Patents

Literature

88results about How to "Reduce the amount of human labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

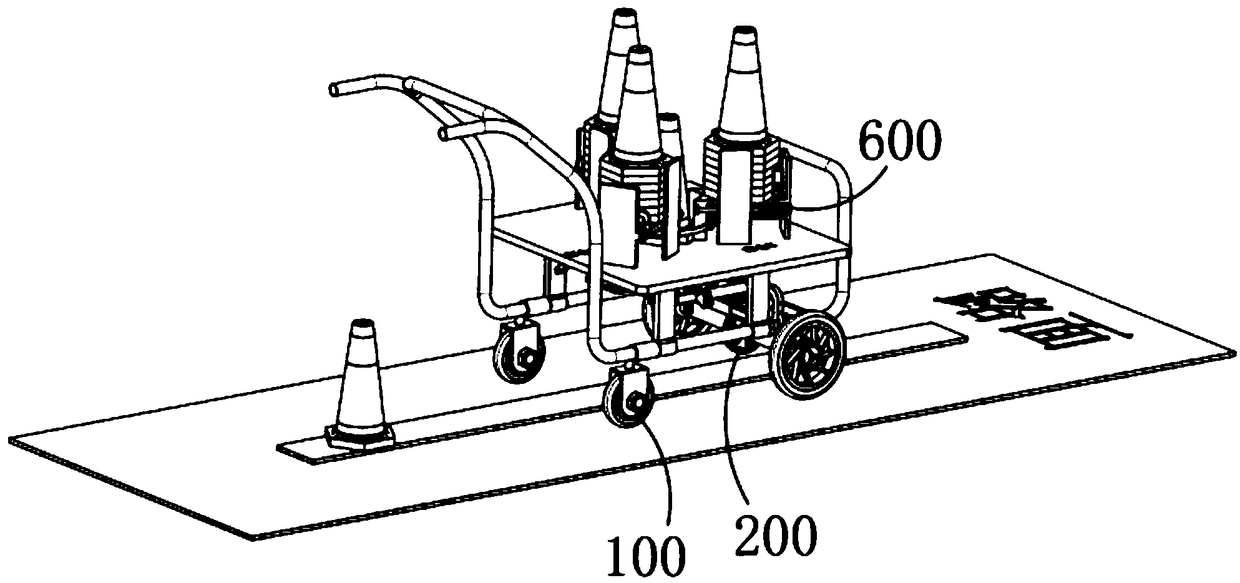

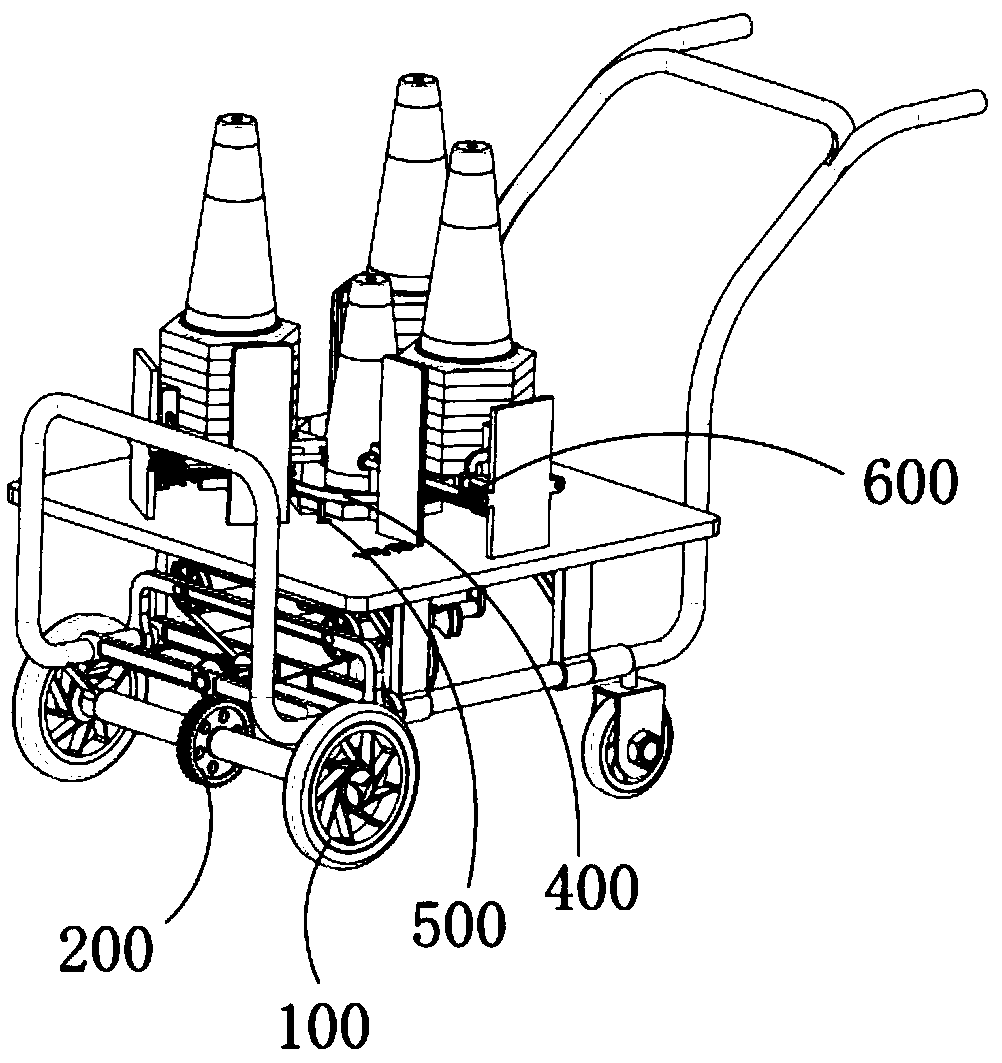

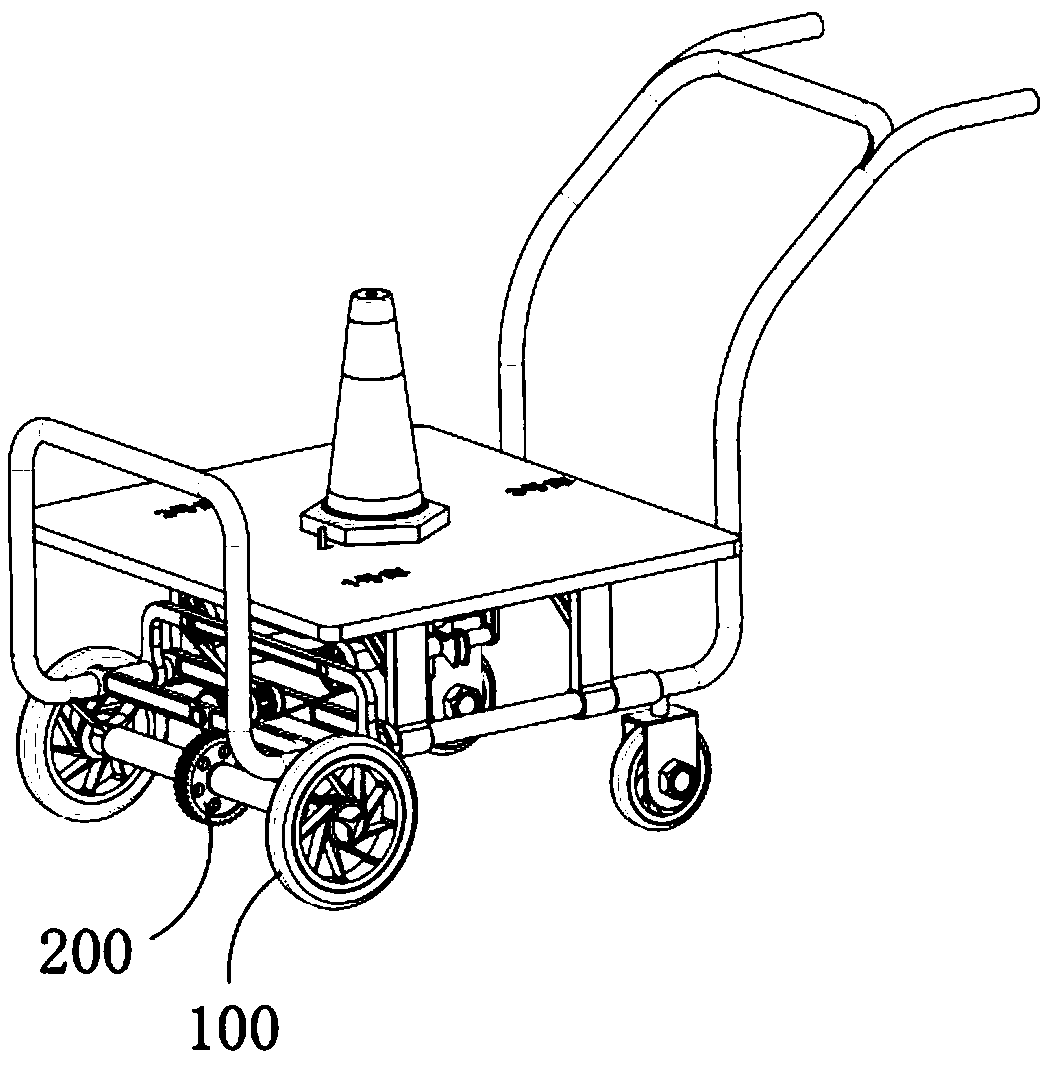

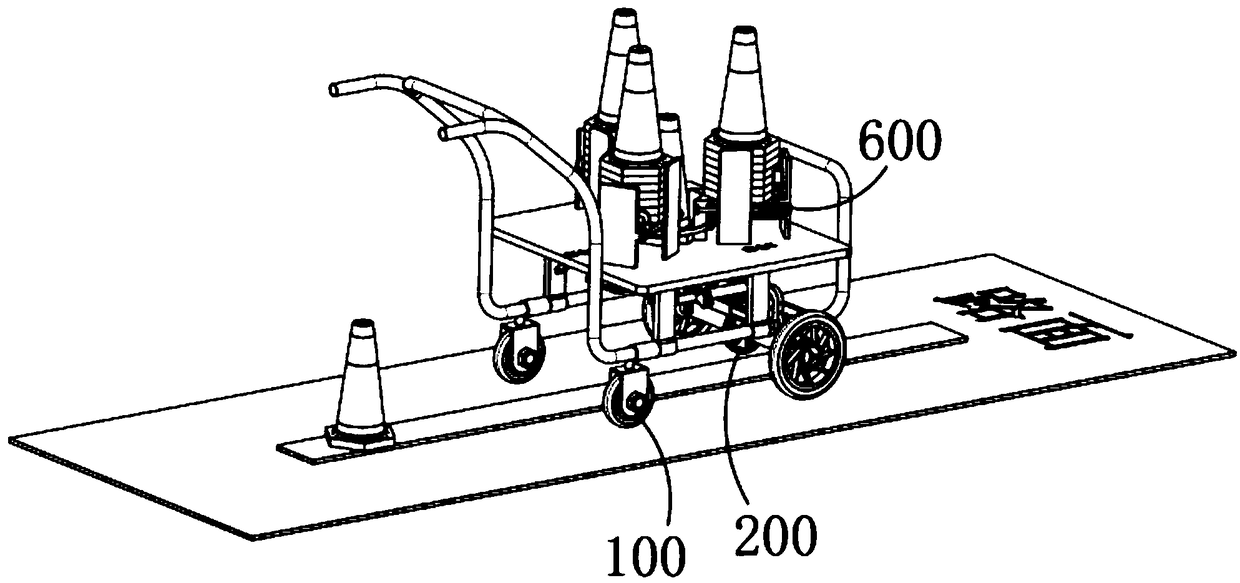

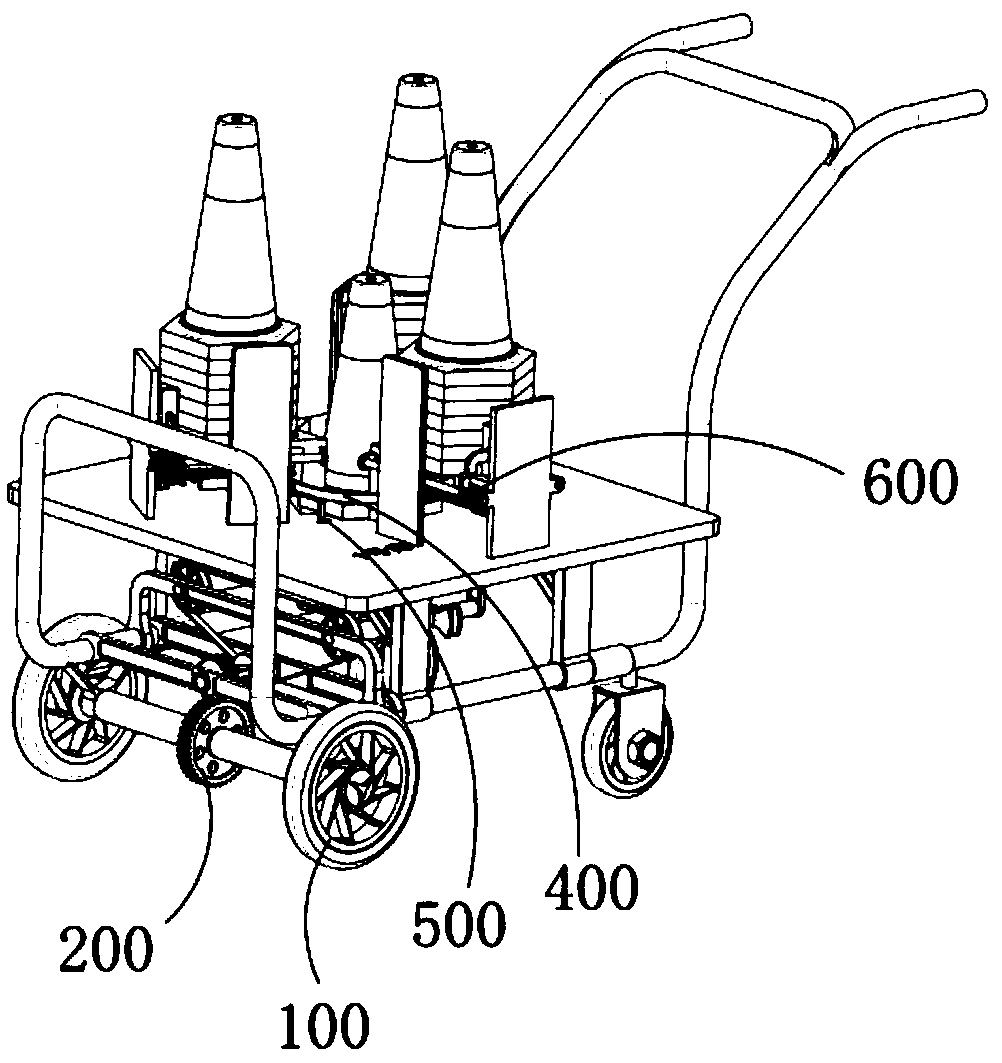

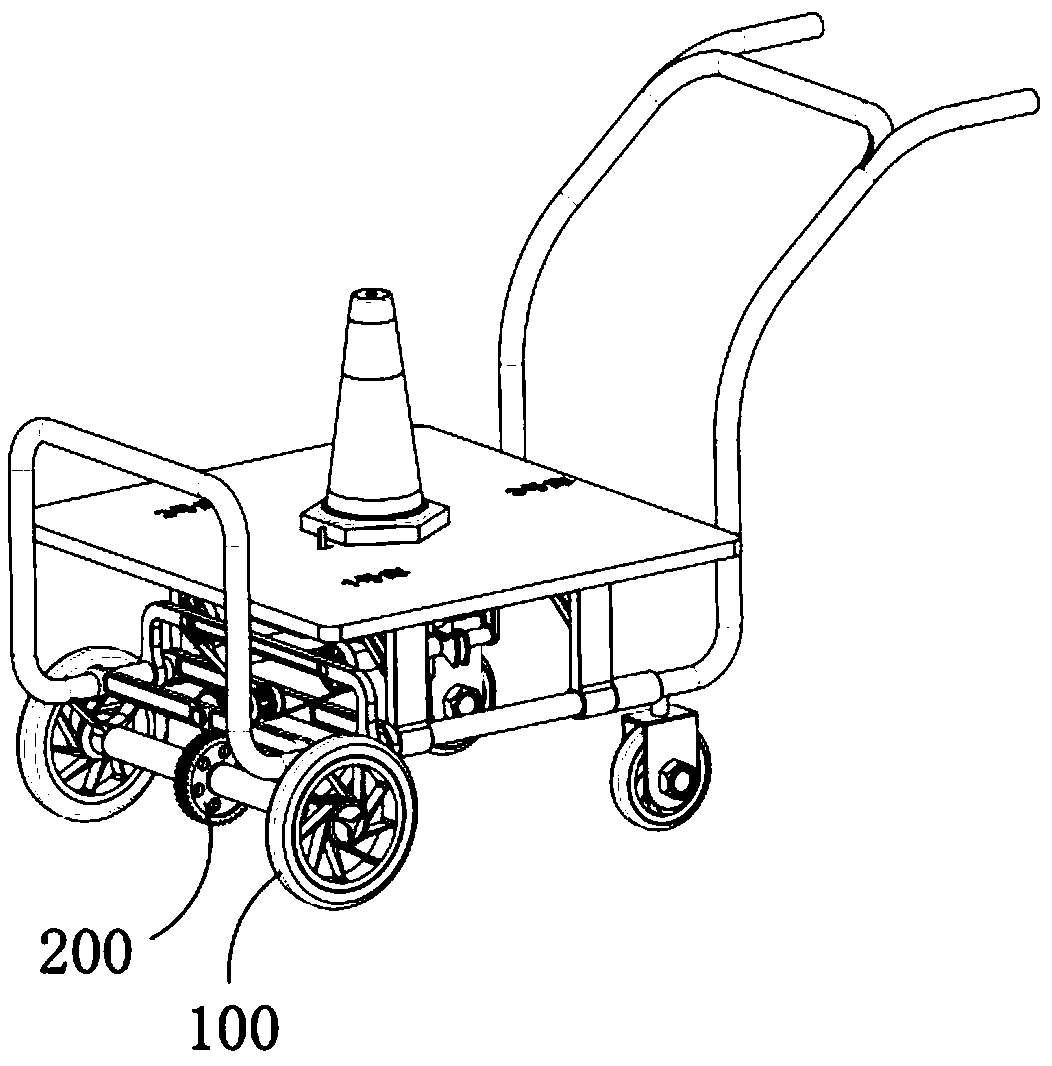

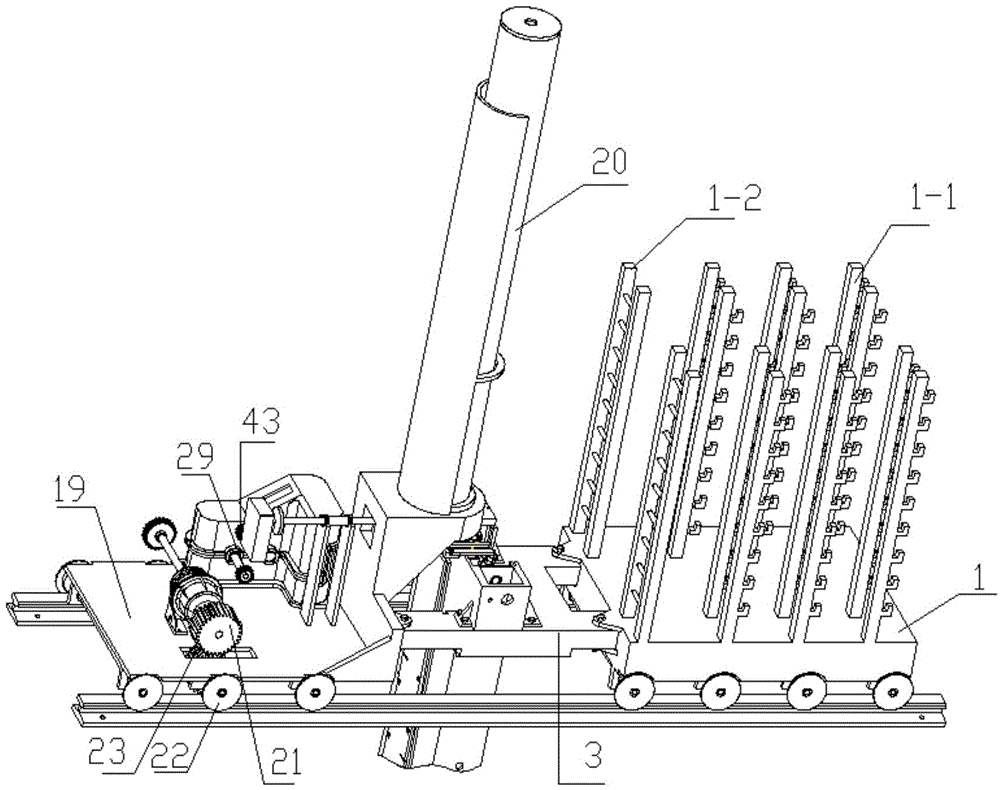

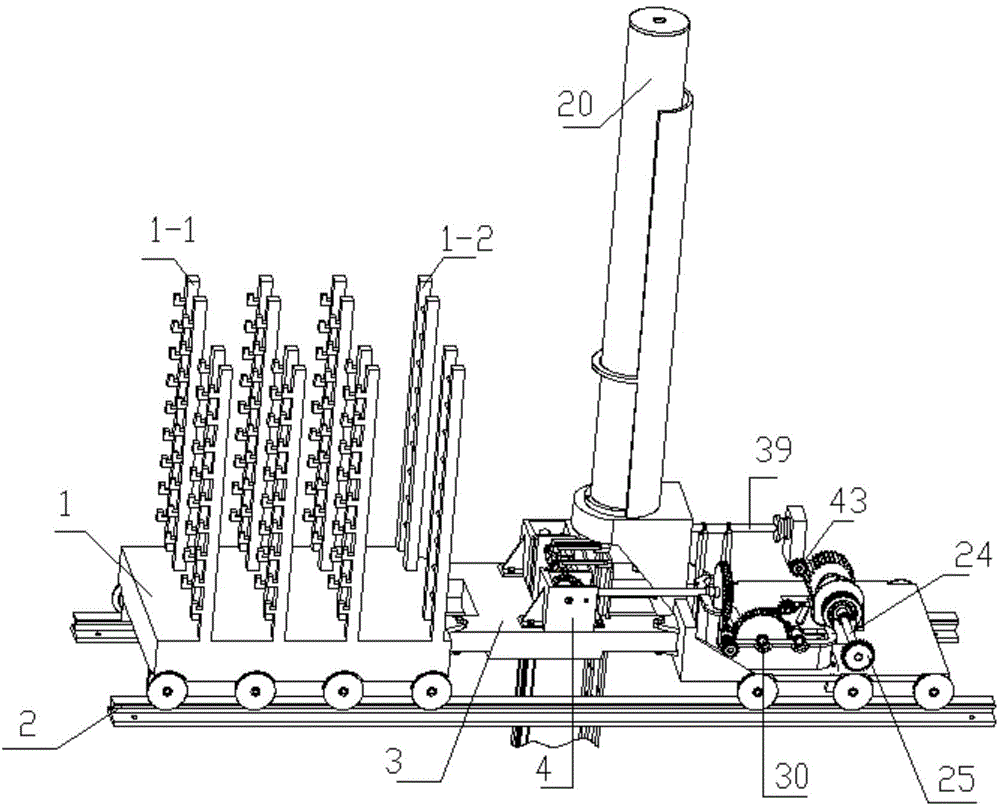

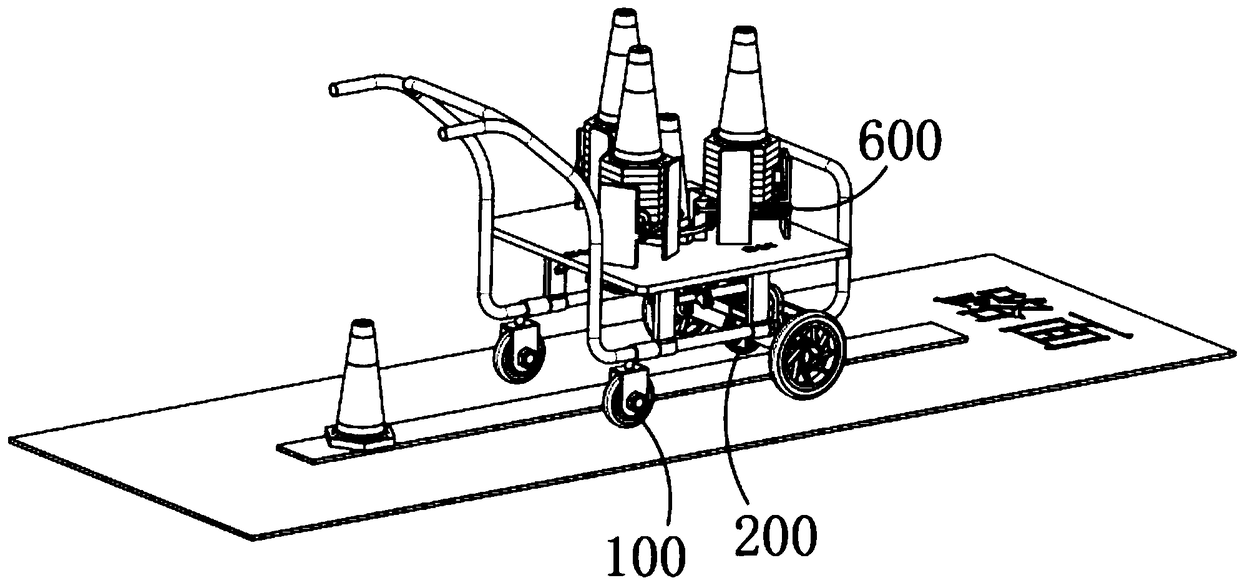

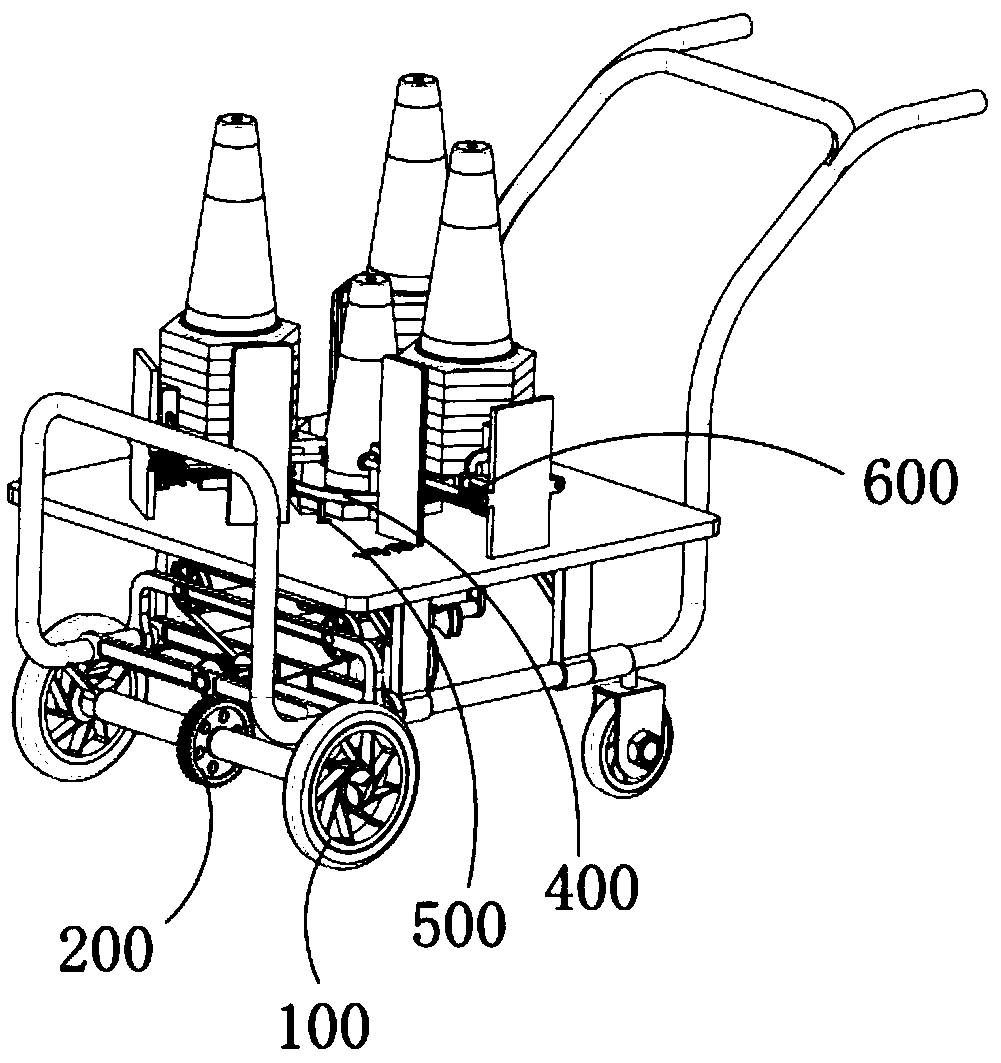

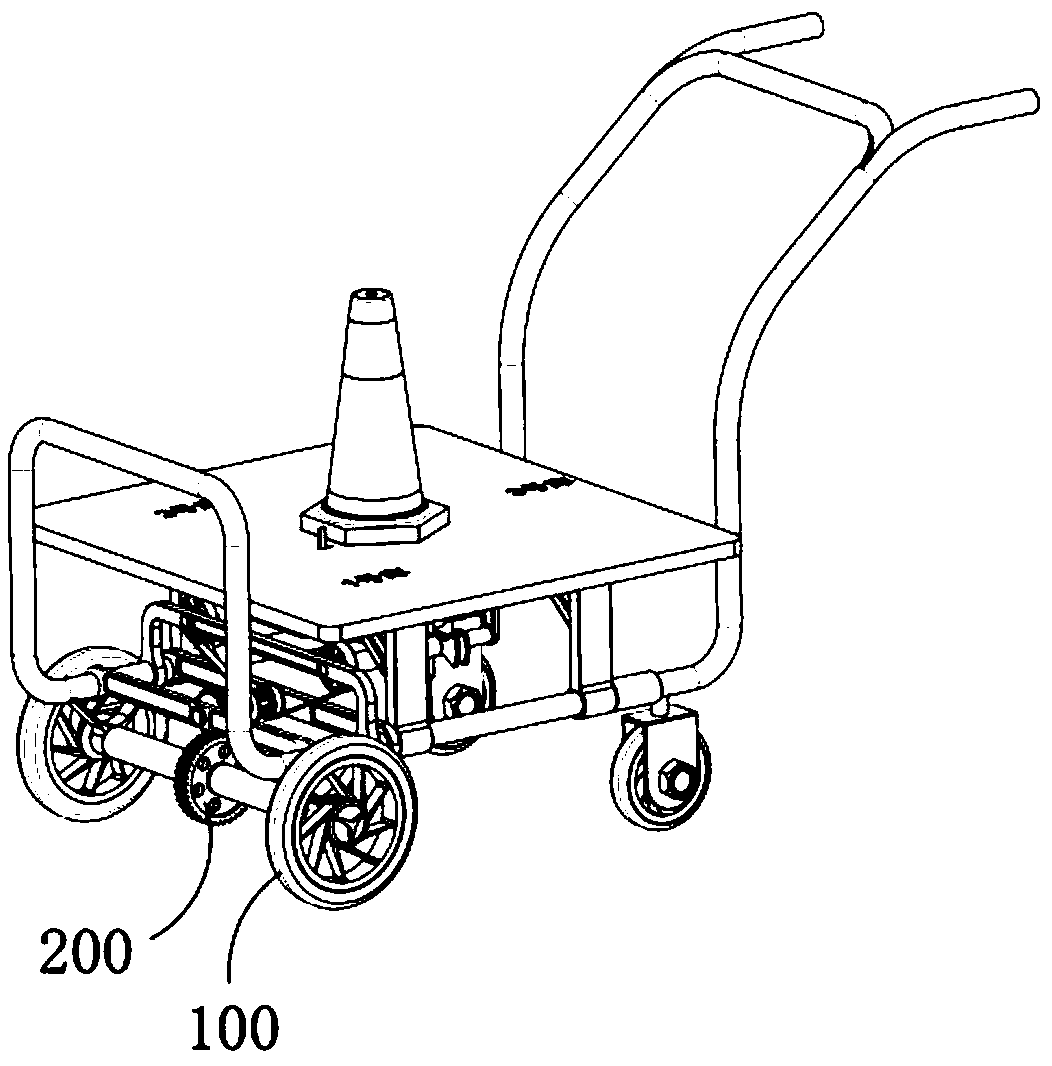

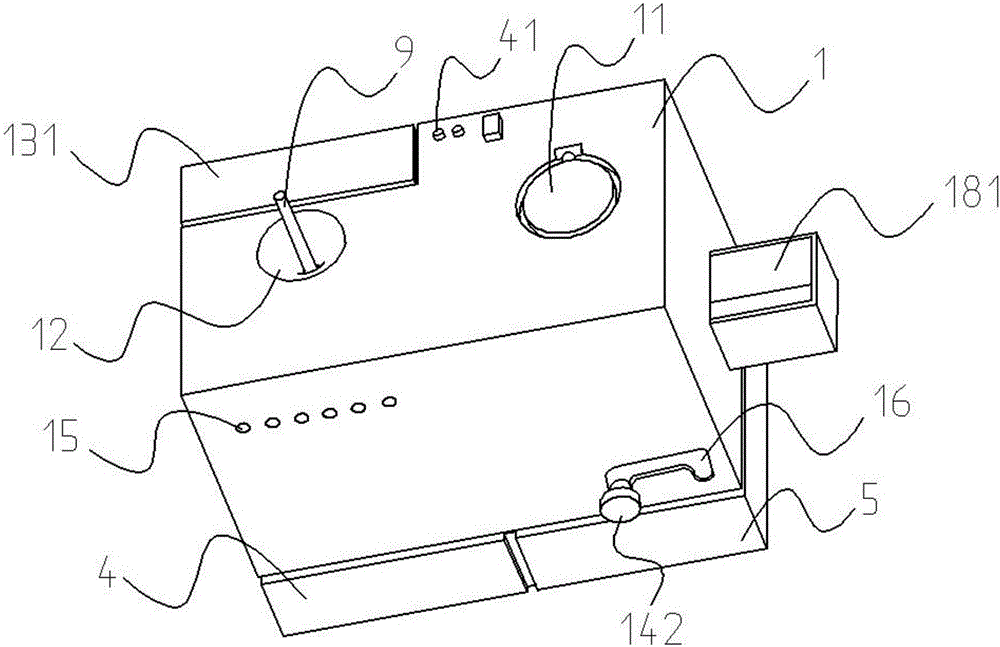

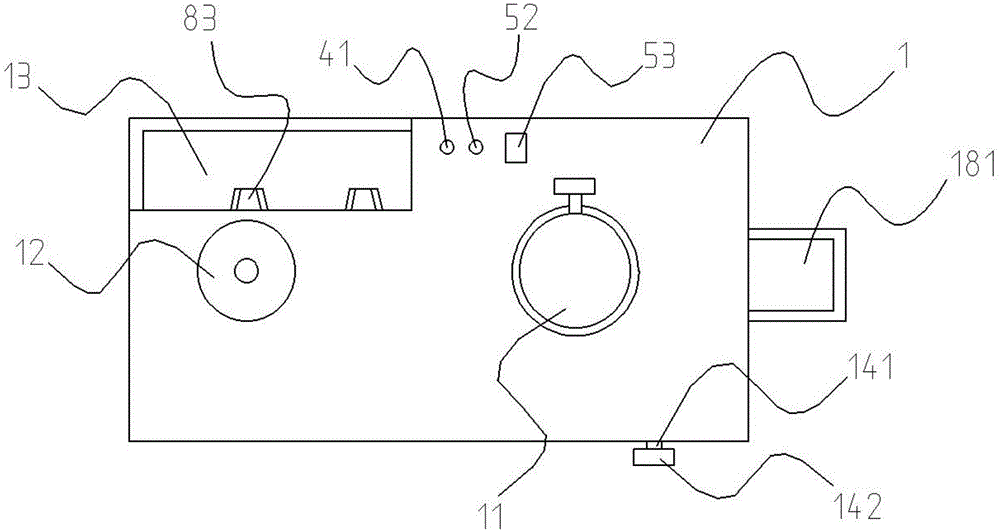

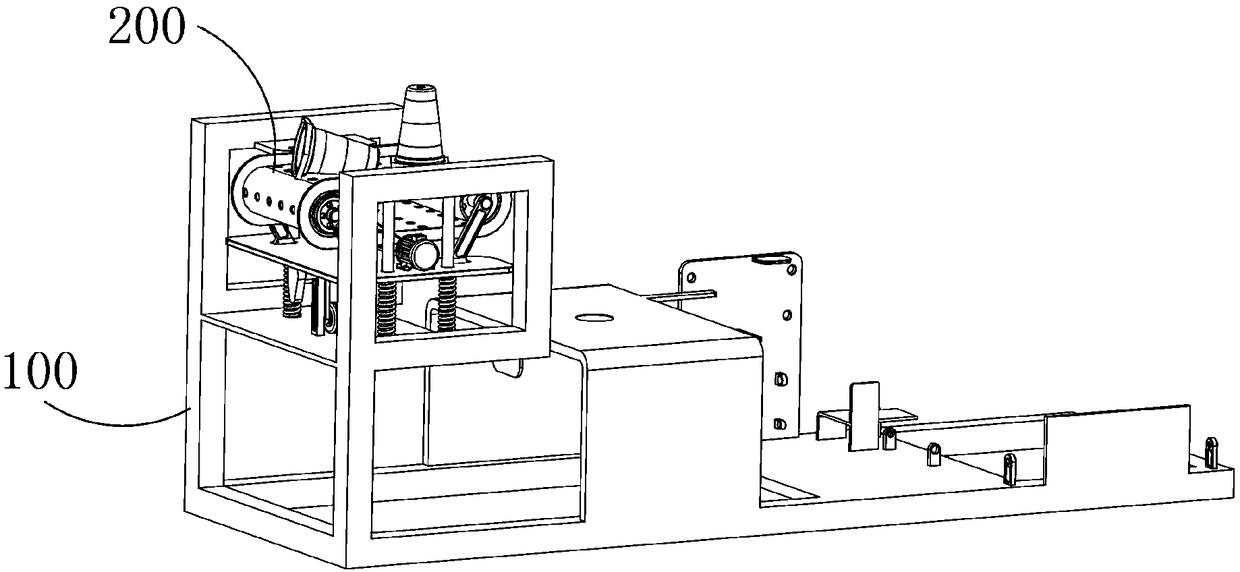

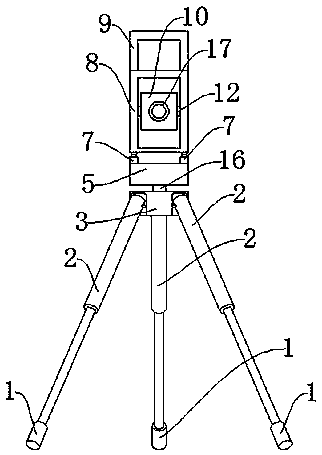

Manual trolley for automatically and orderly setting up roadblocks

InactiveCN109249967ANo action requiredShorten the timeHand carts with multiple axesHand cart accessoriesVehicle frameRoad surface

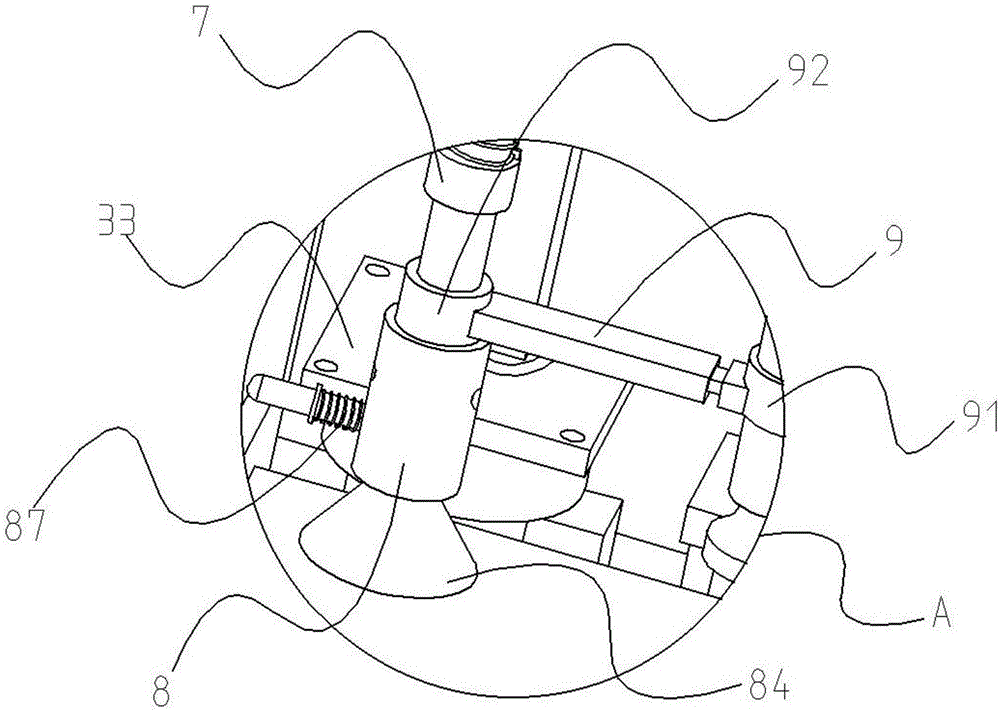

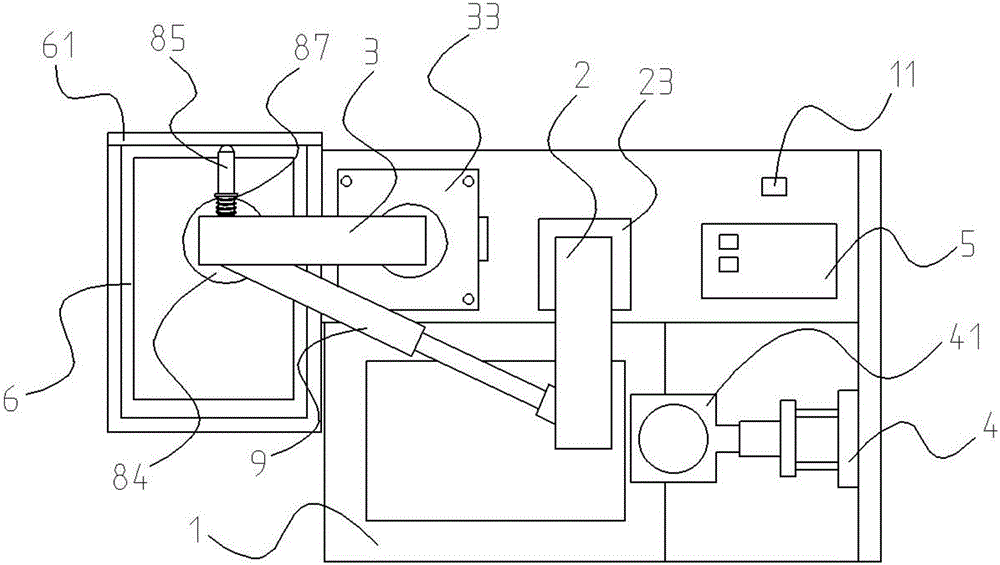

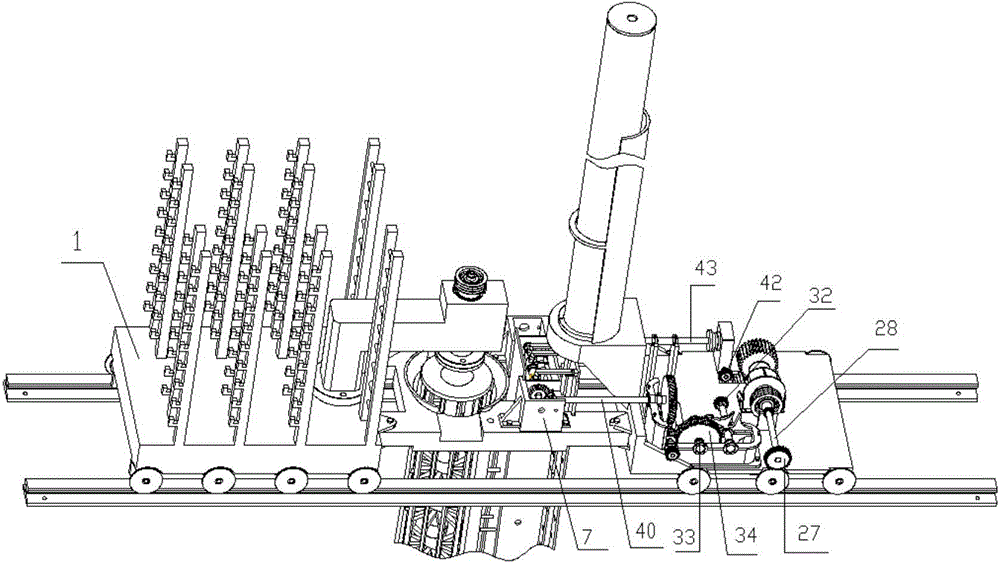

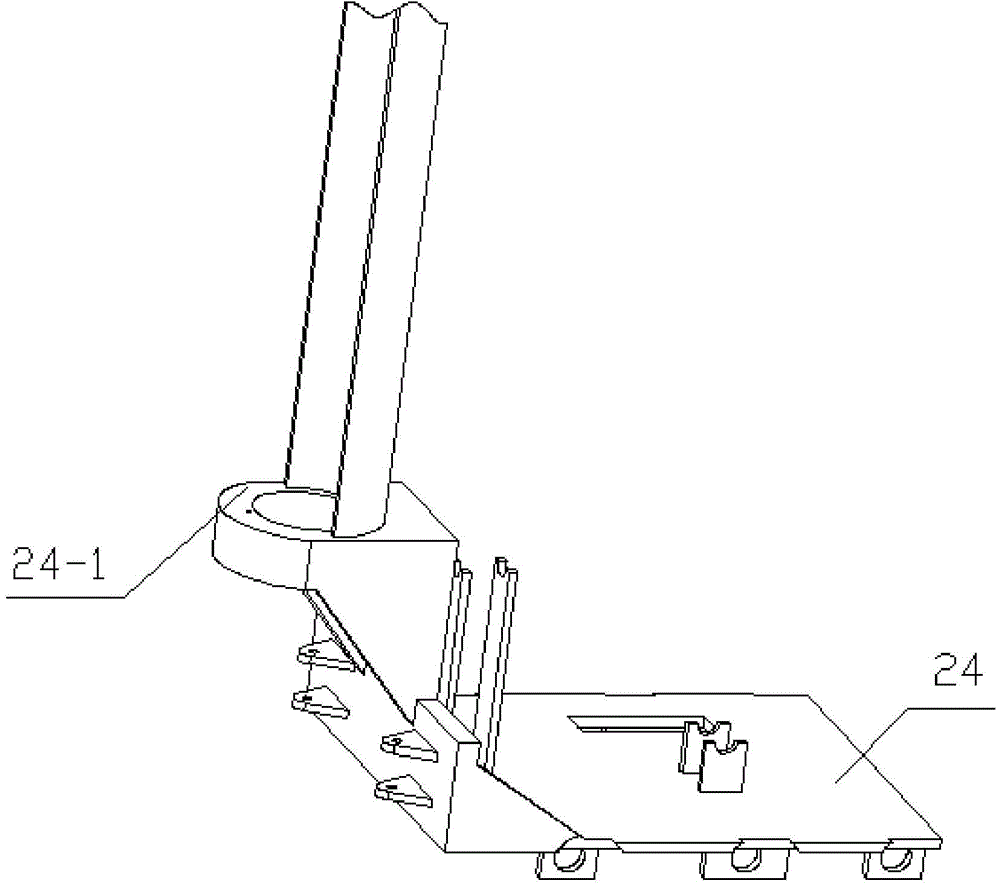

The invention provides a manual trolley for automatically and orderly setting up roadblocks. The manual trolley comprises a vehicle body, a placing system, a pushing system; the placing system and thepushing system are both installed on the vehicle body, and a plurality of groups of neatly stacked roadblock piles are stored in the vehicle body, the placing system is used for orderly placing the roadblock piles on the road surface, the pushing system is used for sensing the condition of placing the roadblock by the placing system and pushing the roadblock pile stored in the vehicle body to thearea where the placing system is located, the vehicle body comprises a vehicle frame; the front wheel member, the rear wheel member, the mounting plate and the mounting plate are horizontally arranged, and the mounting plate is fixedly mounted on the vehicle frame; a mounting hole penetrating