An angle-adjustable laser cleaning machine handheld terminal

A technology of laser cleaning and angle adjustment, used in the field of laser cleaning machines, can solve the problems of high laser directivity and inability to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

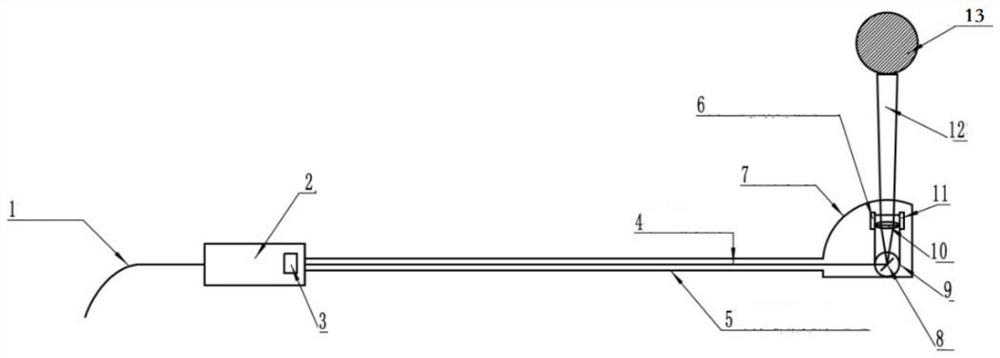

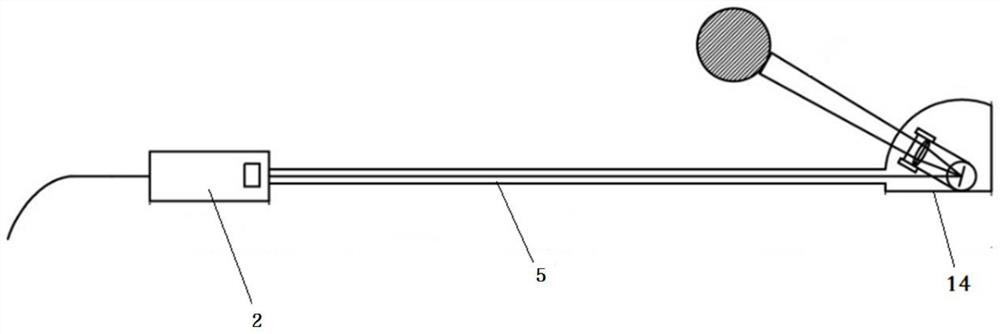

[0045] Such as Figure 1~2As shown, this embodiment discloses an angle-adjustable handheld terminal of a laser cleaning machine, including an external housing mechanism composed of a handheld part 2, a laser beam channel 5, and an accommodating part 14, and the external housing mechanism is used to cover The laser processing mechanism located inside it, the hand-held part 2 is connected with the housing part 14 at the other end through the laser beam channel 5, the laser beam channel 5 can change its length, and the surface of the housing part 14 is provided with an arc-shaped window protection mirror; laser processing The mechanism includes the oscillating mirror 8 and the focusing mirror 10 placed in the accommodating part 14 , the angles of the galvanizing mirror 8 and the focusing mirror 10 are adjustable; it also includes an observing mechanism placed in the accommodating part 14 .

[0046] In order to realize the function of changing the length, the laser beam channel 5 ...

Embodiment 2

[0057] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the observation mechanism further includes a camera 11 disposed in the accommodating portion 14 for observing the surface of the workpiece 13 to be cleaned, and the camera 11 is installed on the focusing lens 10 . Used to observe the workpiece to be cleaned and the cleaning indicator line.

[0058] A controller is arranged in the hand-held part 2, and the controller is connected with the laser output head, the vibrating mirror 8, the laser range finder, the cleaning indicator line emission mechanism and the camera 11.

[0059] A jog switch 3 is also installed on the outside of the handle 2, and the jog switch 3 is connected to the controller.

[0060] It also includes a control panel for parameter setting and display, and the control panel is connected with the controller and the observation mechanism.

[0061] Embodiment 2 is different from Embodiment 1 in the working mode. Specifically, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com