Direct-drop type rectifying and voltage-regulating transformer and manufacturing method thereof

A voltage regulating transformer and transformer technology, applied in the field of transformers, can solve the problems of inconvenient transportation, large drop-down transformers, and excessive weight of drop-down transformers, and achieve the effect of dispersing weight and facilitating transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

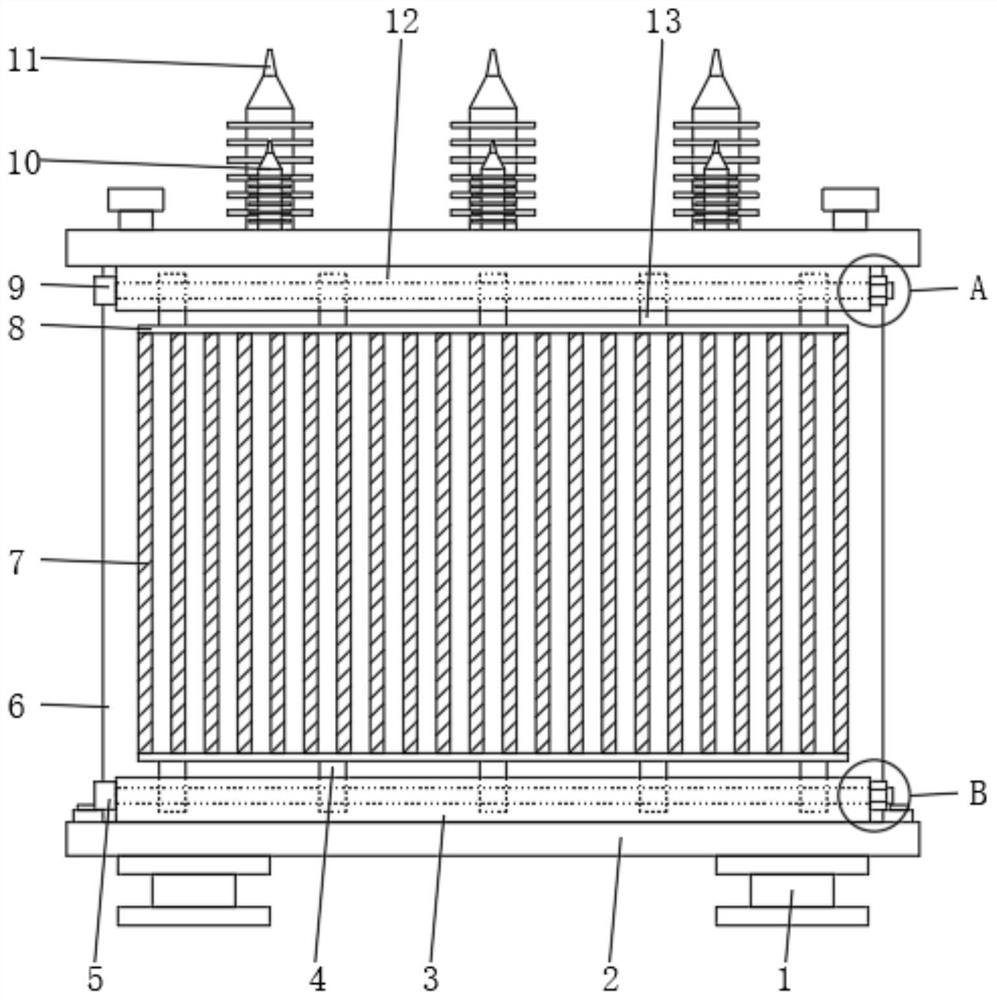

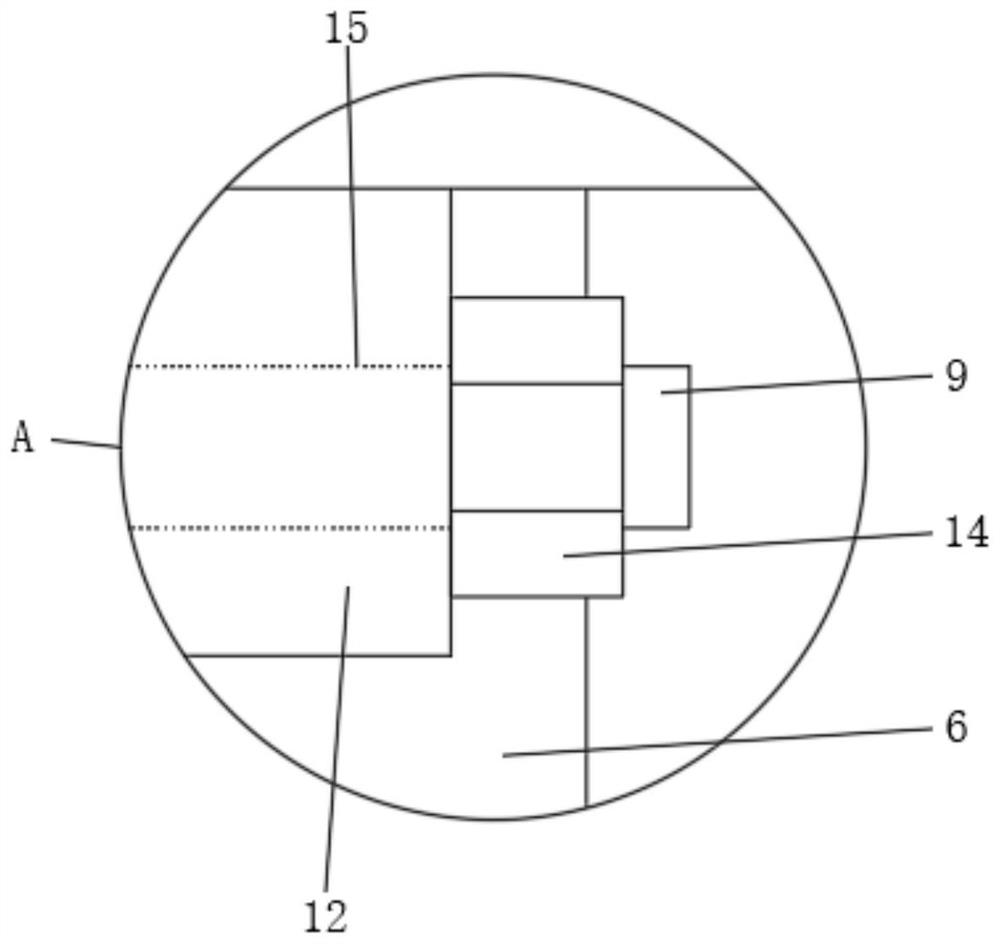

[0039] see figure 1 , Figure 4 and Figure 6 , an embodiment provided by the present invention: a direct-drop rectifying voltage regulating transformer, including a base 2, a first stud 5, a transformer body 6, a heat sink 7 and a second stud 9, and the front end of the upper surface of the transformer body 6 Three low-voltage bushings 10 are fixed equidistantly, and three high-voltage bushings 11 are fixed equidistantly on the rear end of the upper surface of the transformer body 6 . The tops of the front and rear ends of the transformer body 6 are respectively welded with second positioning plates 12, the bottoms of the opposite sides of the two second positioning plates 12 are respectively provided with second slots 22, and the two second positioning plates 12 are respectively provided with a second positioning plate 12. Two through holes 15, the bottoms on both sides of the transformer body 6 are respectively welded with fixing strips 18.

