train anti-roll boat

A train-type, anti-overturning technology, applied in the direction of hull, ship parts, ship construction, etc., can solve the problems of not being able to give full play to ship performance, increase transportation costs, and high production costs, and achieve consistent structure, reduce transportation costs, and lower the center of gravity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

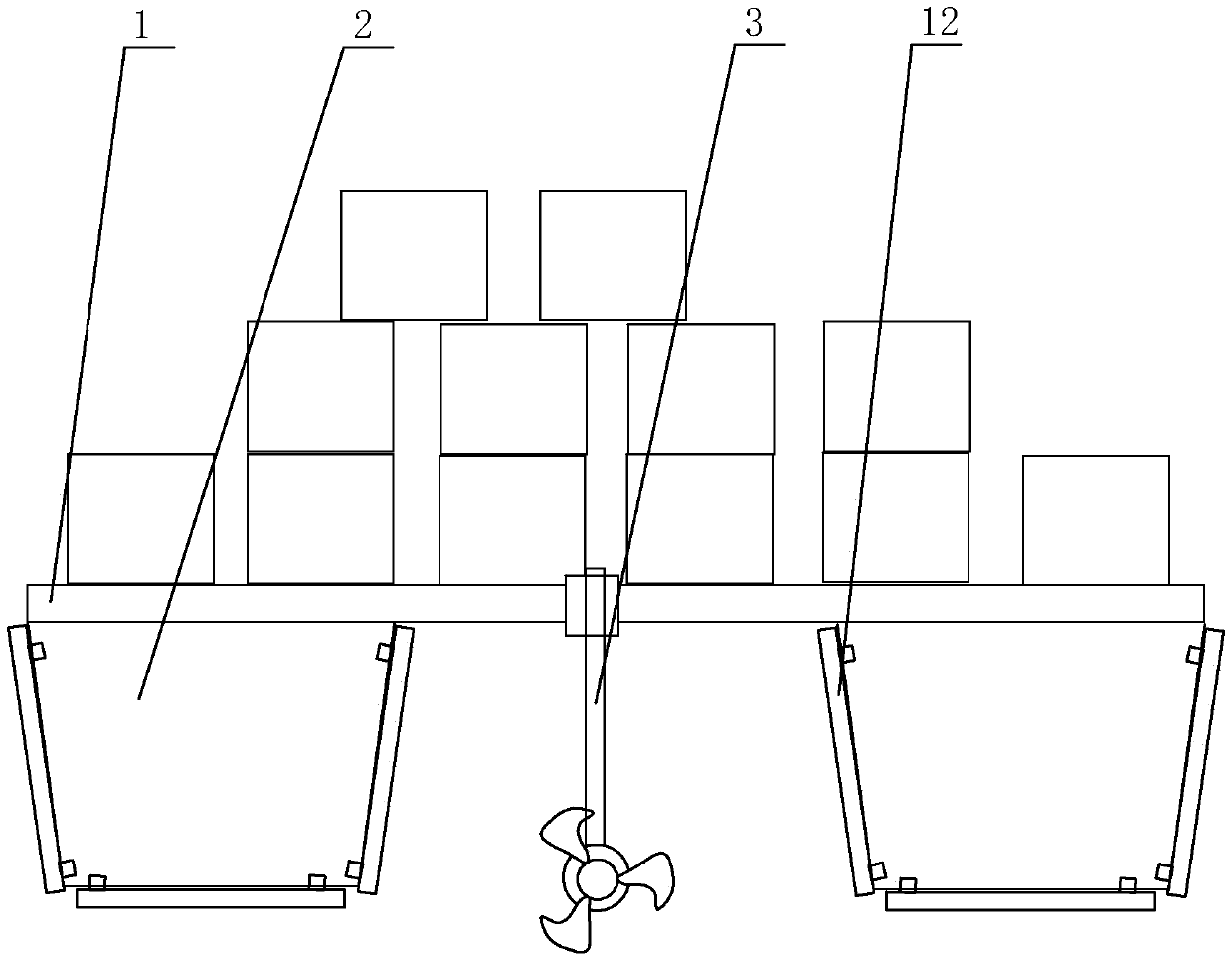

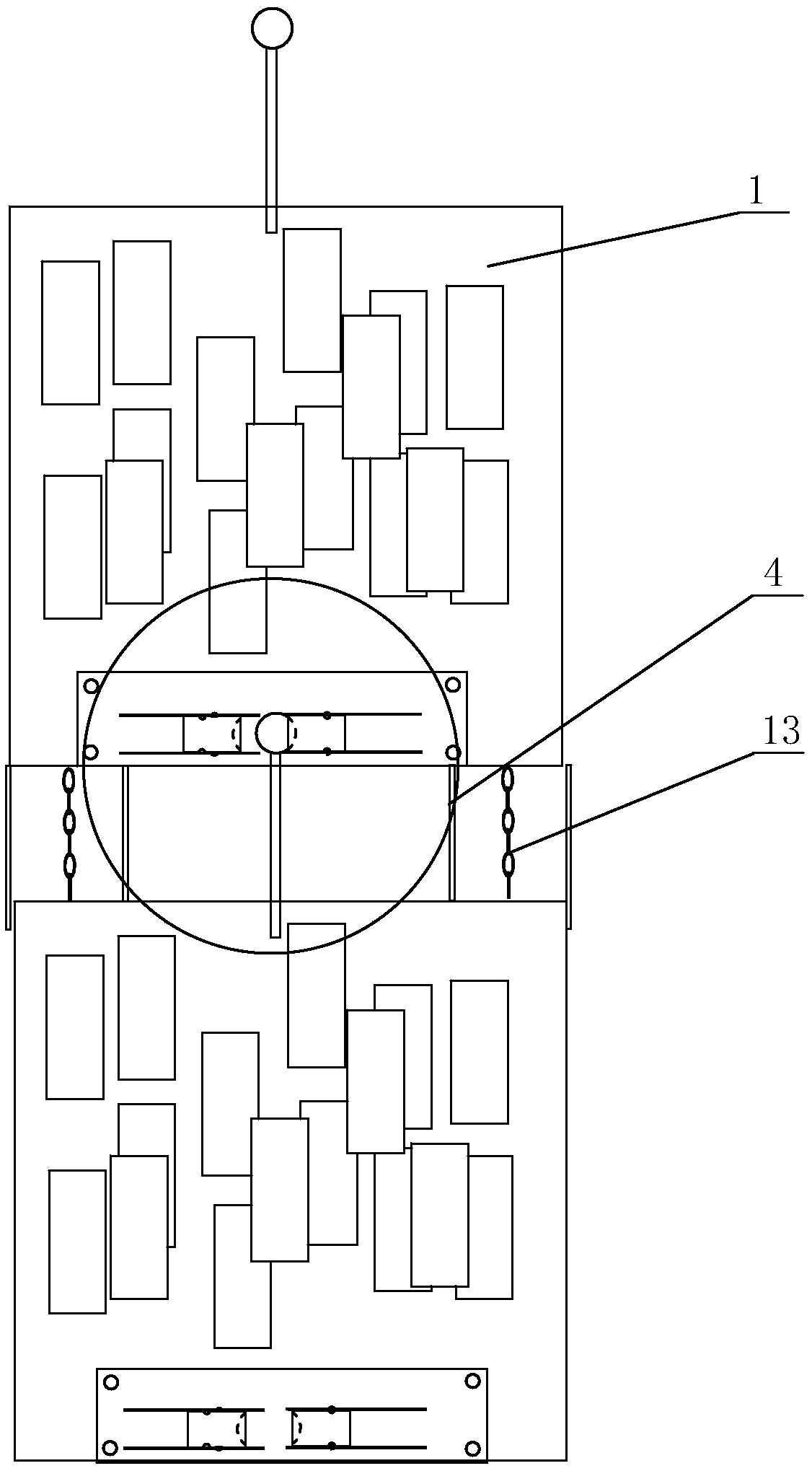

