Distributed anchoring and grouting support device for deep mine fault fracture zone

A support device and broken zone technology, applied in shaft equipment, wellbore lining, bolt installation, etc., can solve problems such as strength limitation and difficulty in sealing fissure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

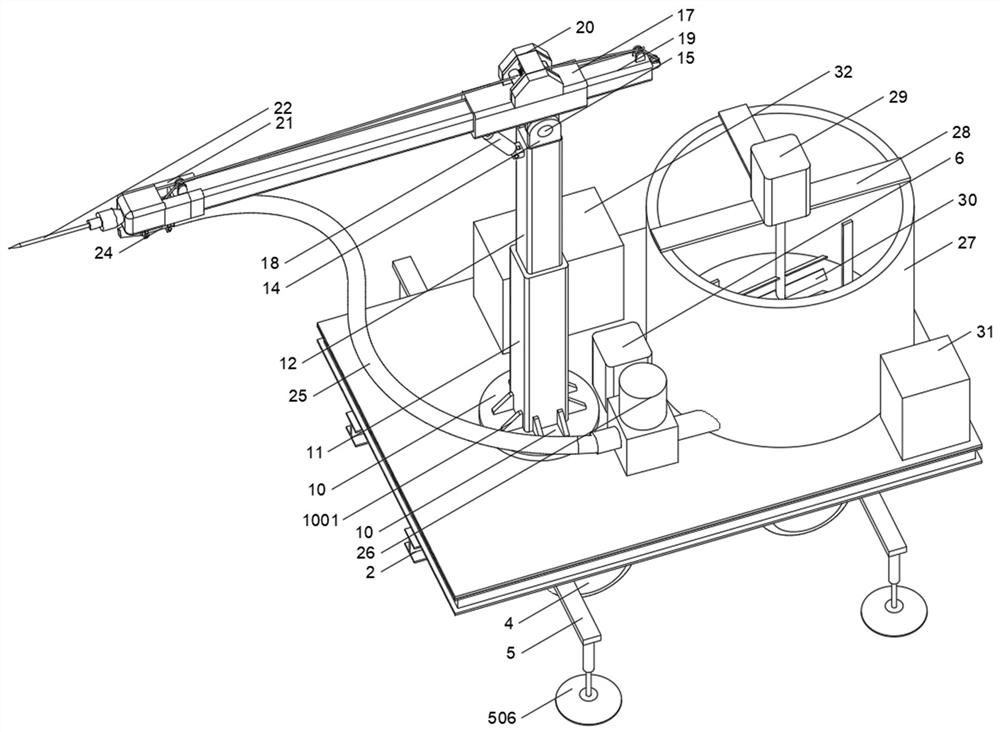

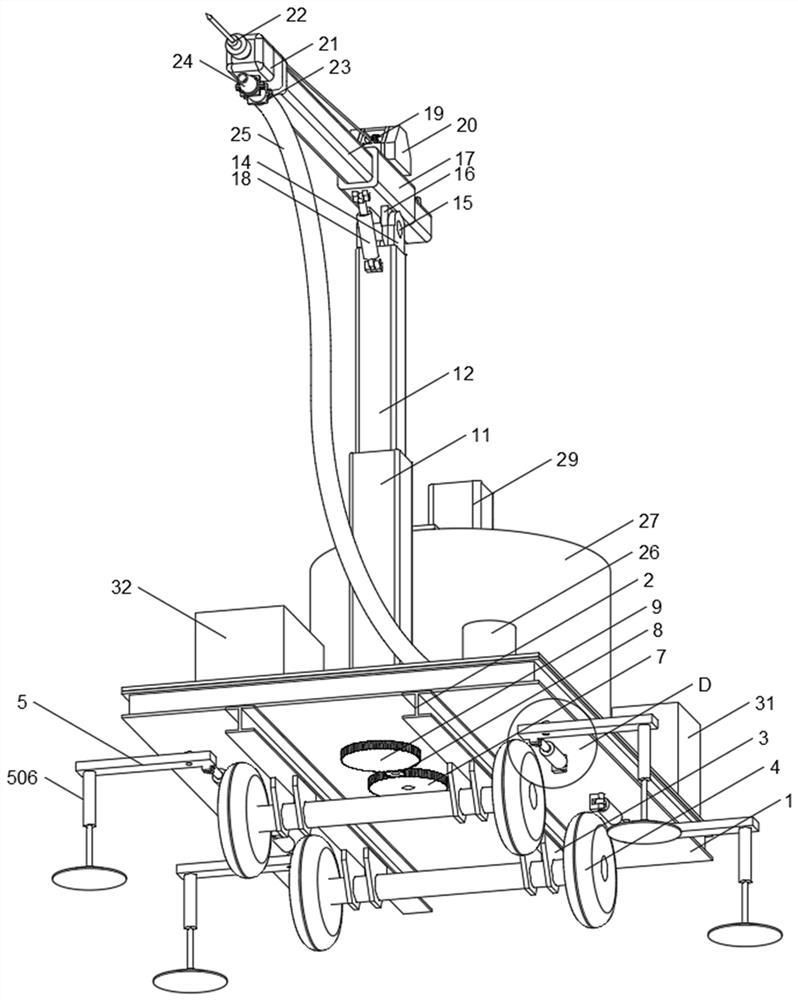

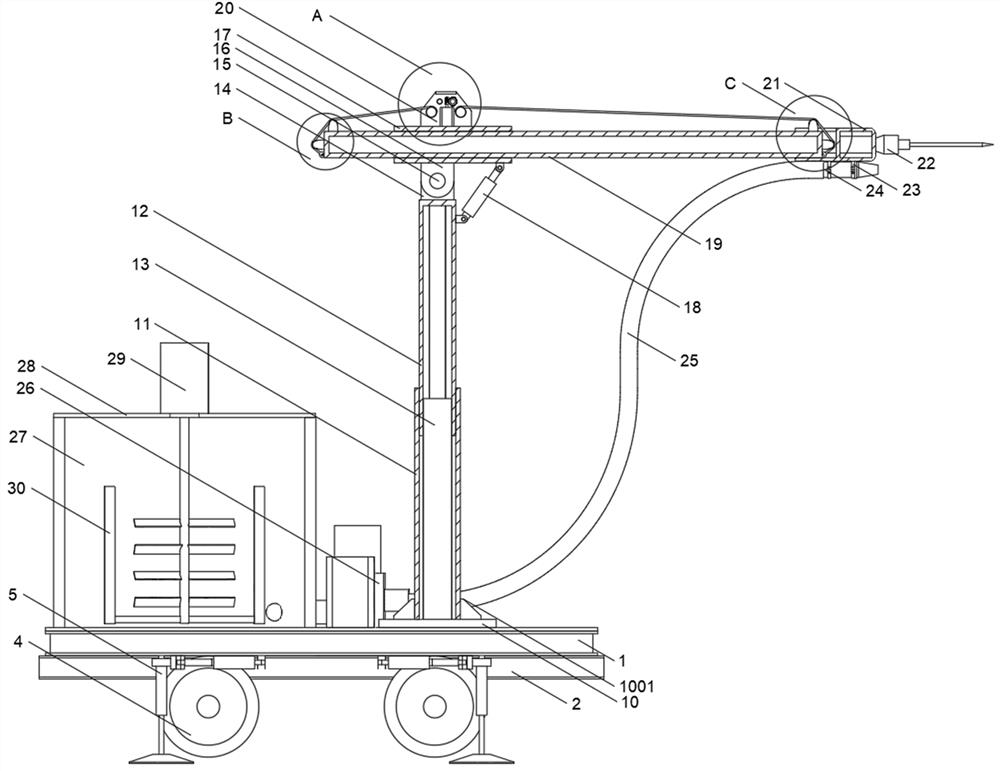

[0029] see Figure 1-Figure 9 , the present invention provides the following technical solutions: a distributed anchoring and grouting support device for fault fracture zones in deep mines, including a working platform 1, and an I-beam 2 and a support mechanism 5 are fixedly installed on the bottom of the working platform 1, and the I-beam The bottom of the steel 2 is equipped with a support wheel 4 through the triangular plate 3, and the top surface of the working platform 1 is fixedly equipped with a motor one 6, and the drive gear 7 fixedly installed on the output shaft of the motor one 6 is driven by an idler gear 8. The driven gear 9, the rotating shaft of the driven gear 9 is fixedly connected to the bottom surface of the base 10, the top surface of the base 10 is fixedly equipped with an outer sleeve 11 and a hydraulic rod 13, and the top of the push rod of the hydraulic rod 13 is fixedly connected Slidingly installed on the inner top surface of the inner slide bar 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com