Automobile radiator installation frame and radiator assembly installation structure

A technology of automobile radiator and installation structure, which is applied in the arrangement of cooling combination of power plant, power plant, vehicle components, etc., can solve the problems of many auxiliary parts, small application range of radiator, low generalization rate, etc. Strength, improvement of limitations, effect of dispersing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

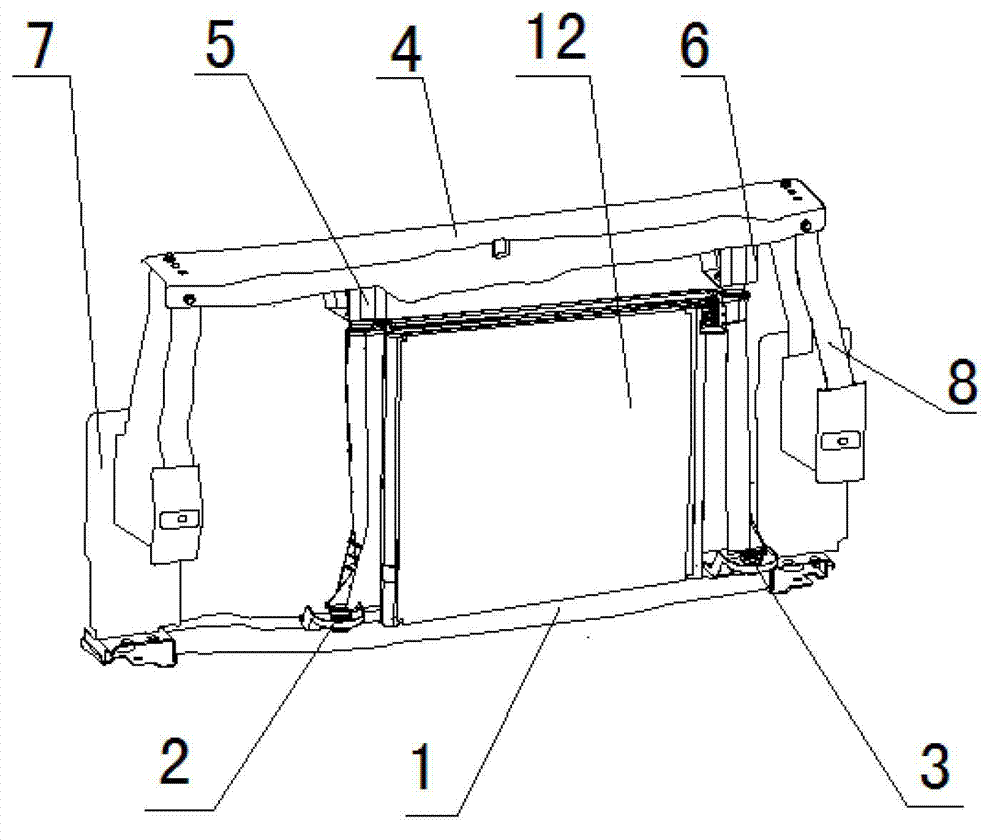

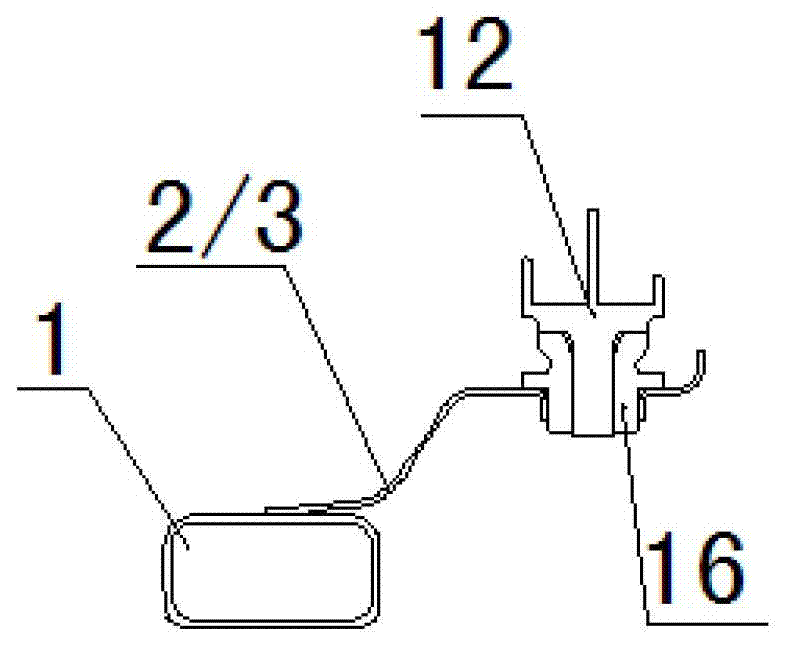

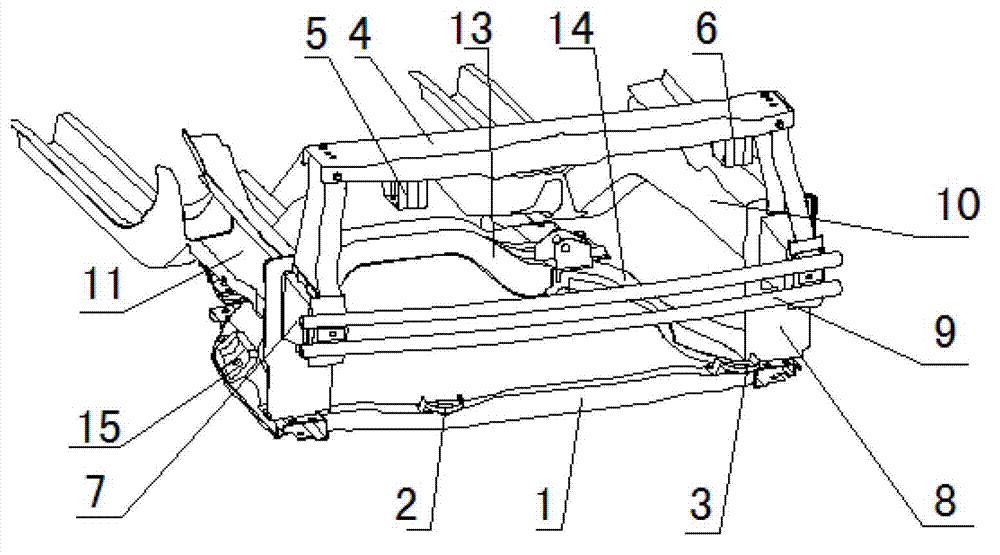

[0017] see figure 1 and figure 2 , the car radiator mounting bracket includes radiator upper beam 4, radiator left upper bracket 5, radiator right upper bracket 6, radiator left column 7, radiator right column 8, engine bracket front beam on the engine bracket assembly 1. Radiator lower left bracket 2. Radiator lower right bracket 3. Wherein the upper left bracket 5 of the radiator and the upper right bracket 6 of the radiator are welded on the upper beam 4 of the radiator as two upper mounting points of the radiator. Radiator left lower bracket 2 and radiator right lower bracket 3 are two "Z"-shaped connecting pieces, the lower plane of which is directly welded on the upper surface of the front beam 1 of the engine bracket, and the flanged hole is opened on the upper plane to connect with the radiator 12. The cylindrical rubber pads 16 are fitted with an interfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com