Patents

Literature

31results about How to "Increase the effective bonding area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

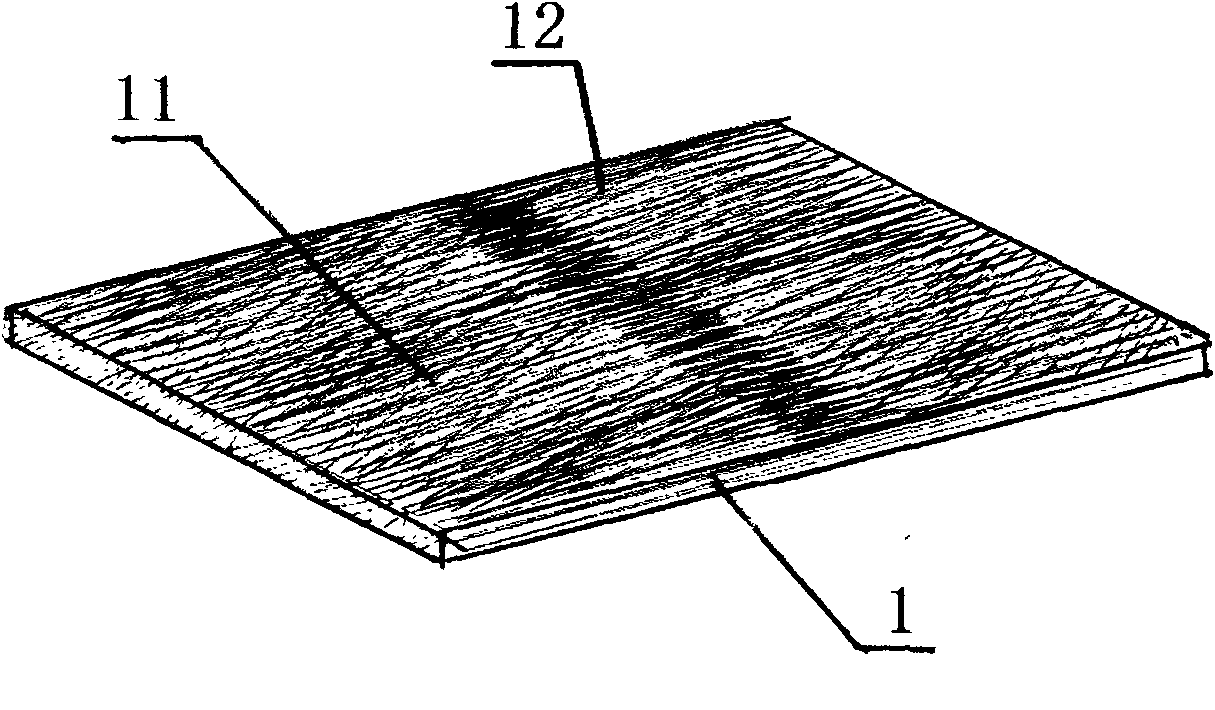

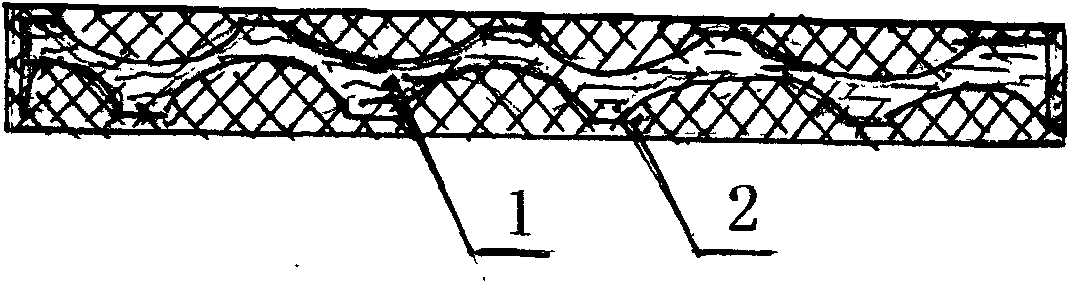

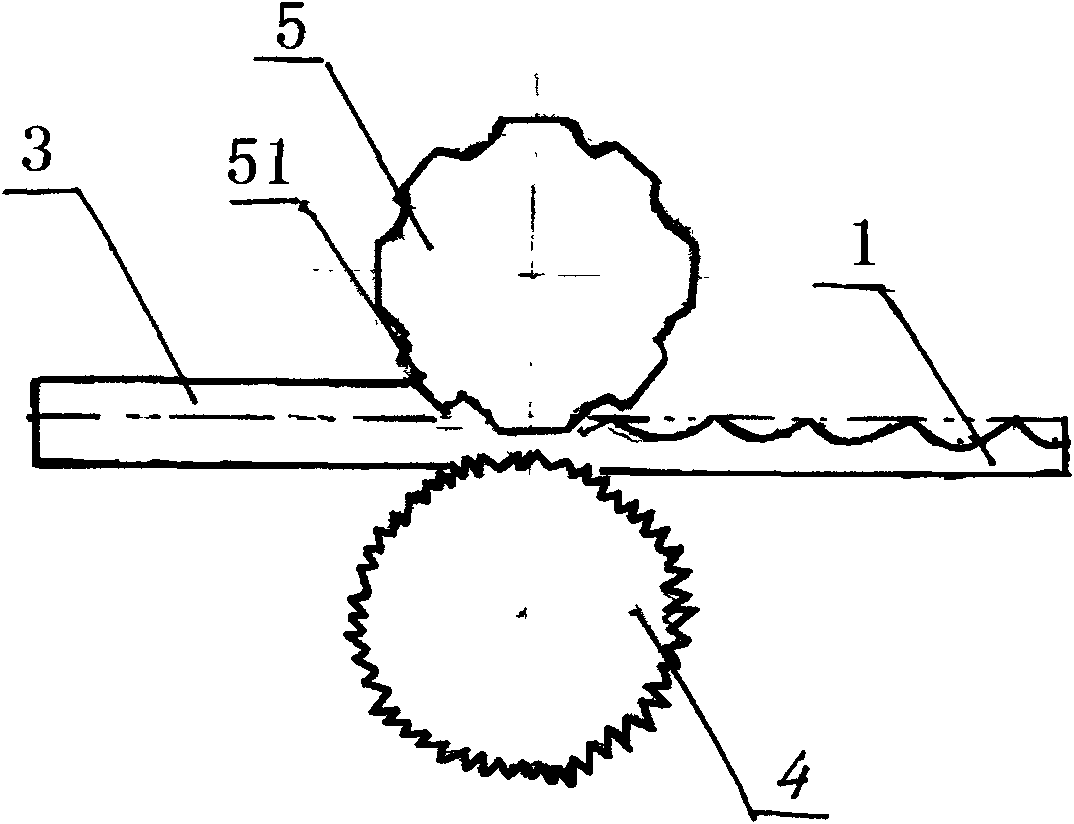

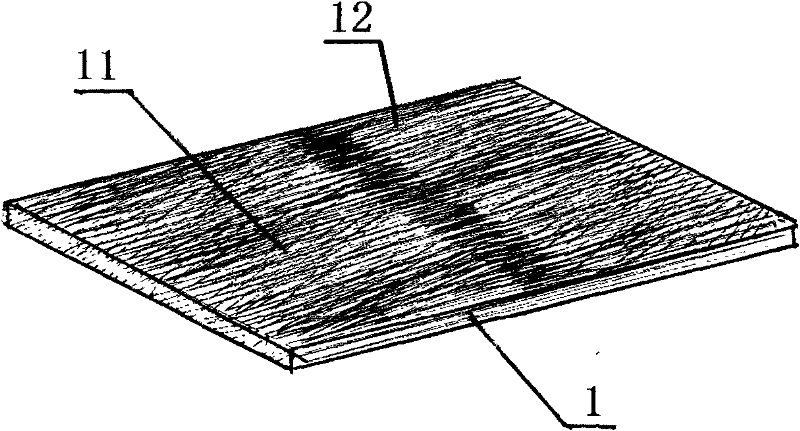

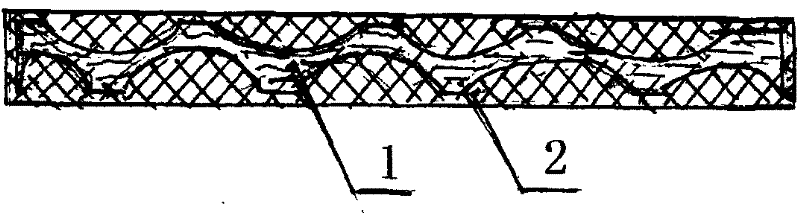

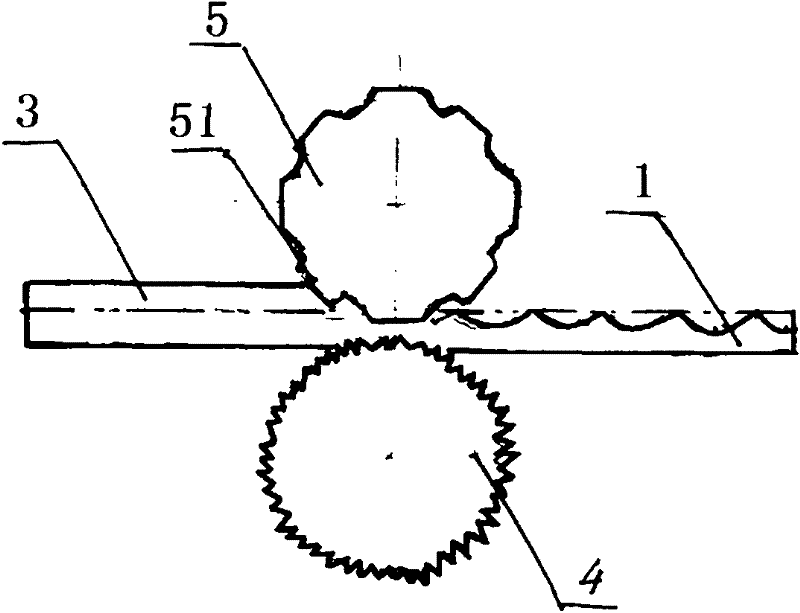

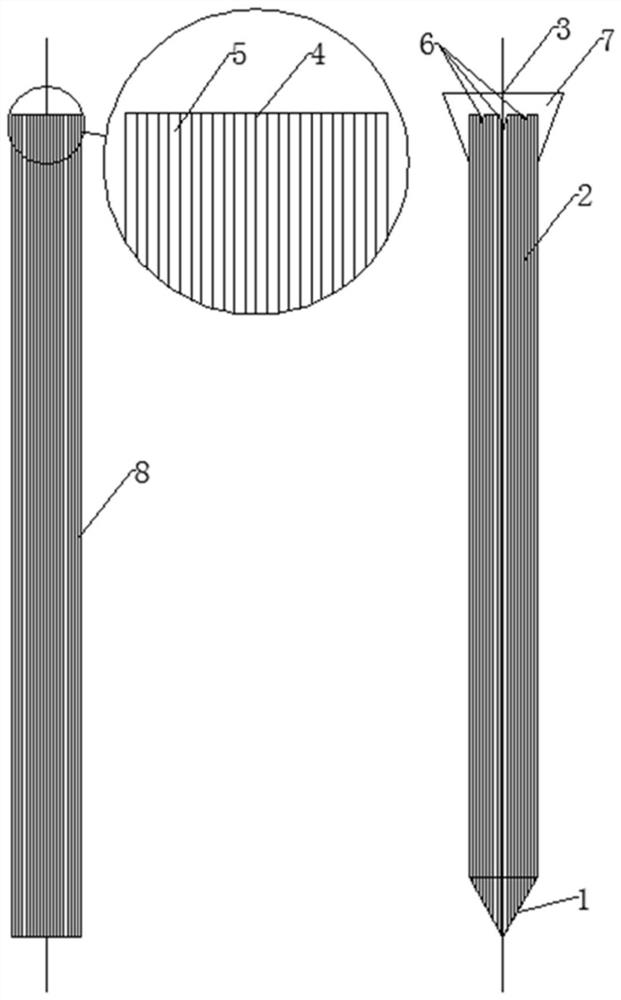

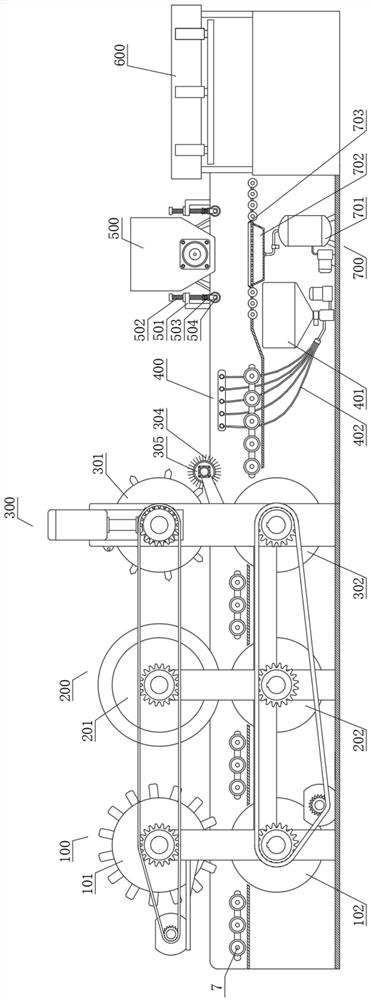

Bamboo fiber reinforced composite material and manufacturing method thereof

ActiveCN101607411AIncrease the effective bonding areaOptimize the penetration pathFlat articlesDomestic articlesHardnessFiber-reinforced composite

