK

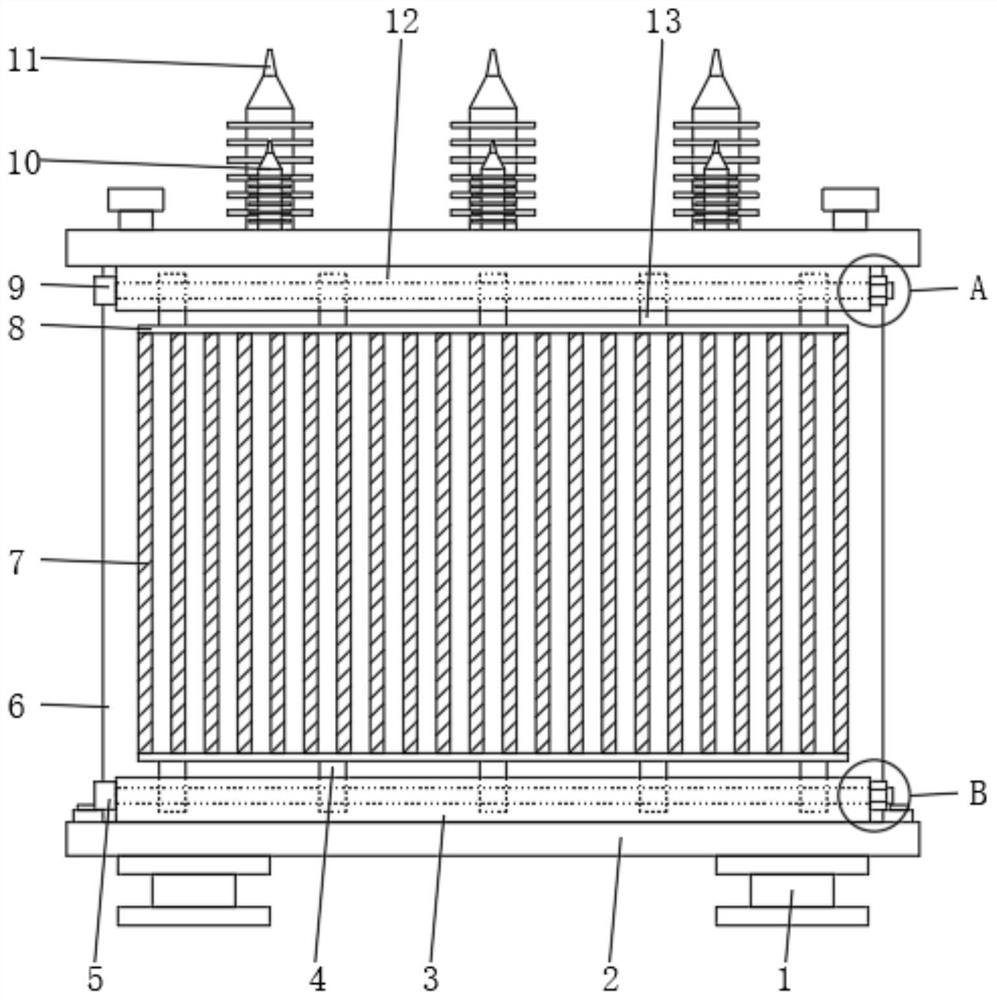

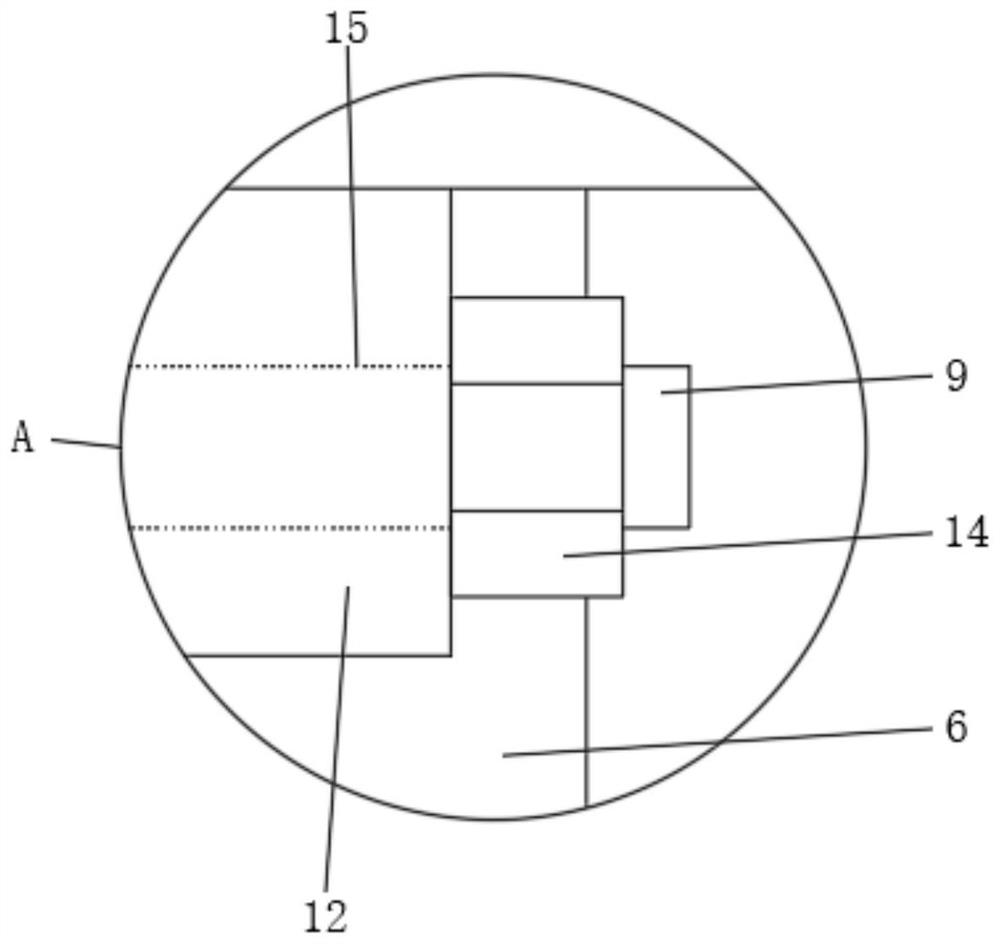

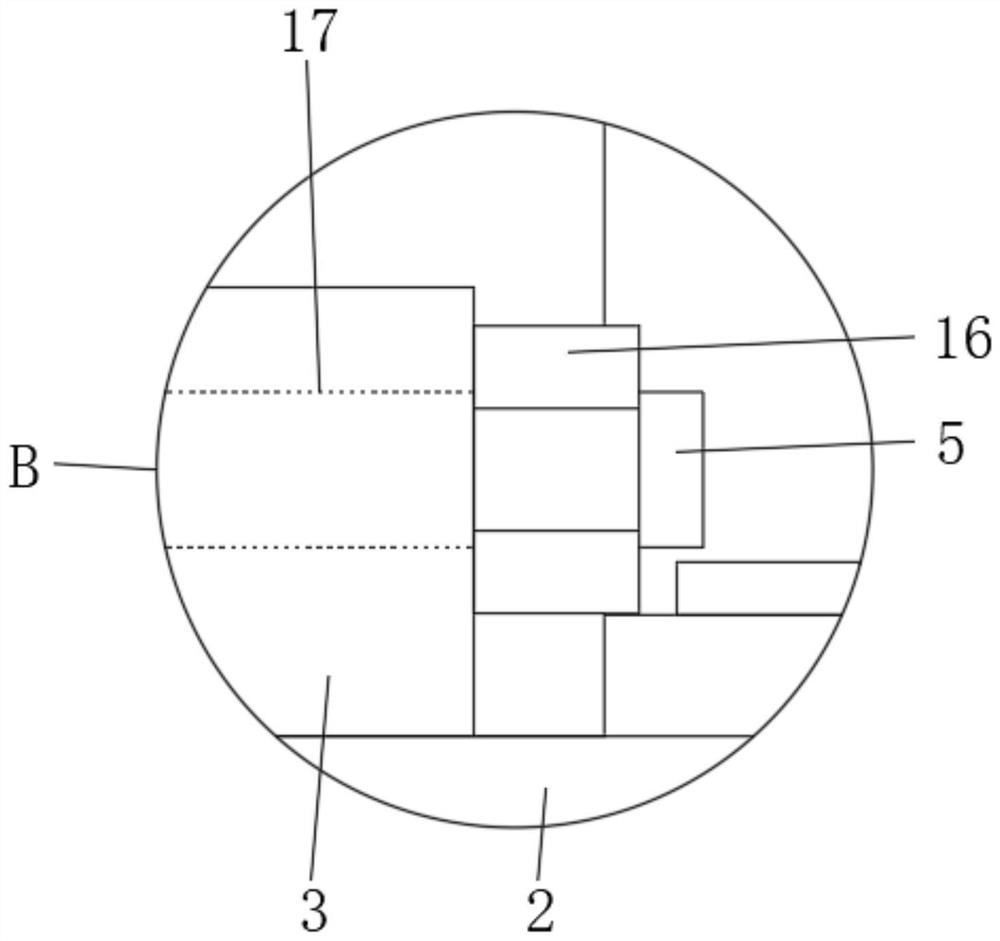

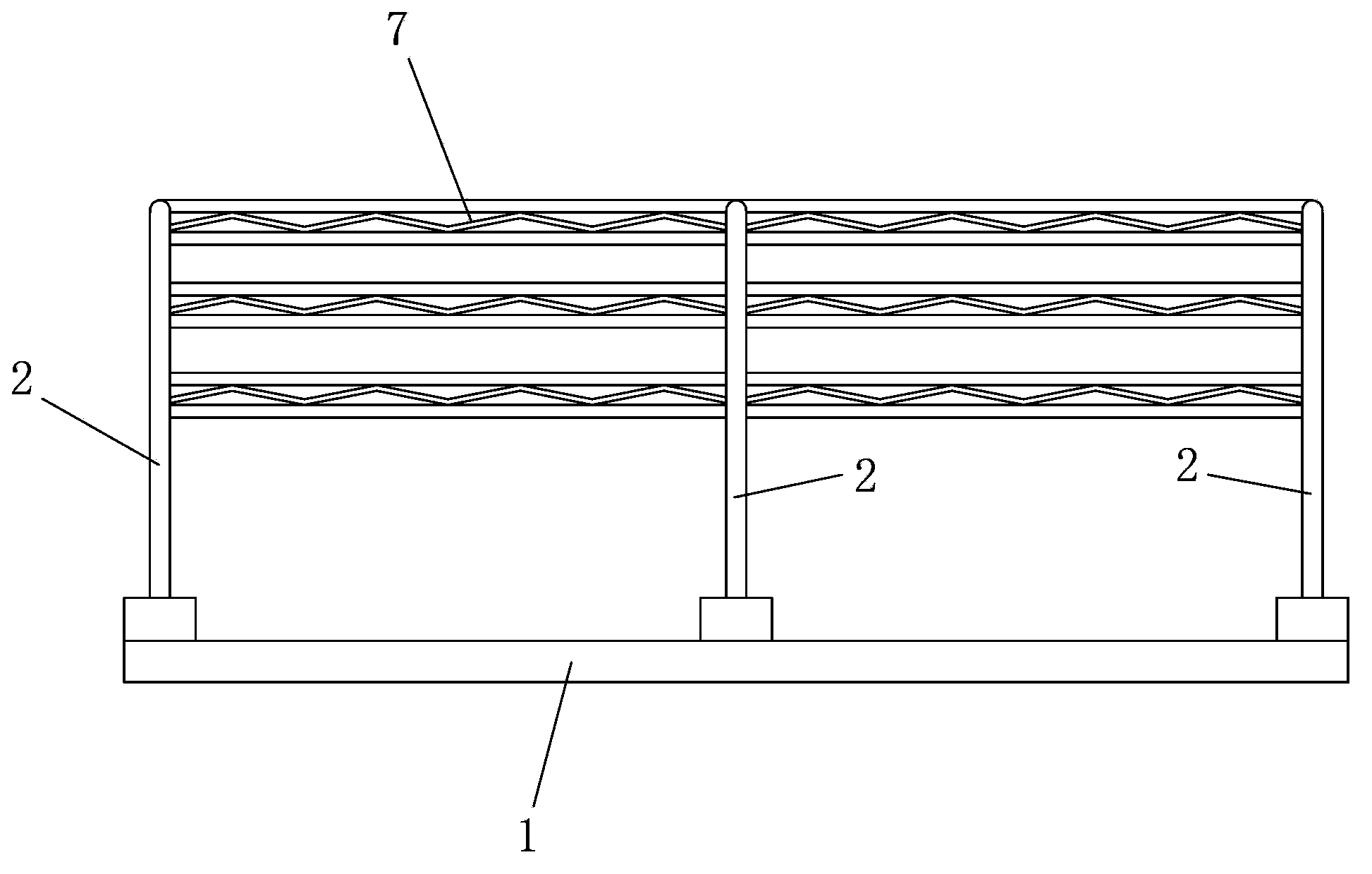

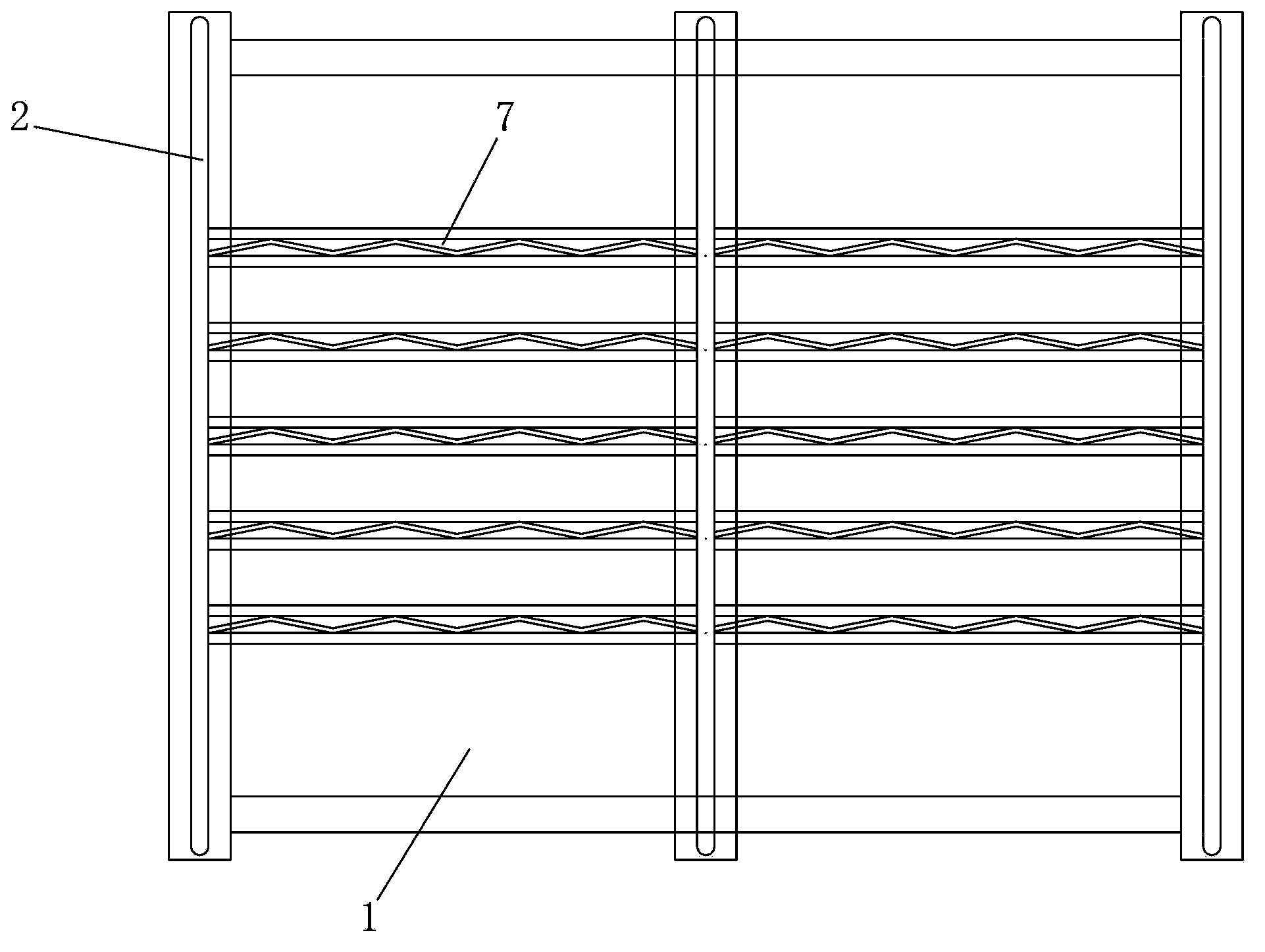

Direct-drop type rectifying and voltage-regulating transformer and manufacturing method thereof

InactiveCN114388223ADispersion weightEasy to transportTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerStructural engineering

The direct-drop type rectifying and voltage-regulating transformer comprises a base, a first stud, a transformer body, cooling fins and second studs, second positioning plates are welded to the tops of the front end face and the rear end face of the transformer body correspondingly, and second inserting grooves are formed in the bottoms of the opposite sides of the two second positioning plates correspondingly; fixing strips are welded to the bottoms of the two sides of the transformer body respectively. I-shaped bottom feet are welded to the two sides of the bottom end of the base correspondingly, first