Reinforced two-path bridge

A dual-channel, reinforced technology, applied in bridges, suspension bridges, bridge forms, etc., can solve the problems of not particularly high overall stability and load-bearing performance, time-consuming and laborious processing, and many materials, saving materials, reducing costs, and improving The effect of lateral strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

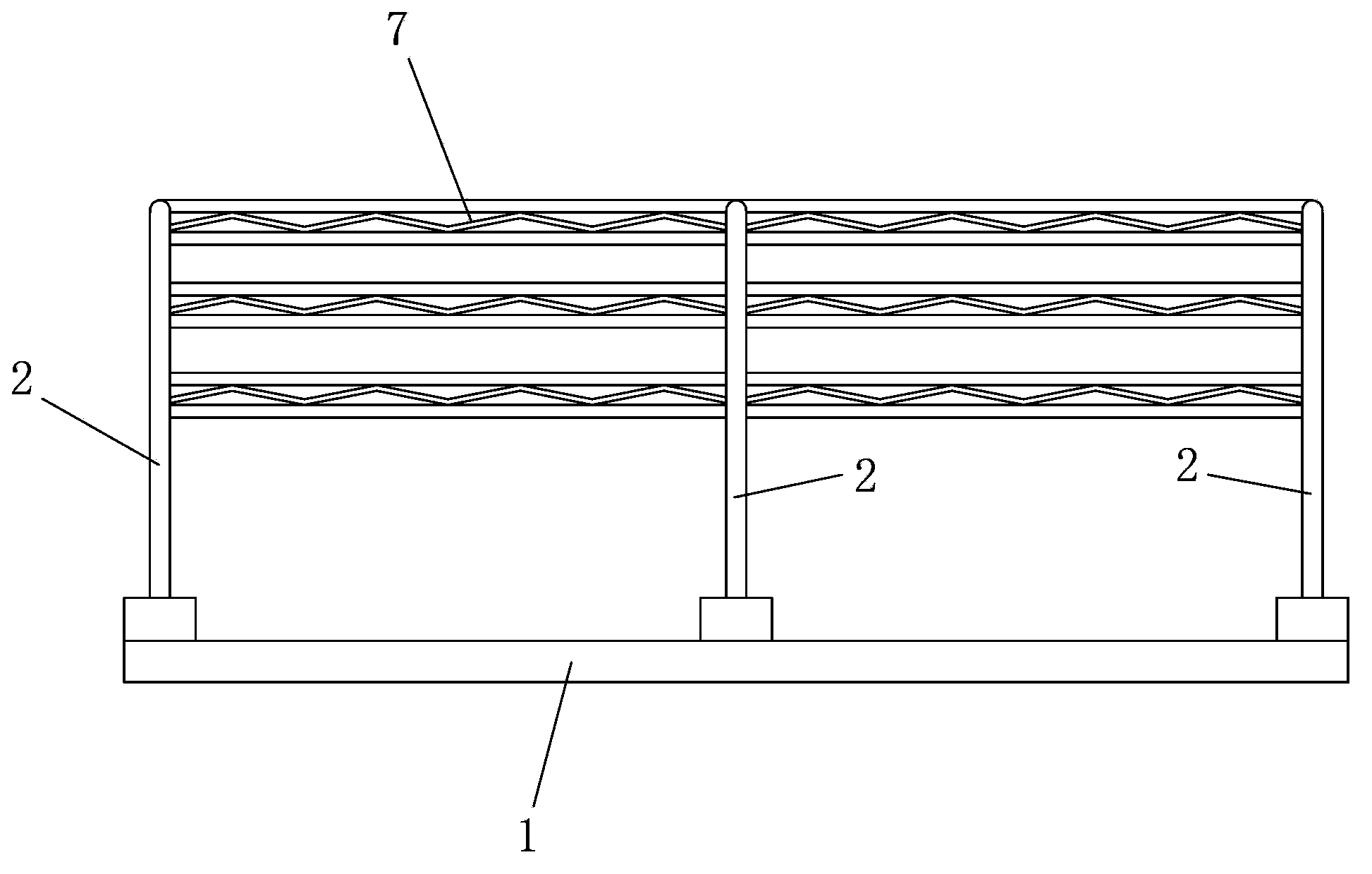

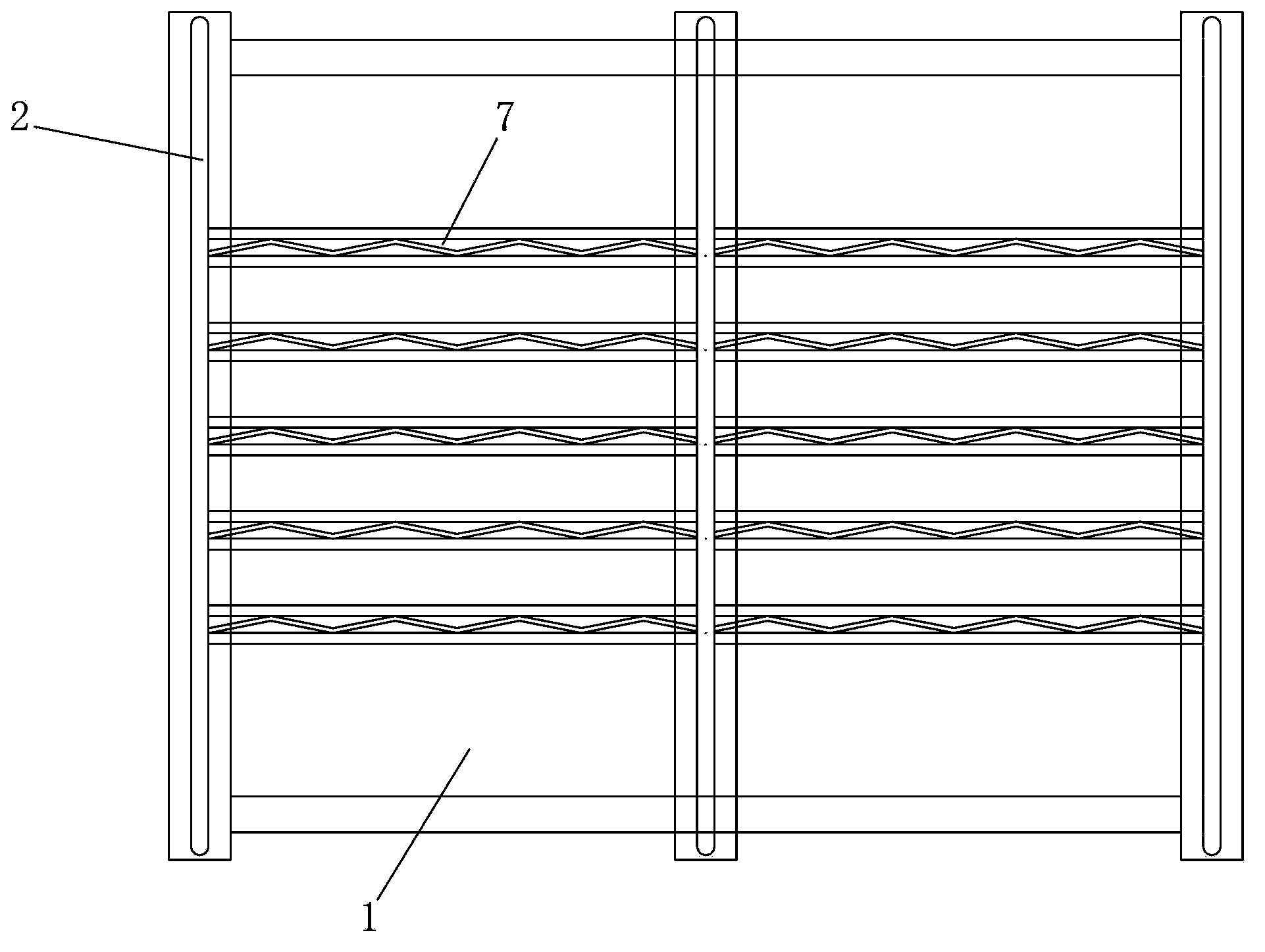

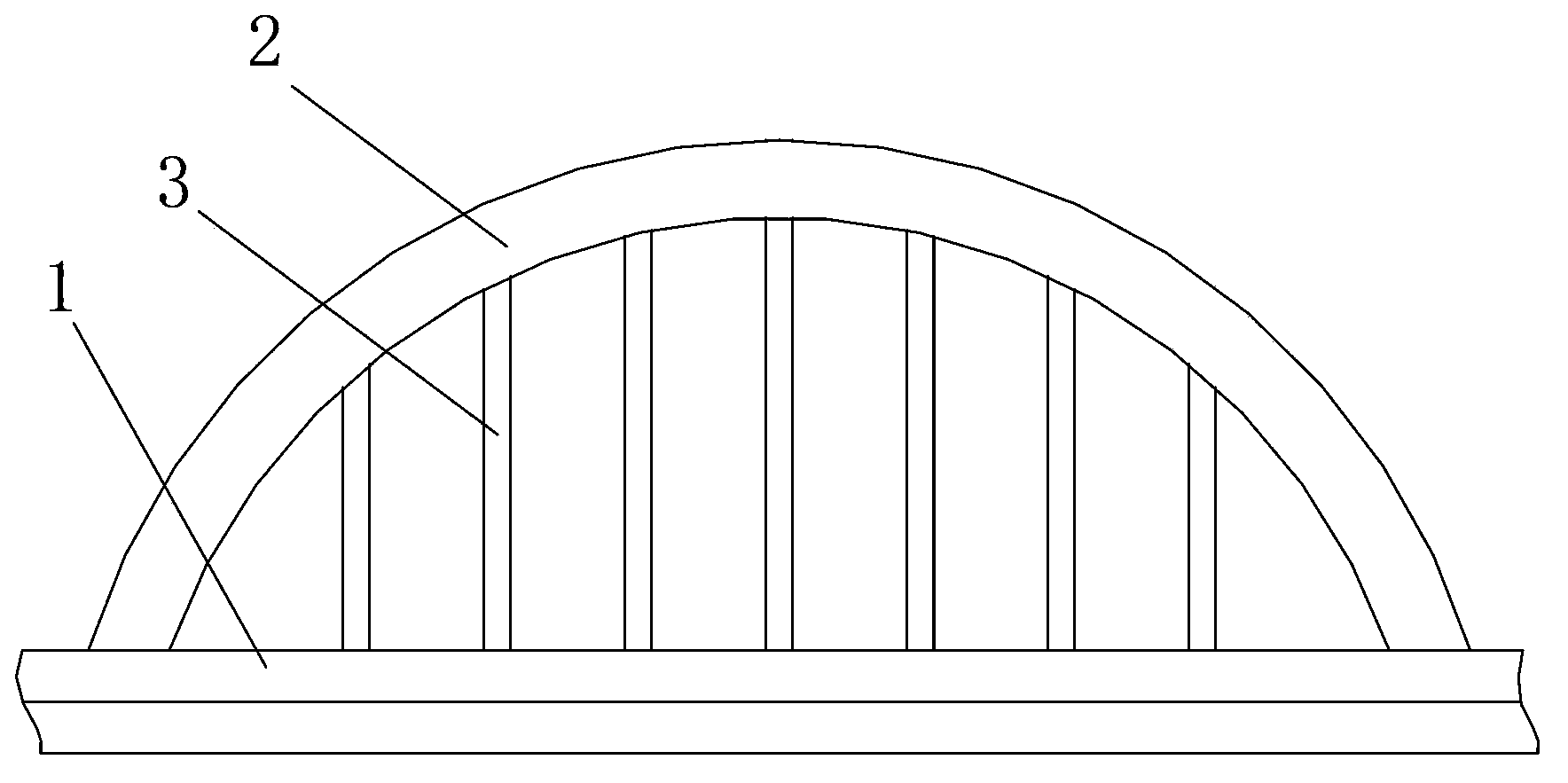

[0024] Embodiment one: if Figure 4 to Figure 6 As shown, a reinforced double-channel bridge includes a bridge deck 1, three arched bridges 2 and load-bearing cables 3 arranged at intervals, and the bridge 2 in the middle of the three bridges 2 is an intermediate bridge 21 vertically arranged , the bridges 2 on both sides