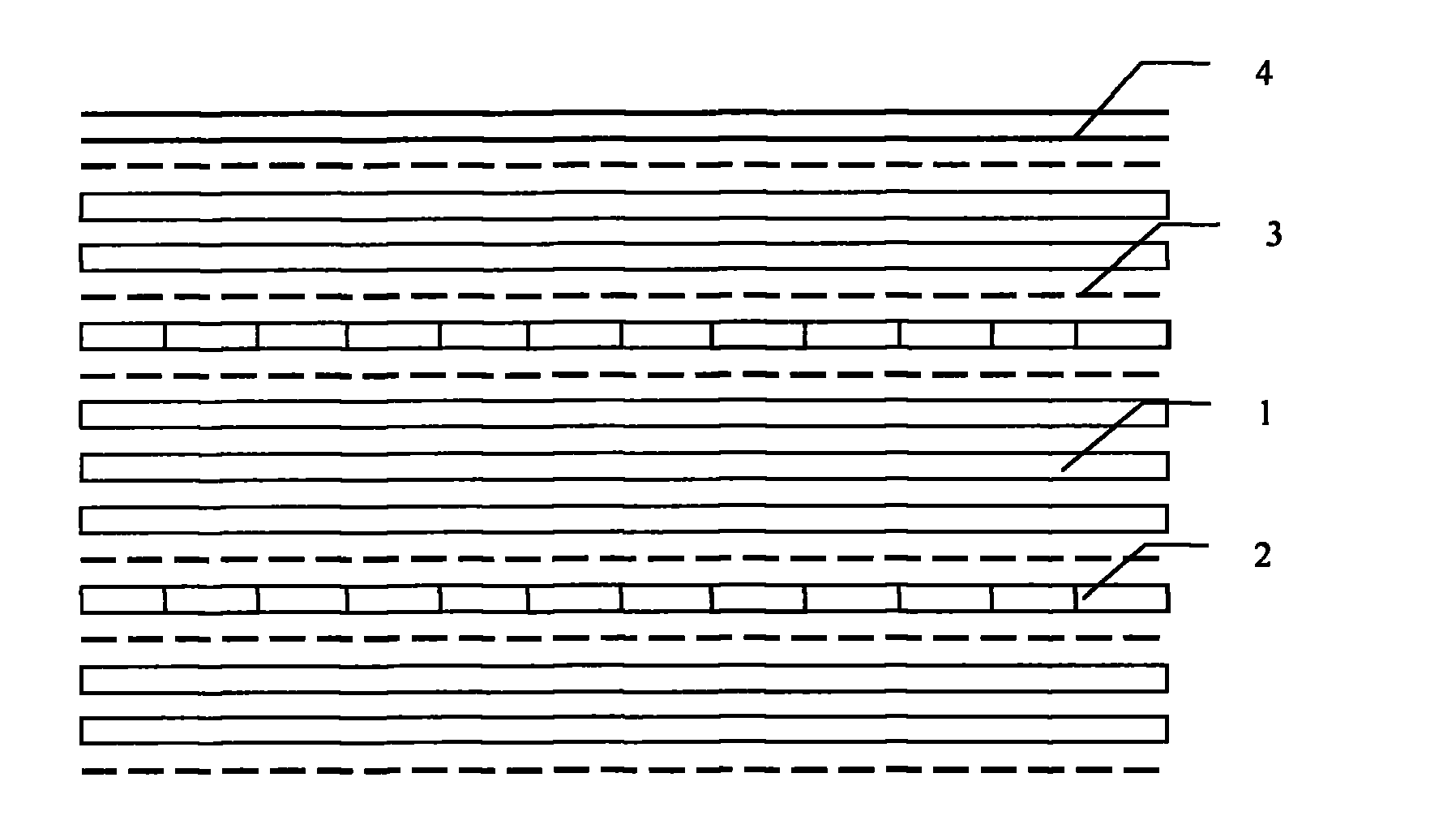

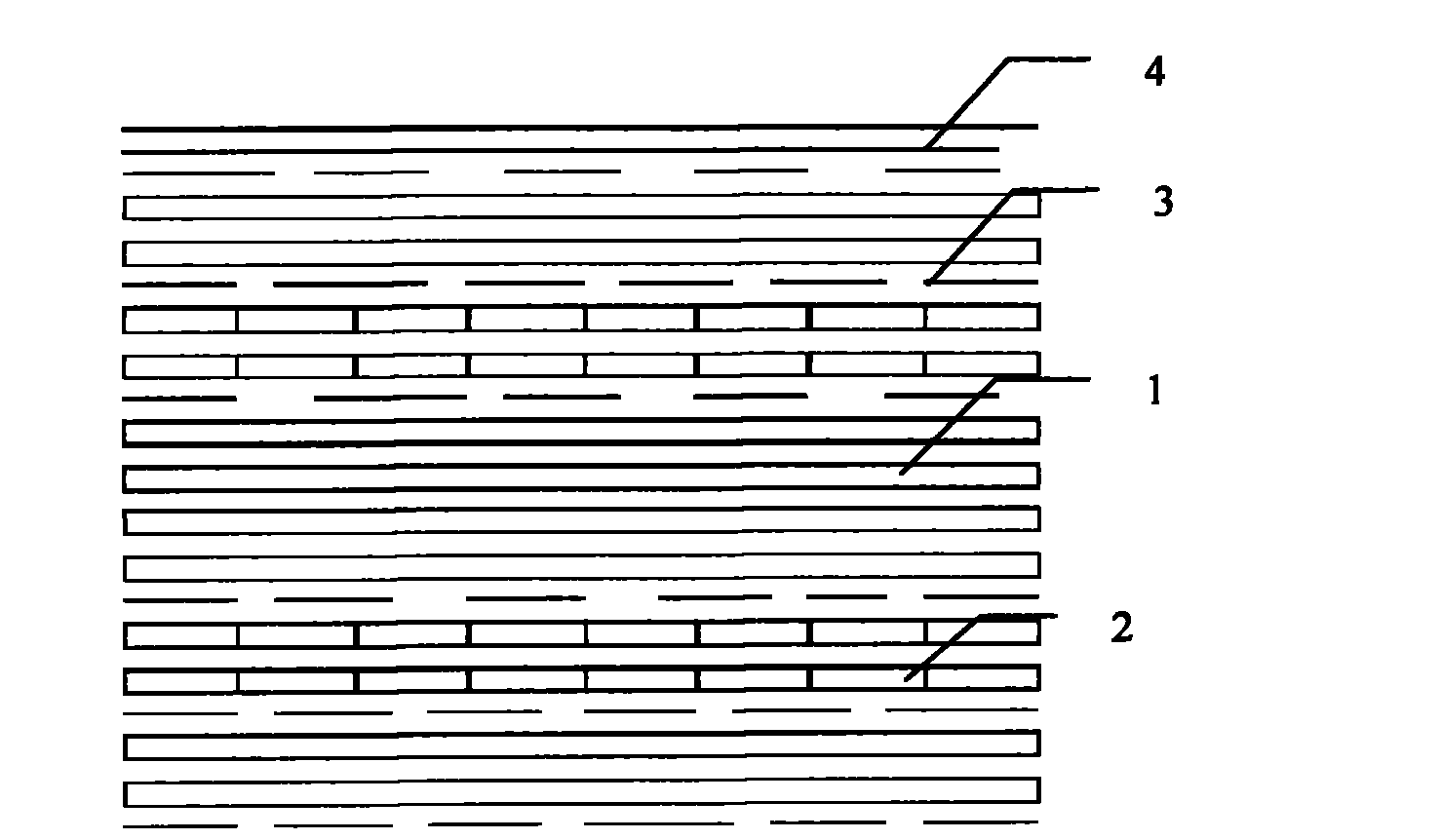

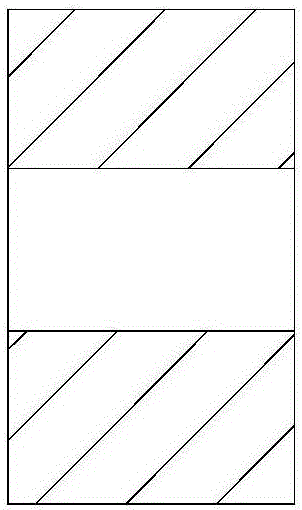

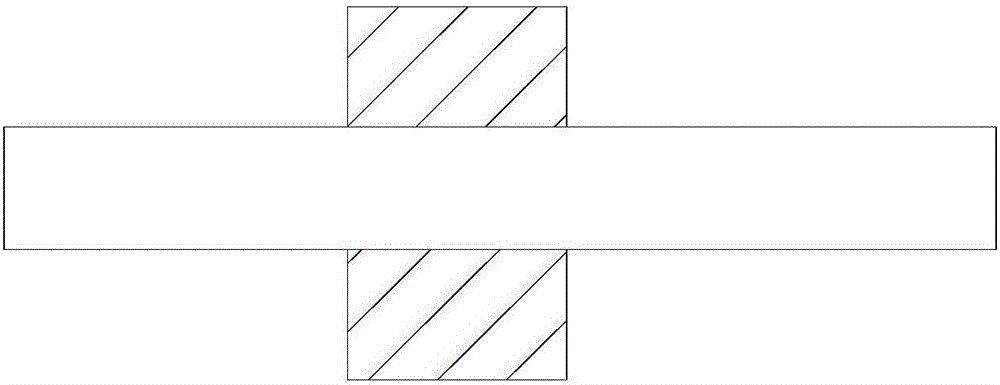

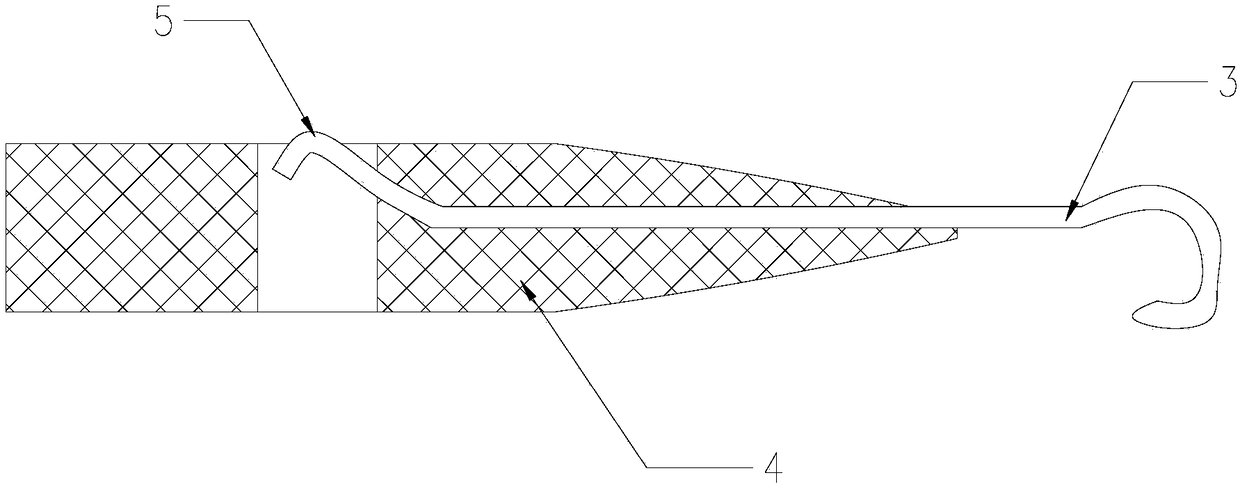

The invention relates to a bamboo fiber reinforced composite material and a manufacturing method thereof. The bamboo fiber reinforced composite material is formed by directional bamboo fiber felt and an adhesive layer; the upper surface and the lower surface and the thickness direction of the directional bamboo fiber felt are respectively provided with a series of longitudinal cracks which are disconnected uniformly and have nonuniform thickness; the manufacturing method thereof comprises the following steps: longitudinally splitting a section of bamboo tube into two semicircular bamboo tubes along the diameter thereof, removing internal segments, defibering the internal arc surface of the semicircular bamboo tube by a driving roller and a defibering roller, then defibering the external arc surface of the semicircular bamboo tube, then carrying out glue applying, hot-pressing and forming the bamboo fiber reinforced composite material; the series of longitudinal cracks which are disconnected uniformly and have nonuniform thickness are defibered from both the internal arc surface and the external arc surface of the semicircular bamboo tube, simultaneously the bamboo green and bamboo yellow are also removed, therefore, the bamboo fiber reinforced composite material and the manufacturing method thereof increase the effective gluing area of the bamboo material, improve the penetration path of the bamboo materials, lead the strength and hardness of the plywood to be greatly improved and having good processing performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

