Forage grass baling machine used for animal husbandry and capable of achieving efficient and automatic feeding

An automatic feeding and baler technology, applied in the field of animal husbandry, can solve the problems of low efficiency, manual loading and unloading, and large space occupied by feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

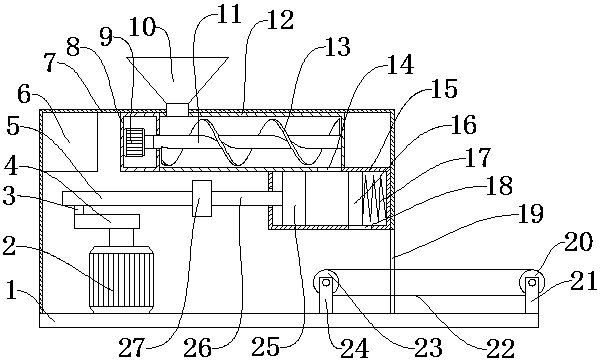

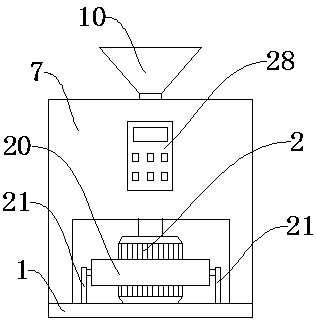

[0027] Such as Figure 1-Figure 3 As shown, a high-efficiency and automatic feeding forage baler for livestock includes a bottom plate 1, a box body 7, and a feeding funnel 10. The box body 7 is fixedly installed on the upper surface of the bottom plate 1, and a storage battery is fixedly installed on the top side of the box body 7. 6. The battery 6 provides electric energy. The top of the box body 7 is fixedly installed on the side away from the battery 6. The support box 8 acts as a support. The support box 8 is provided with a feeding motor 9, which drives the feeding. The side of the support box 8 away from the battery 6 is provided with a feeding box 12. The inside of the feeding box 12 is provided with a horizontally placed feeding rod 11. The feeding rod 11 extends to the inside of the supporting box 8 and is fixedly connected to the feeding motor 9. There are helical blades 13, and a feeding hole 14 is arranged on the lower surface of the feeding box 12 away from the s...

Embodiment 2

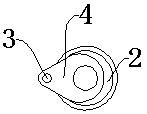

[0029]The difference between this embodiment and Embodiment 1 is that the connecting block 3 is connected with the connecting rod 5 through a bearing, the connecting rod 5 is connected with the rotating shaft 27 through a bearing, the push rod 26 is connected with the rotating shaft 27 by welding, the connecting rod 5, the rotating shaft 27, the push rod The rod 26 and the briquetting block 25 form a connecting rod slider mechanism, the briquetting block 25 squeezes the feed, the driven roller is connected to the first pole 21 through a bearing, the driving roller 23 is welded to the second pole 24, and the driving roller 23 drives the conveyor belt 22 , supported by driven rollers to discharge the pressed feed, the feeding motor 9 is connected with the support box 8 by screws, the feeding motor 9 drives the screw blade 13 to rotate and push the feed, the cam 4 and the drive motor 2 are connected by screws, and the cam 4 drives the motor 2 Rotation becomes swinging, the compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com