positioning plates are welded to the front end and the rear end of the upper surface of the base correspondingly, and first inserting grooves are formed in the tops of the opposite sides of the two first positioning plates correspondingly; connecting plates are welded to the upper ends and the lower ends of the cooling fins correspondingly, first inserting plates are welded to the lower surfaces of the connecting plates at the bottoms of the cooling fins, and second inserting plates are welded to the upper surfaces of the connecting plates at the tops of the cooling fins. The transformer has the advantages that the transformer is split, the weight of the transformer is effectively dispersed, and transportation is convenient.

Owner:佛山市兴智达电子有限公司

Toe corrector

ActiveUS10653582B2Dispersion weightDevices for heating/cooling reflex pointsDevices for pressing relfex pointsEngineeringMechanical engineering

A toe corrector is provided including: a floor part; correction protrusions protruding between each toe from an upper surface of the floor part to correct the toes; a connection part for connecting the upper ends of the correction protrusions so that correction protrusions are put on toes to be fixed; and light emitting units for emitting light by independently generating electricity, which are provided inside the correction protrusions and on the floor part.

Owner:JANG YOUN JUNG

Wrap Around Furniture Glide

ActiveUS20120110786A1Dispersion weightSecure retentionStoolsMulti-purpose toolsMechanical engineeringEngineering

A furniture glide configured to wrap around a base portion of a chair frame is disclosed. The furniture glide is of multi-layer construction. A first layer is flexible and configured to engage the chair frame. A second layer, bonded to the first layer, is cushioned. A third layer is configured too engage the floor and is made of a durable material to handle the wear associated with engaging the floor. Side portions of the first layer wrap around the base portion of the chair to easily attach the furniture glide to the chair.