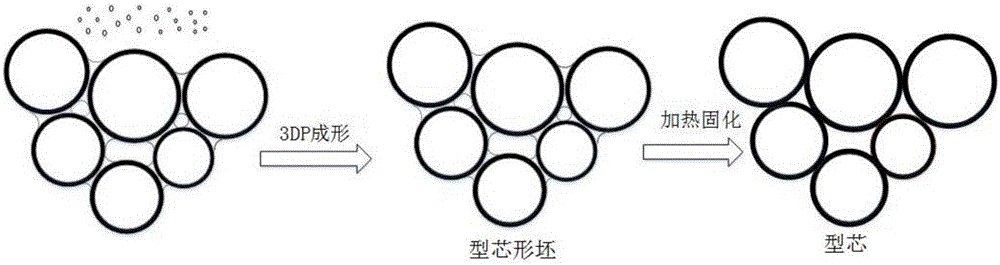

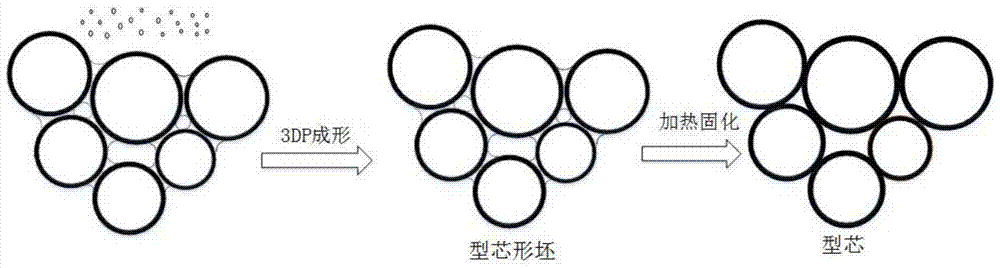

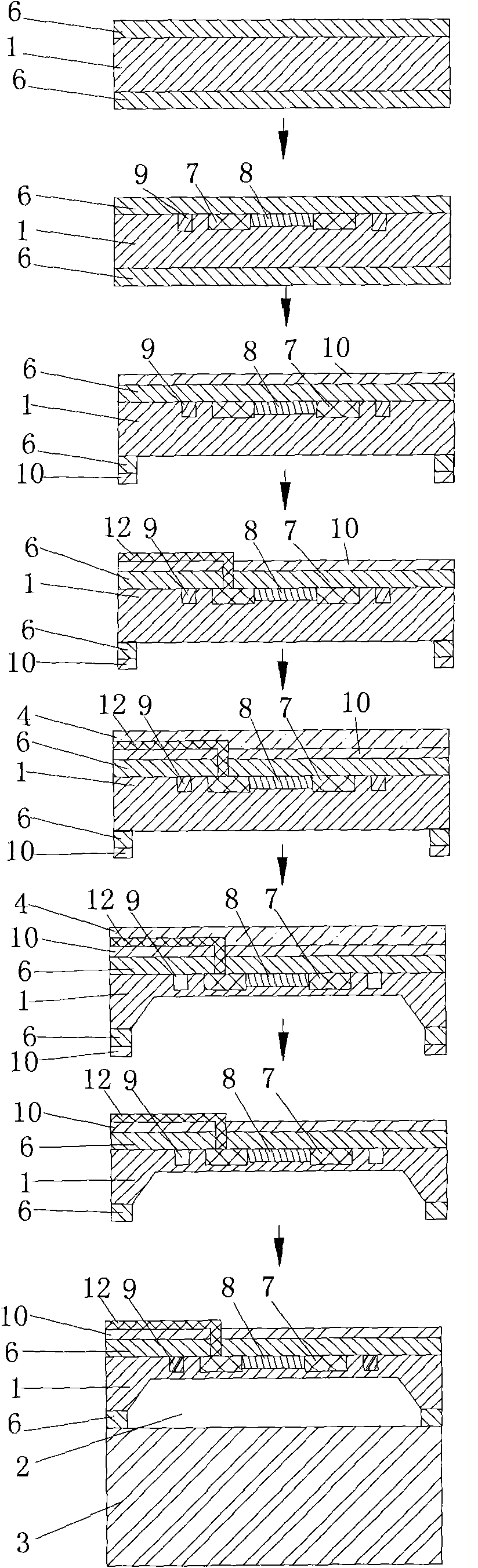

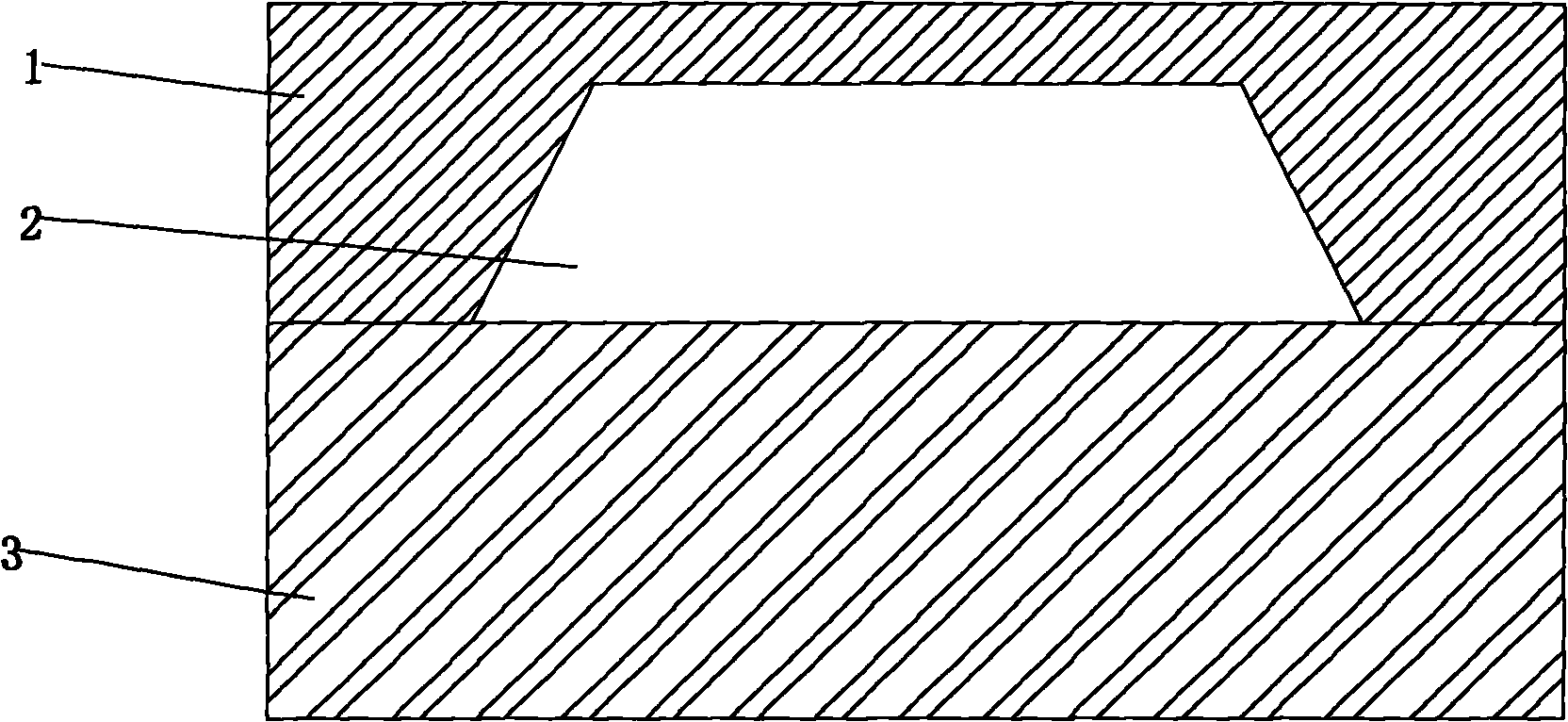

Method for three-dimensional jet-printing, forming and casting of core

ActiveCN105057601AHigh viscosityIncrease surface tensionFoundry mouldsFoundry coresFine structureThin layer

The invention discloses a method for three-dimensional jet-printing, forming and casting of a core. The method comprises the comprises the following steps: (1) spreading film covering sand to form a thin layer, and selectively injecting bonding liquid into the film covering sand by using a three-dimensional jet-printing device so that particles in the film covering sand can be bonded with one another to form a first layer; (2) forming a second layer by using the same method in the step (1), repeating the step (1) until a part is formed completely, and standing the part in a powder bed for a period of time so as to obtain an initially formed blank; and (3) heating the initially formed blank at the temperature of 170-220 DEG C until the bonding liquid completely volatilizes, and cross-linking and curing with phenolic resin, so that the casting of the core is finished. According to the method, the method for three-dimensional jet-printing, forming and casting of the core is simplified; the film covering sand can be accumulated layer by layer without drying conditions among layers, so that the fast casting forming of the core is finished; finally, a produced piece is relatively high in intensity, low in cost and high in efficiency; the method can be used for producing the casting core with the large size and a fine structure, and has a wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

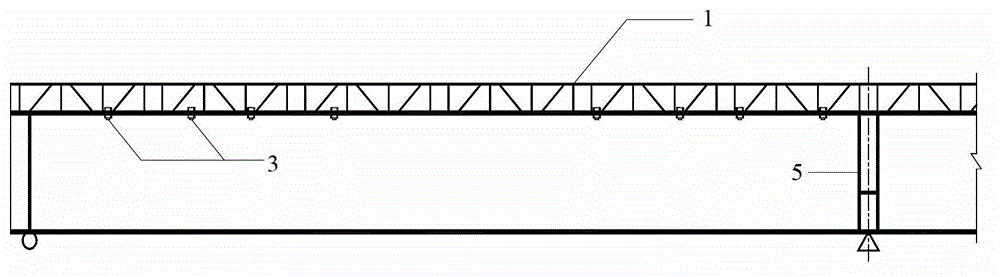

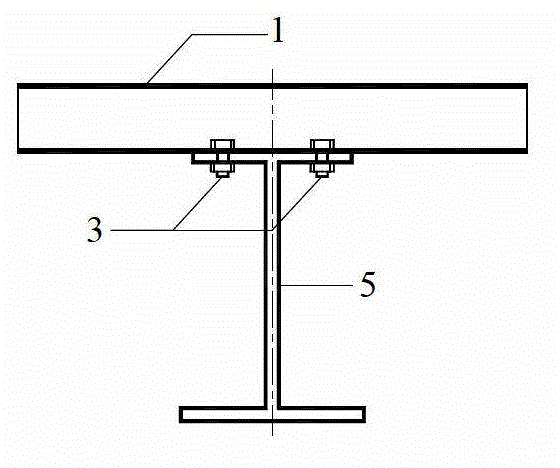

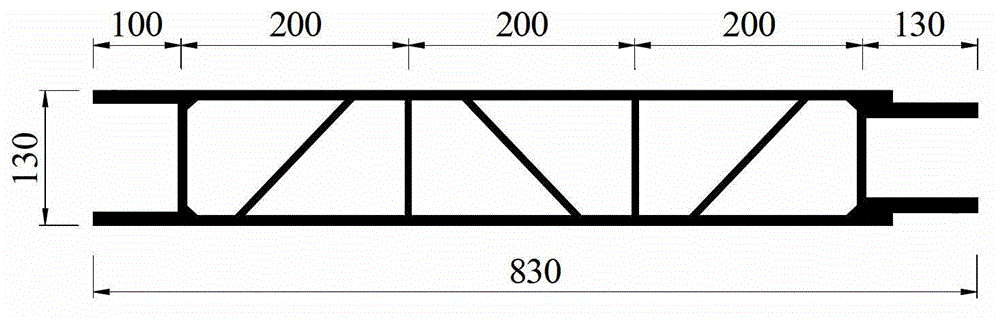

Assembled-type aluminum alloy bridge deck slab-steel girder combined structure

InactiveCN102877411AReduce weightHigh specific strengthBridge structural detailsBridge materialsScrew jointParent material