through the thickness of the mounting plate is formed at the middle position of the mounting plate. The mounting hole is of a regular hexagonal structure matched with the barricade base; and any maximum diagonal line of the mounting hole is perpendicular to the advancing direction of the vehicle body.

Owner:南京幸庄科技创新产业园管理有限公司

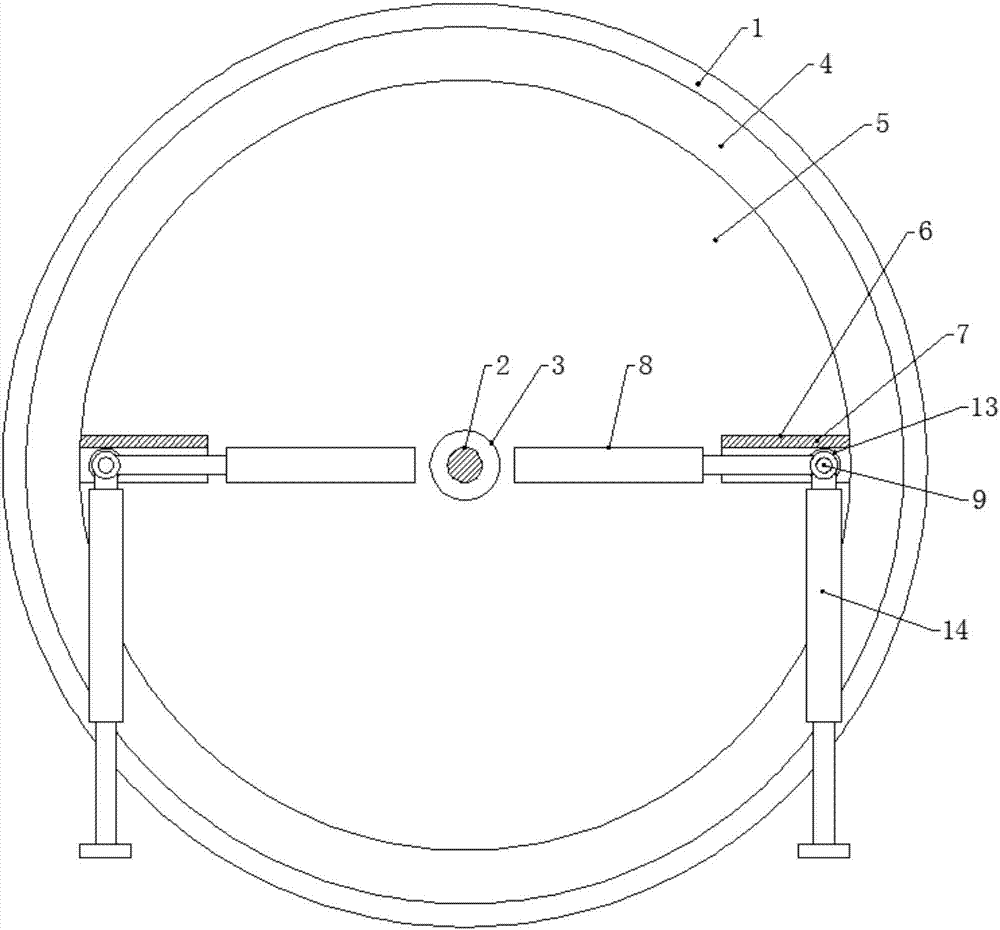

Living prawn growth phenotype detection equipment and method

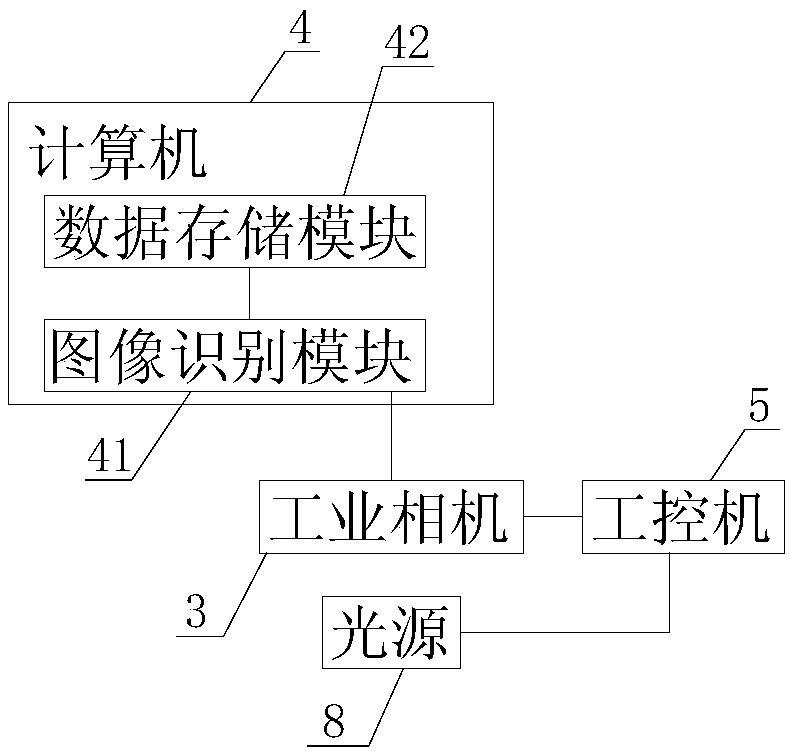

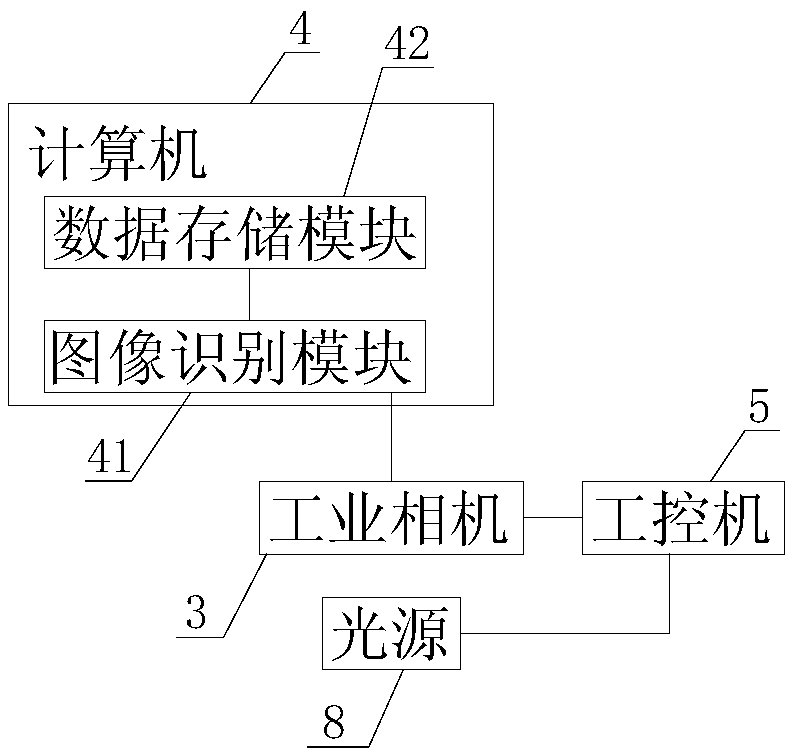

The invention relates to the technical field of living prawn measurement, and particularly discloses living prawn growth phenotype detection equipment and method. The equipment comprises a dark box, atransparent pipeline, industrial cameras, a computer, a light source and an industrial personal computer, wherein the dark box is provided with a waterproof function and a light shielding function; the transparent pipeline is used for placing to-be-detected prawns into water, the transparent pipeline penetrates through the dark box, and the two ends of the transparent pipeline penetrate out of the dark box and communicate with the outside; at least four industrial cameras are uniformly distributed on the periphery of the transparent pipeline and can be used for collecting prawn images in thetransparent pipeline, and the industrial cameras are connected to the dark box; the computer is connected to the industrial cameras, and the computer comprises an image recognition module and a data storage module which are connected to the industrial cameras; the light source is arranged in the dark box and is close to the transparent pipeline; and the industrial personal computer is connected tothe light source and the industrial cameras. According to the equipment and the method, the measurement accuracy can be improved, and the contact with the prawns can be reduced, so that the damage tothe prawns is reduced; and furthermore, the measuring speed is fast, and the efficiency is high.