Owner:BUSHEY RICHARD D +1

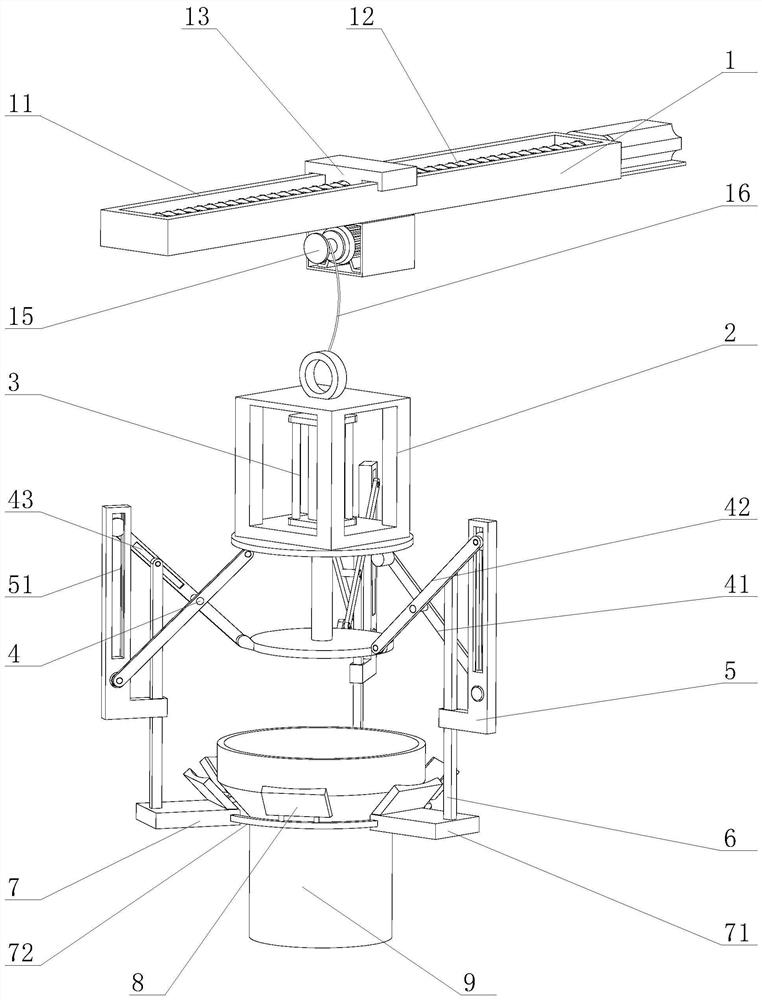

Automatic hoisting clamp

ActiveCN111762679AIncrease contact areaSuspension stabilityLoad-engaging elementsMechanical engineeringClassical mechanics

The invention relates to an automatic hoisting clamp. The automatic hoisting clamp comprises a hoisting portion used for hoisting and a clamping portion which is hung below the hoisting portion and used for clamping a barrel body. The clamping portion drives one ends of shear fork pieces to be opened and closed through a built-in hydraulic cylinder, position change of an L-shaped plate and a straight rod at the other end of each shear fork piece is controlled, and position change of each straight rod drives a telescopic ring connected with the straight rod fixedly to stretch out and draw backto fix the barrel body. According to the automatic hoisting clamp, the three shear fork pieces distributed annularly are controlled through the hydraulic cylinder to synchronously expand and draw back, a first plate of each shear fork piece drives the corresponding L-shaped plate to move, each L-shaped plate and a second plate of the corresponding shear fork piece jointly limit the moving direction of the corresponding straight rod, so that each straight rod carries out inward-retracting and upward operation during clamping, the corresponding telescopic ring connected with the straight rod fixedly is driven to be folded for clamping and move upwards simultaneously, and an inclined supporting plate on each telescopic ring is driven to move upwards to carry out attaching supporting and clamping on a diameter change transition portion of the outer wall of the barrel body.

Owner:付安英

Compact air conditioning module for performing cooling and heating through a single module

ActiveUS10486488B2Easy to installDispersion weightAir-treating devicesVehicle heating/cooling devicesEngineeringAir conditioning