The invention relates to a steel-aluminum alloy combined structure, and in particular discloses an assembled-type aluminum alloy bridge deck slab-steel girder combined structure and connecting mode. The combined structure comprises an assembled-type aluminum alloy bridge deck slab and a steel girder; the connecting mode comprises an aluminum alloy bridge deck slab-steel girder connecting structure (high-strength bolt connection) and aluminum alloy bridge deck slab connecting construction (a stainless steel screw joint), and the assembled-type connection prevents the reduction of the intensity of an aluminum alloy parent material due to welding. The aluminum alloy bridge deck slab-steel girder combined structure provided by the invention has the advantages that the structure is light in weight, durable, easy to machine, high in toughness, rapid to construct, free from maintenance and the like, can be widely applied to damaged bridge deck modification, bridge building, dangerous bridge modification, pedestrian bridge and emergency engineering, and generates favorable social and economic benefits.

Owner:HUNAN UNIV

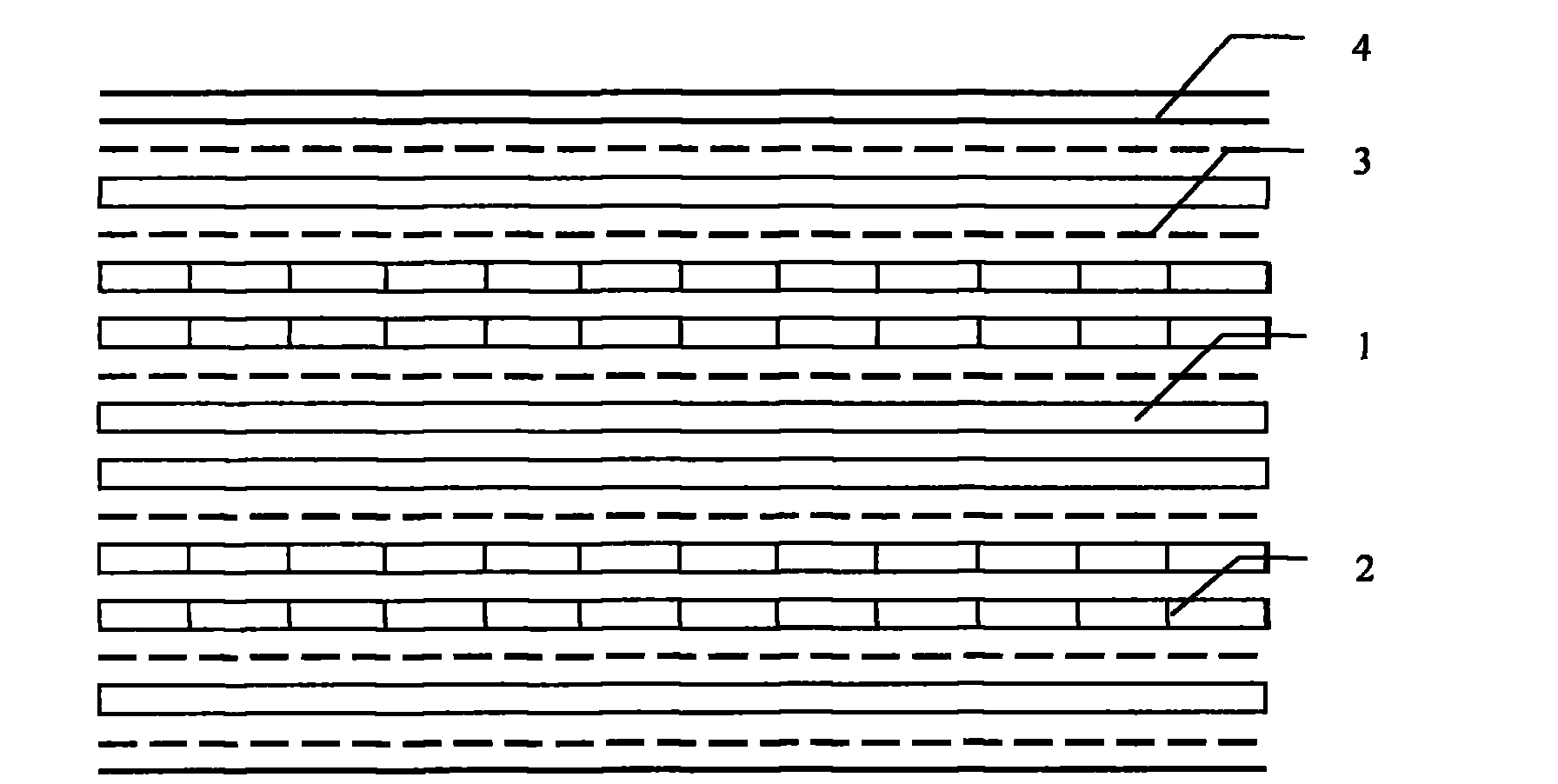

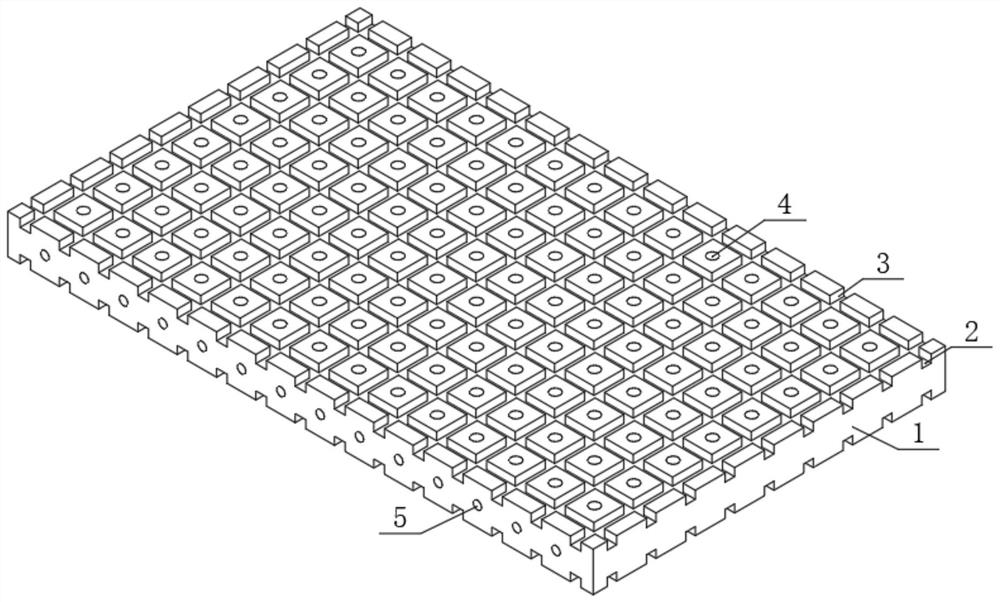

Bamboo composite plywood structure for bottom plate of container and production method thereof as well as product

InactiveCN102658569AQuality improvementIncrease profitWood veneer joiningWood layered productsEngineeringPhenol

The invention relates to a bamboo composite plywood structure for a bottom plate of a container and a production method thereof as well as a product. Bamboo chips are grinded and broomed to form bamboo beam single boards; and the bamboo beam single boards are mechanically weaved form bamboo beam single board curtains. The bamboo composite plywood structure consists of impregnated paper, the bamboo beam single board curtains and wooden single boards. A laminate is in a symmetrical structure; a veneer is double-layer impregnated paper; 4-10 layers of lengthways bamboo beam single board curtains, and 2-4 layers of transverse bamboo beam single board curtains are arranged; a layer of single wooden board is arranged between each lengthways bamboo beam single board curtain and each transverse bamboo beam single board curtain; the laminates are in tooth connection in a length direction when a long log is produced in the conditions, the conditions as follow: phenol glue with middle concentration and middle-low viscosity, and a cold-hot-cold technique are used; the pressure is 3.2-3.5 Mpa / cm<2>; and the hot pressing time is 1 min / mm when the temperature is 135-145 DEG C; the use ratio of a bamboo sheet material is more than 85%, and the used amount for labor is reduced by 40%; the internal stress problem of the bamboo material in a plywood is solved, and the problem that the gluing force is poor as the vertical and transverse bamboo beam single board curtains are directly glued is solved; and the quality is entirely improved, the volume-weight is entirely reduced, and the rigidity is improved.