Owner:杭州飞锐科技有限公司

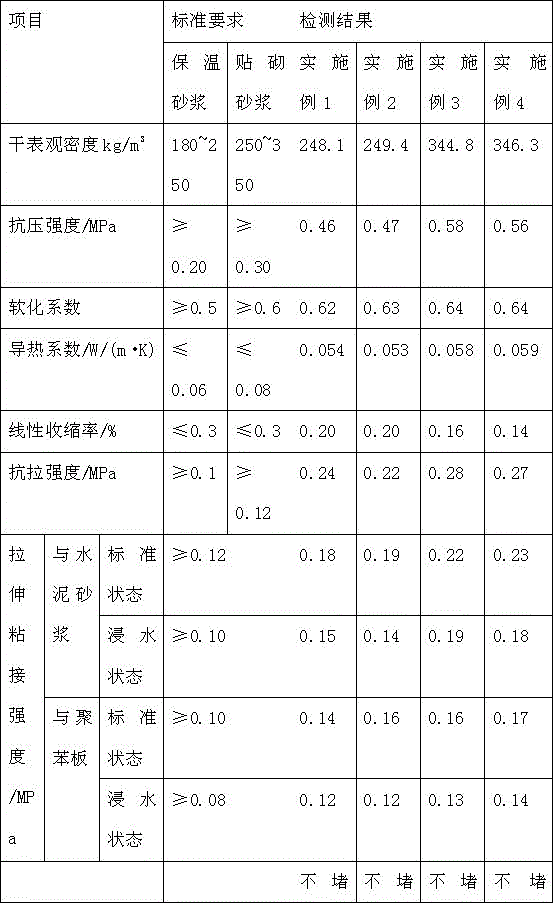

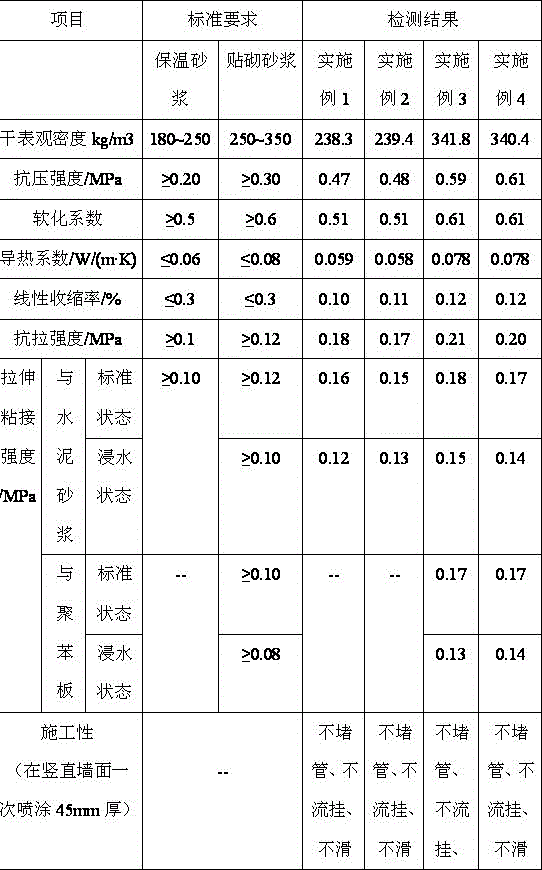

Fluorine-gypsum-based machine-spraying thermal insulation mortar and preparation method thereof

The invention discloses a fluorine-gypsum-based machine-spraying thermal insulation mortar and a preparation method thereof and relates to the field of composite thermal insulation material. The fluorine-gypsum-based machine-spraying thermal insulation mortar comprises, by weight, 65-80 parts of fluorine gypsum powder, 4-8 part of quick lime, 3-8 parts of cement, 10-20 parts of superfine slag powder, 0.5-2.5 parts of thixotropic lubricant, 0.7-2.2 parts of EPS particle, 0.4-1 part of redispersible latex powder, 0-0.5 part of water retaining agent, 0.2-0.6 part of starch, 0.5-1.5 parts of gypsum activator, 0.1-0.5 part of polyvinyl alcohol and 35-55 parts of water. The fluorine-gypsum-based machine-spraying thermal insulation mortar is simple to prepare, good in thermal insulation performance, environmentally friendly, energy-saving, applicable to machine spraying and capable of saving cost.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