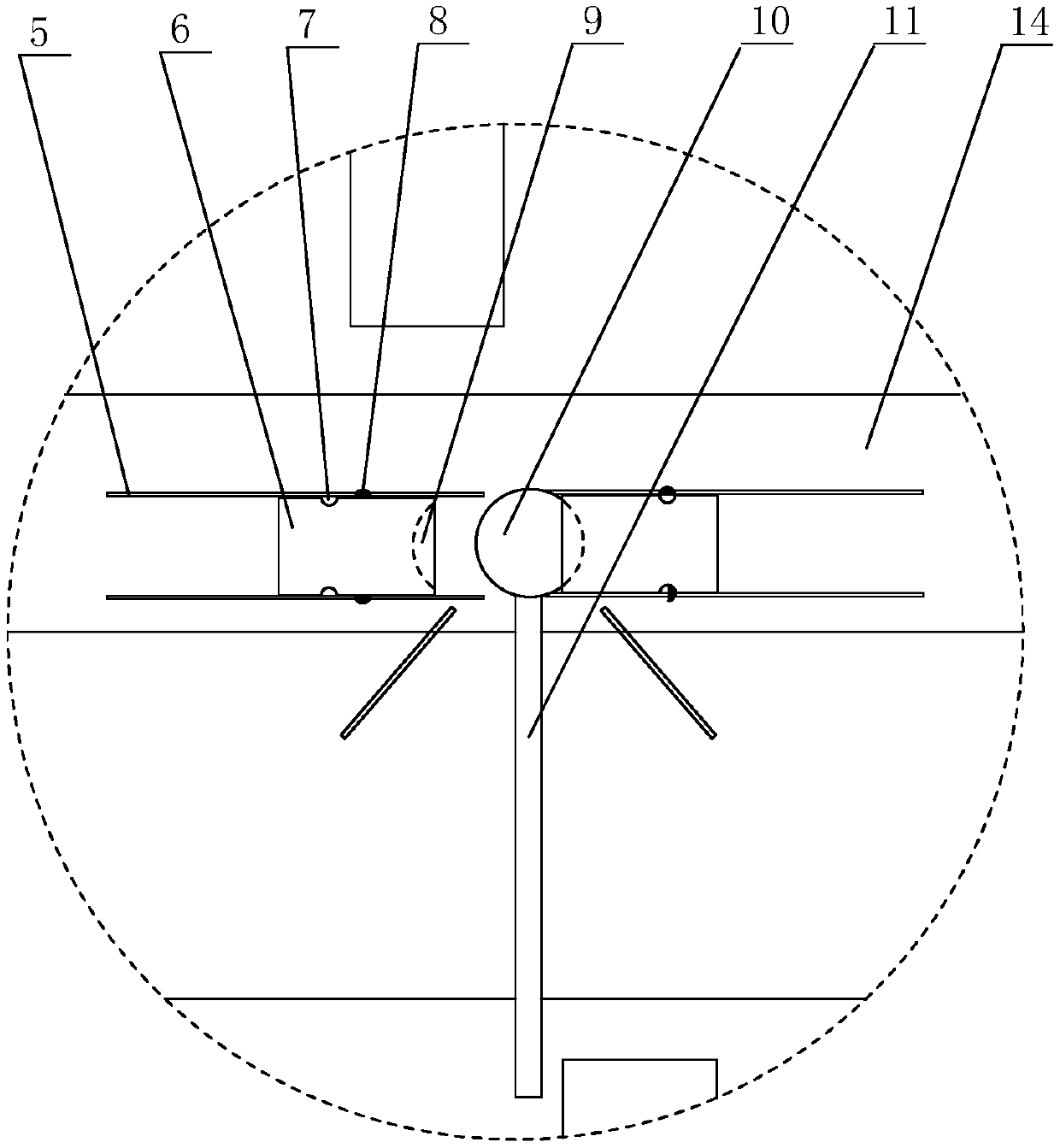

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0027] Such as Figure 1-Figure 5 As shown, the train-type anti-turnover ship of the present invention includes a unit hull 1, the unit hull 1 includes a hull 2, the hull 2 is divided into two parts, and the two hulls 2 are symmetrically arranged on both sides of the hull 1, and the whole hull 1 It is a symmetrical inverted U shape, and a propeller device is arranged at the middle position of the front parts of the two hulls.

[0028] Propeller device 3 comprises motor 19, fixed drive gear 18 on the rotating shaft of motor 19, and drive gear 18 meshes with driven gear 15, and driven gear 15 is fixed on drive shaft 16 at drive gear outside driven gear 15, and drive shaft 16 is installed In the sleeve 17, the sleeve 17 is hinged on the hinged rod 20, the hinged rod 20 is fixed on the lower part of the hull 1, the bottom of the transmission rod 16 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com