Owner:福建省大田县华兴木业有限公司

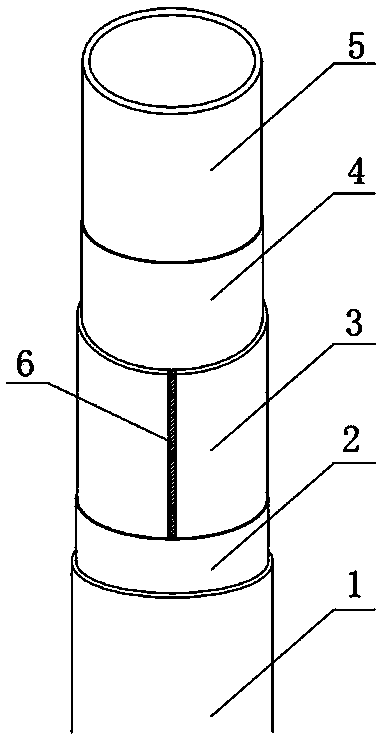

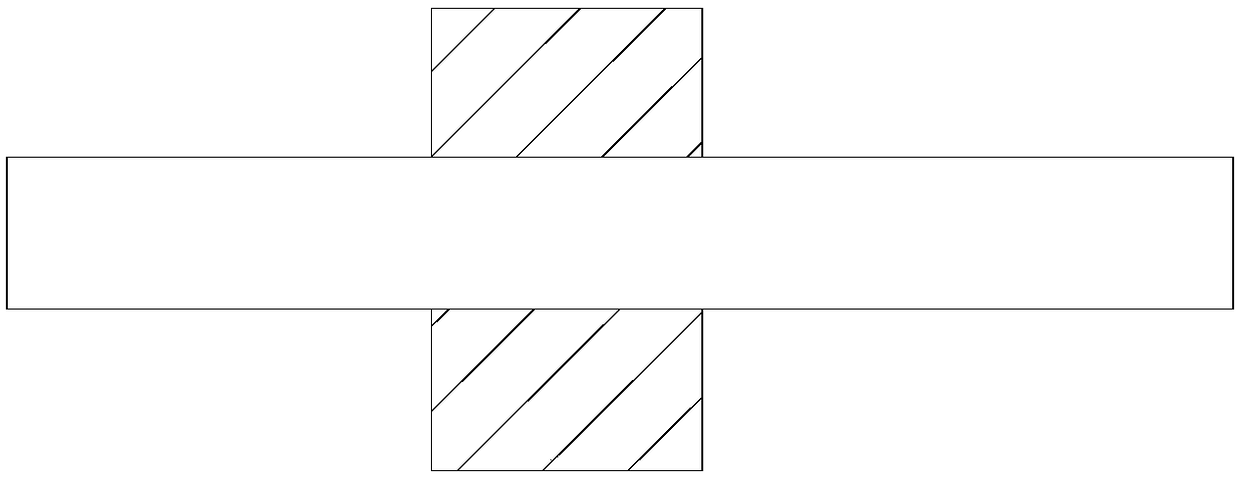

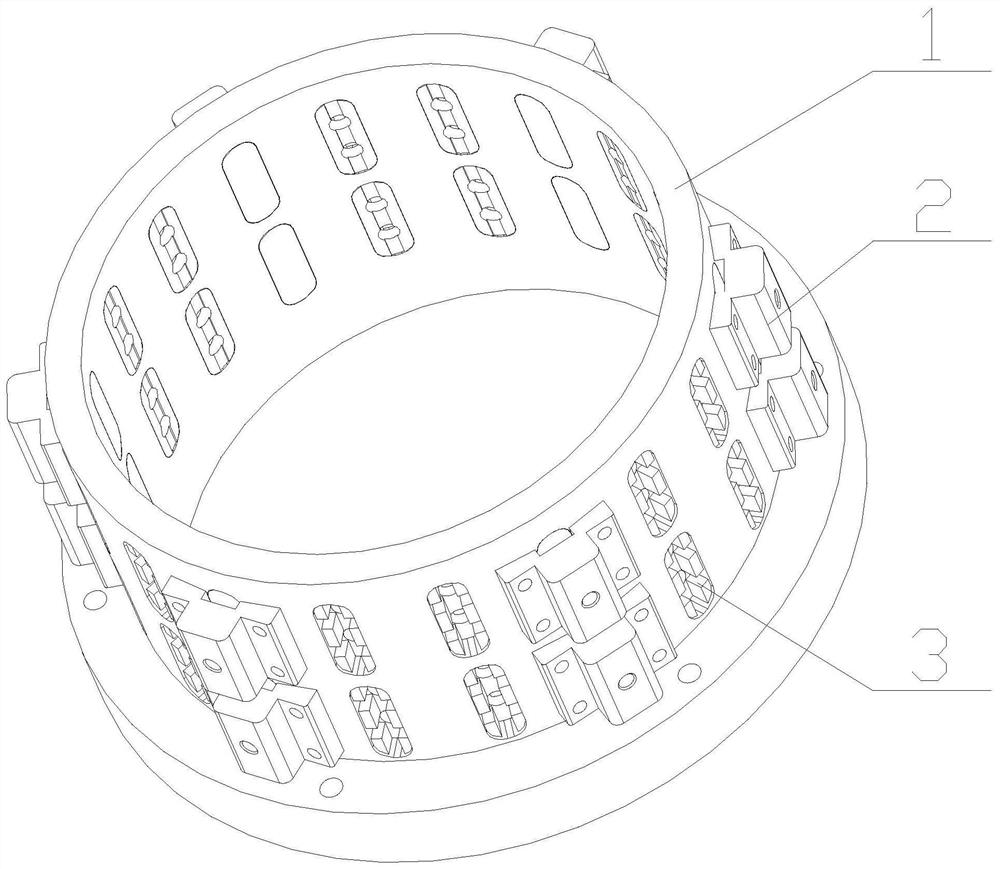

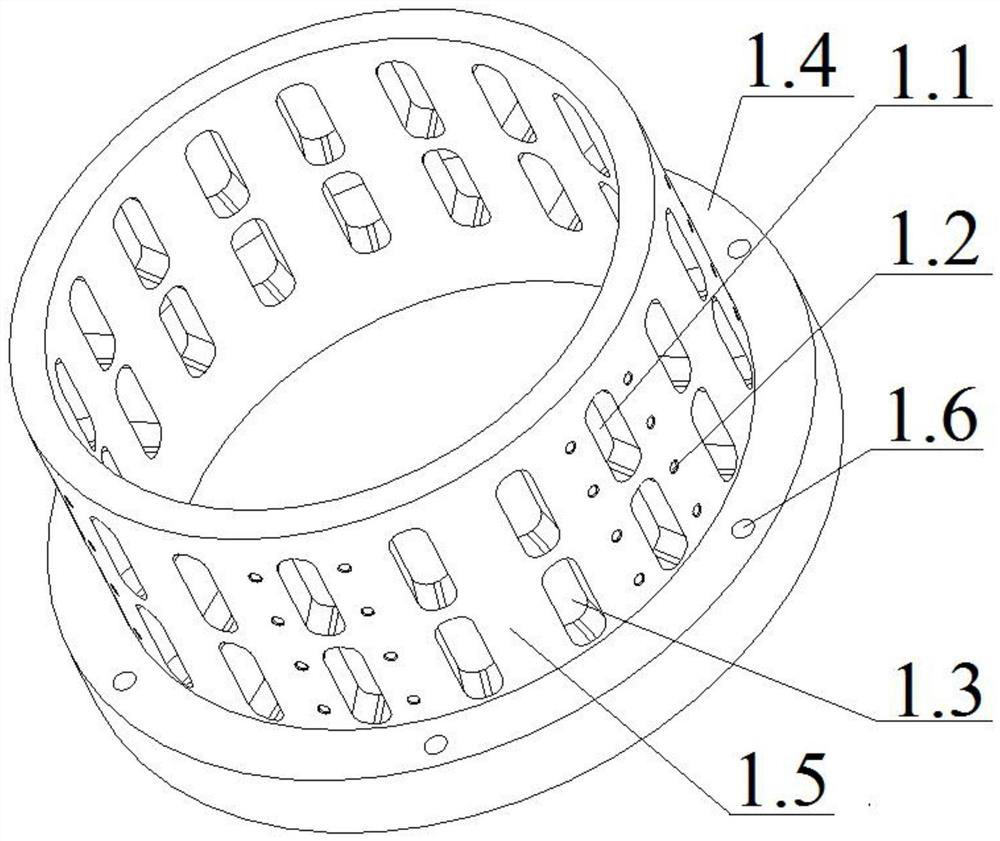

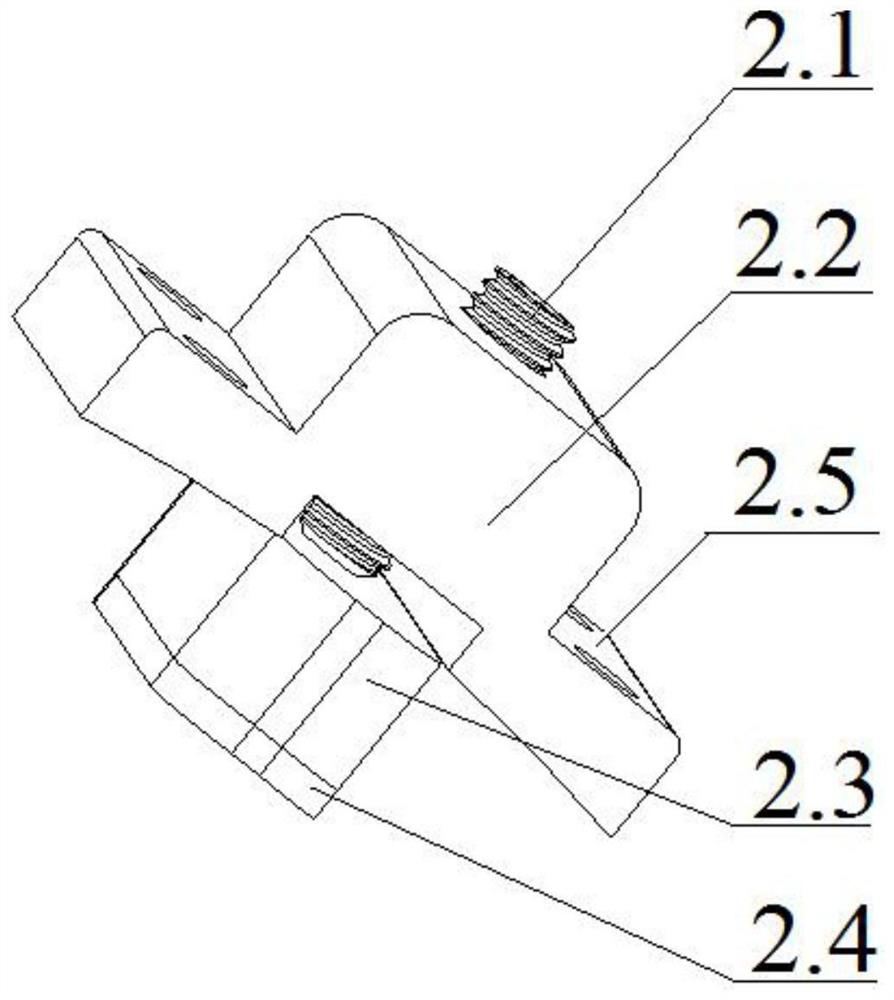

Motor joint for bullet train bogie and manufacture method thereof

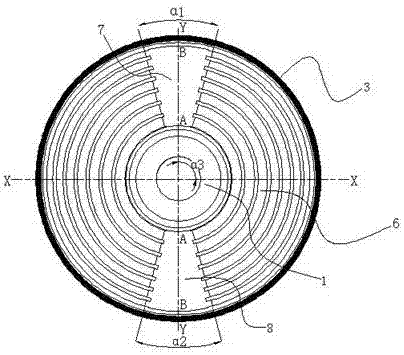

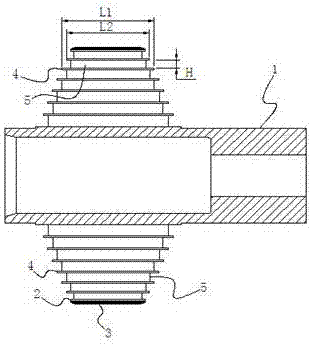

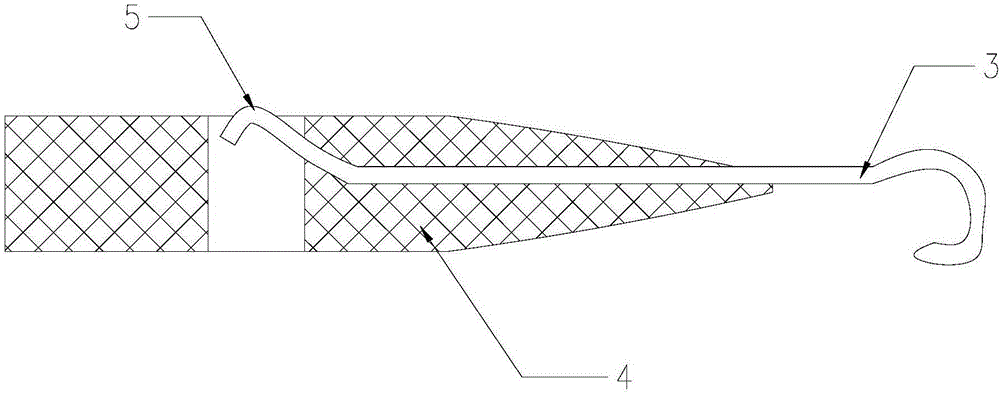

PendingCN107387628AIncrease the effective bonding areaImprove product qualityElectric locomotivesBogiesElectric machineryAutomotive engineering

The invention discloses a motor joint for a bullet train bogie and a manufacture method thereof, wherein the motor joint comprises a metal mandrel, a first metal jacket, a second metal jacket, a plurality of metal spacers, and a plurality of elastic rubber layers; the elastic rubber layers are vulcanized to the metal mandrel, the metal spacers and the first metal jacket to form an elastomer that is pressed into the second metal jacket; the metal spacers, the elastic rubber and the first metal jacket are each of double-segment structure; the elastomer is pressed into the second metal jacket to cause pre-compressive stress for the elastic rubber, a first air isolation segment and a second air isolation segment are formed between the two-segment metal spacers and the elastic rubber, the section of each of the first air isolation segment and the second air isolation segment along the radius of the metal mandrel is sector-shaped, the sector section of each air isolation segment is gradually expanded from the metal mandrel to the second metal jacket. The motor joint has improved quality.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