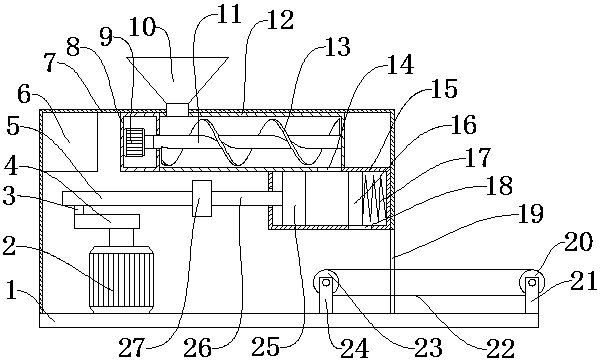

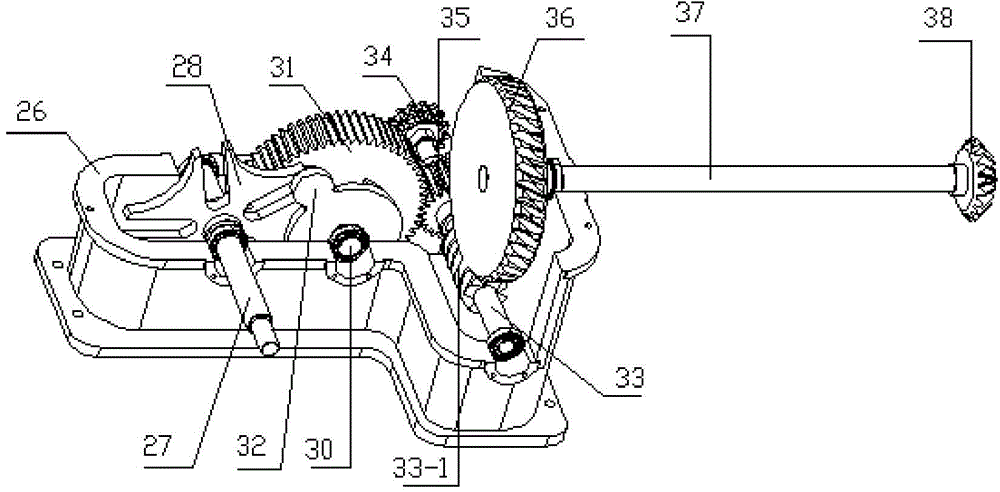

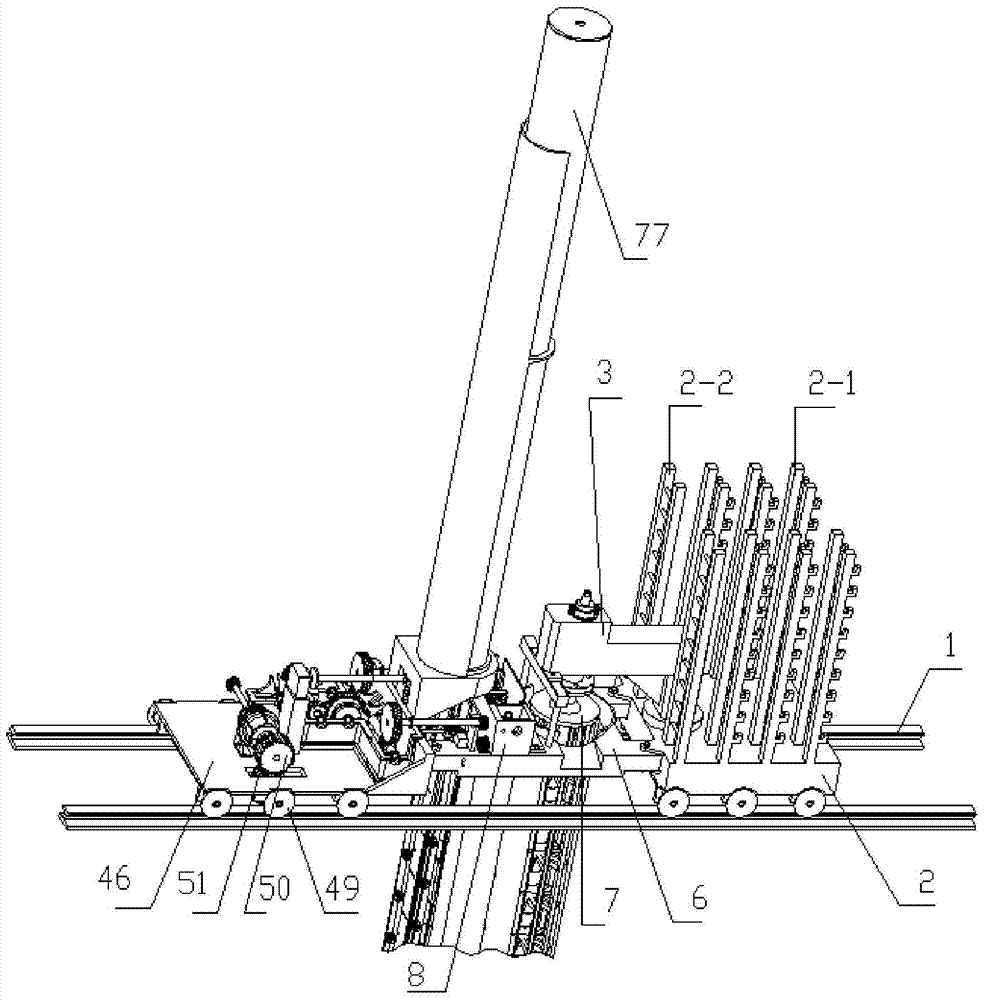

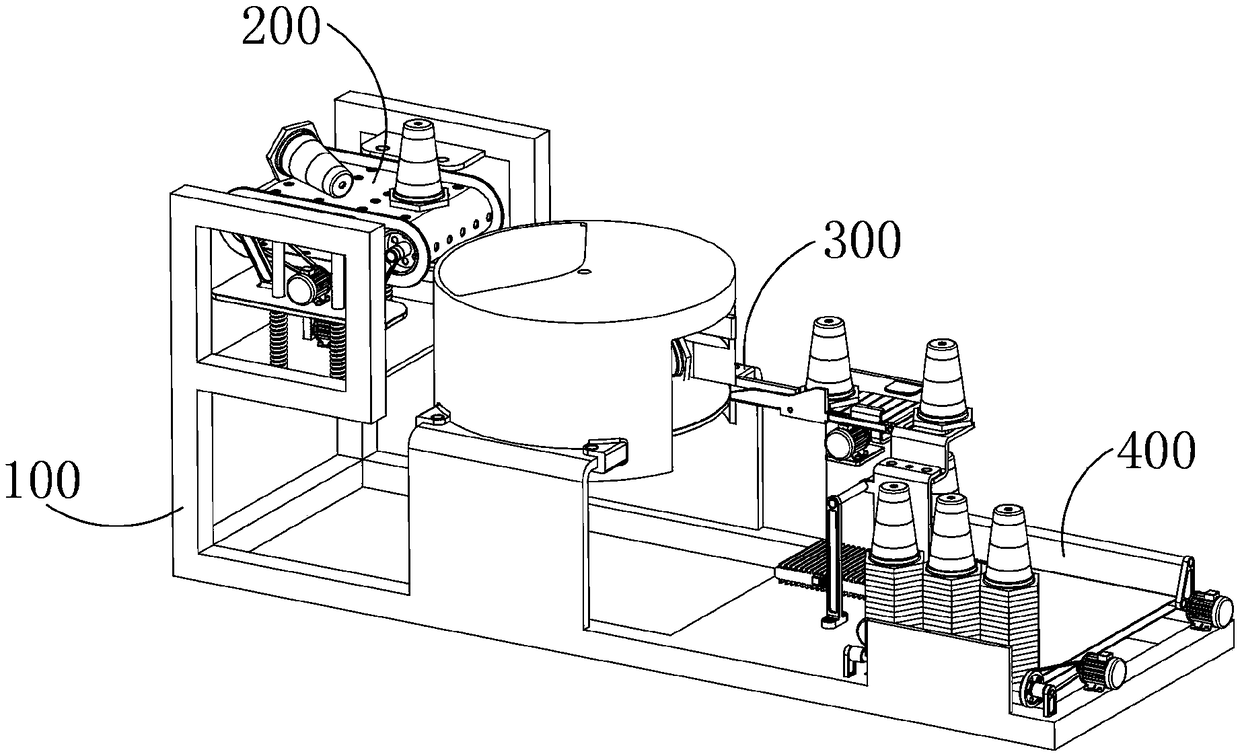

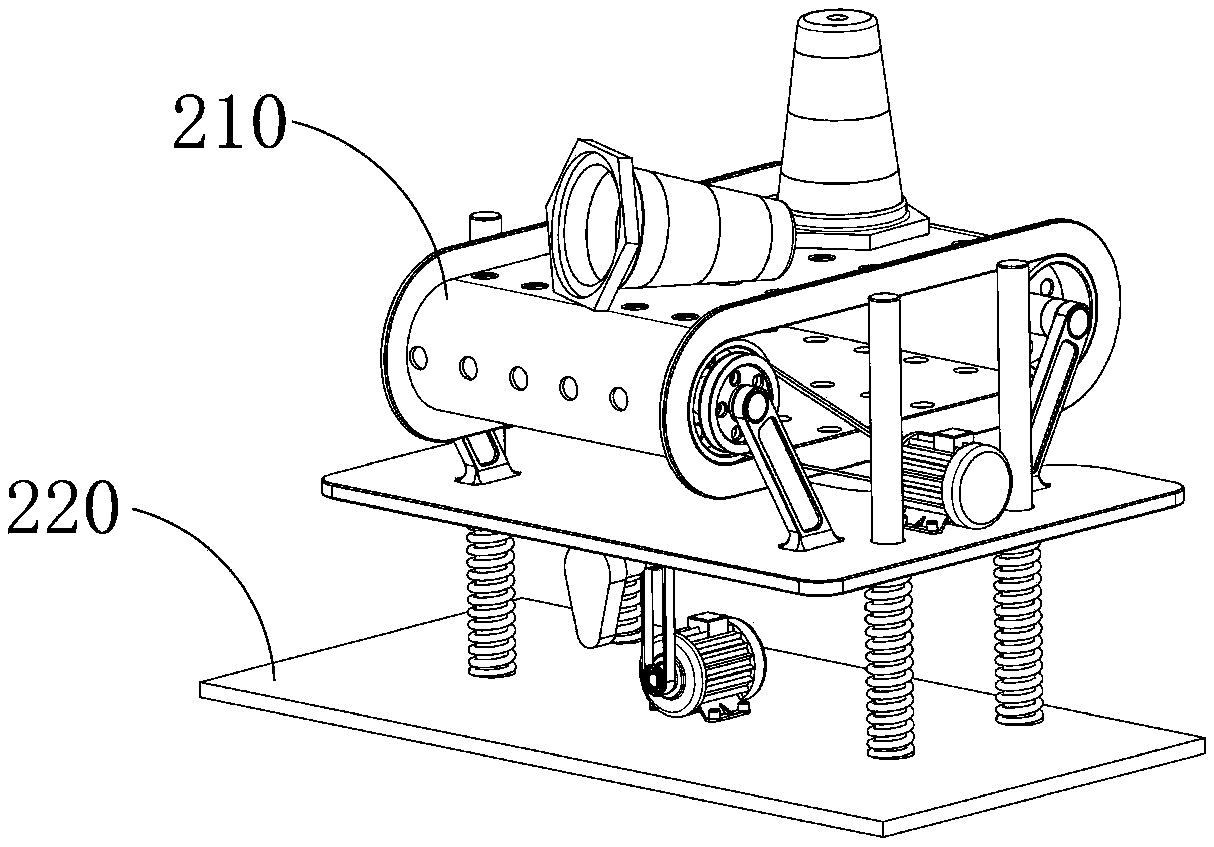

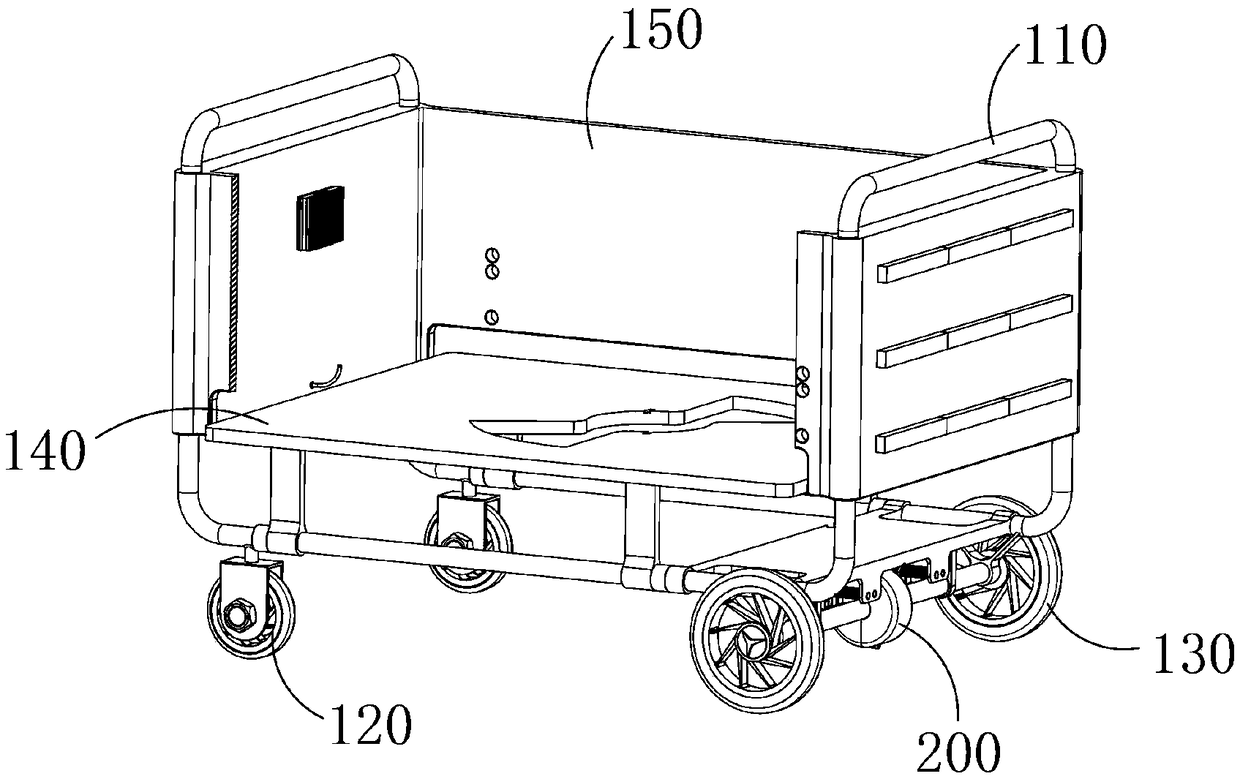

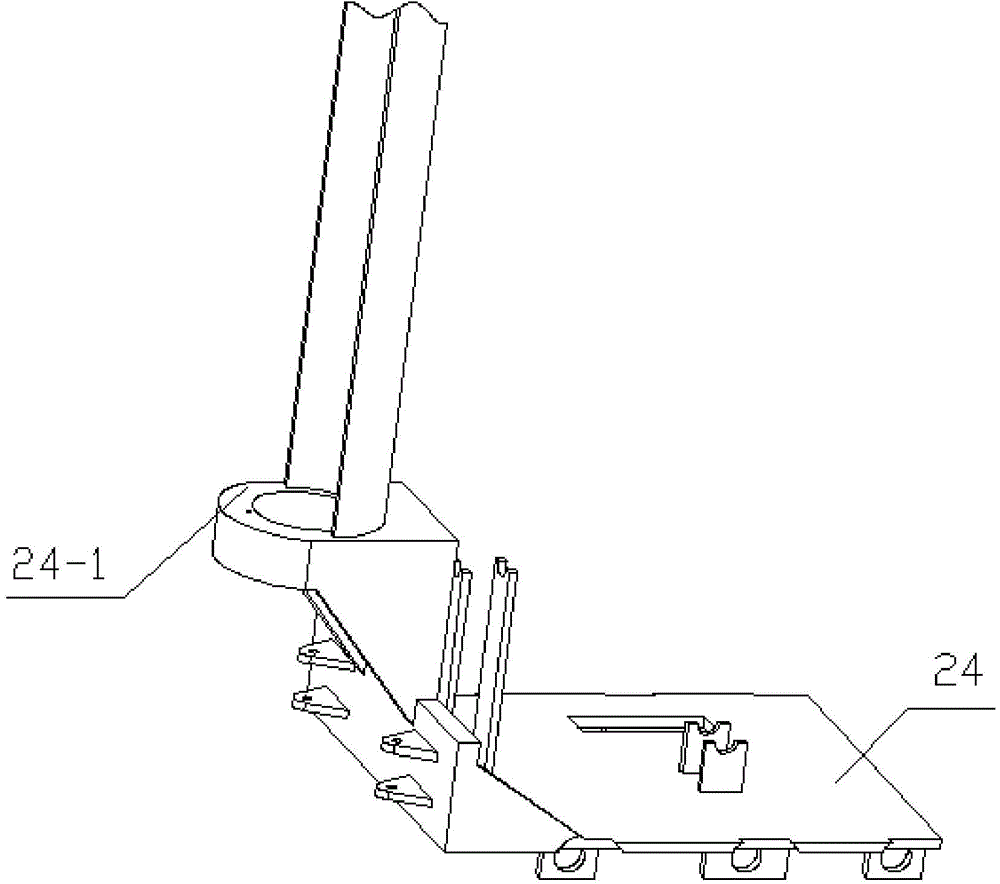

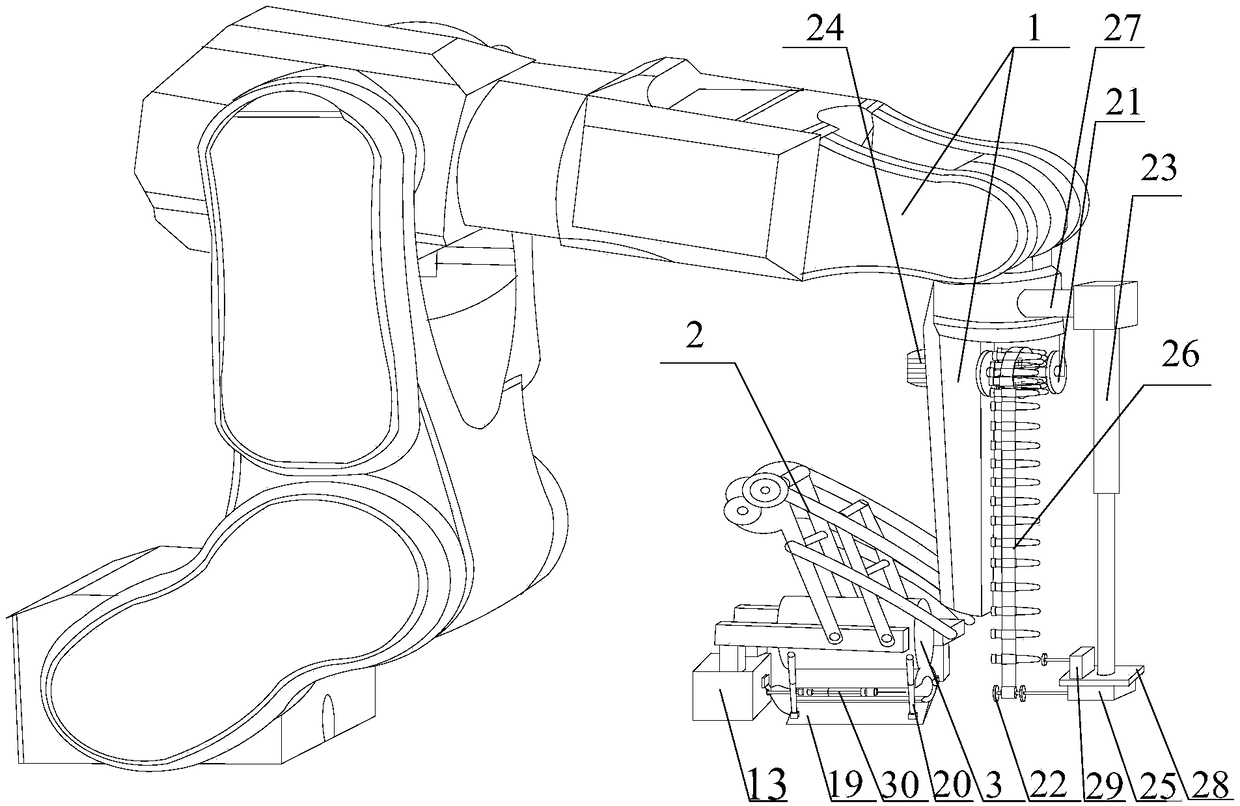

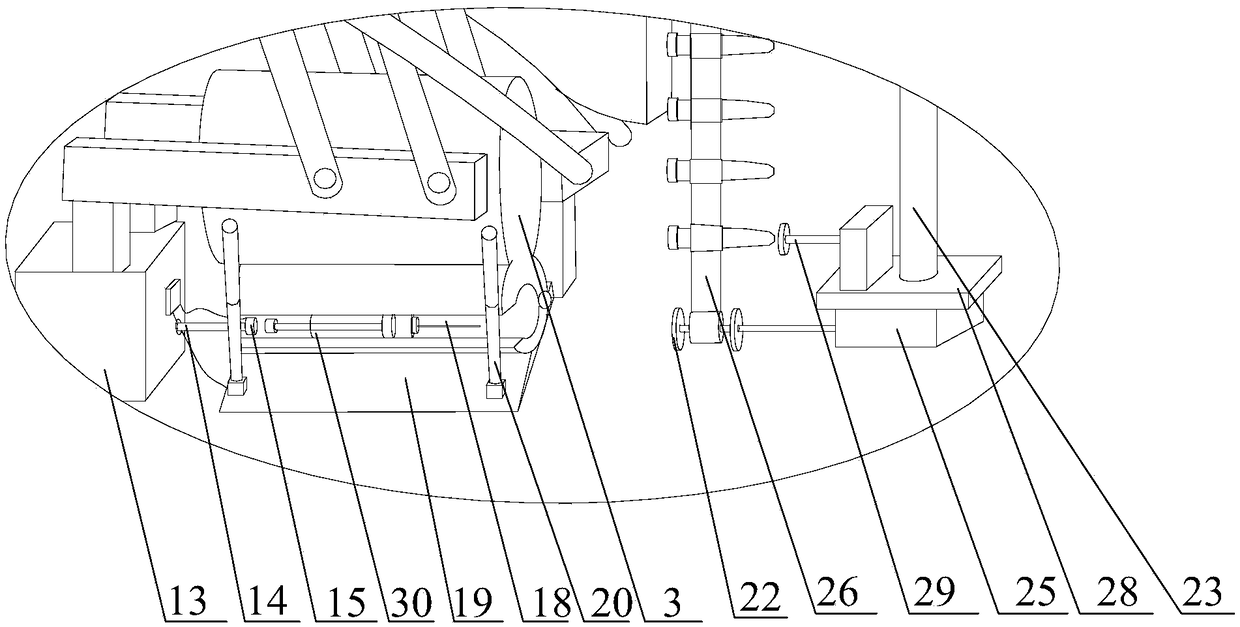

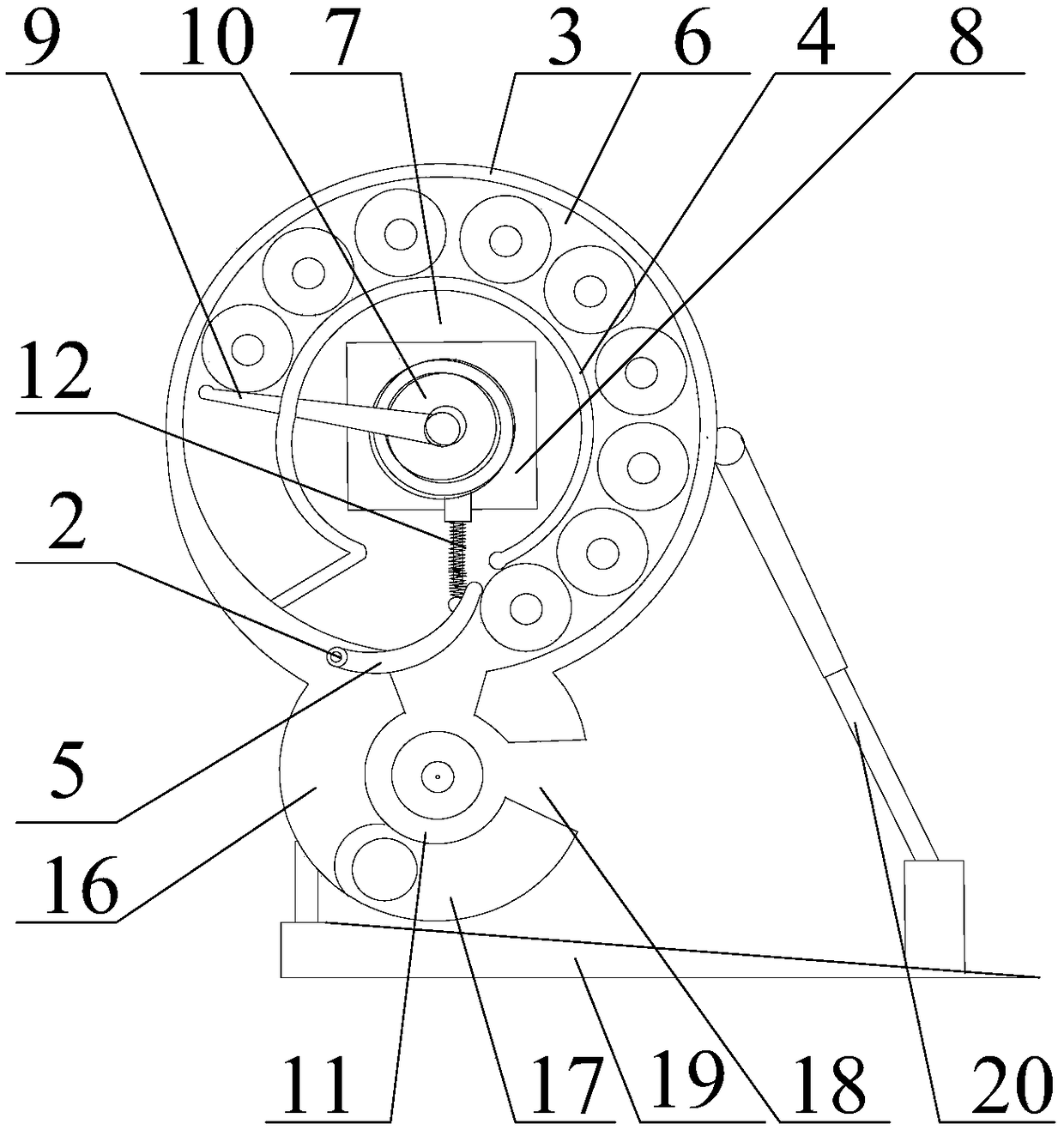

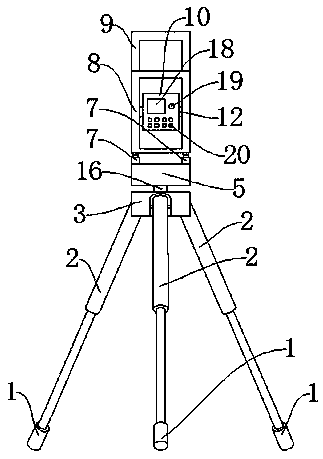

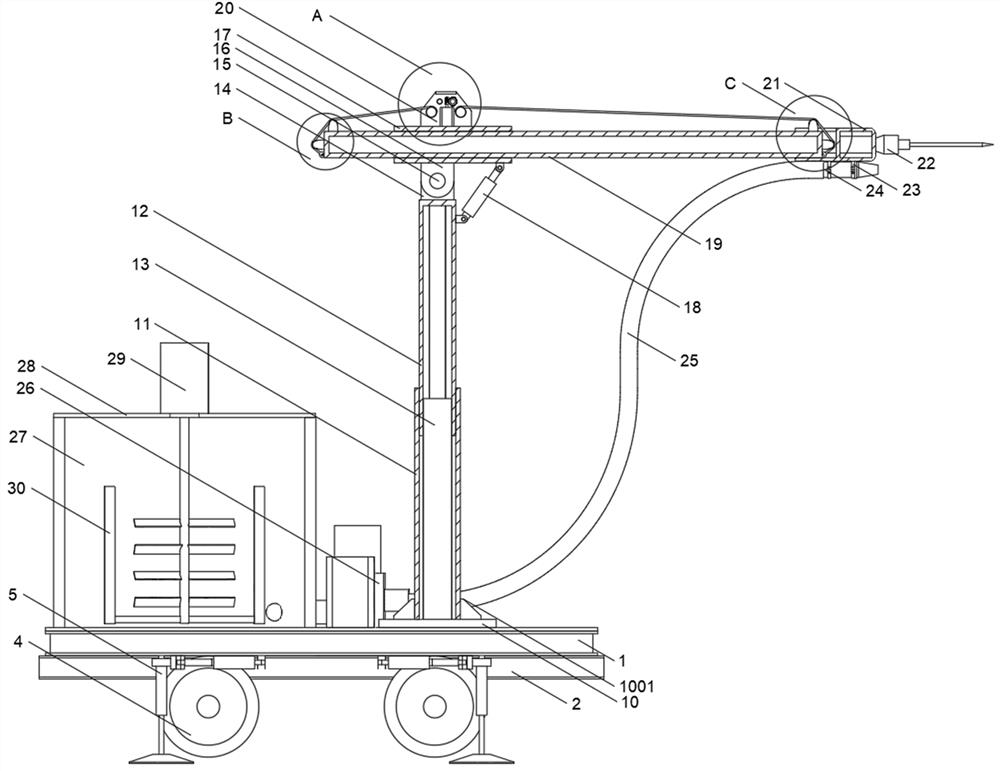

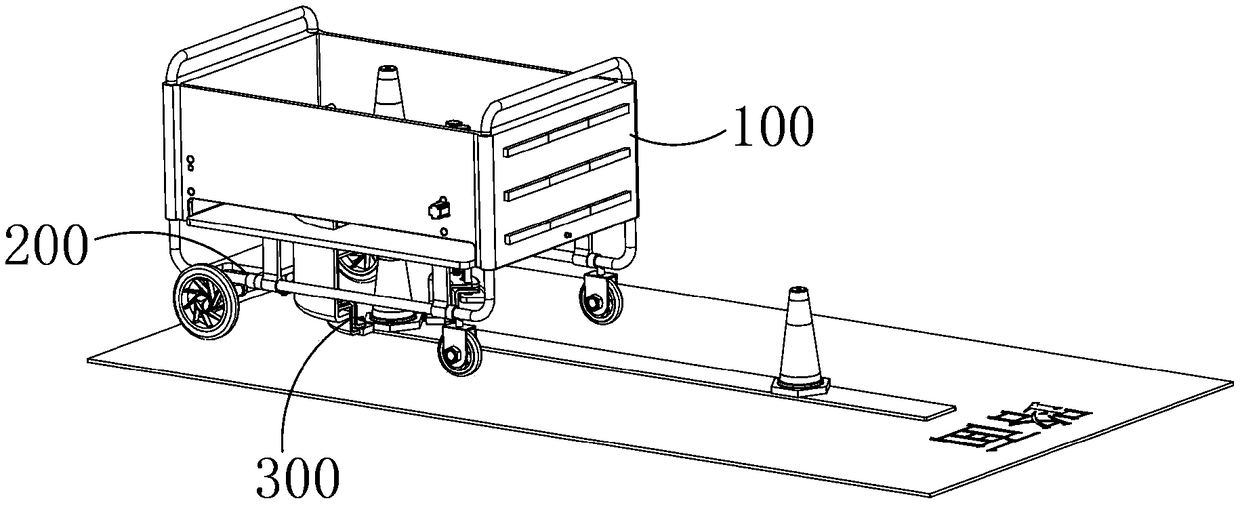

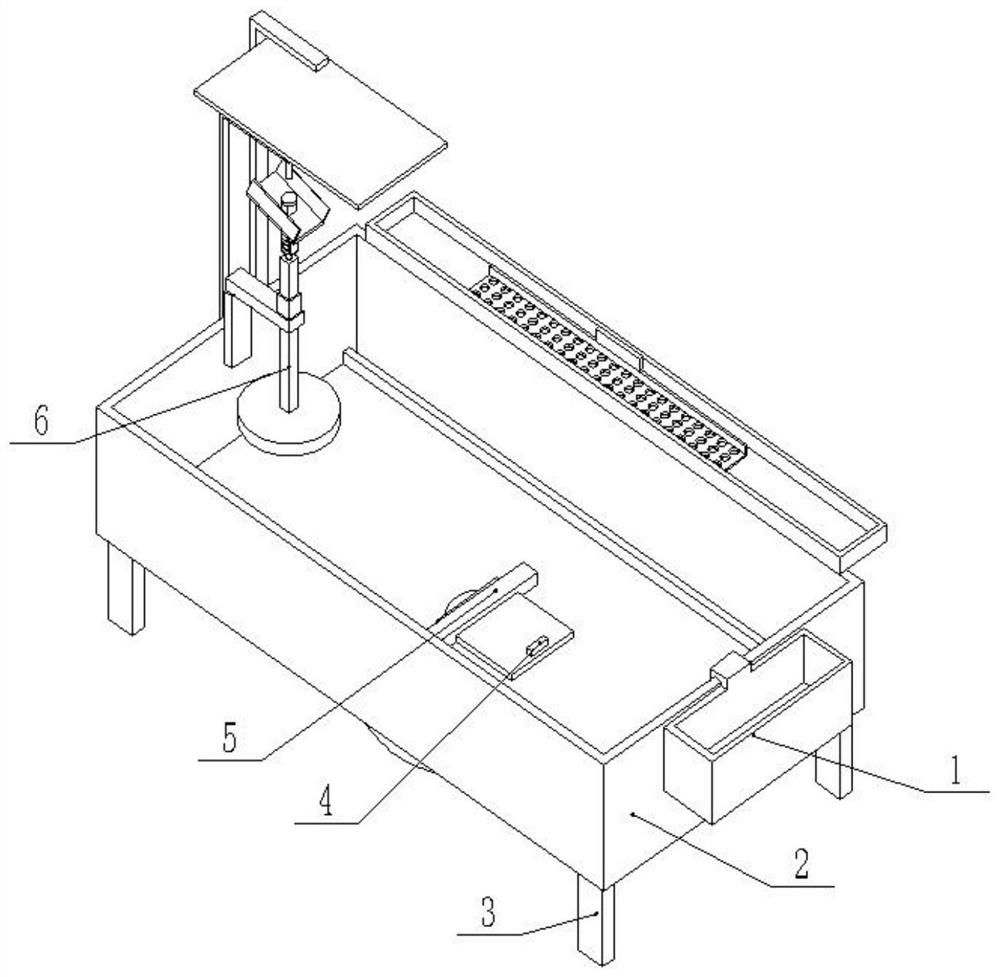

Roadblock placement vehicle for rapid roadblock erection

InactiveCN109183659ANo action requiredShorten the timeTraffic signalsRoad signsRoad surfaceAutomotive engineering

The present invention provides a roadblock placement vehicle for rapid roadblock erection, including a vehicle body, a placement system, and a push system, wherein the placement system and the pushingsystem are both installed on the vehicle body, and a plurality of groups of neatly stacked roadblock piles are stored in the vehicle body, the placement system is used for orderly placing the roadblock piles on the road surface, the pushing system is used for sensing the condition of placing the roadblock by the placing system and pushing the roadblock pile stored in the vehicle body to the areawhere the placing system is located, The roadblock is composed of a base with a regular hexagonal structure and a cone part with a conical structure located above the base. The roadblock piles storedin the vehicle body are provided with four groups, one of which is located in a placement system and the other three groups are stored in a pushing system.

Owner:张习先

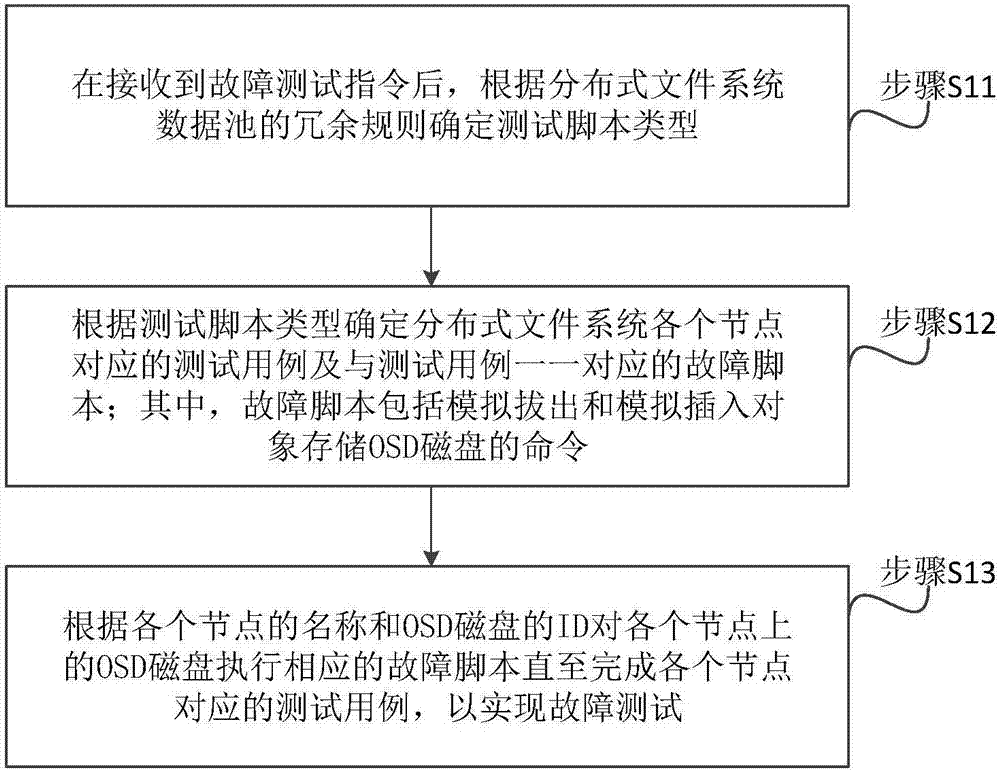

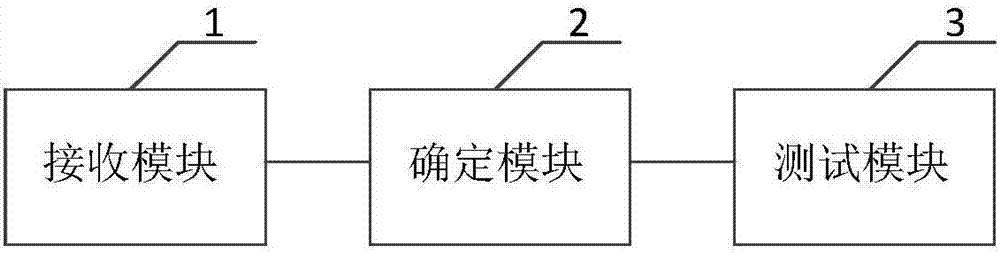

OSD (object-based storage device) disk fault testing method and OSD disk fault testing system

ActiveCN107391333AReduce the amount of human laborShorten the test cycleFaulty hardware testing methodsData switching networksDistributed File SystemObject based

The invention provides an OSD (object-based storage device) disk fault testing method applied to a distributed file system. The OSD disk fault testing method includes: after receiving a fault testing order, determining a testing script type according to a redundancy rule of a data pool of the distributed file system; according to the testing script type, determining test cases respectively corresponding to nodes in the distribute file system and fault scripts in one-to-one correspondence with the test cases, wherein the fault scripts include orders for simulative plugging-out and simulative insertion of OSD disks; according to names of the nodes and IDs (identifications) of the OSD disks, realizing fault testing by executing corresponding fault scripts on the OSD disk on every node until all the test cases corresponding to the nodes are used completely. The OSD disk fault testing method has the remarkable advantages that the amount of labor is decreased, testing efficiency is improved, and cover degree and accuracy of are increased. The invention further provides an OSD disk fault testing system having the same advantages.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Full-automatic seal stamping machine

The invention discloses a full-automatic seal stamping machine and belongs to the technical field of office equipment. The machine comprises a working table, a controller, a connector and a piston body, wherein an air cylinder 1 and a revolving motor are disposed in parallel along one rectangle edge on the working table; a lifting arm is disposed on the air cylinder 1; a lifting rod which faces downwards is firmly disposed under the lifting arm; a seal is firmly installed on the bottom of the lifting rod; a revolving arm is disposed on the revolving motor; an installation box is fixed under a positioning body; a slide-wedge slide hole is formed in the middle of the piston body; a piston ball is disposed on the lower part of the piston rod; the outer side of the piston body is sleeved by a fixation sleeve; and an opened suction disk is also fixed on the inner side of the fixation sleeve. According to the invention, the automation degree is high; practicability is high; the problem that efficiency of existing seal stamping work is low can be solved; a lot of time are saved in daily office work, and manpower labor is reduced; and the full-automatic seal stamping machine is highly practical.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Environment-friendly garden irrigation device

InactiveCN108901768AAvoid enteringSave resourcesGeneral water supply conservationWatering devicesVegetationEngineering

The invention provides an environment-friendly garden irrigation device and relates to the technical field of gardening equipment. The environment-friendly garden irrigation device comprises a bottomplate, wherein a rotating motor is fixedly mounted at the top of the bottom plate, a rotating column is fixedly mounted at the top of the rotating motor, a circular mounting plate is fixedly mounted at the top of the rotating column, two annular sliding grooves are formed in the top of the bottom plate, and annular sliding blocks are separately arranged inside the two annular sliding grooves. According to the environment-friendly garden irrigation device, through the matching of a water collecting port, a water collection tank, a separation screen, a first filter screen and an activated-charcoal purification plate, in a raining period, rainwater is collected through the water collecting port and flows in the water collection tank through the separation screen, and influent rainwater is firstly filtered through the first filter screen and then enters the internal bottom of the water collection tank through the activated-charcoal purification plate; and the device can be used for irrigating plant covers by using treated rainwater or light-polluted water, and thus, resources of tap water are effectively saved.

Owner:宿迁市众创空间科技有限公司

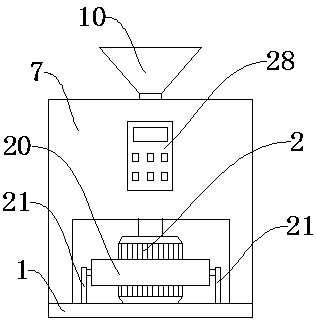

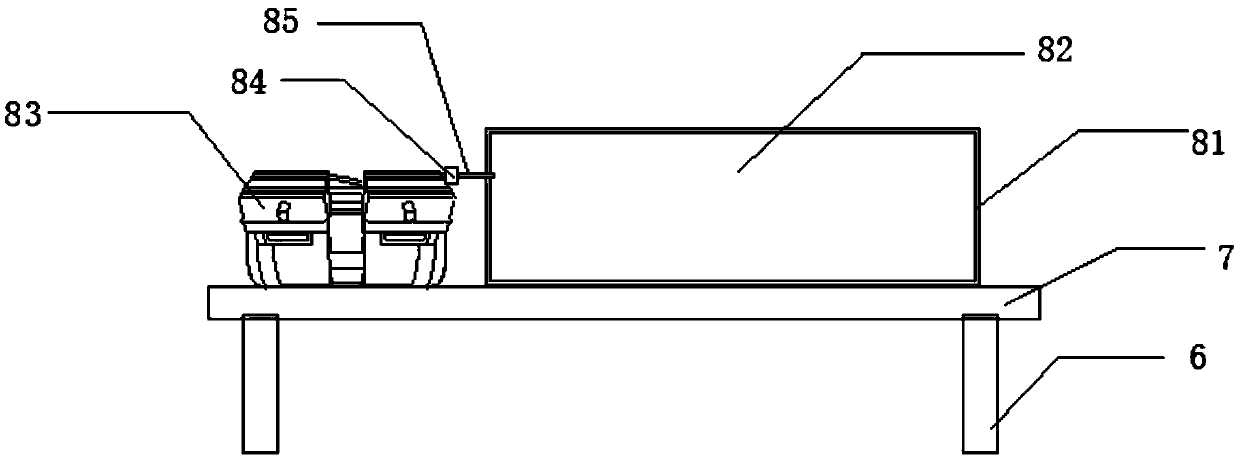

Forage grass baling machine used for animal husbandry and capable of achieving efficient and automatic feeding

The invention discloses a forage grass baling machine used for animal husbandry and capable of achieving efficient and automatic feeding. The forage grass baling machine comprises a bottom plate, a tank and a feeding funnel and is characterized in that the tank is fixedly mounted on the upper surface of the bottom plate, a storage battery is fixedly mounted on one side of the top end inside the tank, a support tank is fixedly mounted on one side, away from the storage battery, of the top end inside the tank, a feeding motor is arranged inside the support tank, a feeding tank is arranged on oneside, away from the storage battery, of the support tank, a feeding rod is horizontally arranged inside the feeding tank, one end, extending into the support tank, of the feeding rod is fixedly connected with the feeding motor, and a spiral blade is fixedly mounted on the feeding rod. The forage grass baling machine has the advantages that a cam is driven by a drive motor to push a compressing block to perform continuous compressing; the feeding motor drives the spiral blade to replace manual feeding; the compressed forage grass is directly discharged by the aid of a drive roller, a driven roller and a conveying belt, so that manpower workload is reduced.

