Tin rinsing device for wire connector

A technology for wire joints and equipment, applied in circuits, connections, electrical components, etc., can solve the problems of poor wire joints, inconvenience for tinning personnel, and easy heating of wires, so as to improve the efficiency of tinning work, save time, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

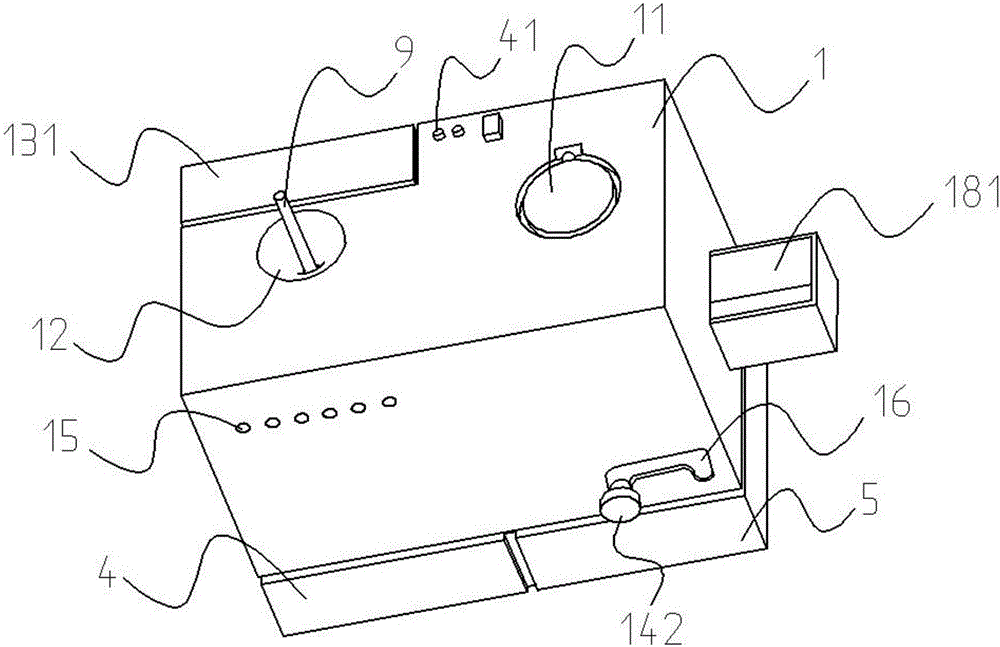

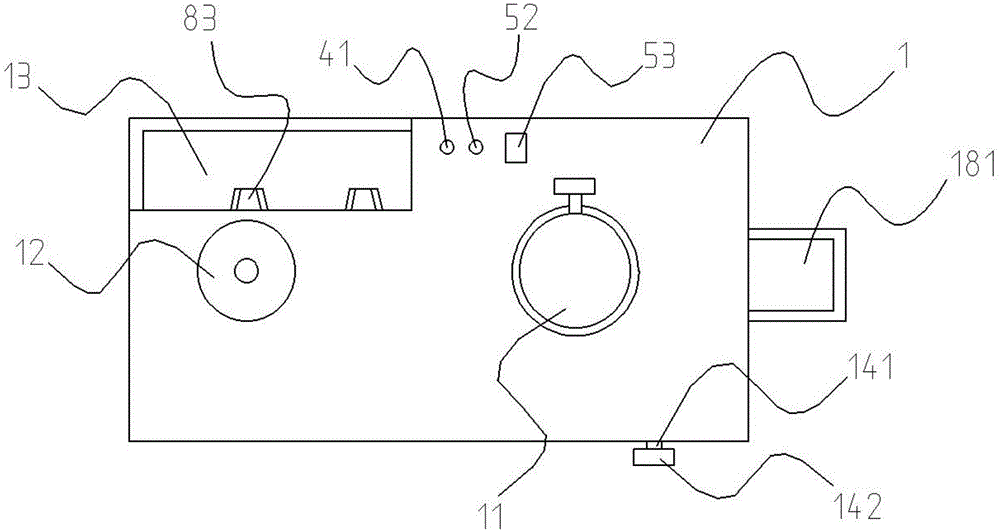

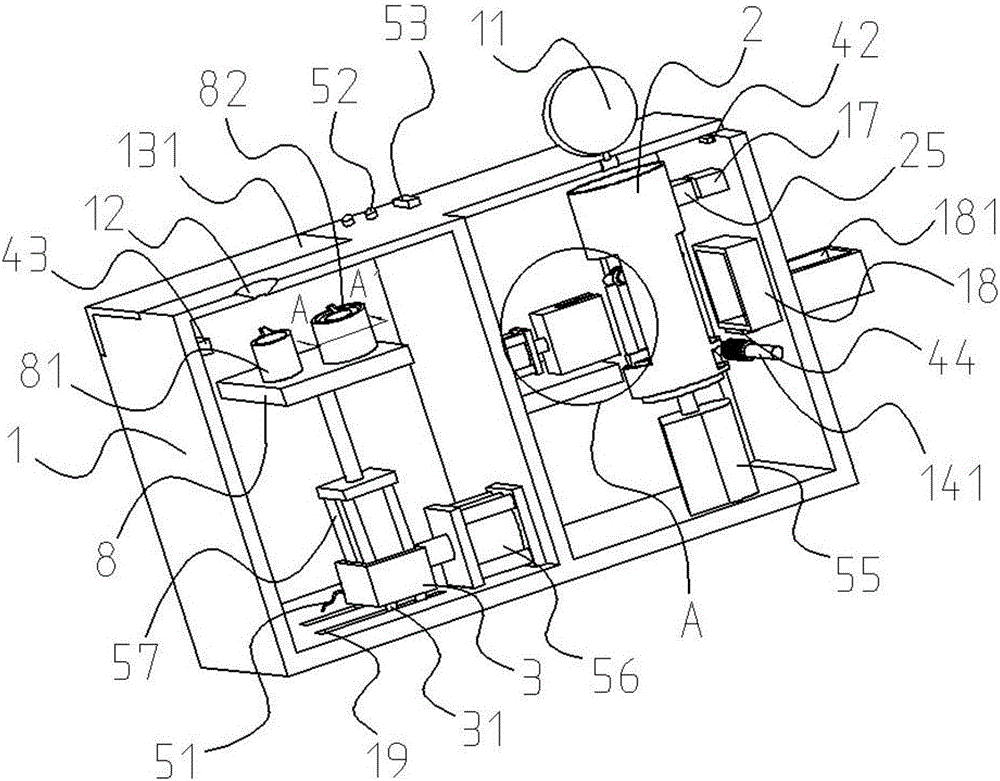

[0042] Such as Figure 1 to Figure 14 As shown in the figure, a tinning equipment for wire joints includes a shell 1, a peeling cover 11, a tinning opening 12, a feeding opening 13, a feeding opening cover 131, a bull's-eye bearing 14, a worm 141, a fixed knob 142, and a cooling hole 15, n-shaped track 16, magnet one 17, outlet lenticels 18, wire sheath holding groove 181, pulley rail 19, rotating sleeve 2, rectangular through hole 21, turbine hole 22, spring fixing frame one 23, spring 231, fulcrum Body 24, magnet two 25, lever body 26, spring fixing frame two 261, fulcrum rotating column 262, sliding column 263, supporting body 3, roller 31, controller 4, completion indicator light 41, infrared sensor one 42, infrared sensor two 43. Infrared sensor three 44, mobile power supply 5, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com