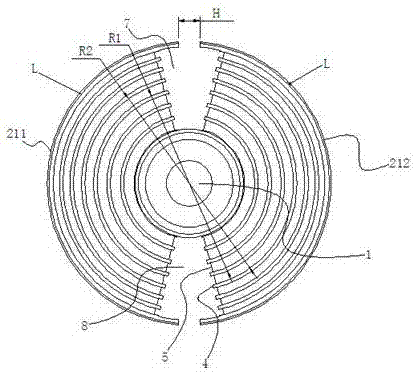

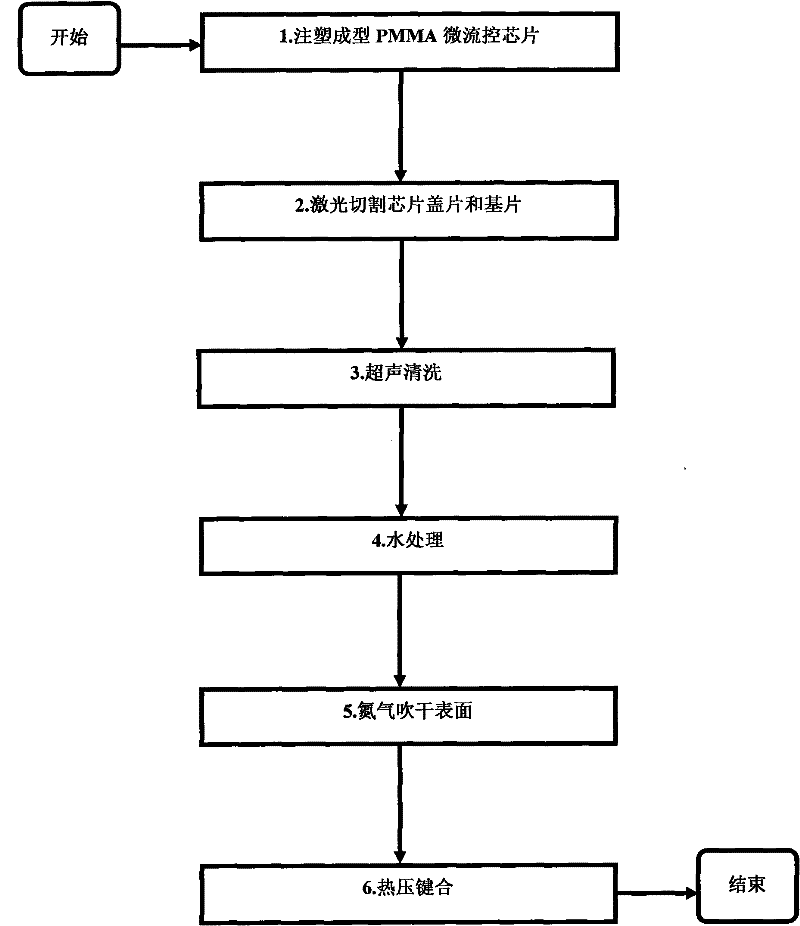

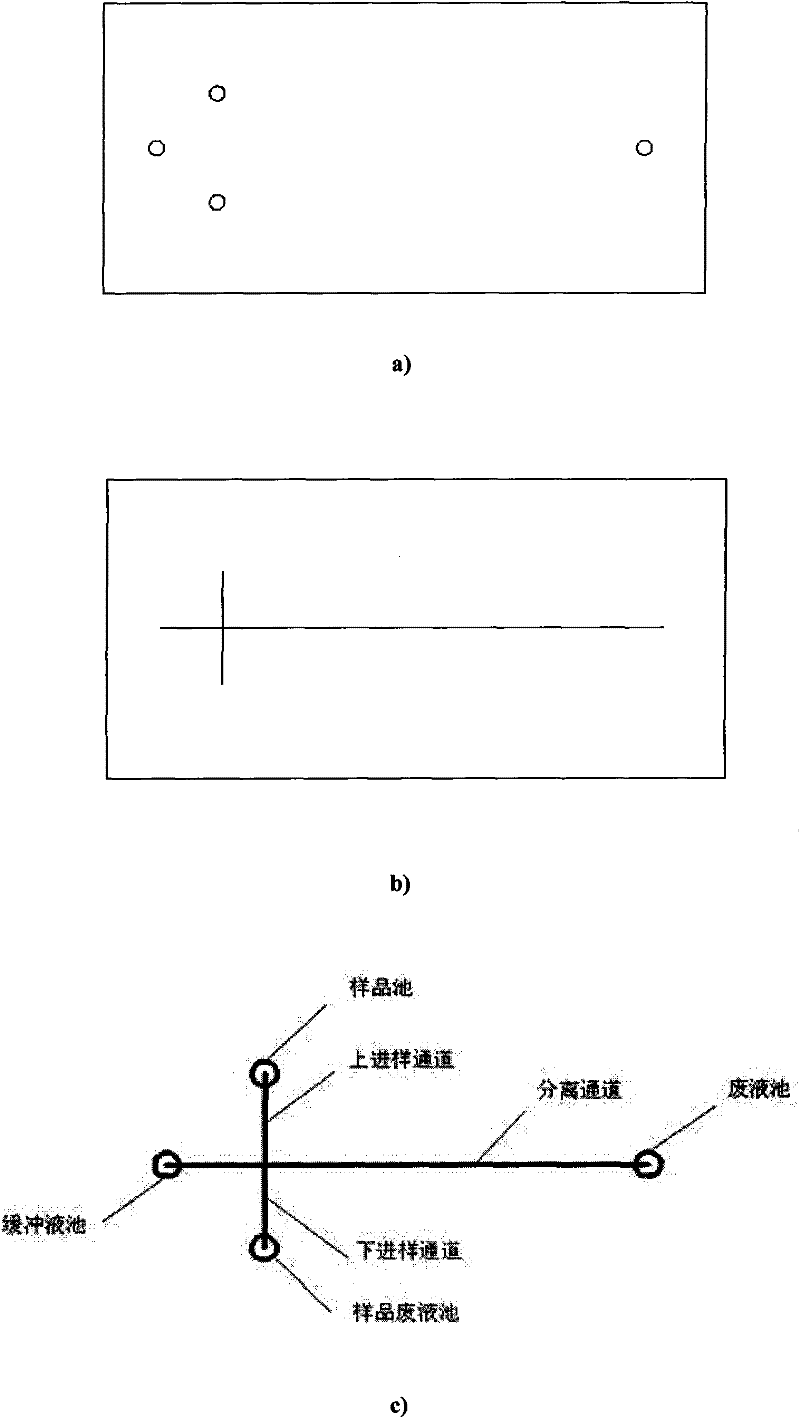

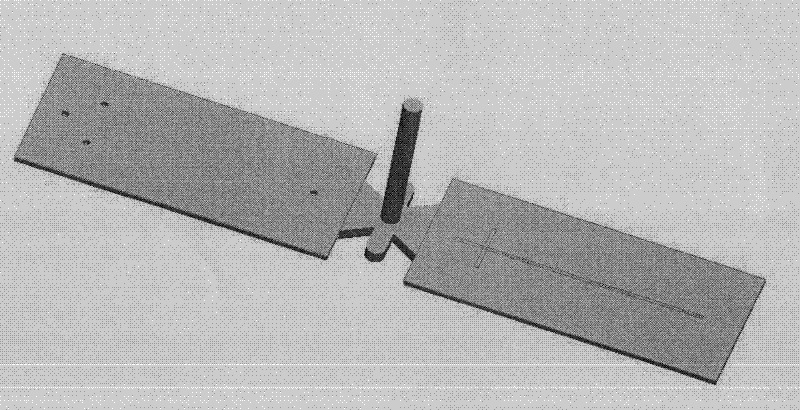

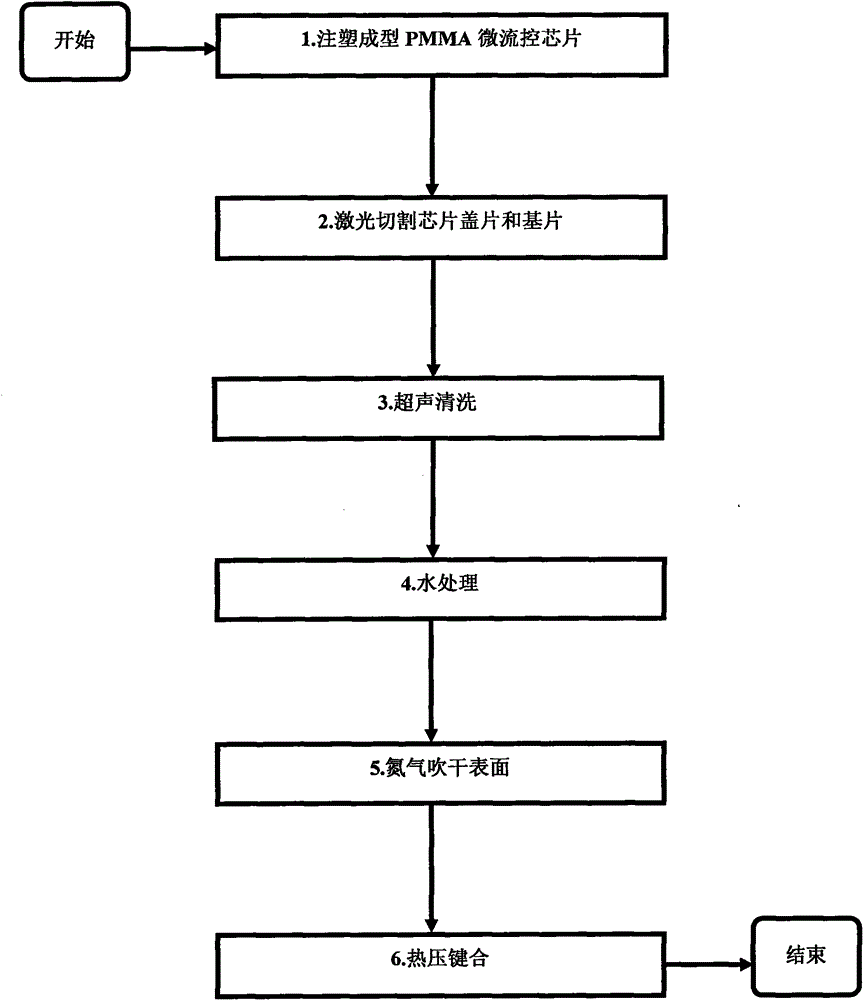

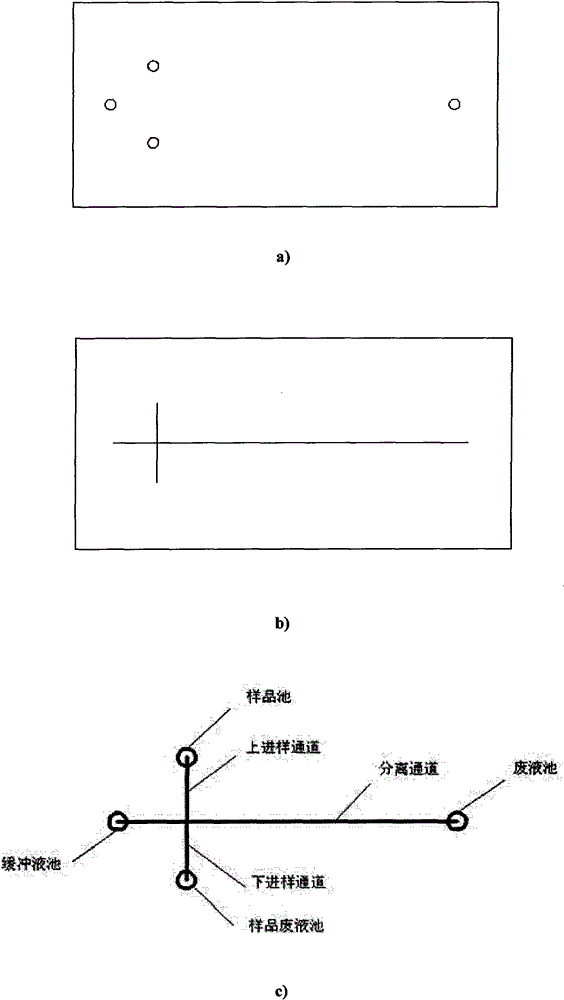

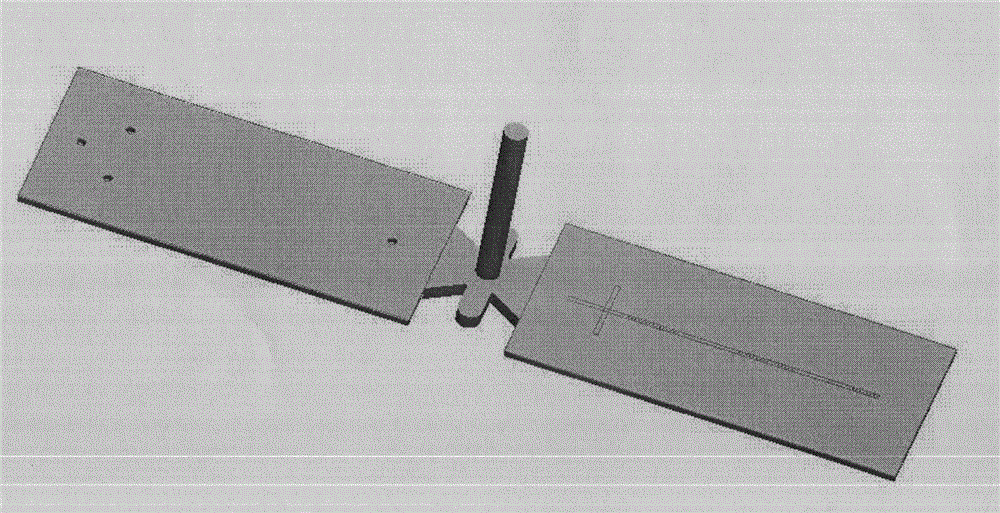

Method for raising hot pressing bonding rate of PMMA micro fluidic chip formed by injection moulding