Owner:黄絜青

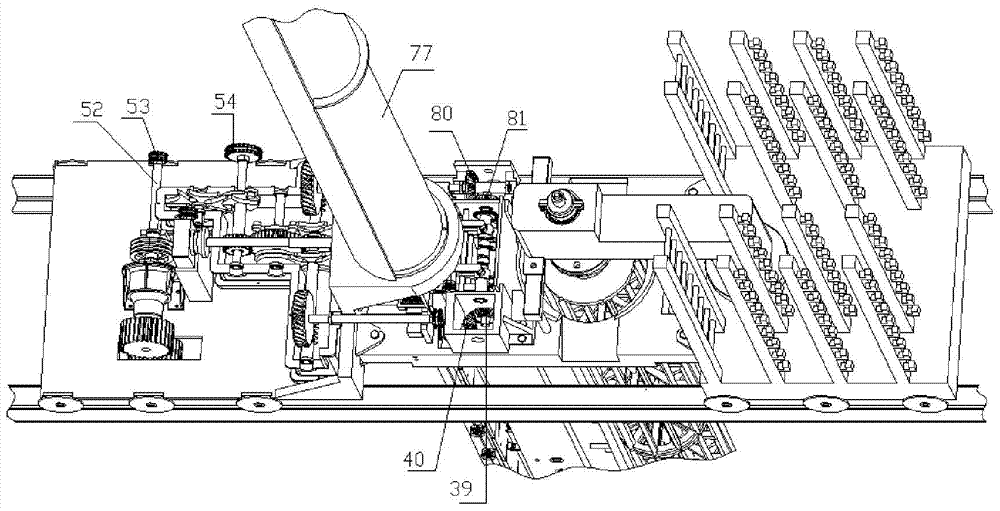

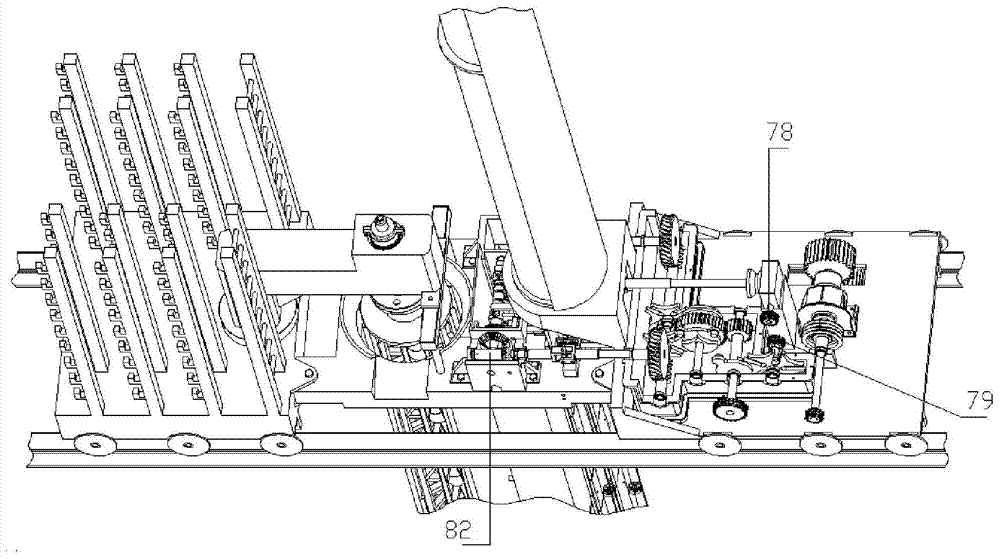

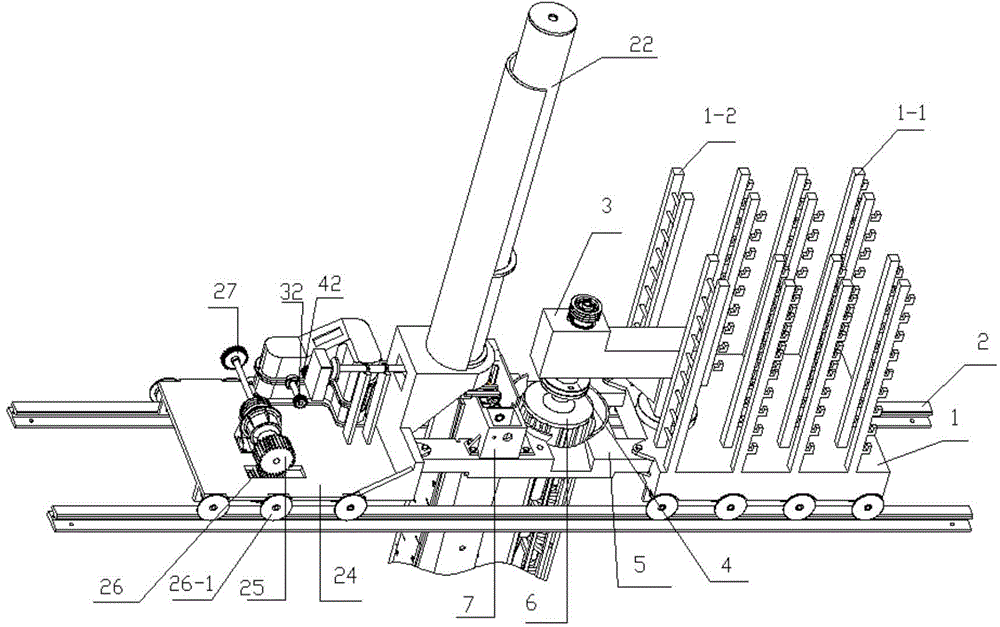

Underground continuous wall reinforcing mesh interweaving machine

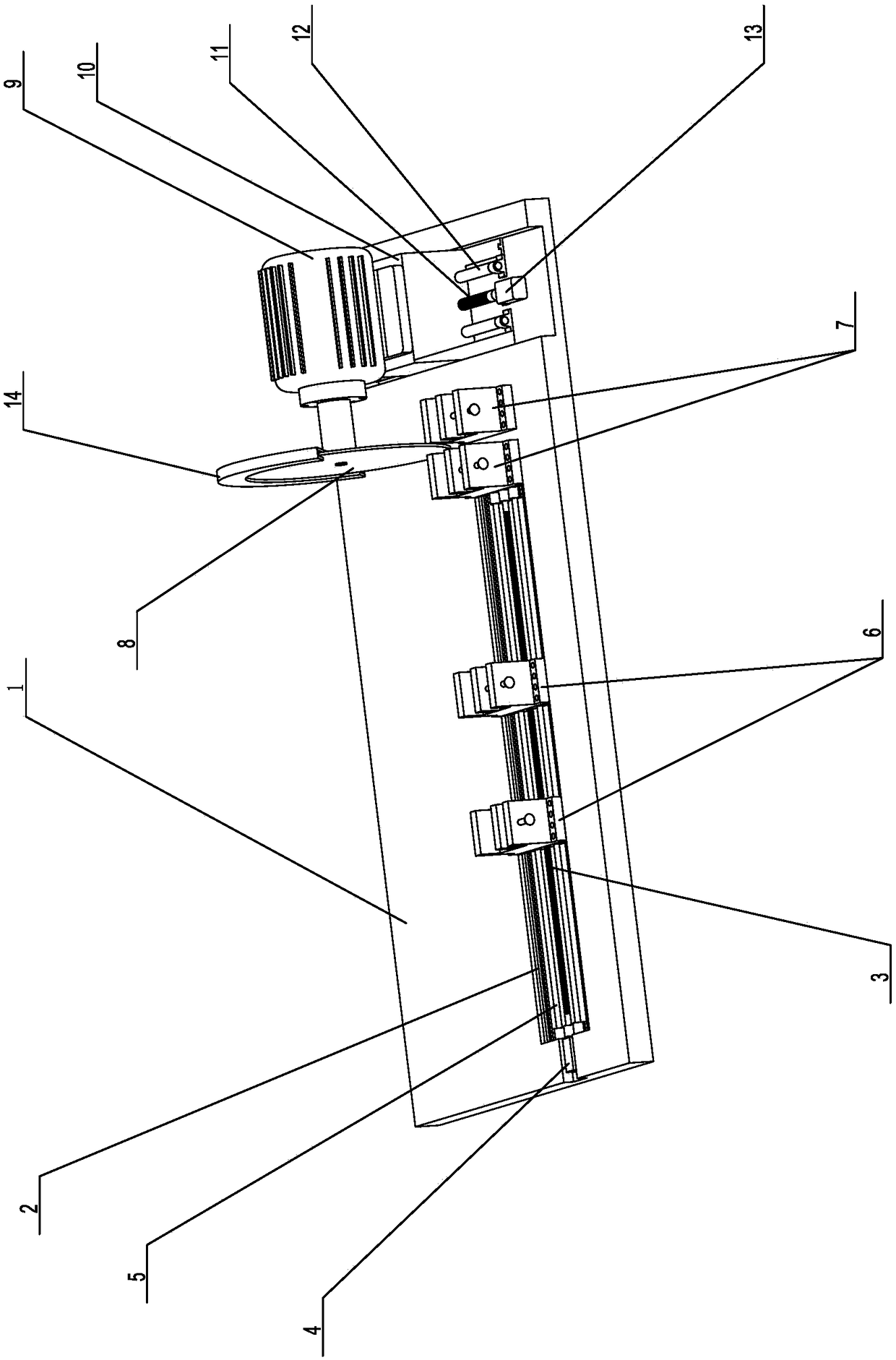

ActiveCN104353765AImprove efficiencyReduce the amount of human laborWire networkSlurry wallTransmitted power

The invention discloses an underground continuous wall reinforcing mesh interweaving machine. In an existing underground continuous wall, a reinforcing steel cage is vertically placed in a guide wall slot by using a crane generally, and the reinforcing steel cage is difficult to hoist and put into the guide wall slot due to large size. According to the underground continuous wall reinforcing mesh interweaving machine, a longitudinal reinforcing steel conveying mechanism is fixed with a driving carriage; an intermittent transmission mechanism is fixed with the driving carriage; two ends of an intermediate support frame are respectively fixed with the driving carriage and a driven carriage; a transverse reinforcing steel rope interweaving mechanism is fixed with the intermediate support frame; a drive mechanism drives the driving carriage and the intermittent transmission mechanism; the intermittent transmission mechanism respectively transmits power to the transverse reinforcing steel rope interweaving mechanism and a longitudinal reinforcing steel conveying mechanism; the transverse reinforcing steel rope interweaving mechanism is used for interweaving reinforcing steel ropes, provided by a transverse reinforcing steel rope storage rack, to and fro; the longitudinal reinforcing steel conveying mechanism is used for enabling reinforcing steel to drop into the reinforcing steel ropes interwoven by the transverse reinforcing steel rope interweaving mechanism to form a reinforcing mesh. According to the underground continuous wall reinforcing mesh interweaving machine, the reinforcing mesh can be automatically woven into an underground continuous wall guide wall slot, and further an underground continuous wall can be fast built.

Owner:GEOTECHN TECH

Method for quickly erecting roadblock onto road surface

ActiveCN109183660ANo action requiredShorten the timeTraffic signalsRoad signsRoad surfaceEngineering

The invention discloses a method for quickly erecting a roadblock onto the road surface, which comprises the following steps: a vehicle body is advanced and a roadblock pile stored in the vehicle bodyis set on the road surface through a placement system; the sensing device in the pushing system senses the state of the roadblock piles stored in the placing system; after the roadblock in the placement system is completely placed on the road surface, the first pushing device pushes the roadblock stack in the roadblock into the placement system; when the roadblock stack pushed into the placementsystem by the first pushing device is completely dropped onto the road surface, the second pushing device pushes the roadblock stack into the placement system. when the roadblock stack pushed into theplacement system by the second pushing device is completely dropped onto the road surface, the third pushing device pushes the roadblock stack into the placement system, and when the roadblock stackis completely dropped onto the road surface, the third pushing device pushes the roadblock stack into the placement system. Staff re-stacked four new roadblocks inside the vehicle.

Owner:长泰鑫顺泰实业发展有限公司

Tin rinsing device for wire connector

The invention provides a tin rinsing device for wire connector, which belongs to the technical field of tin rinsing devices. The device of the invention comprises a shell. The bottom of the shell is provided with a controller and a mobile power supply respectively. The left side and the right side at the top of the shell are provided with a skin removing mouth cover and a tin rinsing mouth respectively. The lower part of the skin removing mouth cover faces right a cylindrical rotation sleeve. The inner wall of the rotation sleeve is fixedly provided with six fulcrum bodies distributed in uniform manner. The lower part of the tin rinsing mouth corresponding to one side at the bottom of a separation cavity is provided with a cylinder (2). The cylinder (2) is connected with a support body. The top of the support body is provided with a cylinder (3). The cylinder (3) is connected with a fixed plate. The left side and the right side of the fixed plate are fixedly provided with a solution tank and a tin solution tank respectively. The circumference of the tin solution tank and the bottom are provided with heat isolation plates. The bottom of the tin solution tank is further provided with an electric heating plate. The tin rinsing device of the invention is highly automatic and practical in use. With the device, the problem can be resolved that in the prior art, tin rinsing efficiency for the wire connector is low. In the working process, time can be saved; labor intensity can be reduced; these advantages made the device a very good one with strong practicability in use.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Intelligent express bag labeling, sealing and packaging integrated packaging machine

PendingCN111703639AAvoid tensionPrevent disengagementWrapper twisting/gatheringLabelling machinesPackaging machineEngineering

The invention discloses an intelligent express bag labeling, sealing and packaging integrated packaging machine. The intelligent express bag labeling, sealing and packaging integrated packaging machine includes a supporting assembly, a bag placing assembly, a traction assembly, a labeling assembly and a sealing assembly. The bag placing assembly is installed on the side of the supporting assembly.The traction assembly is installed on the side of the supporting assembly, the labeling assembly is installed on the side of the supporting assembly, and the sealing assembly is installed on the sideof the supporting assembly. According to the intelligent express bag labeling, sealing and packaging integrated packaging machine, a packaging bag is guided to the sealing position through the cooperation of the bag placing assembly and the traction assembly. Meanwhile, in the guiding process, label paper enters the traction assembly part at the same time, and the labeling assembly is heated to achieve labeling; then the sealing assembly is used for completing the packaging, and the overall integration is higher, the amount of manpower and labor is effectively reduced, the efficiency of packaging is improved, and the possibility of errors is reduced.

Owner:浙江立玛科技有限公司

Polymer fluorogypsum-based machine-spray thermal insulation mortar and preparation method thereof

ActiveCN105948678AHigh strengthImprove water resistanceThermal insulationHydroxypropylmethyl cellulose

The invention discloses a polymer fluorogypsum-based machine-spray thermal insulation mortar and a preparation method thereof. The invention relates to the field of composite thermal insulation materials. The polymer fluorogypsum-based machine-spray thermal insulation mortar comprises the following components, by weight: 60-75 parts of fluorogypsum powder, 4-8 parts of quicklime, 5-12 parts of cement, 15-25 parts of fly ash, 1.0-3.5 parts of instant sodium silicate powder, 0.4-1 part of redispersible latex powder, 0.2-0.6 parts of hydroxypropyl methylcellulose, 0.4-0.9 parts of alpha-starch, 0.7-2.2 parts of EPS granules, and 35-60 parts of water. The mortar can be applied by machine spray, such that construction is fast, labor amount is saved, and cost is saved. With continuous seamless construction, a wall body is full, and a common hollow feeling of a light steel composite wall body is avoided. Wall body stability is good, and problems such as cracking and hollowing of traditional construction materials are solved.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

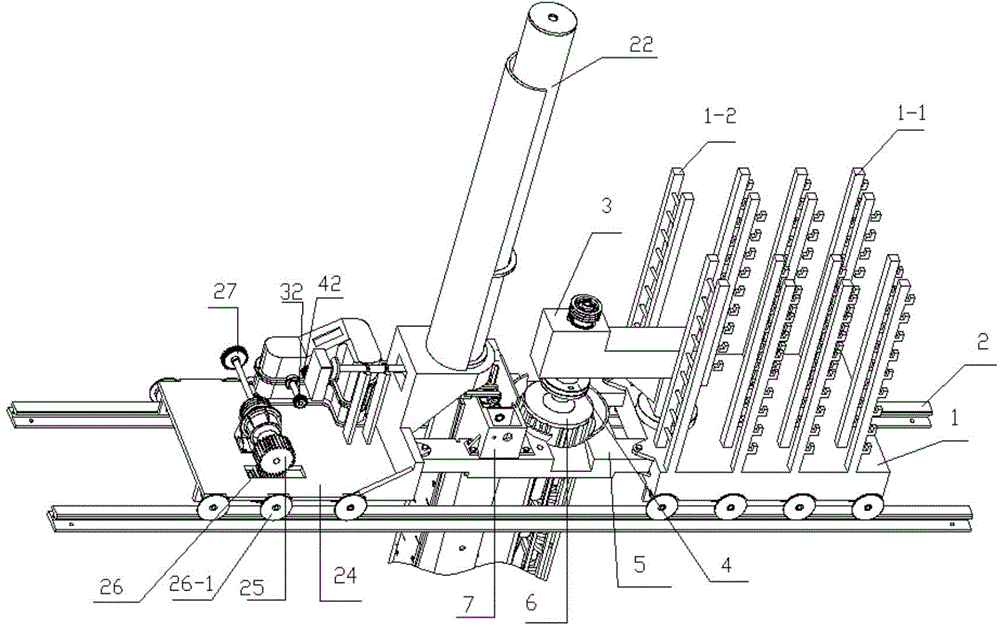

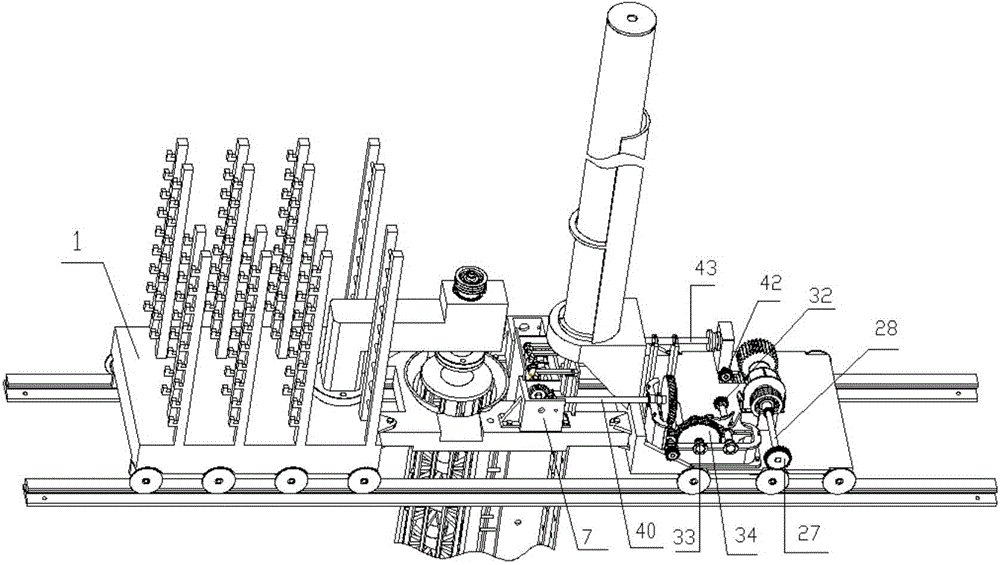

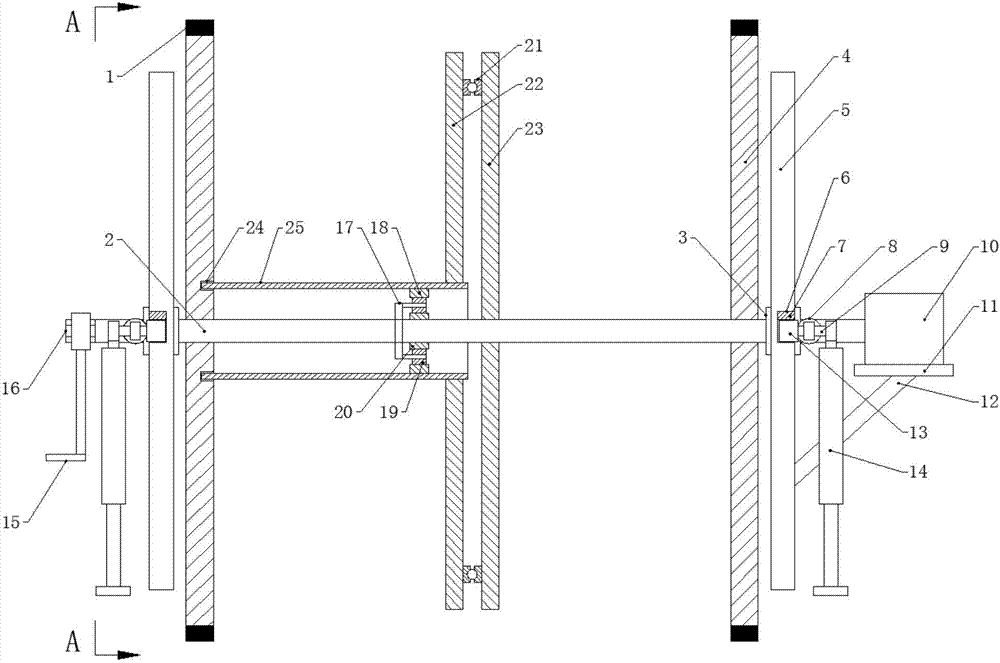

Fully automatic underground reinforcement mesh interweaving machine

ActiveCN104325050AImprove efficiencyQuick buildWire networkSoil-shifting machines/dredgersSlurry wallRebar

The invention discloses a fully automatic underground reinforcement mesh interweaving machine. For an existing underground continuous wall, a reinforcement cage is normally placed in a guide wall groove by using a crane, but the hoisting and the placement of the reinforcement cage into the guide wall groove are difficult; at present, no machine which combines an underground automatic groove digging function and a reinforcement mesh weaving function is available. A driving mechanism is used for driving an active carriage, an intermittent drive transmission and a groove milling mechanism; the intermittent driving mechanism is used for driving a transverse reinforcement rope interweaving mechanism and a longitudinal reinforcement conveying mechanism; the groove milling mechanism is used for digging out a guide wall groove of the continuous wall; the transverse reinforcement rope interweaving mechanism is used for reciprocally interweaving a reinforcement rope provided by a transverse reinforcement rope storage frame in the guide wall groove of the continuous wall; the longitudinal reinforcement conveying mechanism intermittently falls reinforcements; the driving mechanism is used for driving two longitudinal reinforcement connecting mechanisms to roll the reinforcements; the fixed reinforcements fall into the interwoven reinforcement rope along the longitudinal reinforcement guide mechanism to weave the reinforcement mesh. The guide wall groove of the continuous wall can be automatically dug underground, the reinforcement mesh can be automatically woven in the guide wall groove, and the underground continuous wall is quickly established.