of the three bridges 2 are side bridges 22 inclined outwards, and several tension cables 4 are respectively drawn between the bridges 22 on both sides and the upper part of the middle bridge 21, some of which Tensioning cables 4 are arranged crosswise, and their crossing parts are fixedly connected by locking pieces 6 . The load-bearing cables 3 are connected between each bridge 2 and the fixed seat 11 of the bridge deck 1, and the load-bearing cables 3 include a plurality of first cables 31 arranged obliquely and a plurality of second cables 32 with different inclination directions from the first cables 31, The first cables 31 and the second cables 32 are...

Embodiment 2

[0025] Embodiment two: if Figure 4 , Figure 5 and Figure 7 As shown, a reinforced double-channel bridge includes a bridge deck 1, three arched bridges 2 and load-bearing cables 3 arranged at intervals, and the bridge 2 in the middle of the three bridges 2 is an intermediate bridge 21 vertically arranged , the bridges 2 on both sides of the three bridges 2 are side bridges 22 inclined outwards, and several tension cables 4 are respectively drawn between the bridges 22 on both sides and the upper part of the middle bridge 21, some of which Tensioning cables 4 are arranged crosswise, and their crossing parts are fixedly connected by locking pieces 6 . The two sides of the bridge deck 1 are provided with tension beams 5 bent downward in the middle, and the two sides of the tension beams 5 are fixedly connected with the corresponding side bridges 22. 5 and the bridge deck 1, the load-bearing cables 3 include a number of first cables 31 arranged obliquely and a number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com