Automatic filament coiling machine with two hexagonal wheels

A technology of wire collecting machine and hexagonal wheel, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. Fast spinning, smooth rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

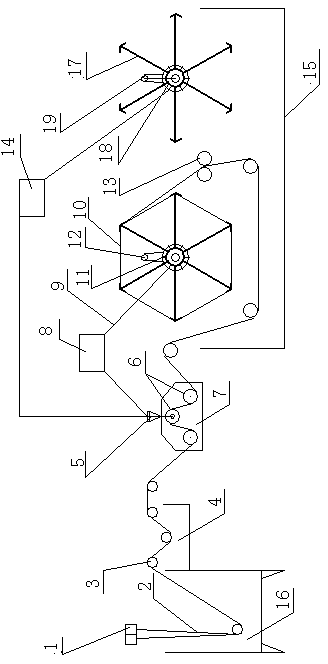

[0008] The structural principle of the double hexagonal wheel automatic wire receiving machine of the present invention is as follows: figure 1 As shown, the double hexagonal wheel automatic wire collection machine, the hollow fiber 2 (hollow fiber ultrafiltration membrane) is connected to the spinning machine 13 through the transmission wheel 6 and the godet roller 3 in the water tank 7, and the hollow fiber 2 output by the spinning machine 13 Connect No. 1 hexagonal wire reel 10 or No. 2 hexagonal reel 17, be provided with two hexagonal reel 10,17, install tension sensor 5 on the transmission wheel 6, tension sensor 5 is connected and installed in by wire 9 No. 1 automatic tension meter 8 and No. 2 automatic tension meter 14 on the wire receiving groove 15, magnetic powder clutches 11 and 18 are installed at the centers of the hexagonal wire receiving wheels 10 and 17, and No. 1 automatic tension meter 8 is connected to No. 1 six The magnetic powder clutch 11 of the side wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com