Owner:GEOTECHN TECH

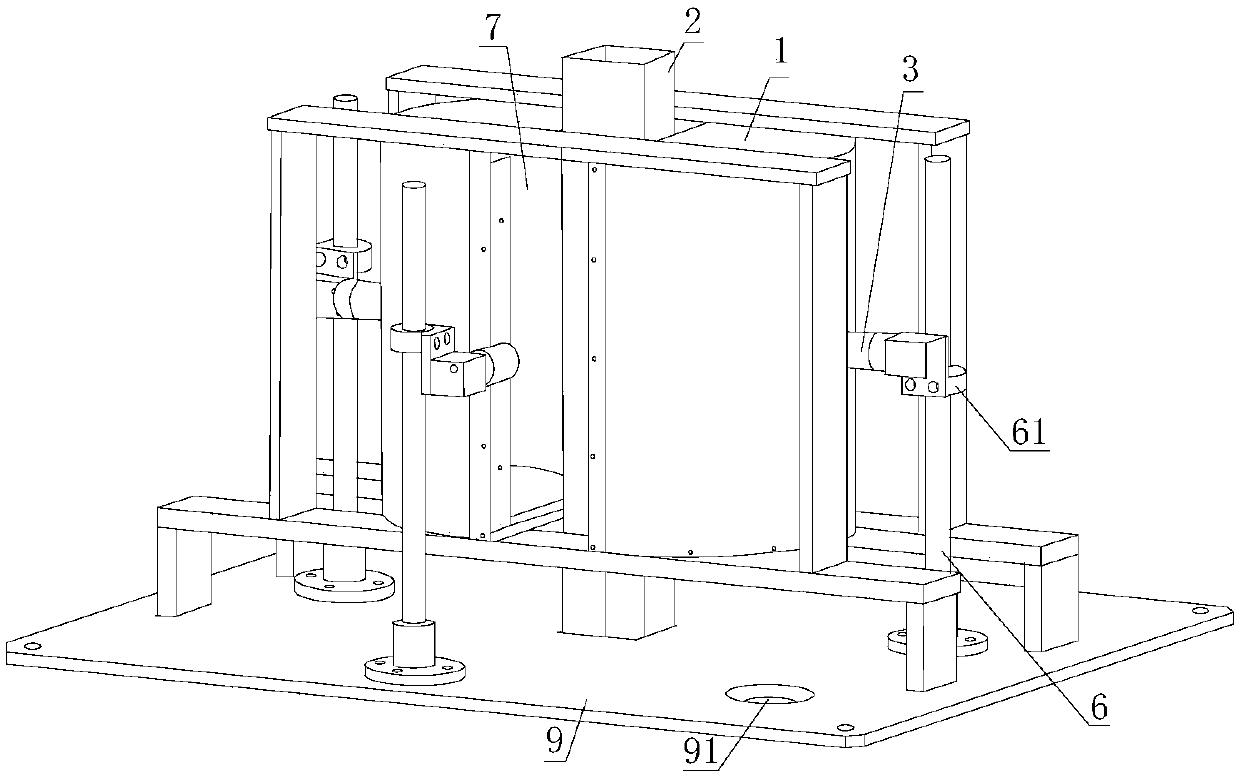

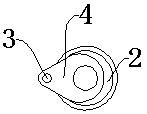

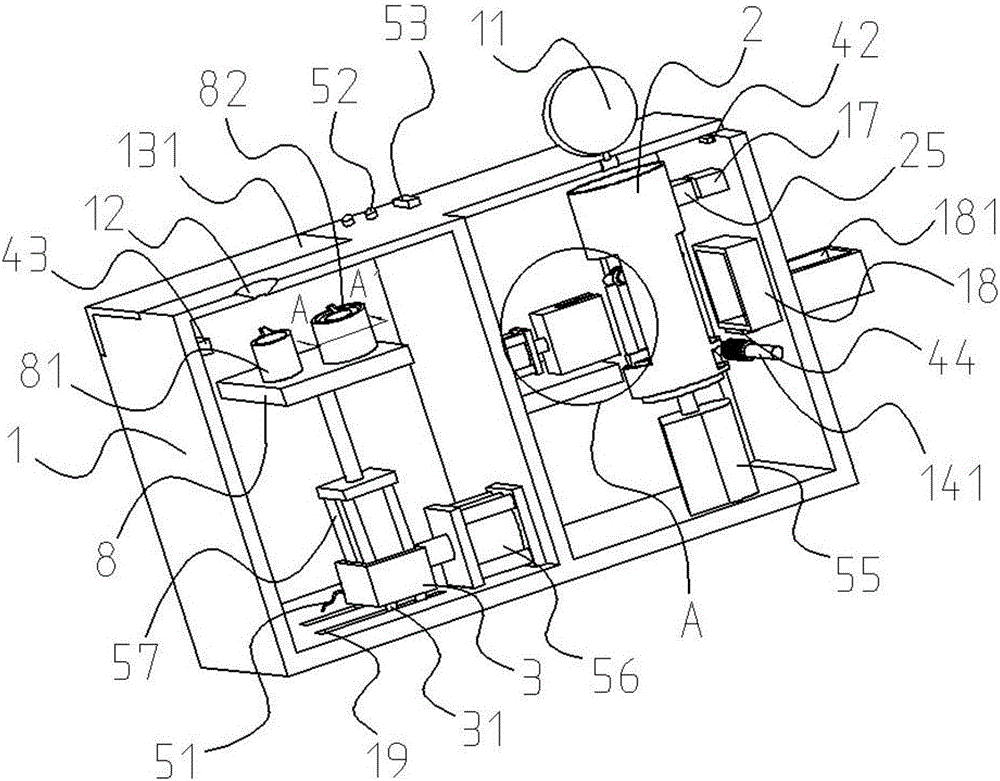

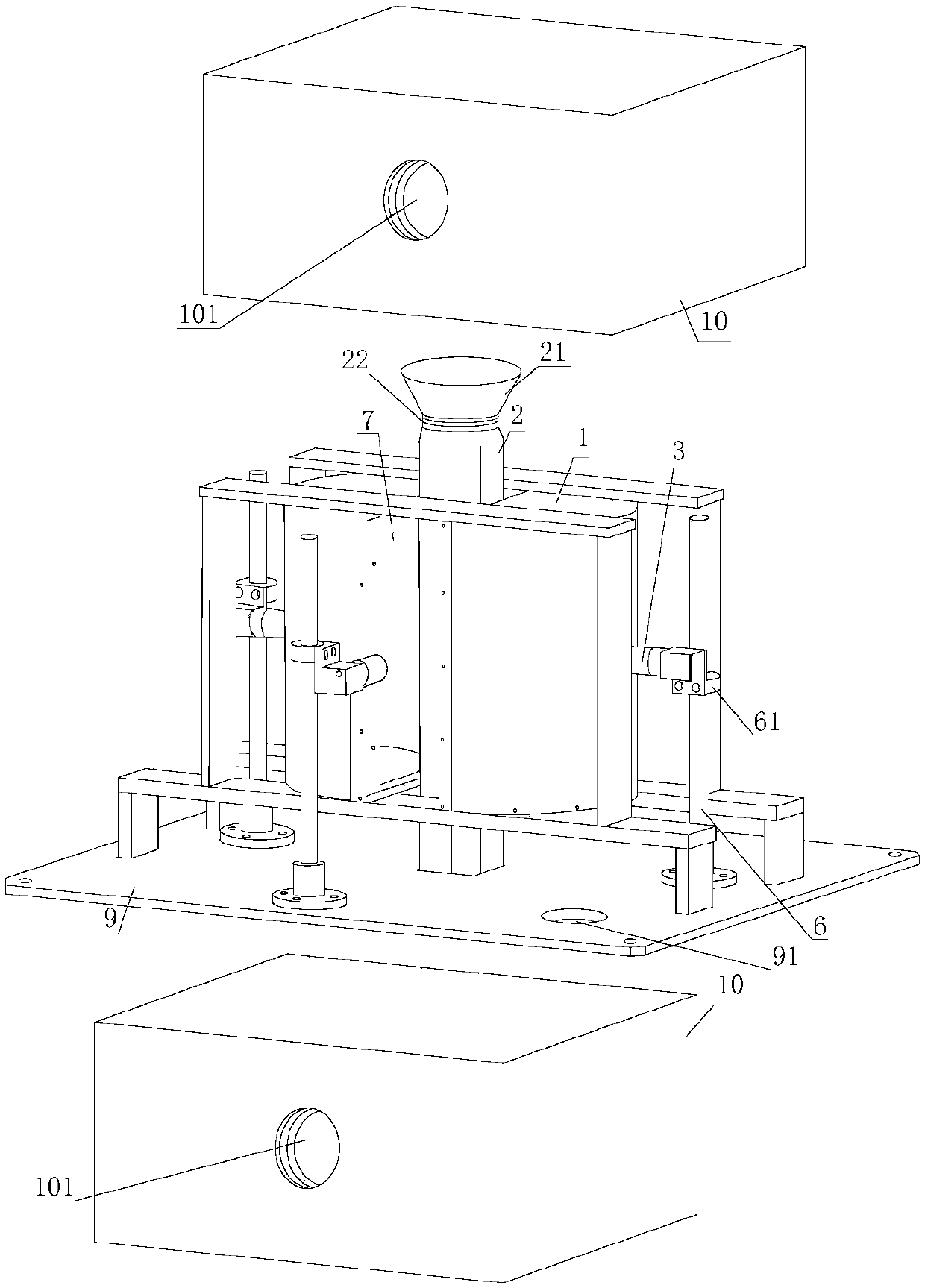

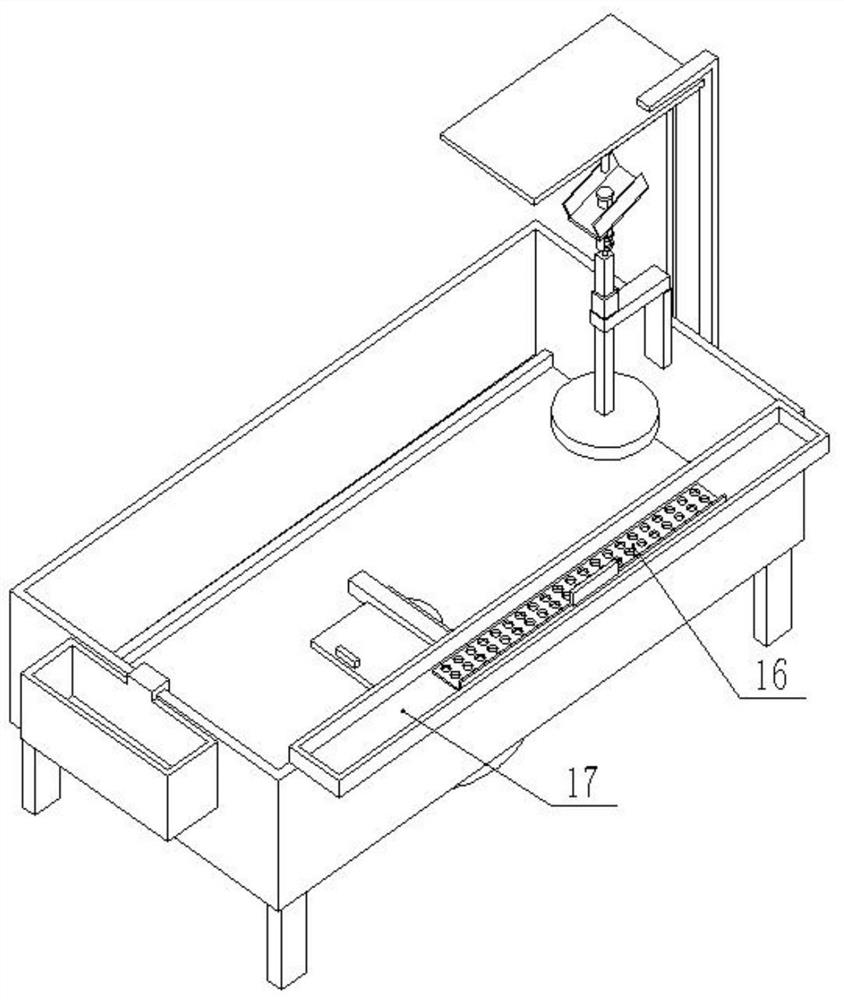

Orderly palletizing stacking machine for stone separation of barricades

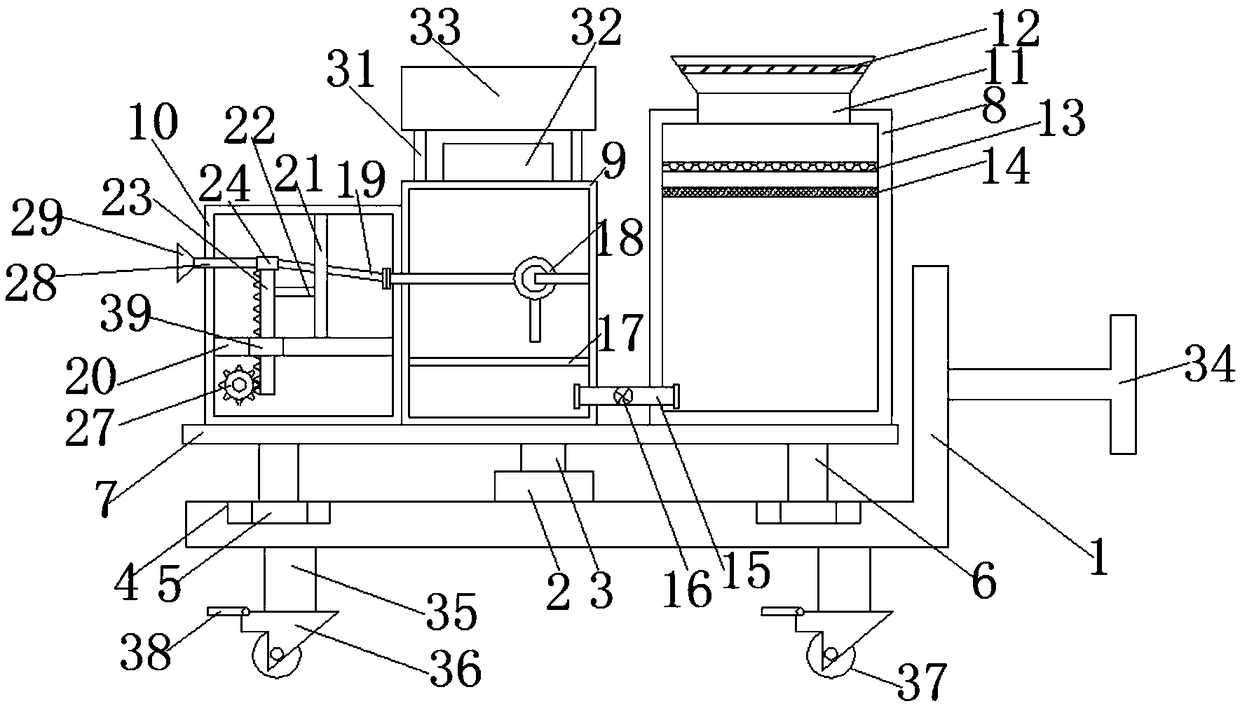

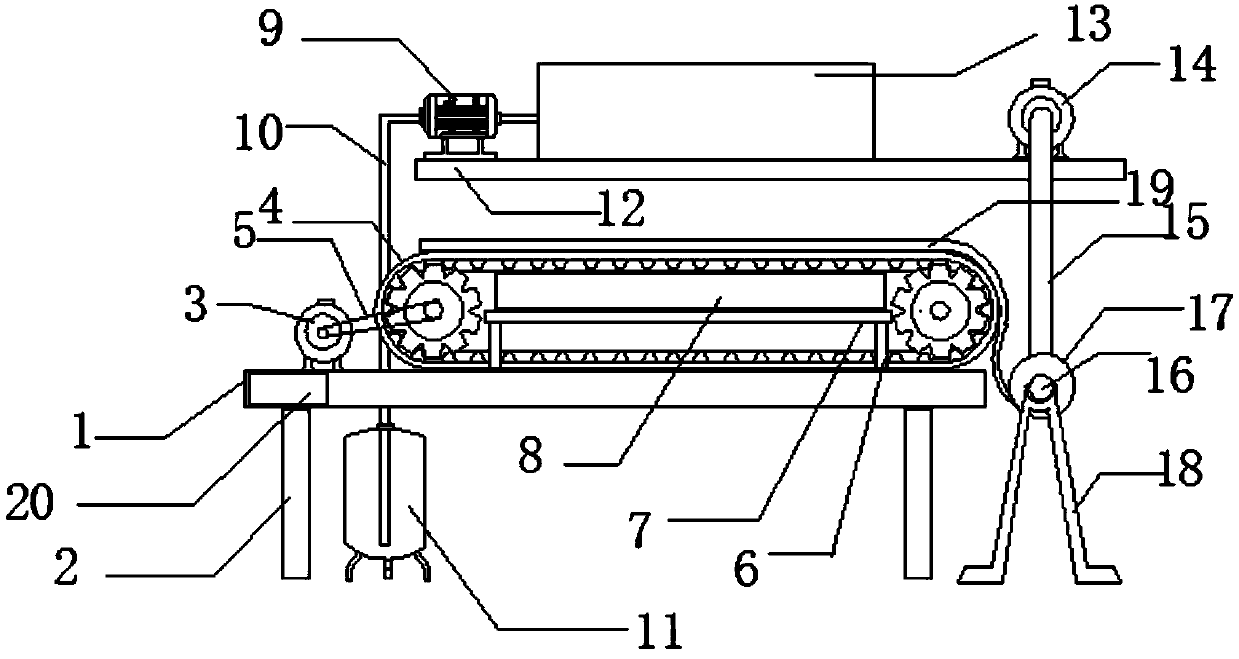

InactiveCN109484868ANeatly stackedHigh degree of automationStacking articlesDe-stacking articlesEngineeringCam

The invention provides an orderly palletizing stacking machine for stone separation of barricades. The orderly palletizing stacking machine includes an installation frame, a screening and conveying device, a sorting device and a palletizing stacking device, the screening and conveying device is used for screening and separating particles such as stones in the barricades and conveying the screenedbarricades into the sorting device, the sorting device is used for orderly arranging the barricades and conveying the arranged barricades to the palletizing stacking device, and the palletizing stacking device is used for palletizing the barricades and orderly stacking the palletized barricades; the screening conveying device includes a conveying mechanism and a screening mechanism, the conveyingmechanism is used for conveying the barricades into the sorting device, and the screening mechanism is used for removing the particles such as the stones in the barricades; and the screening mechanismincludes a fixing plate, a screening motor, a screening transmission component and a cam component, and the conveying mechanism includes an installation board, a conveying motor, a conveying transmission component and a conveying component.

Owner:杨传前

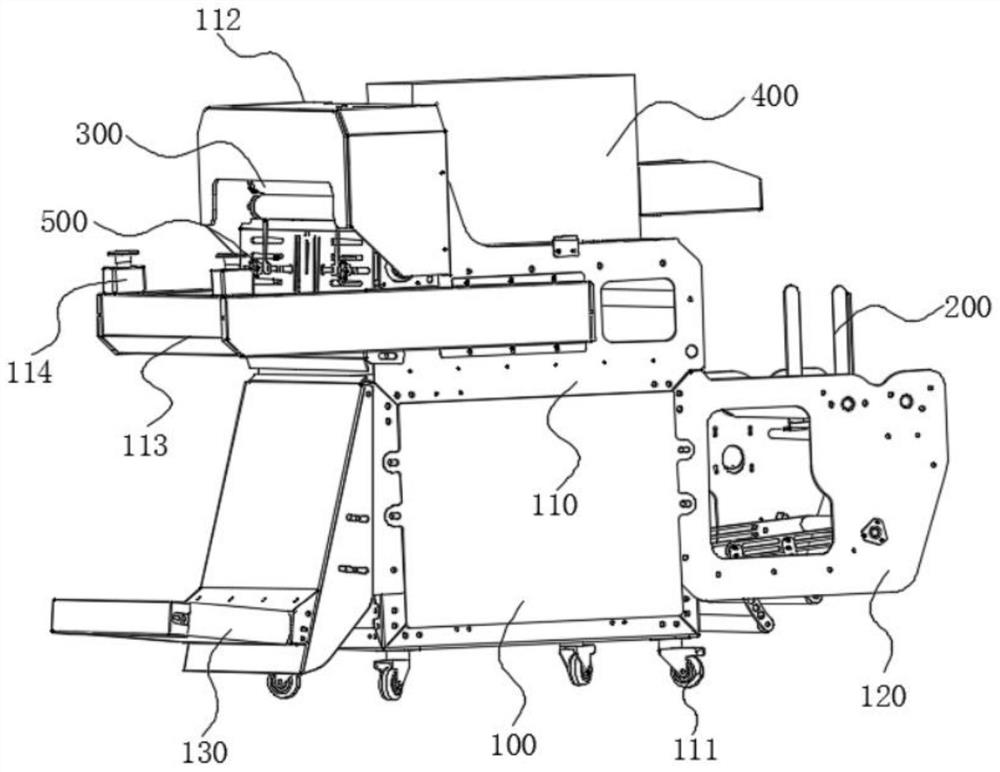

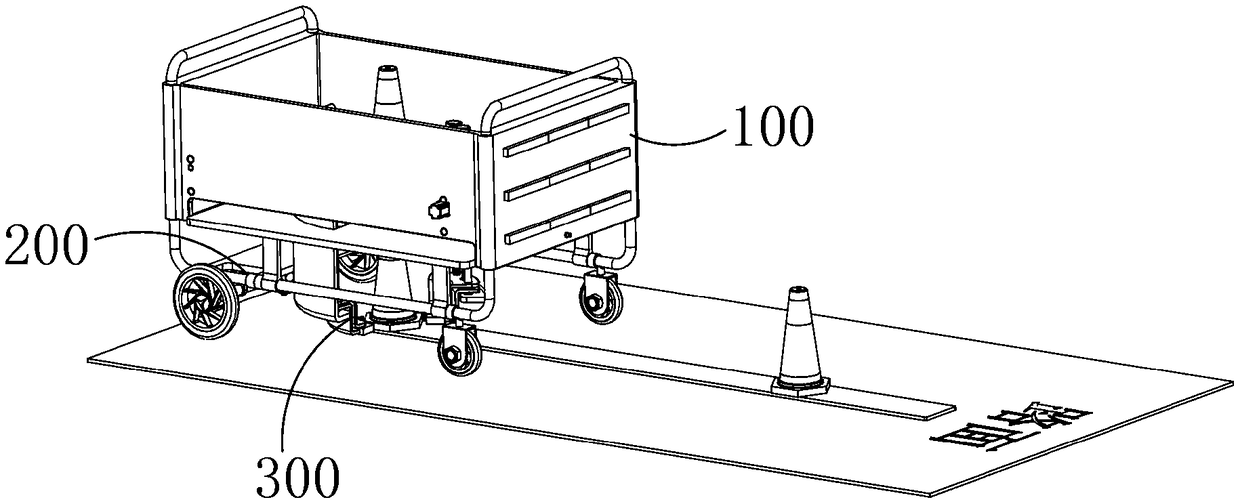

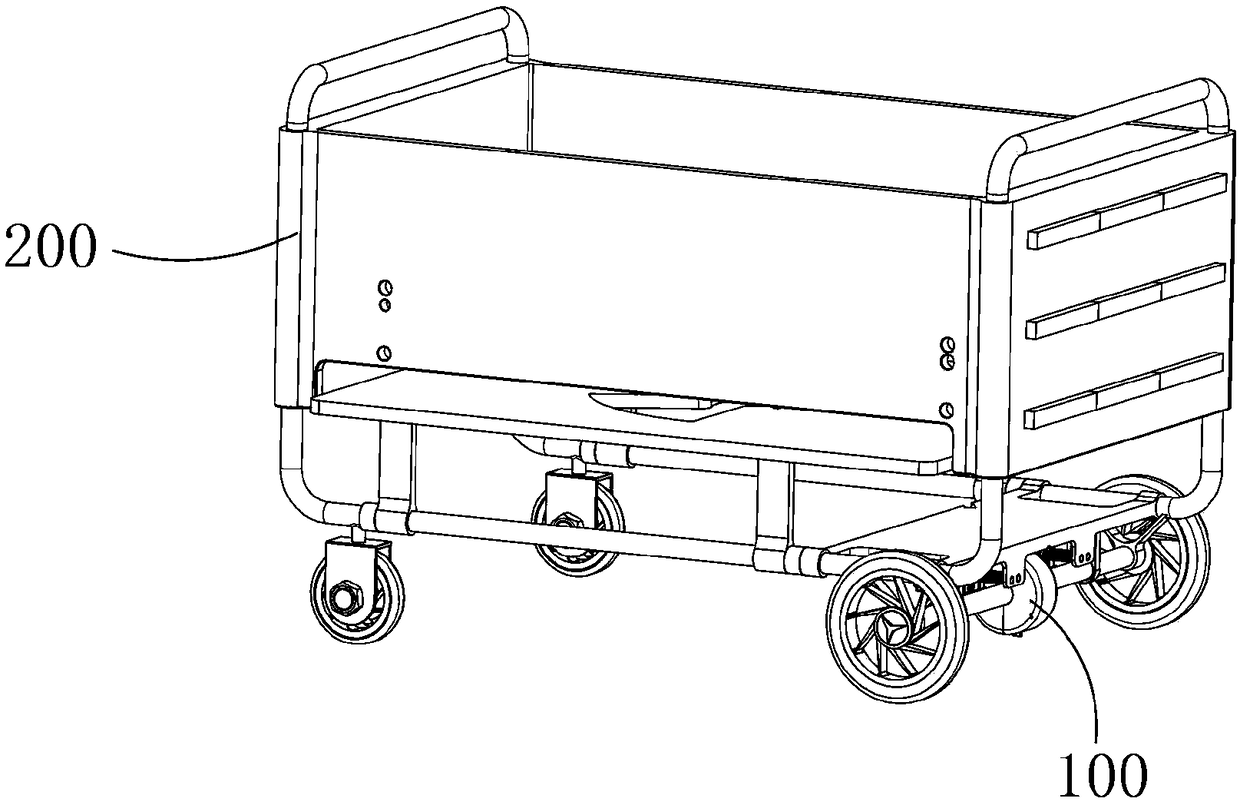

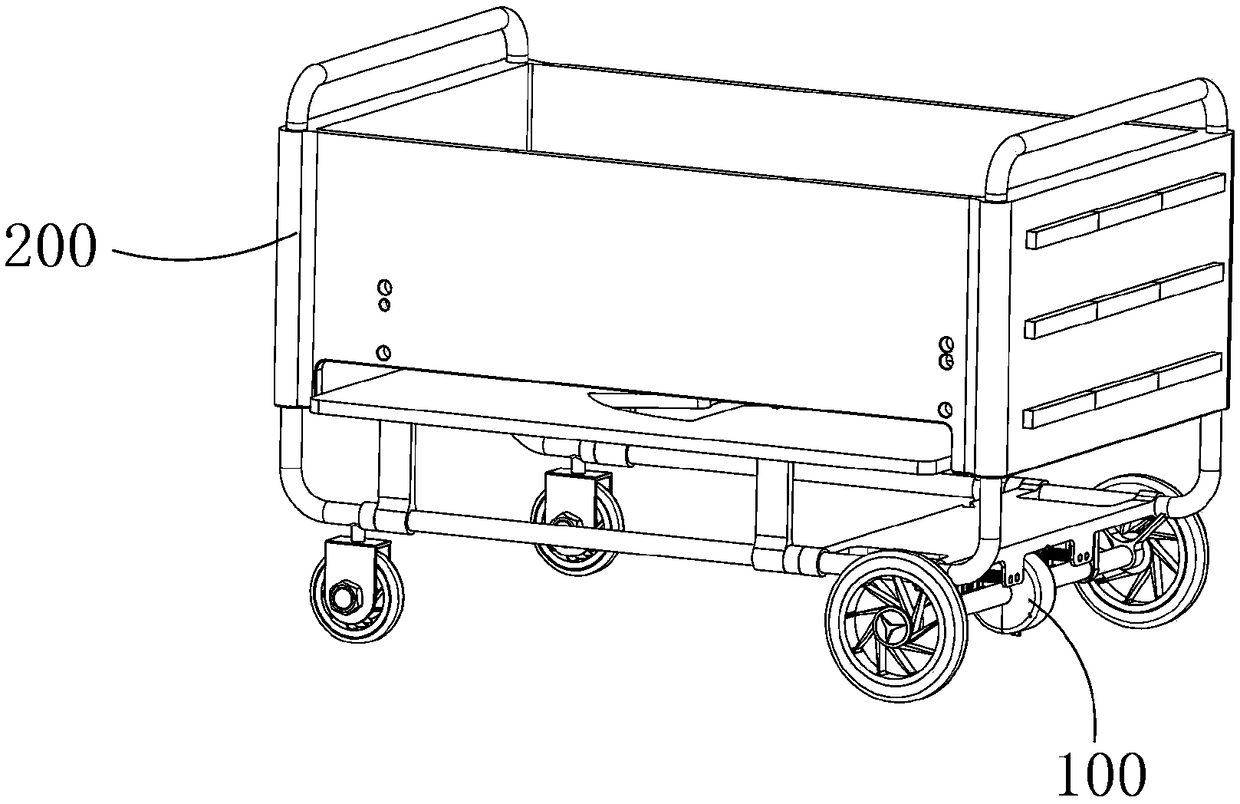

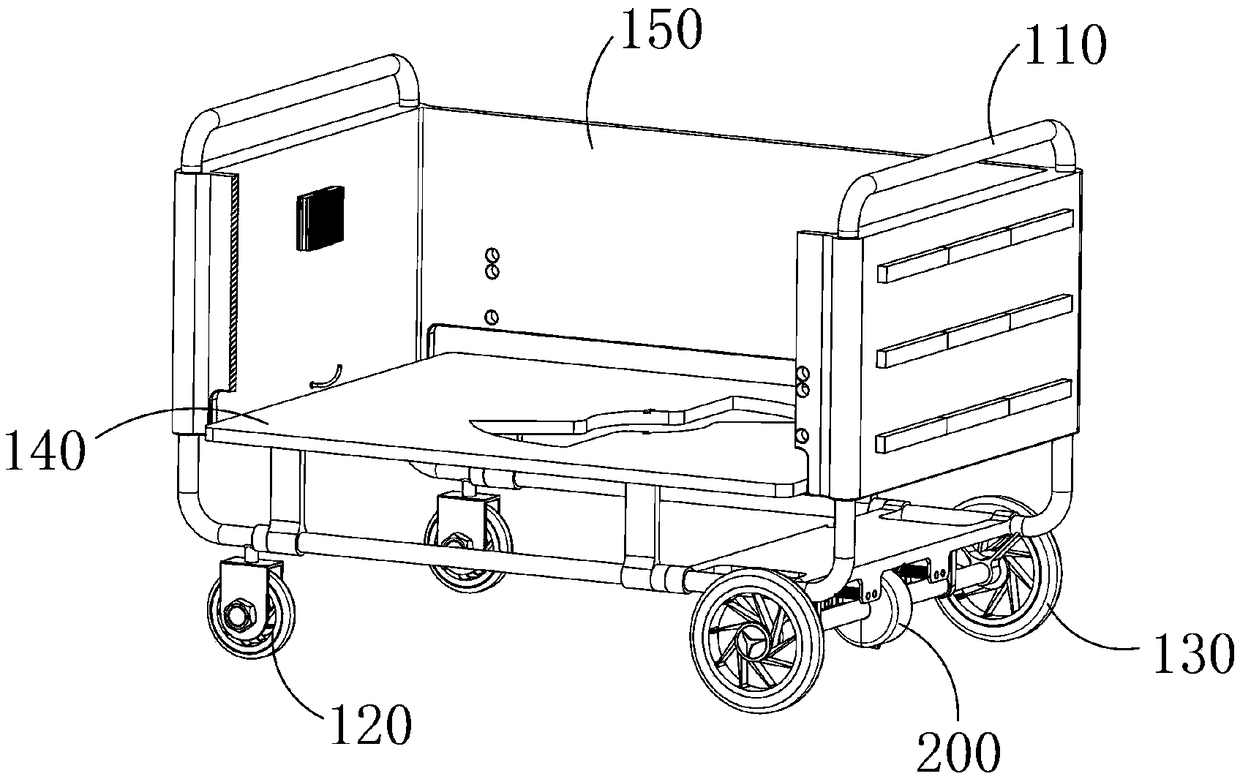

Barricade stacking recycling vehicle

InactiveCN109484840AImprove recycling efficiencyHigh degree of automationConveyor partsMechanical conveyorsEngineeringAutomotive engineering

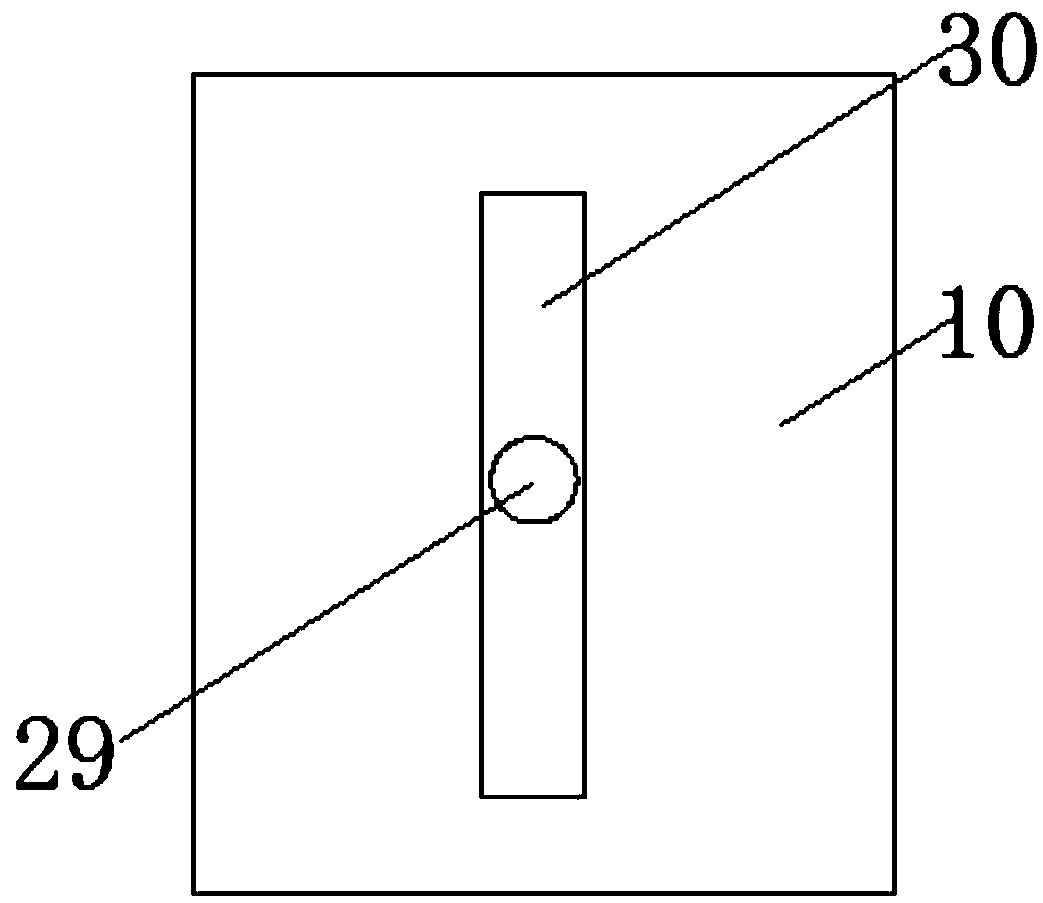

The invention provides a barricade stacking recycling vehicle, which includes an advancing system and a recycling system. The advancing system includes a vehicle body and a driving device for drivingadvancing and steering of the vehicle body, the recycling system is installed on the vehicle body, and the recycling system includes a clamping lifting device for clamping barricades and pulling the barricades up and orderly stacked the barricades into the vehicle body and a limiting supporting device for supporting the barricades orderly stacked into the vehicle body; the vehicle body includes aframe, a front wheel component, a rear wheel component, a bottom plate and a carriage, the bottom plate is arranged horizontally and fixedly installed on the frame, the carriage is of a rectangular ring body structure, the extension direction of the carriage is perpendicular to the ground, and the carriage is fixedly installed on the upper end face of the bottom plate; and the front wheel component and the rear wheel component are both installed on the frame and located on the lower part of the bottom plate.