Owner:HANON SYST

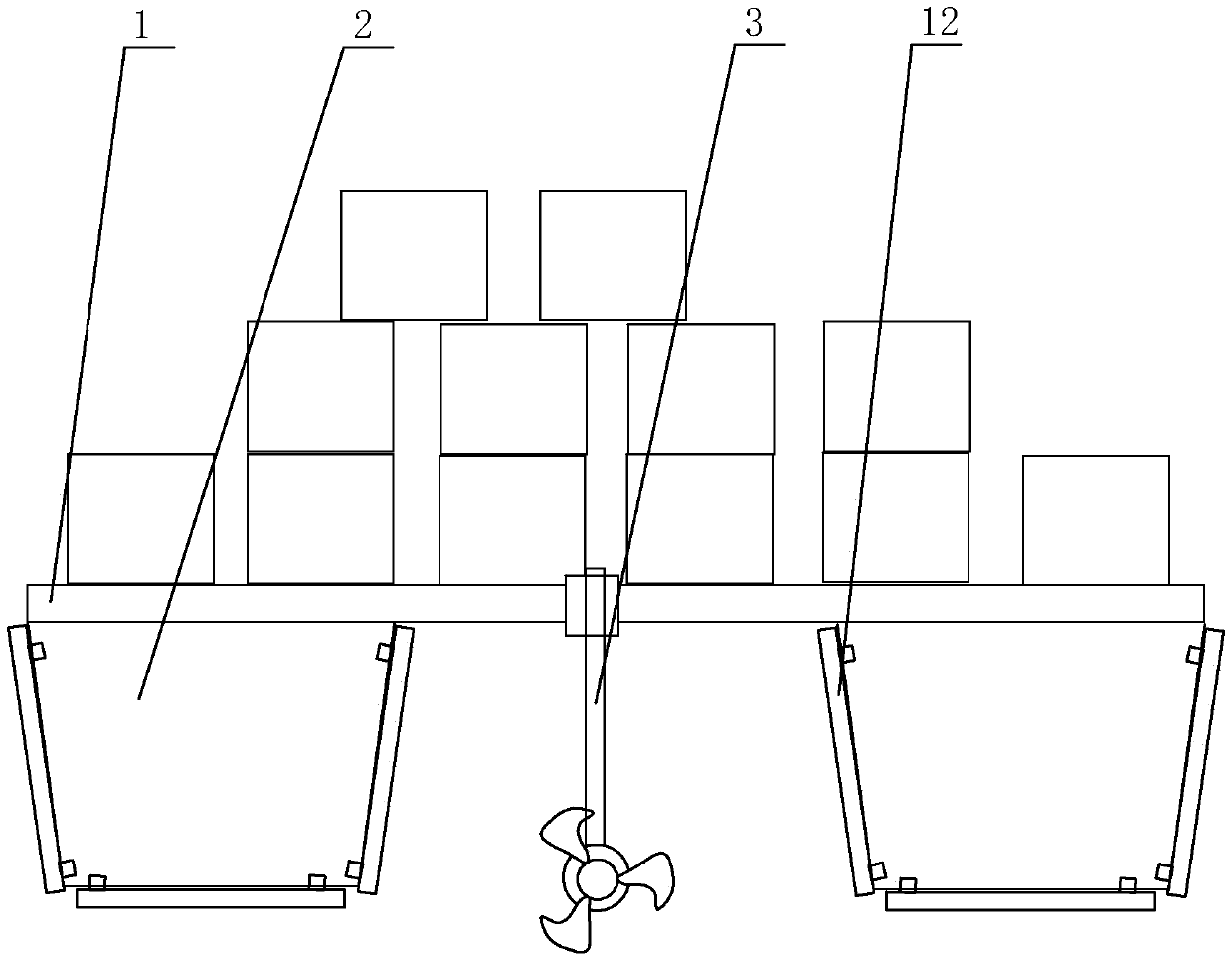

train anti-roll boat

ActiveCN106275238BConsistent structureDispersion weightWatercraft hull designPropulsive elementsProduction linePropeller

The invention relates to a train type overturning preventing ship, and belongs to the field of vessels. The ship comprises unit hulls, wherein each of the unit hulls comprises ship bodies; the ship bodies of each unit hull are divided into two parts, and are symmetrically arranged on the two sides of the corresponding hull; the whole hull adopts a symmetrical inverted U shape; a propeller is arranged at the central position of the front part of the two ship body parts; each unit hull can be connected with another unit hull in an end-to-end manner, and the using number of the unit hulls can be determined according to the total quantity of goods, so that the transporting cost is greatly reduced; besides, the structures of the unit hulls are consistent, so that large-batch unit hulls can be produced by one production line; and the ship bodies adopt an inverted U shape, so that the weight of the whole hull is dispersed, the gravity center of the whole hull is lowered, accidents of ship overturning is prevented to a great extent, the resistance of water to the whole ship body is reduced, and fuel is saved.

Owner:丁乃祥

Reinforced two-path bridge

InactiveCN102817310BImprove lateral strengthDispersion weightSuspension bridgeArchitectural engineeringBridge deck