Embodiment 2

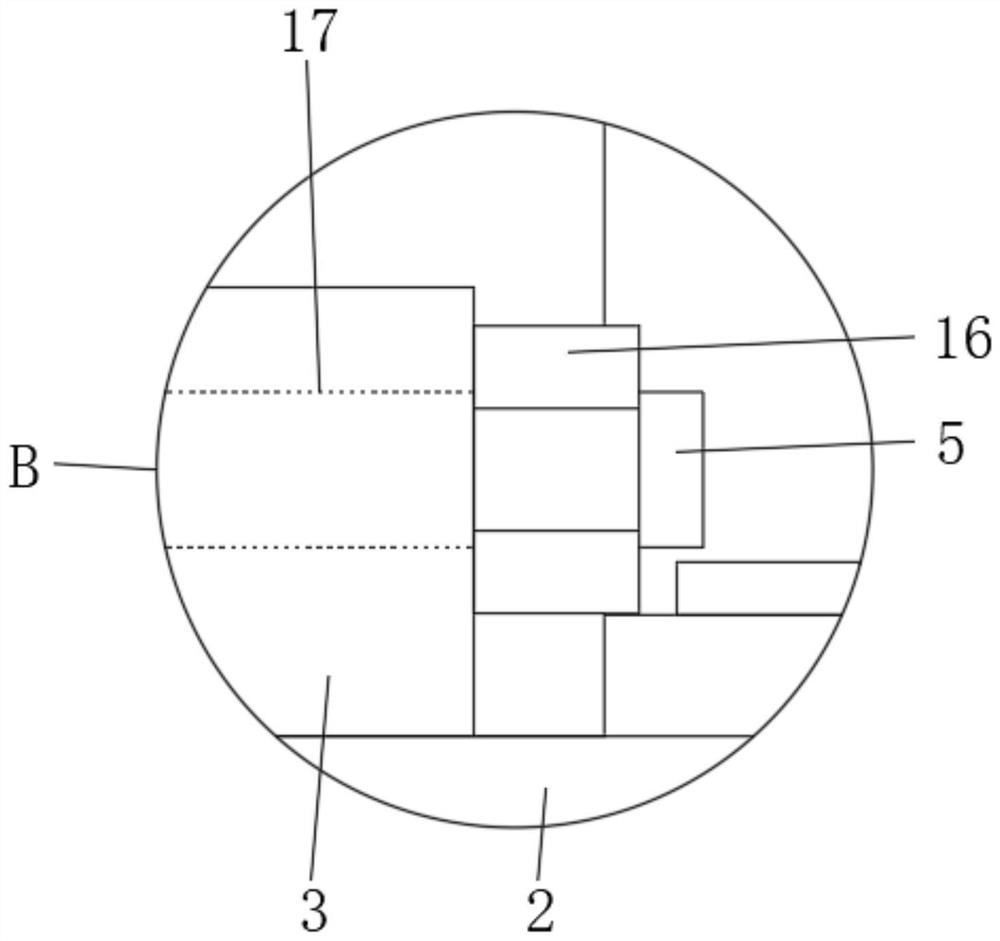

[0041] see figure 1 and Figure 5 , an embodiment provided by the present invention: a direct-drop rectifying voltage regulating transformer, I-shaped feet 1 are respectively welded on both sides of the bottom end of the base 2, and the two I-shaped feet 1 are symmetrical to the central axis of the bottom end of the base 2 distributed. The front and rear ends of the upper surface of the base 2 are respectively welded with a first positioning plate 3, and the tops of the opposite sides of the two first positioning plates 3 are respectively provided with a first slot 20, and the two first positioning plates 3 are respectively provided with a first positioning plate 3. A through hole 17 .

Embodiment 3

[0043] see Figure 1 to Figure 4 , an embodiment provided by the present invention: a direct-drop rectifying voltage regulating transformer, the upper and lower ends of the heat sink 7 are respectively welded with a connecting plate 8, and the lower surface of the connecting plate 8 at the bottom of the heat sink 7 is welded with a first plug-in plate 4. The upper surface of the connecting plate 8 on the top of the heat sink 7 is welded with a second plug-in plate 13 .

[0044] The second inserting plate 13 is inserted into the second slot 22 correspondingly, the second stud 9 passes through the second inserting plate 13 and the second positioning plate 12 from the second through hole 15, and one end of the second stud 9 is threadedly mounted with The second fastening nut 14, the bottom end of the transformer body 6 is installed on the upper surface of the base 2 between the two first positioning plates 3, the fixing bar 18 fixing bolts 19 are fixed with the base 2, and the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com