Owner:杨传前

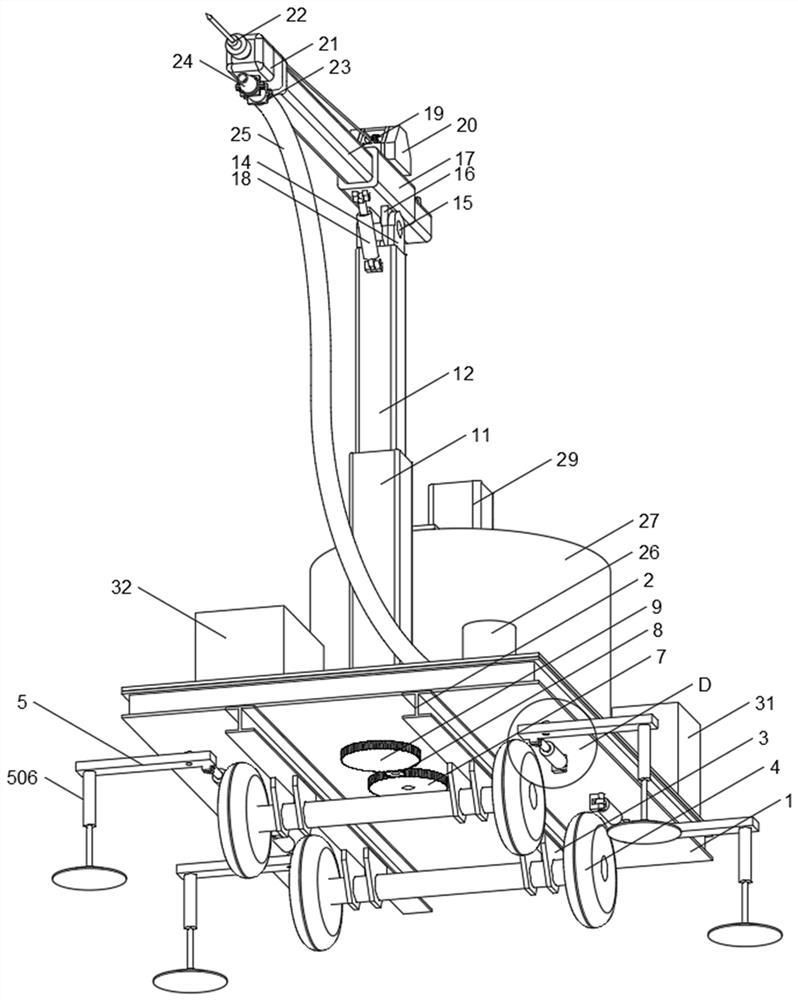

Full-automatic underground continuous wall reinforcement mesh weaving machine

The invention discloses a full-automatic underground continuous wall reinforcement mesh weaving machine. The existing underground continuous wall has the problem that the reinforcement cage is vertically put into the wall guide groove by the crane, and the size of the reinforcement cage is large, so the hoisting and putting of the reinforcement cage into the wall guide groove are difficult. A machine which integrates underground automatic grooving and automatic reinforcement mesh weaving is not invented at present. The full-automatic underground continuous wall reinforcement mesh weaving machine is characterized in that a driving mechanism is used for driving an active vehicle carriage, an intermittent transmission mechanism and a groove milling mechanism, the intermittent transmission mechanism is used for respectively transferring power to a transverse reinforcement rope weaving mechanism and a longitudinal reinforcement conveying mechanism, the groove milling mechanism is used for digging the wall guide groove of the continuous wall, the transverse reinforcement rope weaving mechanism is used for weaving a reinforcement rope in the wall guide groove of the continuous wall, the reinforcement rope is provided by a transverse reinforcement rope storage frame, and the longitudinal reinforcement conveying mechanism can do intermittent movement to put the reinforcements into the reinforcement rope weaved by the transverse reinforcement rope weaving mechanism, so as to weave the reinforcement mesh. The full-automatic underground continuous wall reinforcement mesh weaving machine has the advantage that the wall guide groove of the continuous wall can be automatically dug under the ground, and the reinforcement mesh is automatically weaved in the wall guide groove, so the underground continuous wall is quickly built.

Owner:GEOTECHN TECH

Intelligent blood sampling device capable of achieving automatic needle exchange

InactiveCN108852375AFully automatedAvoid enteringSensorsBlood sampling devicesInsertion stentNeedle exchange

The invention discloses an intelligent blood sampling device capable of achieving automatic needle exchange. A propeller is removed from a needle insertion adjustment support at the tail end of an operation arm of an existing blood drawing robot, a needle exchange mechanism, a needle push mechanism, a blood drawing needle separation mechanism and a needle seal mechanism are added, the improved robot is provided with a specific syringe, through the structure, the improved blood drawing robot can automatically complete the processes of needle exchange, blood drawing, needle seal and needle separation, the manual labor amount is greatly reduced, the automation process of blood drawing of the robot is achieved, needle taking is conducted conveniently, the problem is effectively avoided that people are more easily scratched by a syringe needle during needle taking or assembly, and the device has high economic and practical value; meanwhile, by adopting the needle seal structure, a needle cover covers the syringe needle, bacteria in air can be prevented from entering blood of the syringe from a syringe needle hole, the precision of following blood detection can also be improved accordingly, and the device is safe and hygienic.

Owner:矫海燕

Simple quick dyeing device for textiles

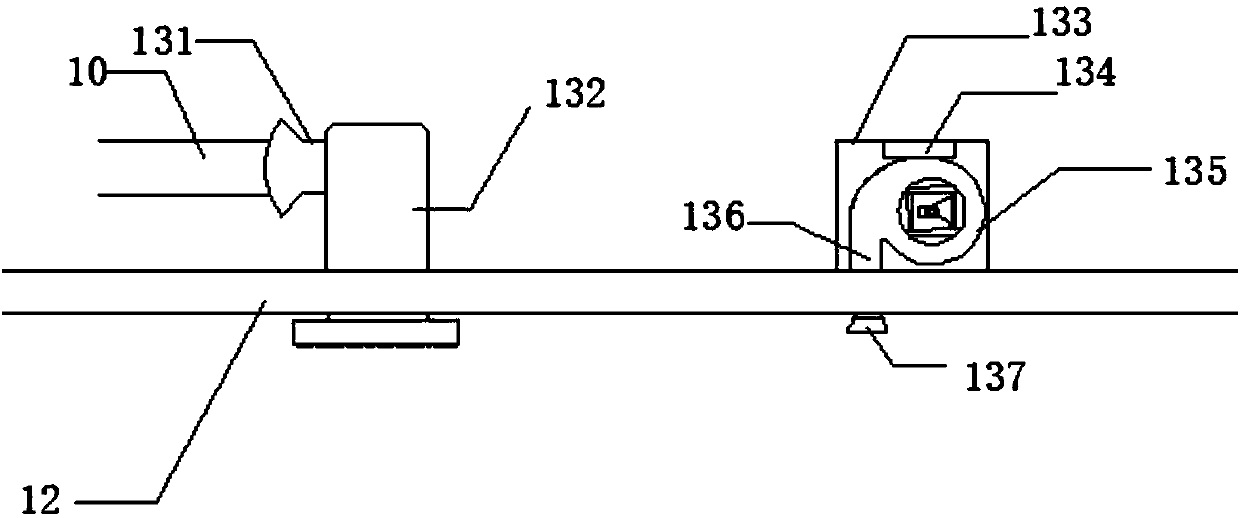

InactiveCN107687055AReduce material wasteReduce the amount of human laborTextile treatment machine arrangementsTextile treatment by spraying/projectingElectric machineryWater pipe

The invention discloses a simple quick dyeing device for textiles, comprising a first support plate and a high-pressure water pump. First support racks are fixedly and symmetrically fixed to two endsof the lower surface of the first support plate, a first motor is fixedly connected to one end of the upper surface of the first support plate, one end of the upper surface of the first support platefar away from the first motor is provided with a conveyer belt, one end of the high-pressure water pump close to the first motor is communicated with a water pipe, the bottom end of the water pipe iscommunicated with a dye tank, and a third support plate is fixedly connected to the surface of the bottom of the high-pressure water pump. The invention relates to the technical field of textile equipment. The simple quick dyeing device for textiles has the advantages that quick high-pressure spray dyeing is provided for textile fabrics, drying and color fixing are provided in time, the textile fabrics can be dyed evenly, and waste of material is decreased; fabric may be neatly coiled to the surface of a winding drum through roller rolling, so that working efficiency is improved.

Owner:HUZHOU BORUN IND

Fully automatic interweaving method for reinforcing bar nets of underground continuous wall

The invention discloses a fully automatic interweaving method for reinforcing bar nets of an underground continuous wall. At present, the design conception of integrating an underground automatic dug groove and an automatic knitted reinforcing bar net into a whole does not exist. The method disclosed by the invention specifically comprises the steps that a starting groove segment of a wall guiding groove of a continuous wall is dug out; reinforcing bar ropes of m reinforcing bar rope rollers are equally divided into n groups, one end of each reinforcing bar rope penetrates through a horizontal reinforcing bar rope interweaving mechanism, and is fixed on the side wall of the wall guiding groove of the continuous wall; a driving compartment advances, the wall guiding groove of the continuous wall is dug out by a groove milling machine, and the reinforcing bar ropes are continuously drawn out of the reinforcing bar rope rollers; every two groups of the reinforcing bar ropes are successively and sequentially divided into a reinforcing bar net interweaving unit; the horizontal reinforcing bar interweaving mechanism drives two groups of reinforcing bar ropes of each reinforcing bar net interweaving unit to be interwoven in a reciprocating manner in the wall guiding groove of the continuous wall, when the reinforcing bar ropes are interwoven once, n / 2 reinforcing bars respectively fall into one reinforcing bar net interweaving unit by a longitudinal reinforcing bar conveying mechanism, so that n / 2 reinforcing bar nets are woven. Through the adoption of the method disclosed by the invention, the wall guiding groove of the continuous wall can be automatically dug, and at the same time, the reinforcing bar nets can be automatically woven in the wall guiding groove.

Owner:GEOTECHN TECH

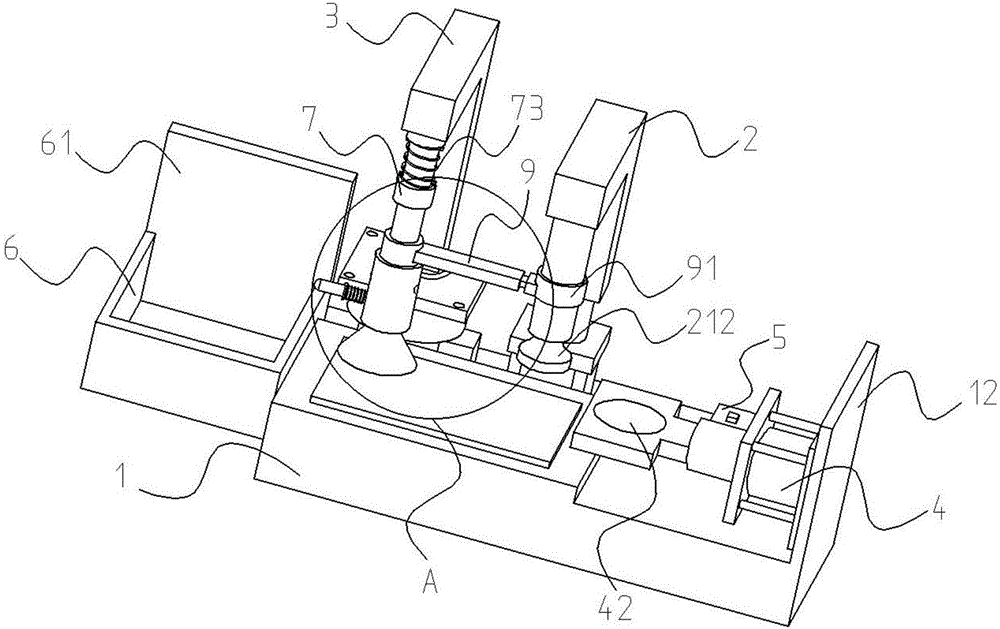

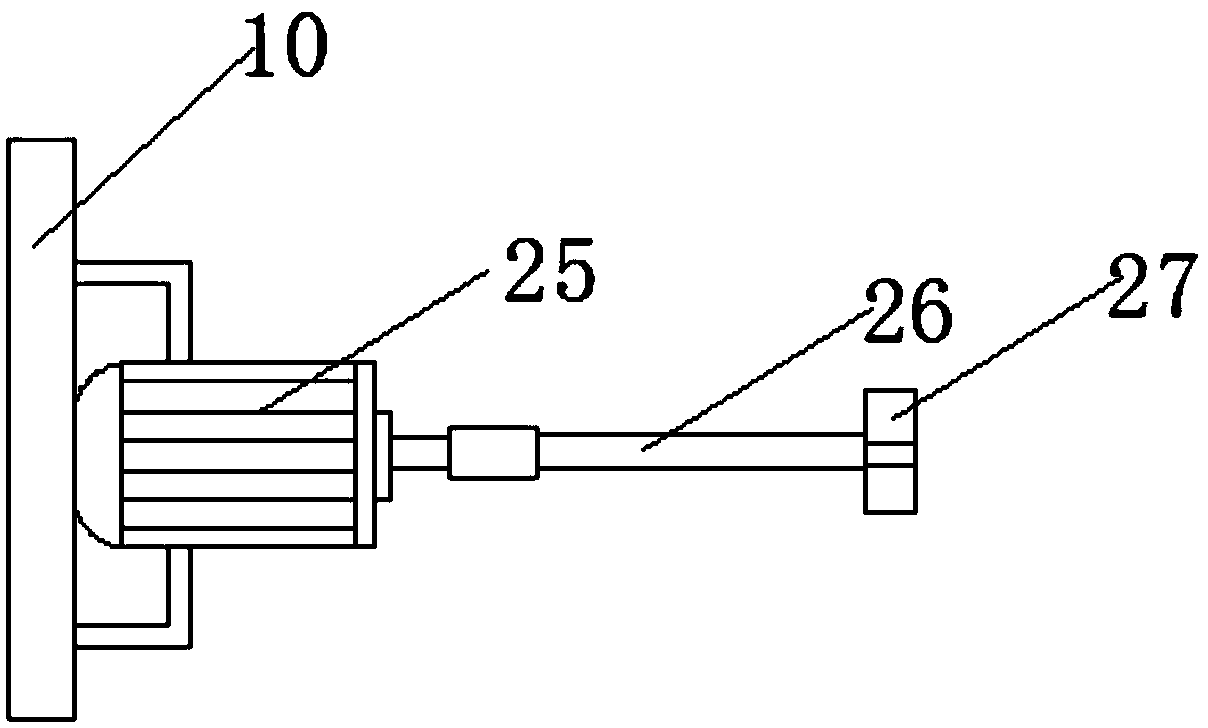

Automatic feeding type grinding wheel cutting machine

PendingCN108326712ASimple structureEasy to manufactureGrinding carriagesGrinding drivesBall screwEngineering

The invention provides an automatic feeding type grinding wheel cutting machine. The automatic feeding type grinding wheel cutting machine comprises a bottom plate which is provided with an X axis ball screw, an X axis motor, two X axis guide rails, a movable clamp and two fixed clamps; a grinding wheel fixed to a grinding wheel driver is arranged between the two fixed clamps, and the grinding wheel driver is arranged on a driver supporting base; and the driver supporting base achieves movement on the Y axis through a Y axis ball screw and two Y axis guide rails. According to the grinding wheel cutting machine, a motor is adopted to drive the ball screws to achieve linear movement of a cut piece and the grinding wheel, full-automatic mechanical cutting is achieved, and the defects of existing manual operation are overcome; on one hand, the labor amount of manpower is greatly reduced, and the work efficiency is improved, and on the other hand, the safety performance is high, and the safety of an operator is guaranteed; besides, movement of the cut piece and the grinding wheel is accurate, cutting is flat, the cutting effect is good; and the grinding wheel cutting machine is simple in structure and can be easily manufactured.

Owner:QINZHOU UNIV

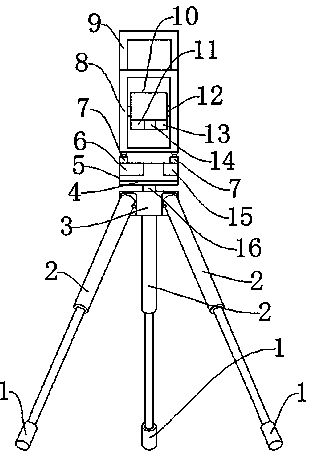

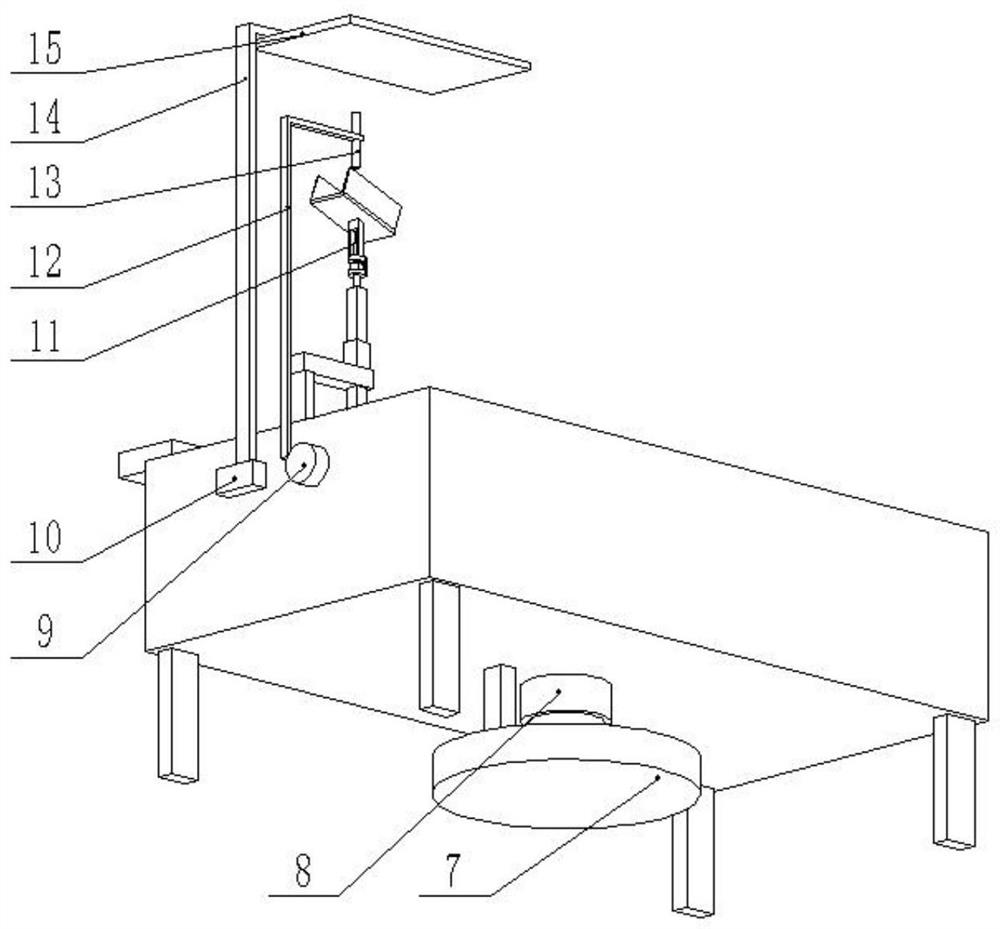

An image acquisition device for geological exploration

InactiveCN108953921BAdded automatic leveling functionReduce the amount of human laborProgramme controlTelevision system detailsGyroscopeGeological survey

The invention discloses an image acquisition device for geological exploration, which includes a telescopic support rod, a horizontal support, and a handle. A telescopic support rod is arranged on the periphery of the horizontal support. A second rotating shaft is provided in the middle of the upper surface of the horizontal support, a support box is provided at the top of the second rotating shaft, a first gyro sensor is provided below the inside of the support box, and a side above the first gyro sensor is provided A battery, a controller is provided on the side away from the battery above the first gyro sensor, and electric push rods are fixedly installed on the four corners of the upper surface of the support box. The beneficial effects are as follows: 1. Multi-directional acquisition is realized by setting the second rotating shaft; 2. The automatic leveling function is increased by setting the first gyro sensor and the electric push rod to reduce the amount of human labor; 3. By setting the first rotating shaft, no The casing can be rotated when the camera is used to protect the camera in the bracket frame; 4. By setting the handle, it is convenient to carry and move.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

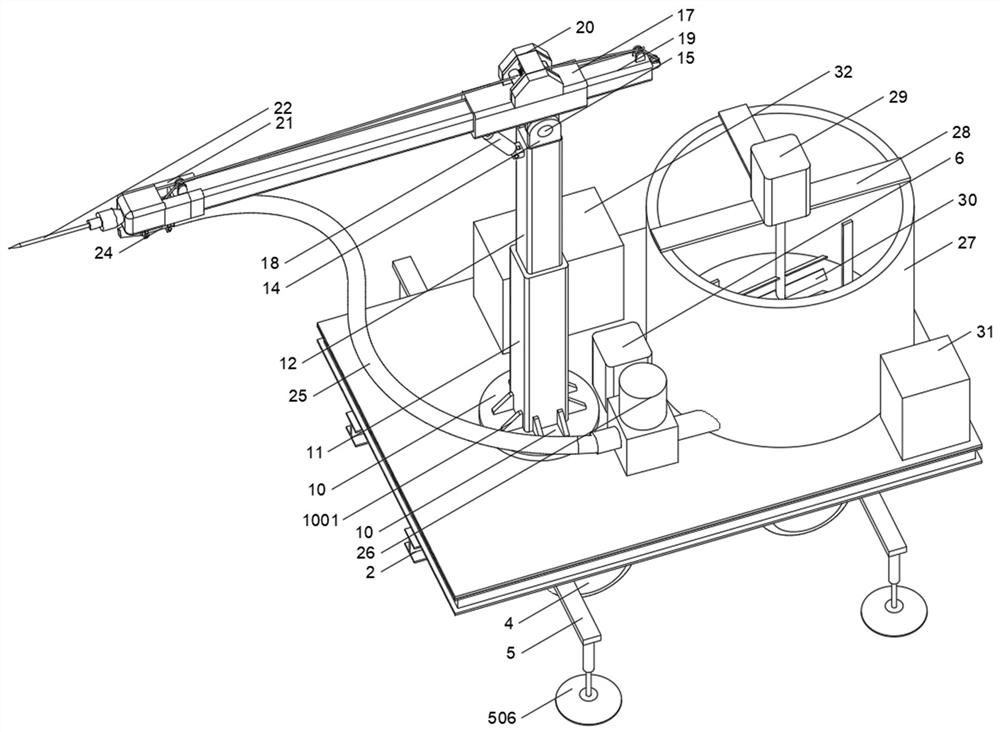

Distributed anchoring and grouting support device for deep mine fault fracture zone

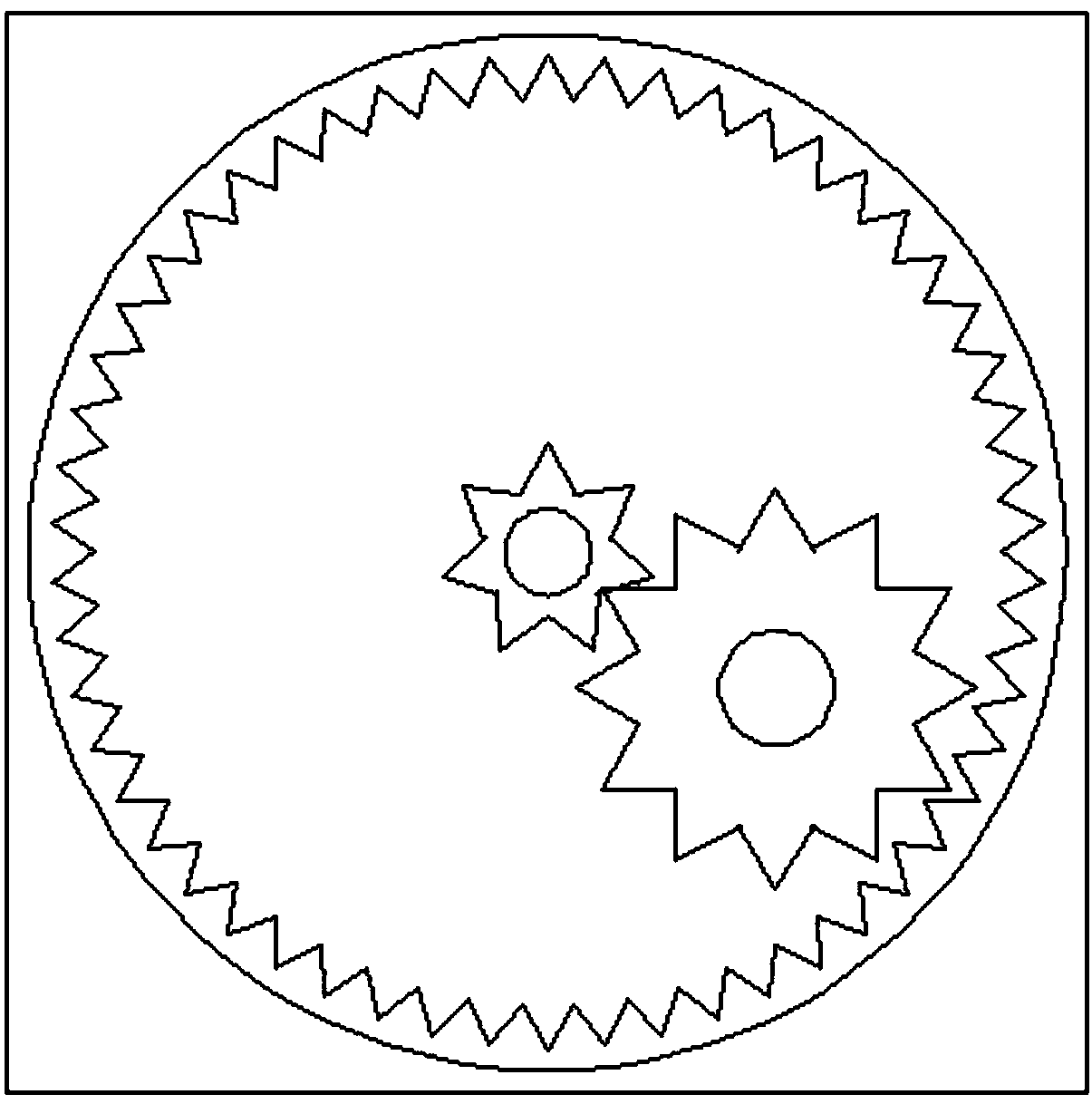

ActiveCN112761691AImprove support strengthImprove connection strengthUnderground chambersTunnel liningGear wheelFracture zone

The invention belongs to the technical field of mining equipment, and particularly relates to a distributed anchoring and grouting support device for a deep mine fault fracture zone. The distributed anchoring and grouting support device comprises a working platform, wherein a first motor installed on the top face of the working platform is in driving connection with a base through a driving gear, an idle wheel and a driven gear; an outer sleeve and a second hydraulic rod are fixedly installed on the top face of the base; the top face of an inner sliding rod connected to the top end of the second hydraulic rod is rotationally connected with a fixing base; the front side face of the inner sliding rod is rotationally connected with the fixing base through the second hydraulic rod; a translation arm is installed on the inner side of the fixing base in a sliding mode; a translation mechanism is installed on the top face of the fixing base; an electric pick and a grouting spray head are installed at the front end of the translation arm through a connecting sleeve; and the grouting spray head is connected with a stirring tank through a hose and a cement pump. Cement can be used immediately after being adjusted through the stirring tank and a stirring anchor, then the positions of the movable electric pick and the grouting spray head are adjusted, so that the operation of distributed anchoring and grouting support in a roadway and a shaft is completed, and the support level and the support efficiency are effectively improved.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

Moveable cable wire wrapping device capable of winding and unwinding wires synchronously

The invention discloses a movable winding device for synchronous retraction and release of cables, relates to the technical field of electric wires and cables, and solves the problems that the cable winding device cannot move by itself and the retraction and release cannot be carried out synchronously. The invention includes a rotating shaft and a The winding reel mechanism is sleeved at both ends of the rotating shaft. The end of one side of the rotating shaft is connected with a driving motor. The winding reel mechanism includes a winding reel a and a winding reel b with a diameter larger than that of the winding reel a. The winding reel b is fixedly sleeved on On the rotating shaft, there are two telescopic rods arranged radially on the outer surface of winding reel a, and a chute with a toothed rack corresponding to the telescopic rods is provided radially on the winding reel a, and the end of the telescopic rod is connected with a horizontal rotatable rod. The connecting rod, one end of the connecting rod located in the chute is provided with a gear a matched with the rack, the other end of the connecting rod is connected with a telescopic cylinder, and a separating disc mechanism is arranged between the winding disc mechanisms at both ends.