Owner:SUZHOU UNIV

Solar panel installation tool

Owner:KING KEVIN

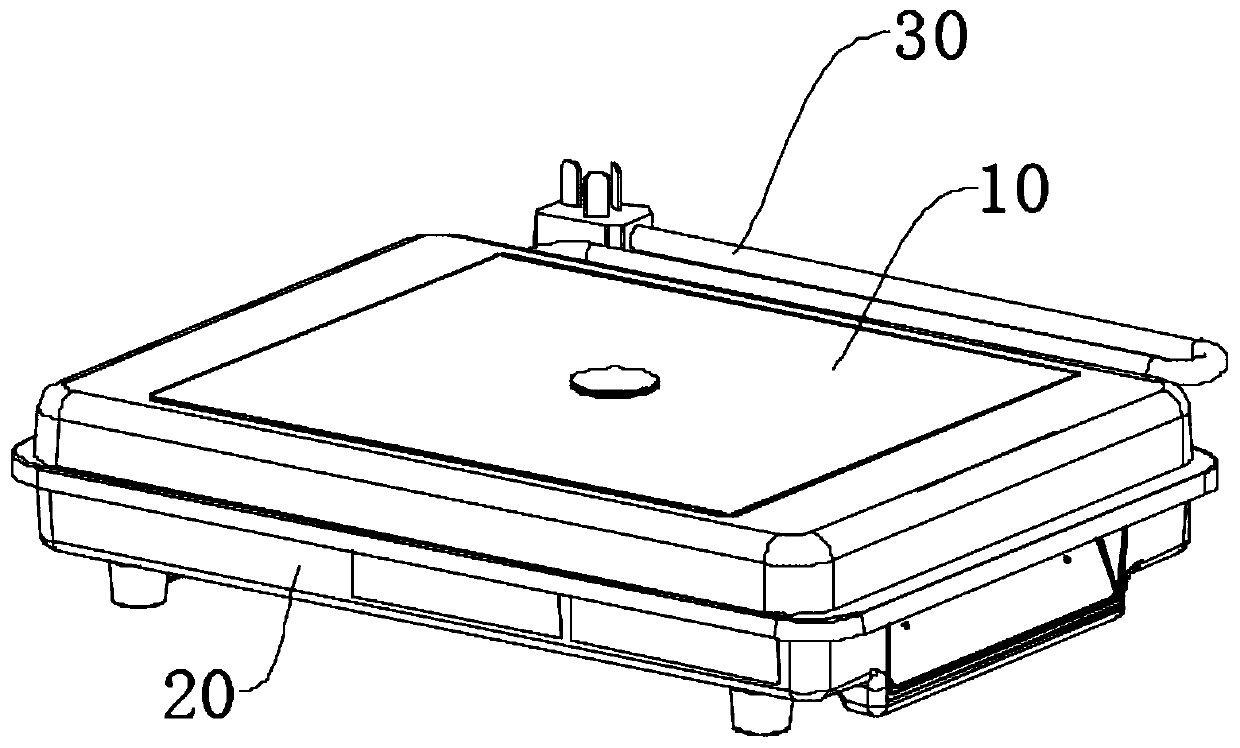

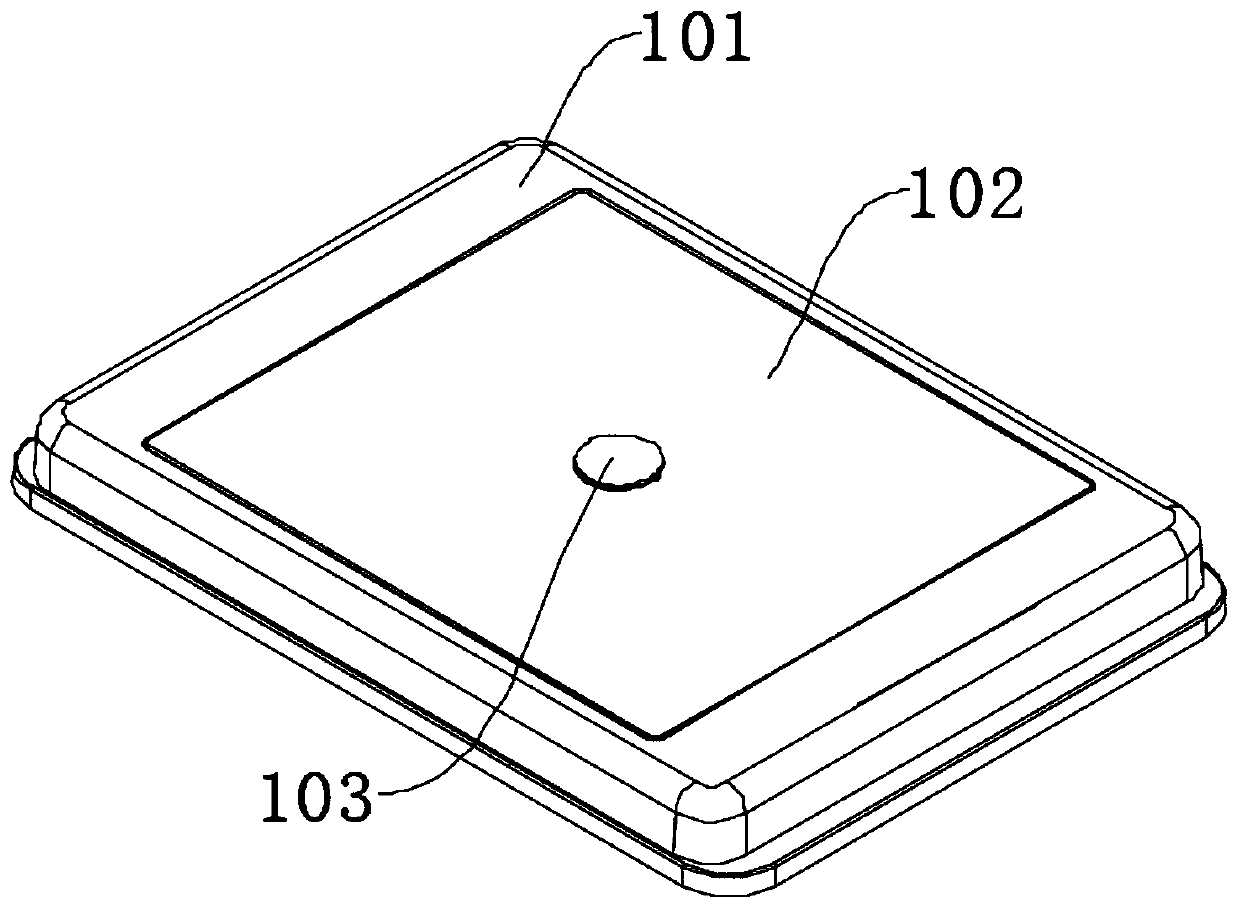

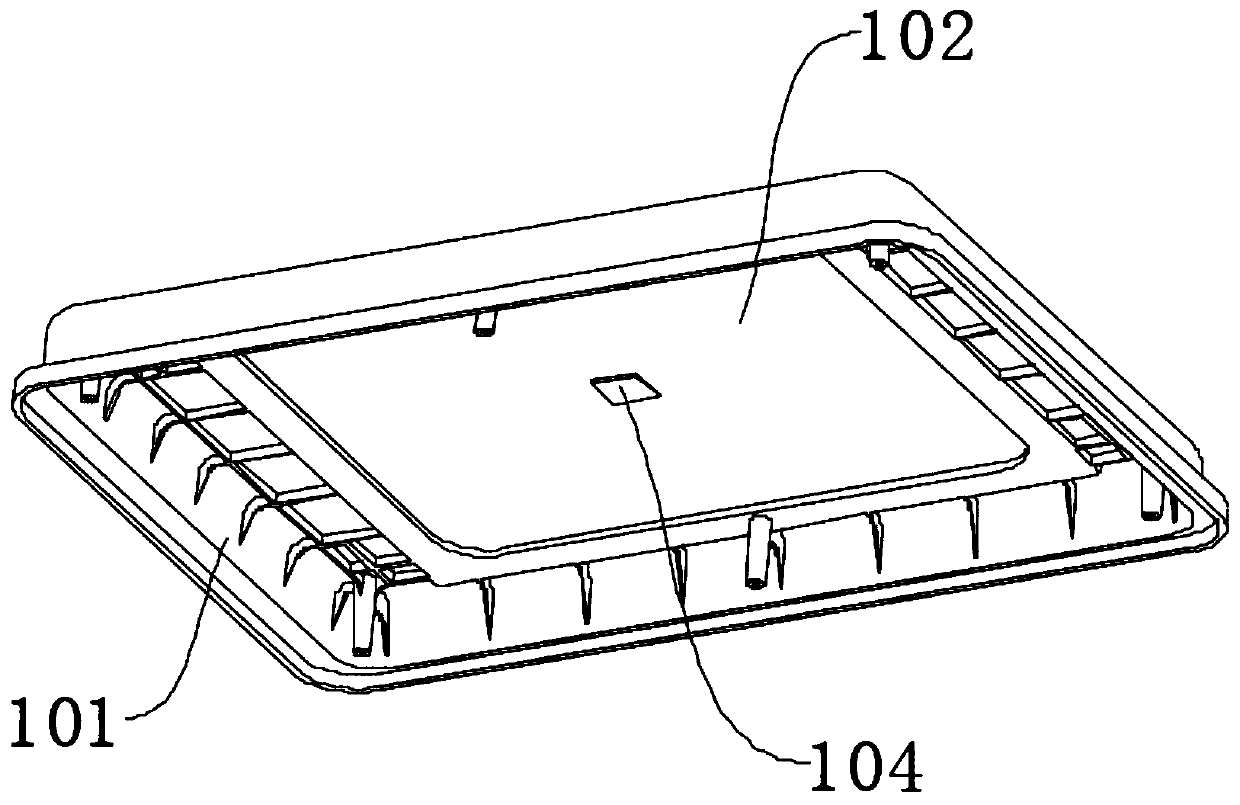

Electromagnetic oven temperature sensing structure and method

PendingCN110594802AEasy to collectIncrease costStoves/ranges foundationsDomestic stoves or rangesHeat conductingInduction cooking

