Special tire grasping device for tire dismounting machine

A technology of grabbing device and tire changer, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of high labor intensity, tire damage, cumbersome handling, etc., achieving a high degree of automation, stable operation, and lightening The effect of human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

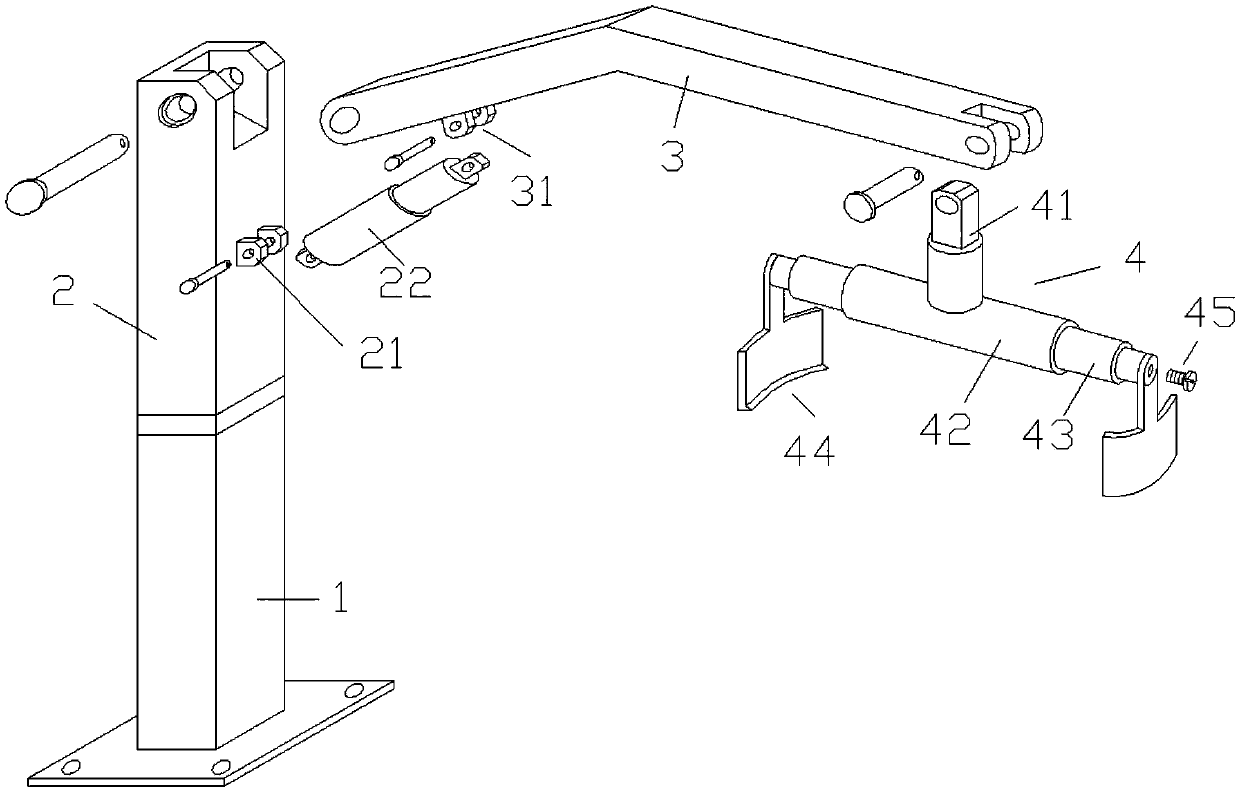

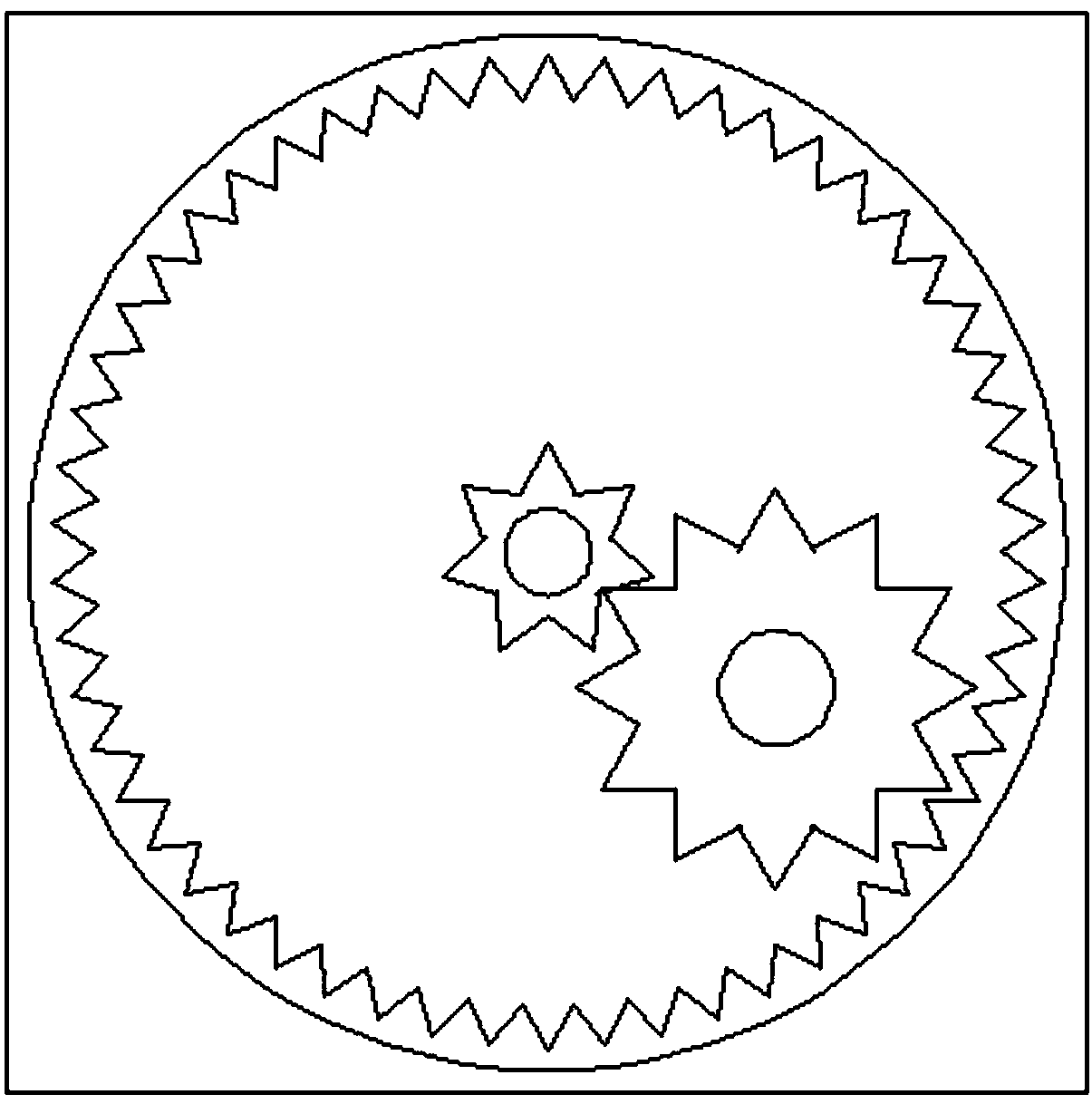

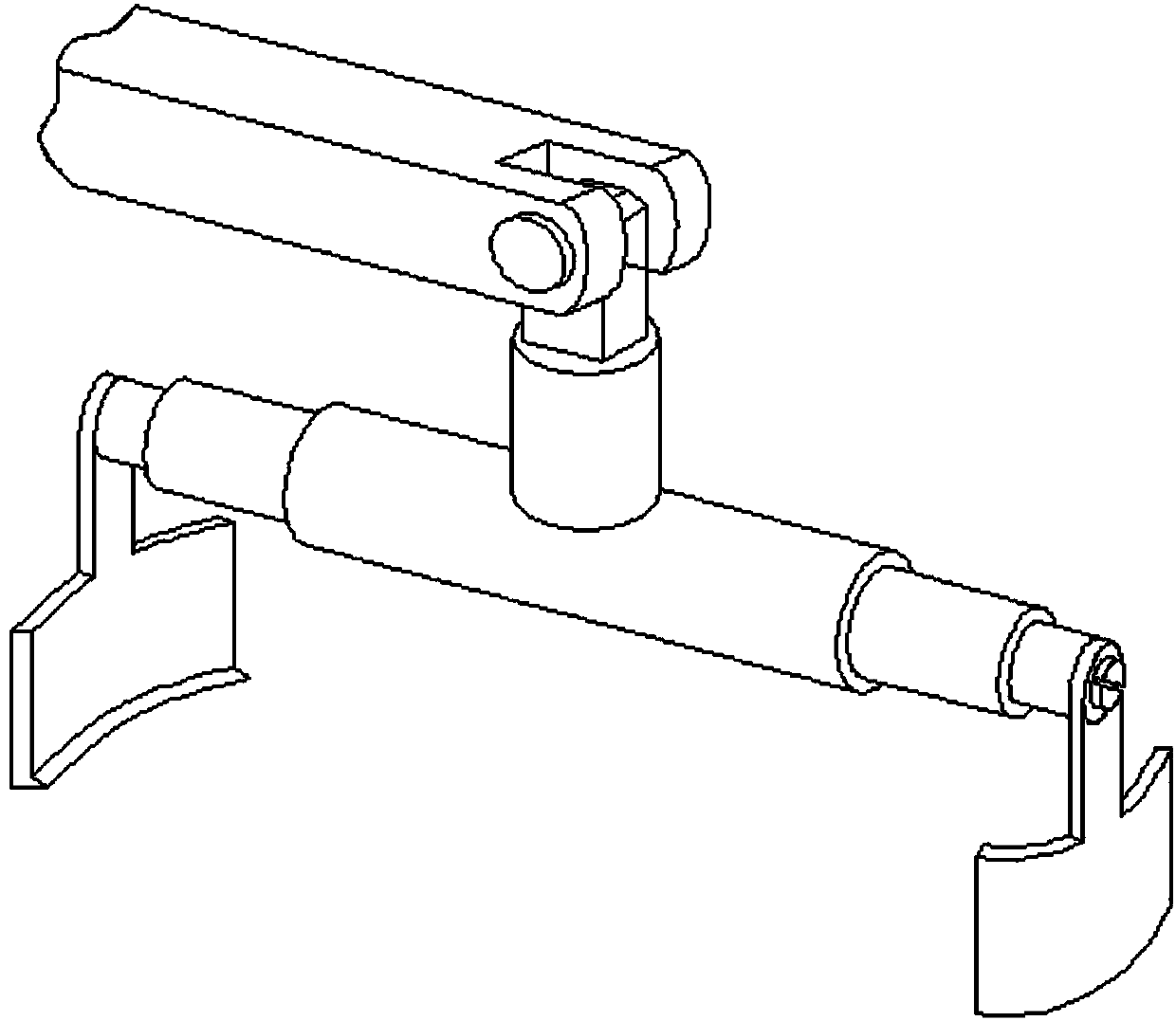

[0022] Embodiment: a special tire grabbing device for a tire changer, including a fixed column 1, a rotating column 2, a curved arm 3, a grasping claw 4, and a control system; the bottom of the fixed column 1 is connected to the support seat, and the bottom of the rotating column 2 is connected to the fixed column 1 is connected at the upper end, one end of the crank arm 3 is connected with the upper end of the rotating column 2, and the upper end of the grasping claw 4 is connected with one end of the crank arm 3, and the crank arm 3 and the grasping claw 4 are connected by pins to form a swing structure; the lower end of the fixed column 1 is welded In the middle position on the upper side of the support seat, the outer ring of the deceleration structure is installed inside the upper end of the fixed column 1, and an interference fit is adopted between the two. The idle speed motor is installed inside the lower end of the rotating column 2, and the sun gear is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com