Owner:河南大松仪器设备有限公司

Seed shrimp body shape detection and selection device and method

The invention relates to the technical field of seed shrimp measurement, in particular to a seed shrimp body shape detection and selection device and method. The seed shrimp body shape detection and selection device comprises a dark box with waterproofing and shading functions; a transparent pipeline for supplying water and allowing seed shrimps to pass through, wherein the transparent pipeline runs through the dark box, and both ends of the transparent pipe pass through the dark box to communicate with the outside world; at least four industrial cameras which are evenly distributed around thetransparent pipeline, can collect images of seed shrimps in the transparent pipeline, and are connected to the dark box; a computer connected to the industrial cameras, wherein the computer comprisesan image recognition module connected to the industrial cameras and a data storage module; a light source disposed in the dark box and adjacent to the transparent pipeline; and an industrial controlcomputer connected to the light source and the industrial cameras. The device and method can improve the measurement accuracy, reduce the contact with the seed shrimp, and reduce the damage of the seed shrimp; and the measurement speed is fast and the efficiency is high.

Owner:杭州飞锐科技有限公司

Special tire grasping device for tire dismounting machine

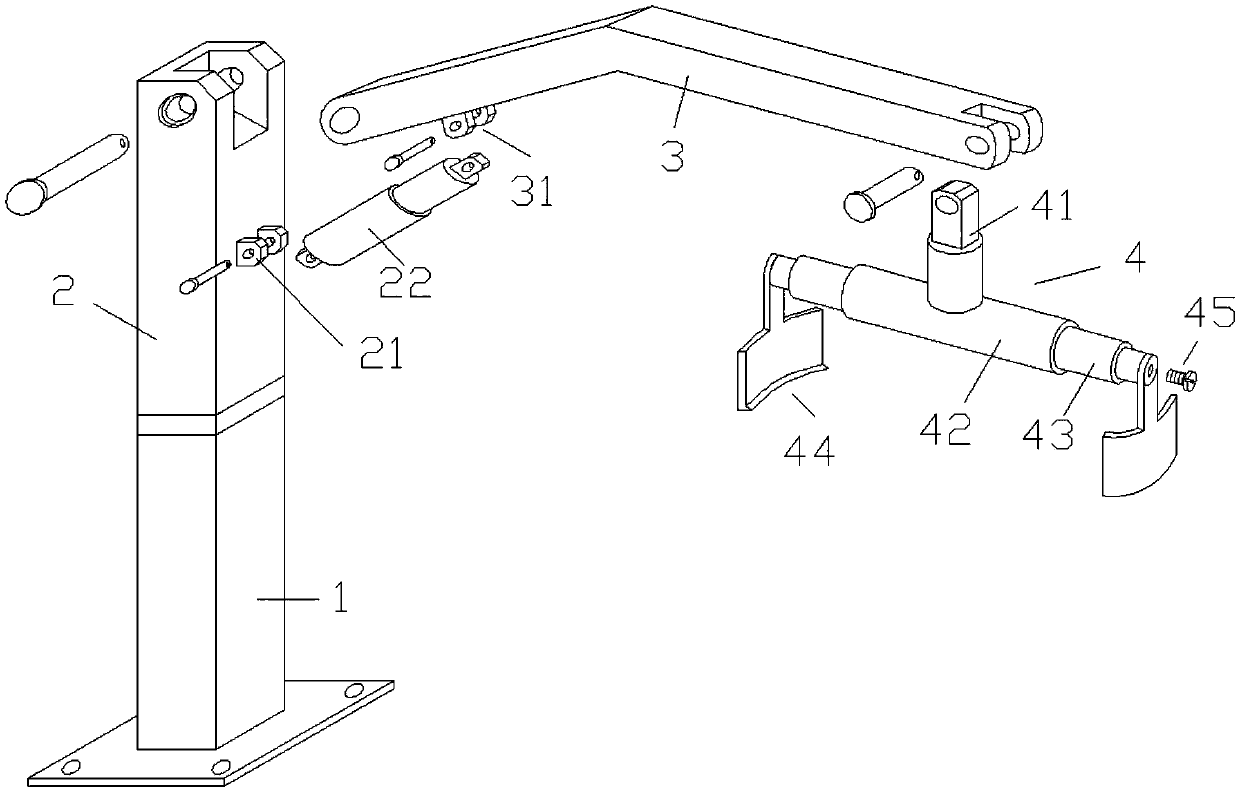

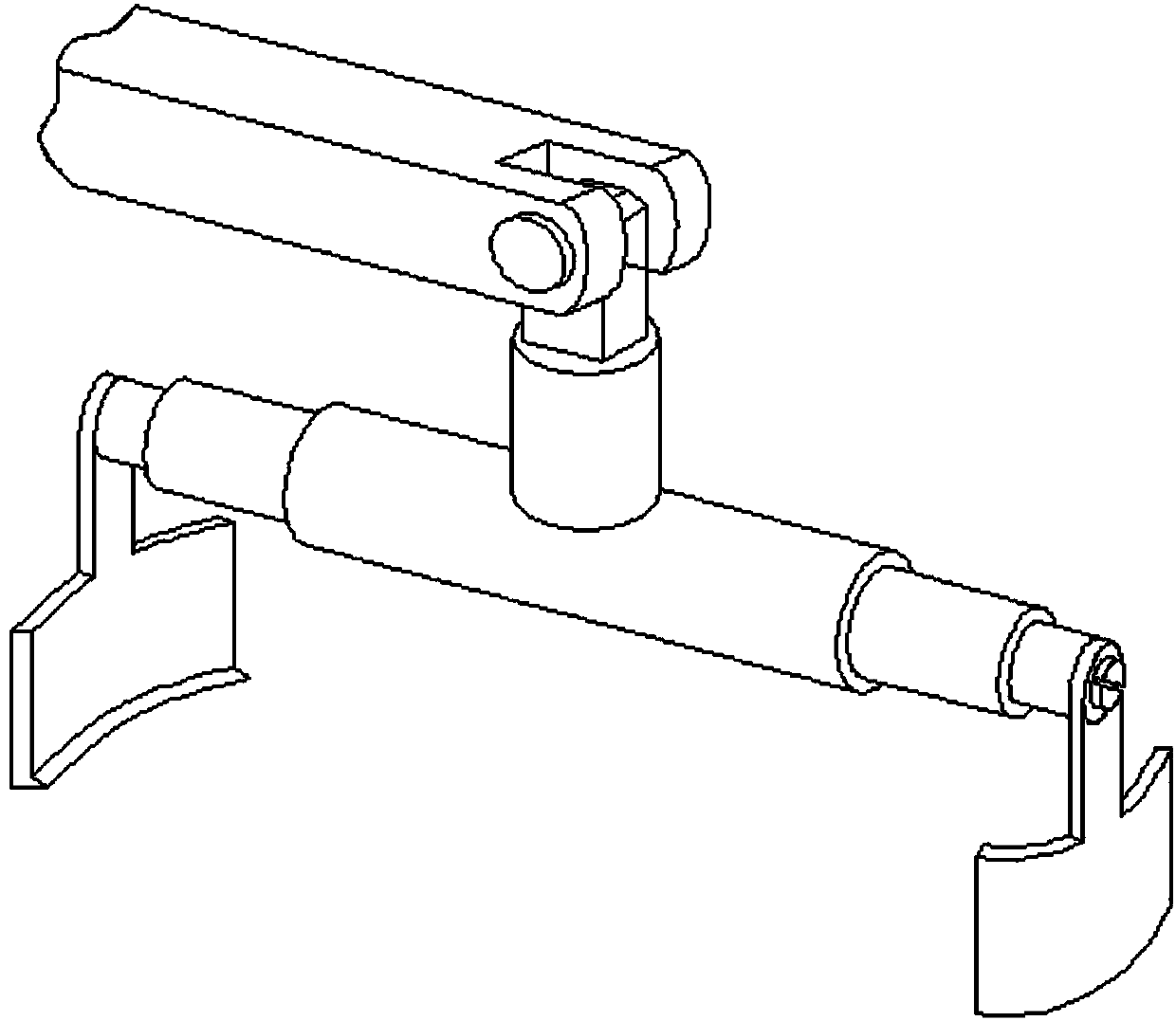

The invention discloses a special tire grasping device for a tire dismounting machine. The special tire grasping device comprises a fixing column, a rotating column, a crank arm, a grasping claw and acontrol system, wherein the bottom end of the fixing column is connected with the support base; the bottom of the rotating column is connected with the upper end of the fixing column; one end of thecrank arm is connected with the upper end of the rotating column; the upper end of the grasping claw is connected with one end of the crank arm. Due to connection and cooperation of different components, and application of the control system, automation of the grasping, movement and placing process of a tire is achieved, the lower parts of clamping claws are of arc-shaped structures, bulges are arranged inside the bottom ends of the clamping claws, a tire can be effectively clamped by using the structure, and reliable clamping is ensured; due to adoption of a planet speed reduction structure,very high working efficiency and applicability are achieved; due to adoption of a hydraulic column, the whole device is operated stably and flexibly; as the hydraulic cylinder of the grasping claw isof a two-section extension structure, a large-diameter tire can be grasped; the special tire grasping device has the characteristics of being high in automation degree and simple to operate, the workload of operators is reduced, and the working efficiency is improved.

Owner:重庆鼎雄商贸有限公司

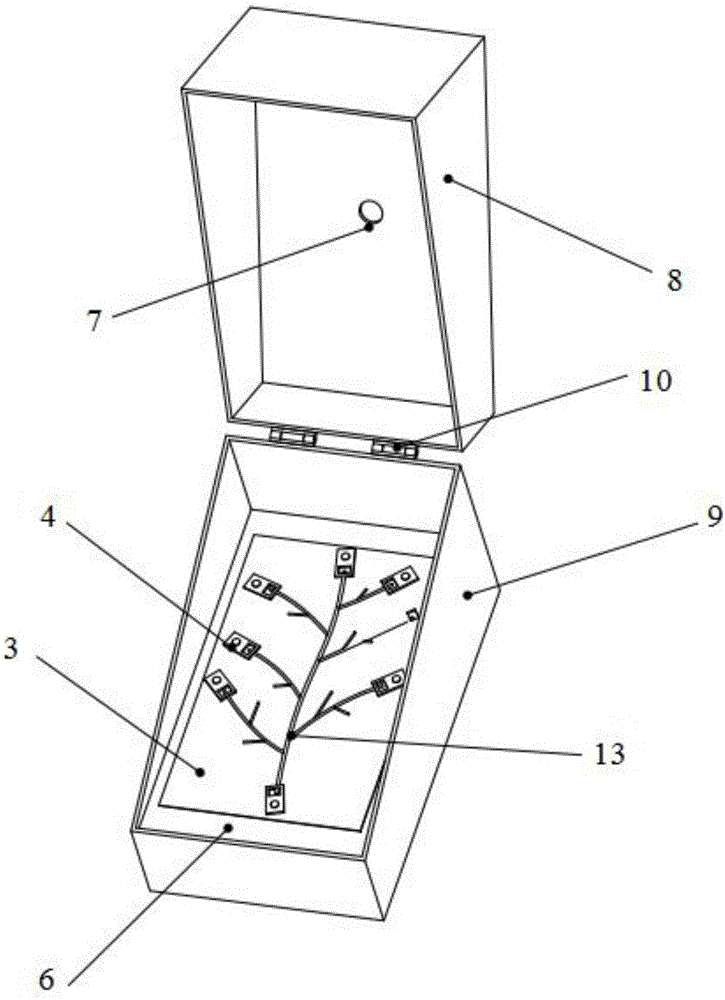

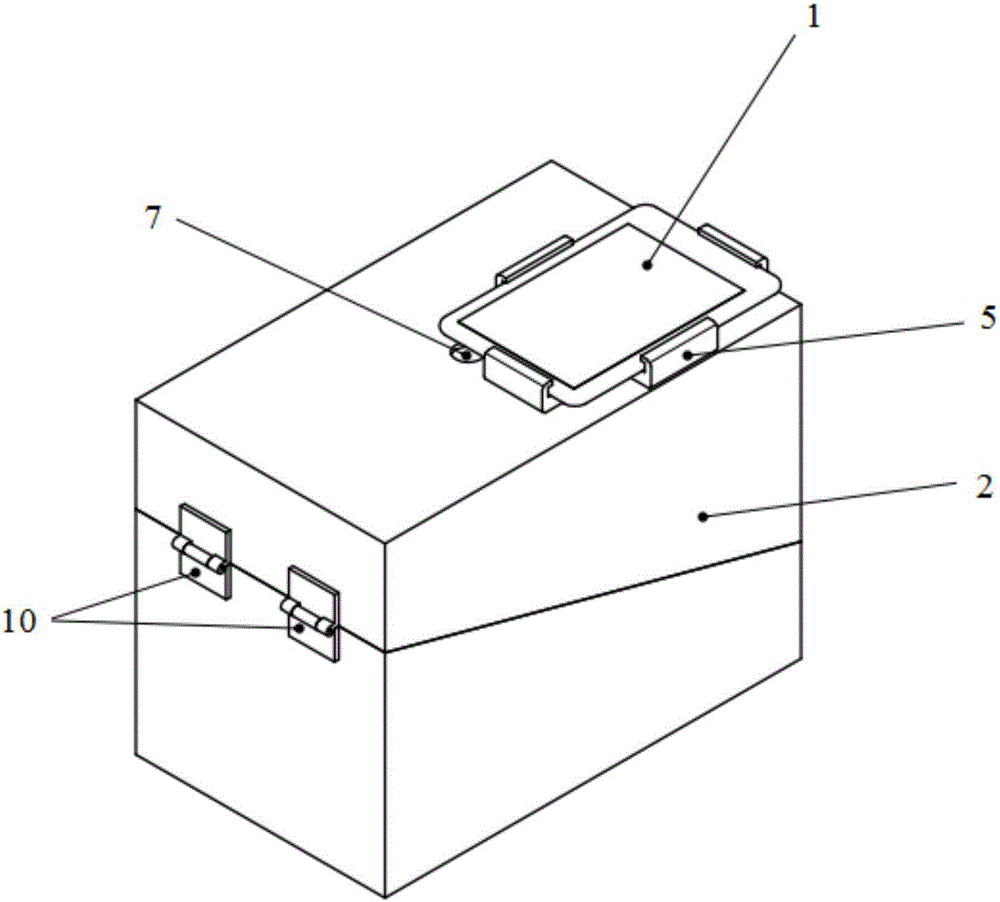

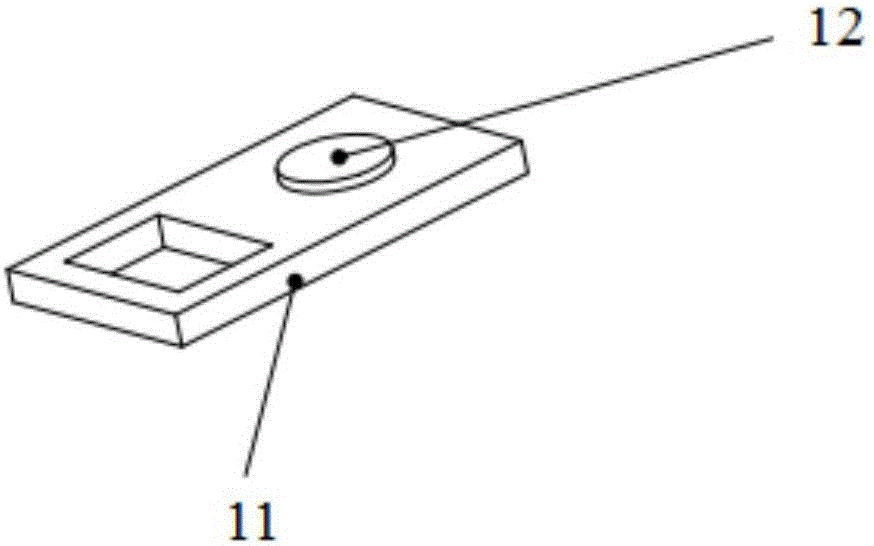

Tablet computer-based rice spike phenotype analyzer and use method thereof

InactiveCN106404780ASimple structureLow costInvestigation of vegetal materialTablet computerBiochemical engineering

The invention provides a tablet computer-based rice spike phenotype analyzer and a use method thereof, wherein the rice spike phenotype analyzer includes a tablet computer (1), a box body (2), a backlight board (3), transparent magnetic positioning pieces (4), a tablet computer fixing seat (5) and an iron board (6); the tablet computer (1) is mounted on the tablet computer fixing seat (5); the tablet computer fixing seat (5) is arranged at the top of the box body (2); the backlight board (3) is mounted on the iron board (6), a rice spike (13) is placed on the backlight board (3), and all branches of the rice spike are pressed by a plurality of transparent magnetic fixing pieces (4); the tablet computer (1) is provided with a camera, a topology structure, the grain number, the branch number and the length data of the rice spike are calculated through shot photos of the rice spike. The analyzer has the advantages of simple structure, low cost, easy popularization and application and high universality.

Owner:SHANGHAI JIAO TONG UNIV

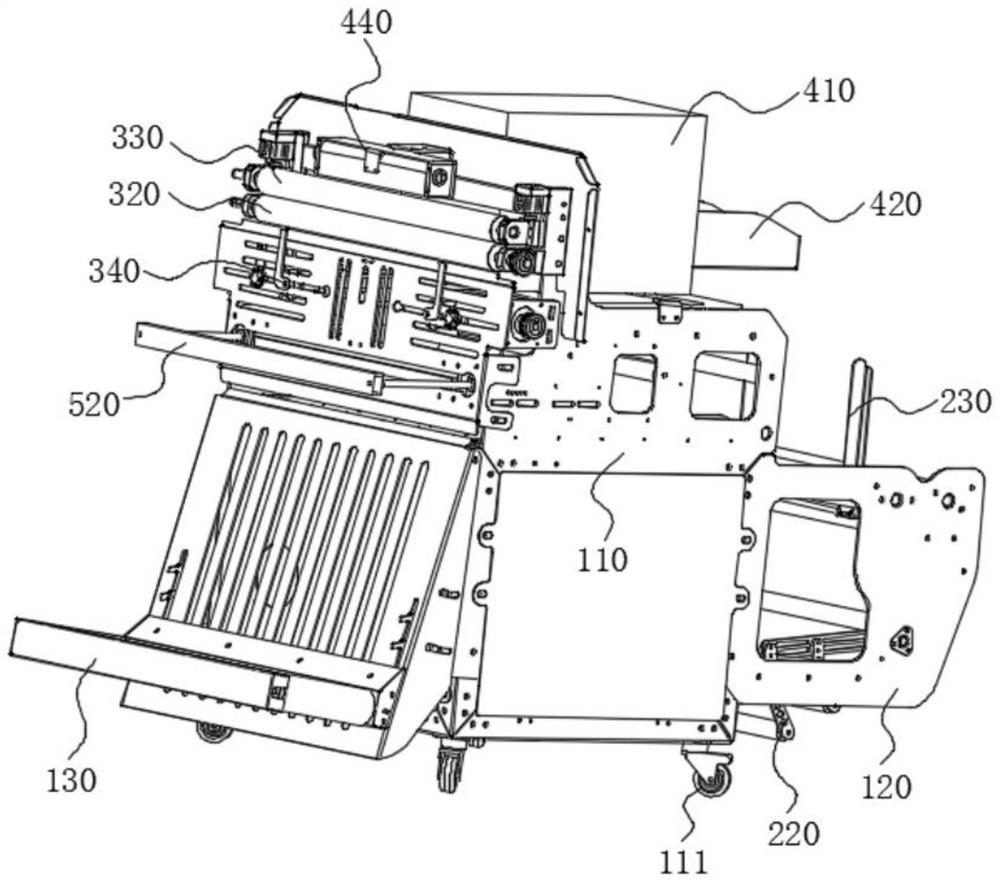

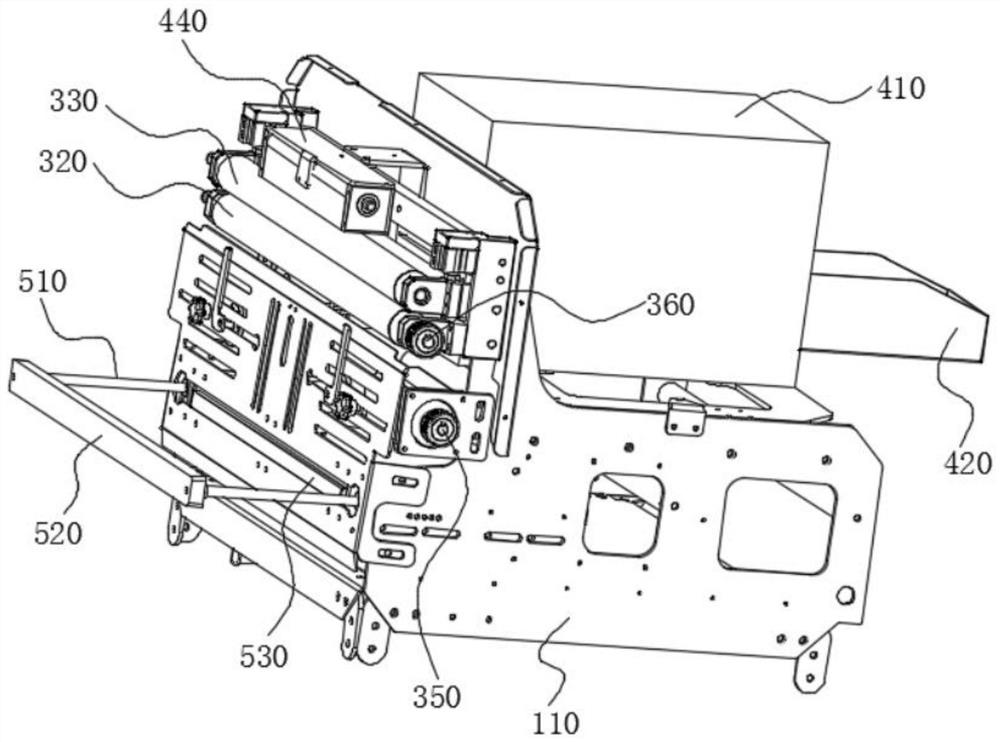

Recovery vehicle for orderly palletizing and recovering roadblocks

InactiveCN109183650AImprove recycling efficiencyHigh degree of automationTraffic signalsRoad signsAutomotive engineering

The invention provides a recovery vehicle for orderly palletizing and recovering roadblocks, including a forward system and a recovery system, wherein the forward system comprises a vehicle body; andthe recovery system comprises a clamping lifting device for clamping the roadblock and pulling it up and stacking it into the vehicle body in an orderly manner, and a limit support device for supporting the roadblock stacked into the vehicle body in an orderly manner.

Owner:杨传前

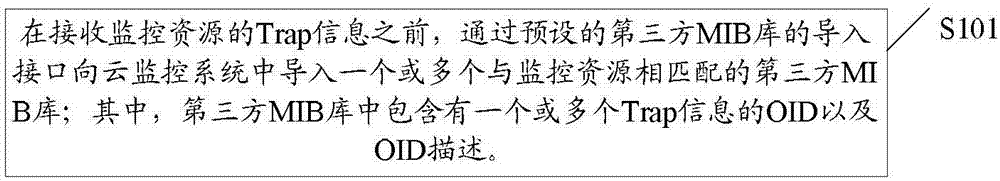

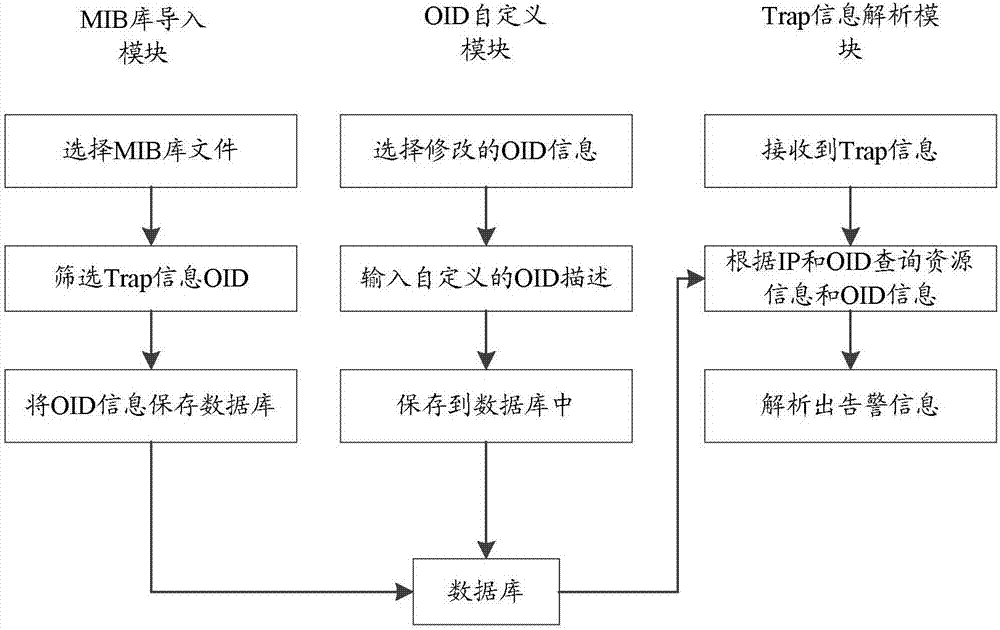

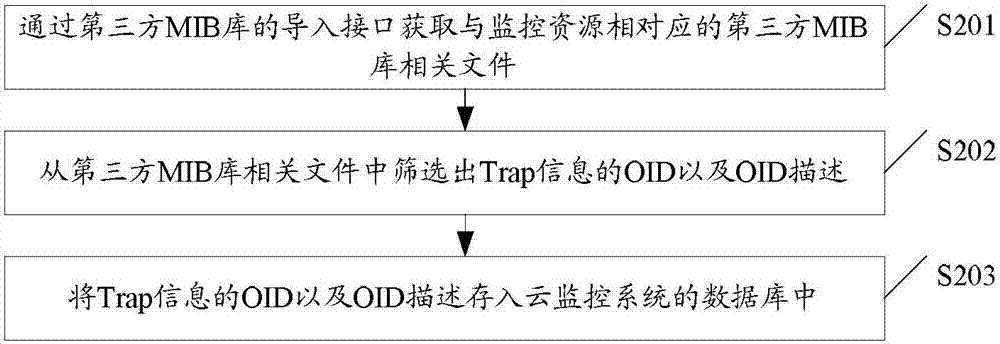

Management information base MIB database configuration method and device

InactiveCN107241415AReduce the amount of human laborImprove configuration efficiencyTransmissionThird partyManagement information base

The embodiment of the invention discloses a management information base MIB database configuration method comprising the following steps: before receiving monitoring resource Trap information, using a preset third party MIB database import interface to import one or more third party MIB databases matched with the monitoring resource into a cloud monitoring system, wherein the third party MIB database contains one or more Trap information OID and OID descriptions. The embodiment also discloses a MIB database configuration device. The method uses the preset third party MIB database import interface to import one or more third party MIB databases matched with the monitoring resource into the cloud monitoring system, thus reducing labor sum, improving configuration efficiency, and reducing maintenance cost.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Automatic control device for livestock drinking

InactiveCN111657163AReduce the amount of human laborReduce manual laborAnimal watering devicesCrop livestockAutomatic control

An automatic control device for livestock drinking belongs to the field of livestock automation equipment. A water outlet baffle is mounted in a limiting support, a buoy is fixed on the inner wall ofa water tank, an adjusting device is mounted above the buoy, a water inlet pipe is mounted on a first support, and a fishing rack is placed on a storage rack. Clear water flows into the water tank from the upper portion of the water inlet pipe, foam rises along with the water level, a rubber pad rises accordingly, the rubber pad seals the bottom of the water inlet pipe along with contact between the rubber pad and the bottom of the water inlet pipe, and the water inlet pipe stops water incoming; when the water level in the water tank is gradually reduced, a gap is formed between the rubber padand the water inlet pipe, clear water from the water inlet pipe can continuously flow into the water tank, and after the water level reaches the preset water level, the rubber pad seals the water inlet pipe again to finish the process of keeping the water level stable, so that the process of filling water on time by workers is replaced, the labor force is saved, and sufficient water supply is ensured.

Owner:荆门怡盛源环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com