The invention relates to the technical field of electromagnetic oven temperature measurement, and discloses an electromagnetic oven temperature sensing structure and method. According to the technicalscheme, the electromagnetic oven temperature sensing structure comprises a cover and a base connected with the cover, wherein the cover comprises a cover body and a black crystal plate arranged at the position of the cover body; a high heat-conducting metal plate is bonded and fixed over the center of the black crystal plate through heat-conducting glue; a heat-conducting pad is attached under the center of the black crystal plate; and the base comprises a base shell, a circuit board fixed to the inside of the base shell, a heat dissipation fan arranged on one side of the circuit board and acoil disc fixed to the inside of the base shell and positioned above the circuit board. According to the scheme of the electromagnetic oven temperature sensing structure and the method, the design isnovel and ingenious, and the temperature measurement accuracy is high.

Owner:嘉兴顾翔制冷设备有限公司

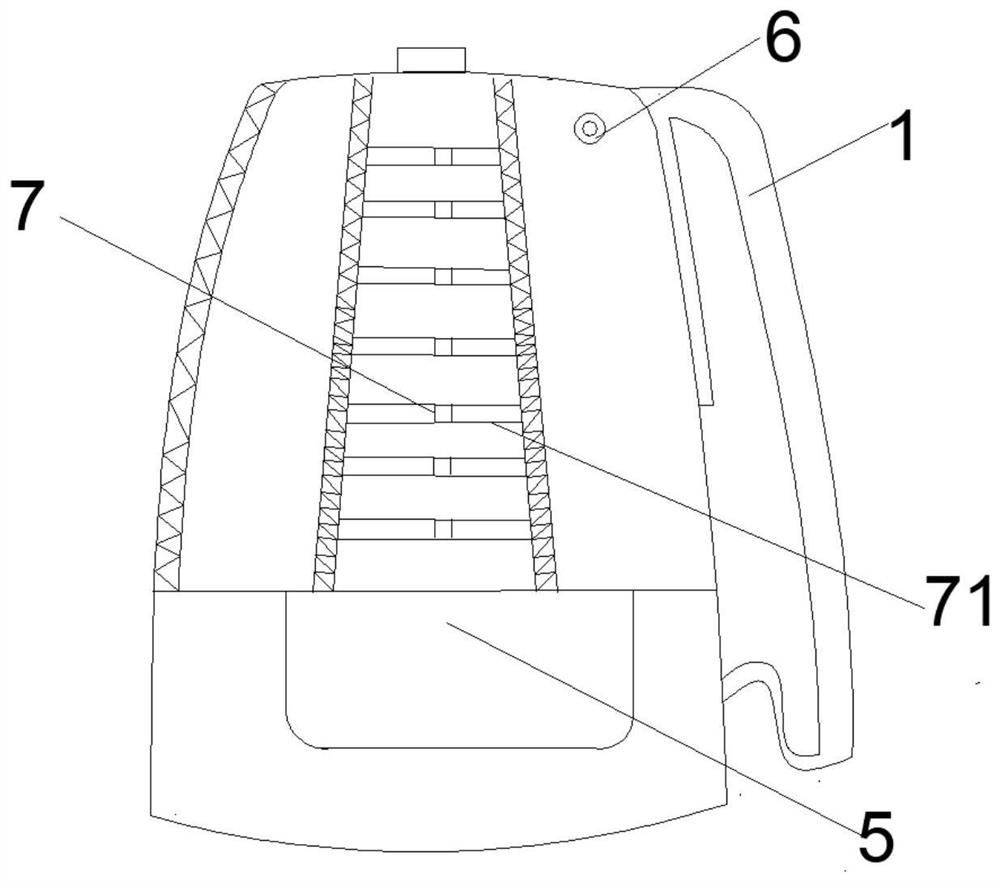

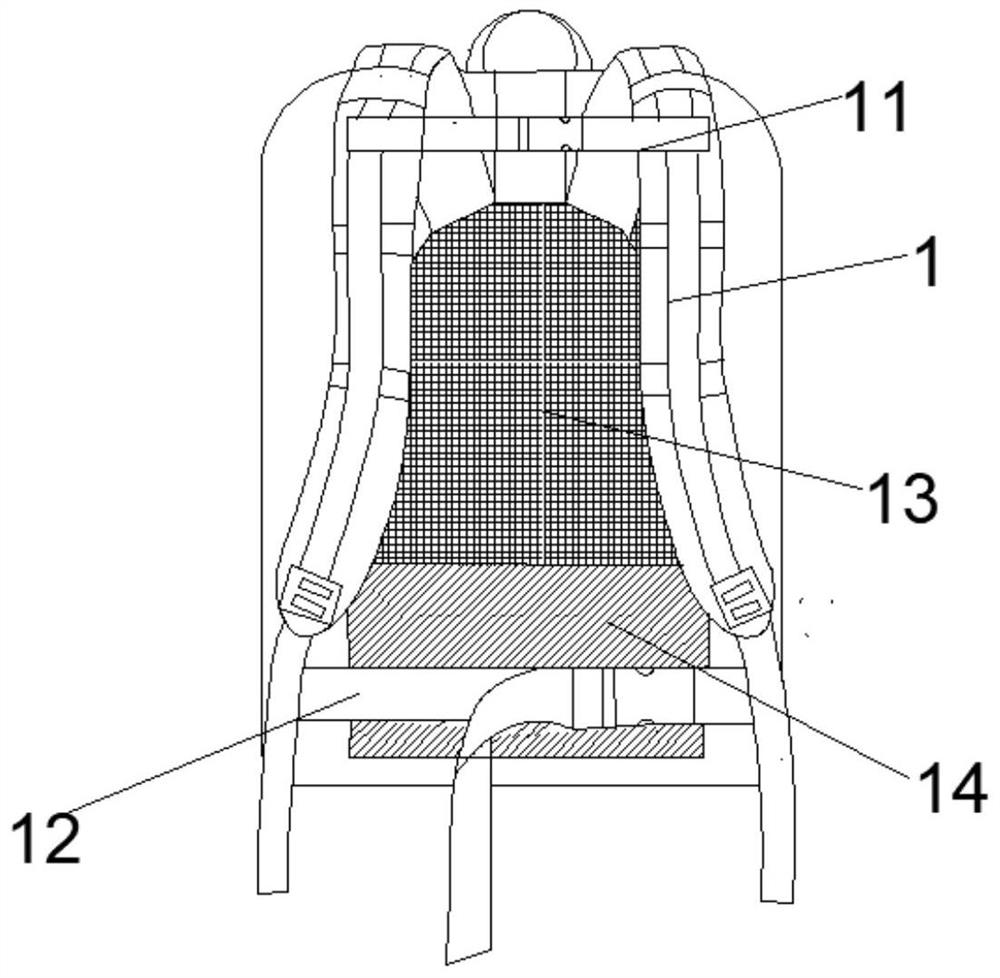

A combat backpack for preventing damage from multi-angle fall and impact and its production process

ActiveCN111972818BAvoid damageEasy to useTravelling sacksOther accessoriesRadio equipmentProcess engineering

The invention discloses an anti-multi-angle drop-impact-damaged combat backpack and a production process thereof, which comprises a buffer protection box, a sandwich bag, an antenna punching hole, and a side bag, wherein the side bag is provided with a through hole, thereby realizing The convenience of storage and use of military equipment (such as radio equipment), military equipment and its related accessories can be stored and taken easily and can be used normally in combat backpacks. At the same time, due to the protective effect of the buffer protection box, its impact resistance performance It is strong and more suitable for combat needs. Its production process includes material preparation → backpack body production → strap production → buffer protection box production → sandwich bag production → perforation processing → splicing and stitching → partition production → quality inspection → packaging. The packaging device includes a bracket on which a feeding conveying device, a grabbing mechanism, a bag-supporting device, a heat-sealing device and a discharging device are sequentially fixed, which realizes the full automation of the packaging process of the combat backpack and improves the work efficiency. Reduced labor costs.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