InactiveCN102190287AEfficient treatment methodLow costPrecision positioning equipmentSoldering apparatusMicrofluidic chipMicro fluidic

Provided is a method for raising the hot pressing bonding rate of a PMMA micro fluidic chip formed by injection moulding. The invention is directed to the field of micro manufacture technology, especially relates to a method for raising the hot pressing bonding quality of a micro fluidic chip. The method is characterized in that carrying out water processing before hot pressing bonding; unlike a traditional hot pressing bonding process flow of from ultrasonic cleaning to drying in a baking oven to hot pressing bonding, a new process flow of from ultrasonic cleaning to water processing to drying the surface with nitrogen to hot pressing bonding is adopted. According to the invention, problems of complex processing method, high cost and negative influence on system operational performance in processing methods such as ultraviolet ray and MMA monomer surface modification and the like are overcome. The processing method is characterized by high efficiency, low cost, unchanged microfluid system performance and simple operation. At a same hot pressing bonding technological parameter, compared to untreated chips, the effective bonding areas of the chips treated with the method provided in the invention substantially increase, the bonding rates averagely increase 20 percent, thereby the bonding quality of the chips is effectively improved.

Owner:DALIAN UNIV OF TECH

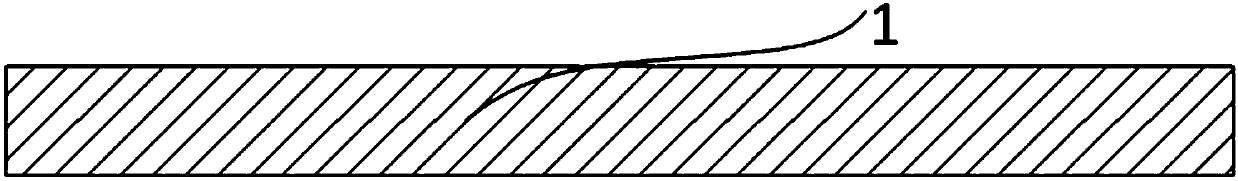

Composite steel-plastic pressure tube and manufacturing method thereof

InactiveCN103759080AIncrease the effective bonding areaHigh bonding strengthRigid pipesTubular articlesButt weldingAdhesion strength

The invention discloses a composite steel-plastic pressure tube and a manufacturing method thereof, and belongs to the technical field of composite steel-plastic tubes. The composite steel-plastic pressure tube comprises an outer plastic layer, an outer glue layer, an inner glue layer and an inner plastic layer. A steel tube with the rough surface is arranged between the outer glue layer and the inner glue layer. In the manufacturing process of the composite steel-plastic pressure tube, a laser texturing roller carries out rolling and texturing on an adopted steel plate, so that a rough surface is formed on the steel plate, and then the steel plate is processed into steel belts with required widths; the steel belts are rolled to be of tubular shapes under the extrusion state, and an inner plastic layer tube coated with hot melt glue is inserted synchronously; the tungsten electrode argon arc butt welding process is adopted for welding of welding lines, and a steel tube is formed; through a high frequency heater, adhesion of the inner plastic layer tube and the steel tube is achieved; the hot melt glue coats the steel tube, and the outer plastic layer is arranged outside the steel tube. According to the composite steel-plastic pressure tube, the adhesion strength between the outer plastic layer and the steel tube is high, the pressure-bearing capacity is high, and the production cost is low.

Owner:XINXING DUCTILE IRON PIPES CO LTD

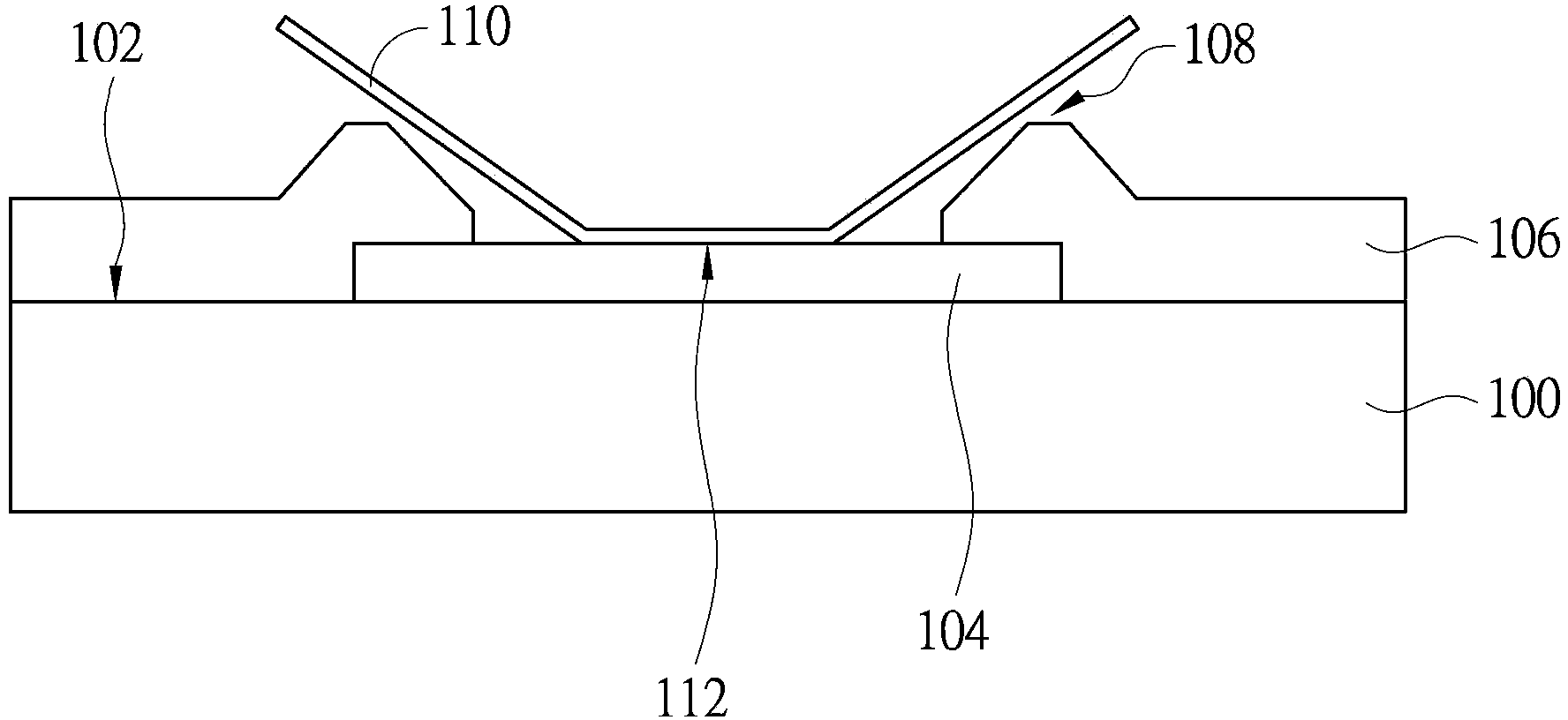

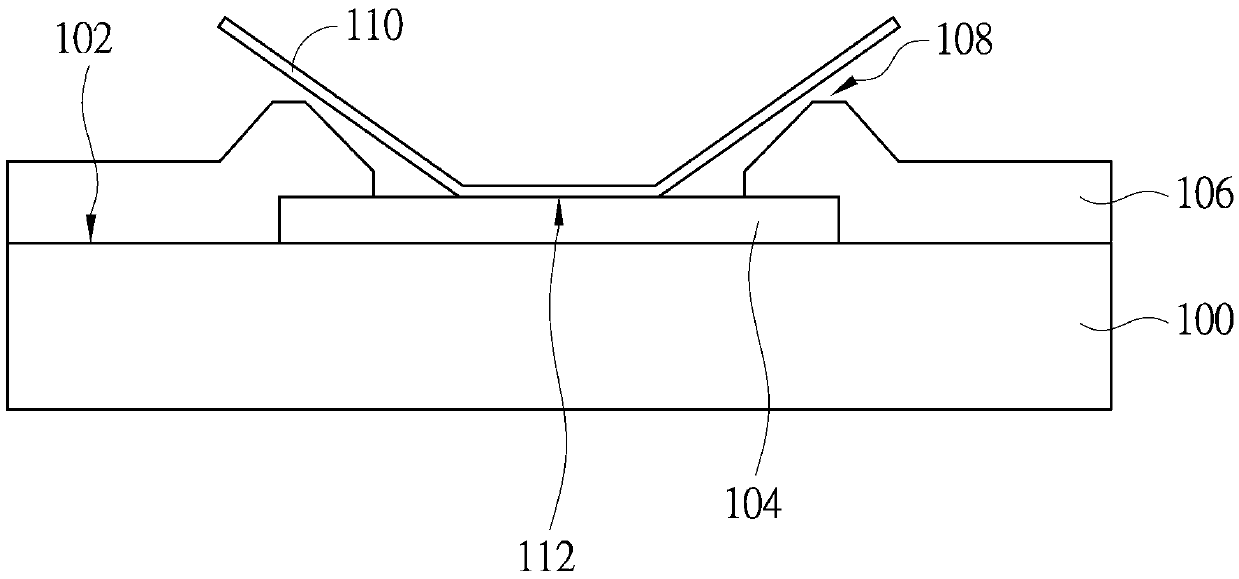

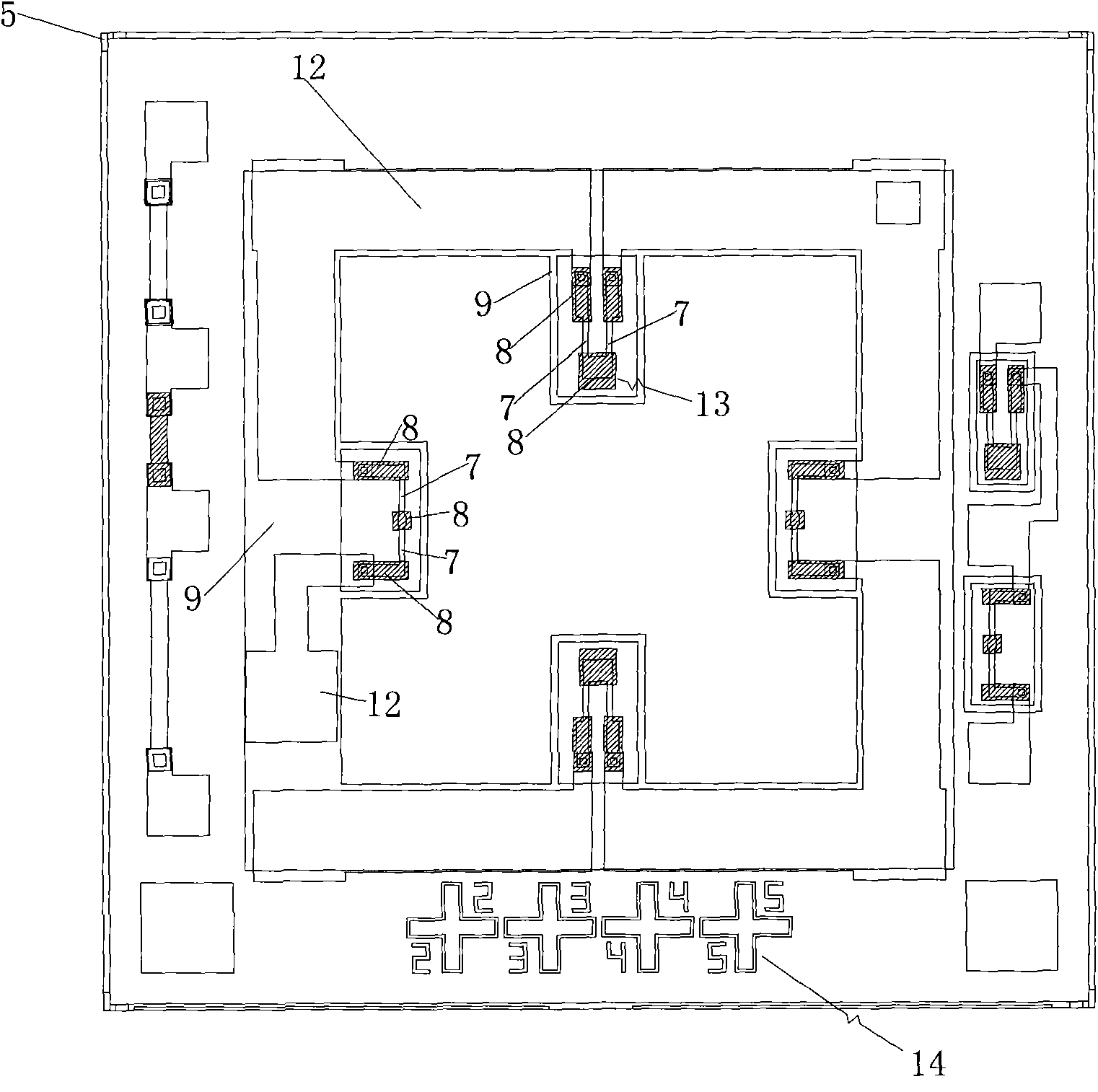

Bonding encapsulation structure and method suitable for radio frequency MEMS and method