An automated lifting fixture

ActiveCN111762679BDispersion weightSuspension stabilityLoad-engaging elementsHydraulic cylinderControl engineering

The invention relates to an automatic hoisting fixture, which includes a hoisting part for hoisting and a clamping part suspended below the hoisting part for clamping a barrel, and the clamping part drives the shears through a built-in hydraulic cylinder. One end of the fork is opened and closed to control the position change of the L-shaped plate and the straight rod at the other end of the scissors. The position change of the straight rod drives the fixedly connected telescopic ring to expand and contract to fix the barrel. In the present invention, three circularly distributed scissors are controlled by a hydraulic cylinder to expand and contract synchronously. The first plate of the scissors drives the L-shaped plate to move, and the L-shaped plate and the second plate of the scissors jointly define a straight bar. The direction of movement makes the straight rod move inward and upward when clamping, driving the fixedly connected telescopic ring to close and clamp while the telescopic ring moves up, driving the diagonal brace on the telescopic ring to move to the diameter of the outer wall of the barrel Change the transitional part for fitting support and clamping.

Owner:付安英

Virtual image display device

Image lights formed by a light emitting device and a virtual-image forming member and external light transmitted through a visibility adjusting member and the virtual-image forming member can be observed in parallel in a see-through manner. In the observation of the external light, the visibility adjusting member enables visibility adjustment corresponding to the eyesight of a wearer. Therefore, the wearer can observe the external light without wearing a device for visibility adjustment such as glasses. Therefore, it is possible to suppress an increase in the size of a virtual image display device.

Owner:SEIKO EPSON CORP

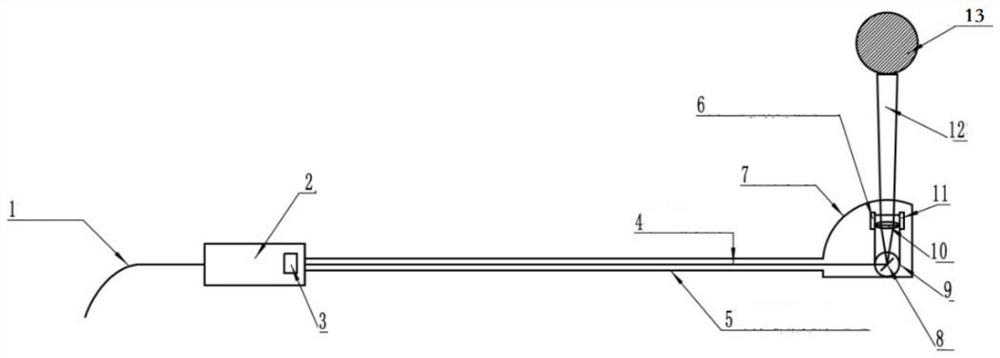

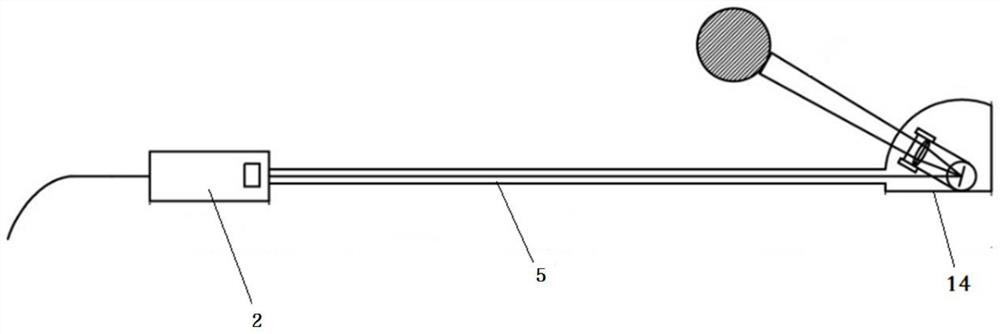

An angle-adjustable laser cleaning machine handheld terminal

ActiveCN110434125BDispersion weightEasy to cleanCleaning processes and apparatusGalvanometerEngineering

Owner:SHANDONG ZHONGSHI YITONG GRP +1

Apparatus for holding a container on an uneven surface

ActiveUS11466808B2Easily stored and packaged and transportedQuick transitionStands/trestlesWork benchesEngineeringEquipment use

Owner:KLEIN DAVID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com