PendingCN107814351AFlat distributionIncrease the effective bonding areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEtchingRadio frequency

The invention relates to a bonding encapsulation structure and method suitable for radio frequency MEMS. The method comprises the steps that organic materials are spin-coated on an encapsulation coverplate and patterned, then Cr and Au are sputtered, and an encapsulation cover plate with the uniformly distributed organic materials and cavities is obtained by using a method that the cavities are etched with a TMHA solution. The cover plate full of the cavities is made from a high-resistance silicon material, and the cavities are obtained through wet etching by using the TMAH solution. By meansof the encapsulation method, the organic materials can be smoothly distributed in a bonding area, the effective bonding area of wafer-level bonding is increased, and then the airtightness, the reliability and other performance of the product obtained after bonding are improved. A low-temperature bonding technology is adopted to conduct low-temperature encapsulation of a radio frequency device, and while good mechanical strength and airtightness are achieved, the requirements for encapsulating the RF MEMS device which is sensitive to temperature are met.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

Bamboo fiber reinforced composite material and manufacturing method thereof

ActiveCN101607411BIncrease the effective bonding areaOptimize the penetration pathFlat articlesDomestic articlesFiber-reinforced compositeHardness

The invention relates to a bamboo fiber reinforced composite material and a manufacturing method thereof. The bamboo fiber reinforced composite material is formed by directional bamboo fiber felt and an adhesive layer; the upper surface and the lower surface and the thickness direction of the directional bamboo fiber felt are respectively provided with a series of longitudinal cracks which are disconnected uniformly and have nonuniform thickness; the manufacturing method thereof comprises the following steps: longitudinally splitting a section of bamboo tube into two semicircular bamboo tubesalong the diameter thereof, removing internal segments, defibering the internal arc surface of the semicircular bamboo tube by a driving roller and a defibering roller, then defibering the external arc surface of the semicircular bamboo tube, then carrying out glue applying, hot-pressing and forming the bamboo fiber reinforced composite material; the series of longitudinal cracks which are disconnected uniformly and have nonuniform thickness are defibered from both the internal arc surface and the external arc surface of the semicircular bamboo tube, simultaneously the bamboo green and bambooyellow are also removed, therefore, the bamboo fiber reinforced composite material and the manufacturing method thereof increase the effective gluing area of the bamboo material, improve the penetration path of the bamboo materials, lead the strength and hardness of the plywood to be greatly improved and having good processing performance.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

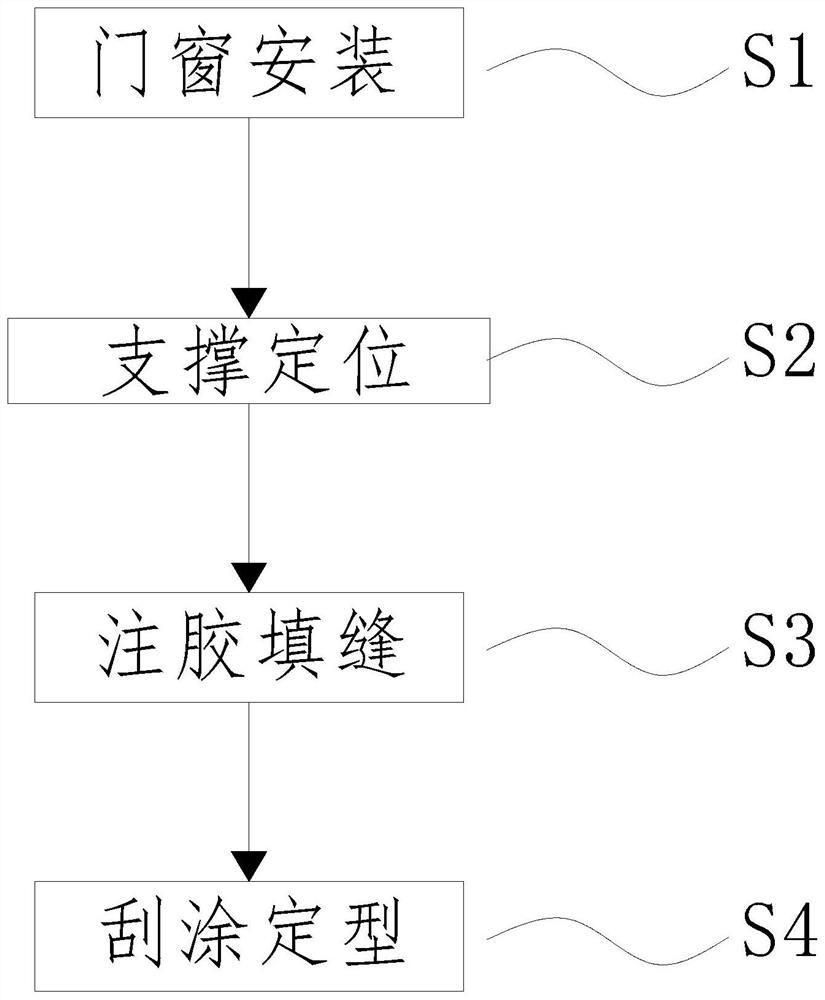

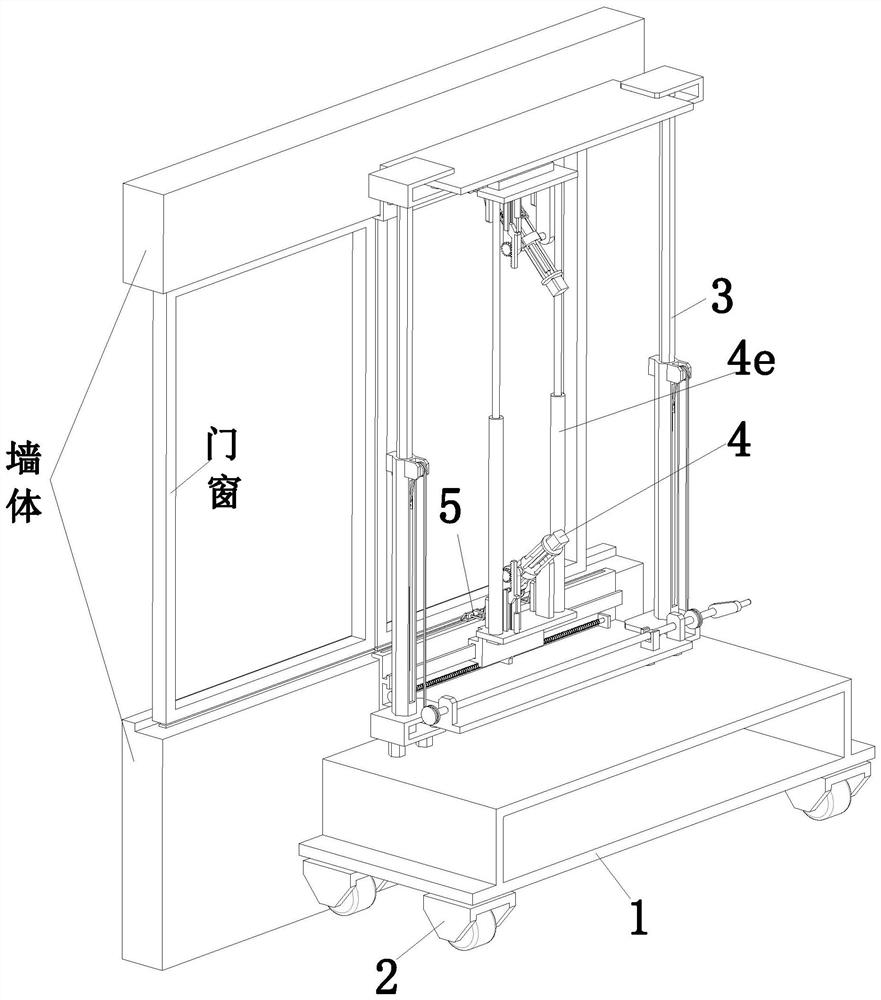

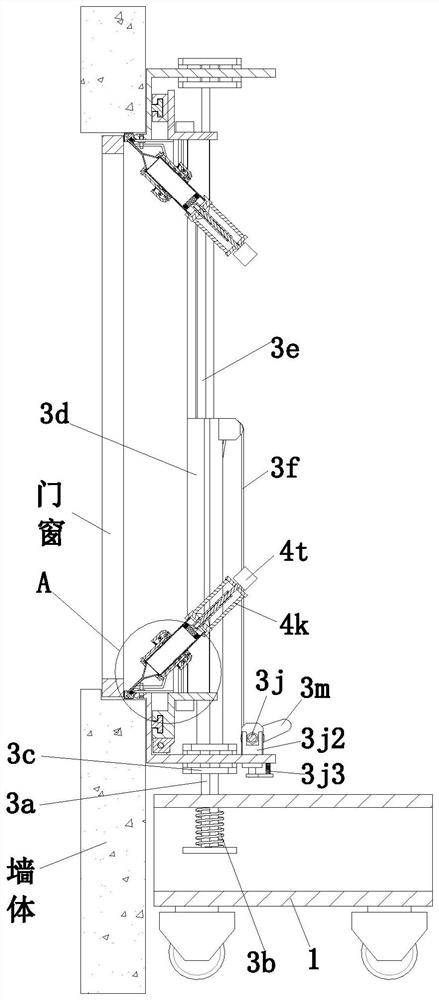

Method for filling and repairing building door and window mounting gaps by using gap filling glue

InactiveCN113250418AEasy to moveReduces the likelihood of a hard crashFrame fasteningAdhesive glueStructural engineering

The invention relates to a method for filling and repairing building door and window mounting gaps by using gap filling glue. A device for filling and repairing the building door and window mounting gaps by using the gap filling glue is used and comprises a moving frame, universal wheels, a positioning mechanism, a gap filling mechanism and a blade coating mechanism. The method for filling and repairing the building door and window mounting gaps by using the gap filling glue can solve the problems that in the process of filling and repairing building door and window mounting gaps with the gap filling glue, different height changes of the upper side and the lower side of the door and window mounting position are difficult to adapt, the included angle between the glue outlet position of glue and the door and window mounting gaps is difficult to keep consistent, the extrusion uniformity of the glue at the door and window gap positions is difficult to control, secondary pollution to surrounding wall surfaces is caused by excessive extrusion of the glue, dust removal treatment is more difficult to carry out on the mounting gaps before the glue is filled, and the filled glue is scraped, spread, dried and cooled quickly and the like are solved.

Owner:席灵军

Method of manufacturing solar cell

InactiveCN104112791AReduce thicknessIncrease the effective bonding areaFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

Owner:MOTECH INDUSTRIES

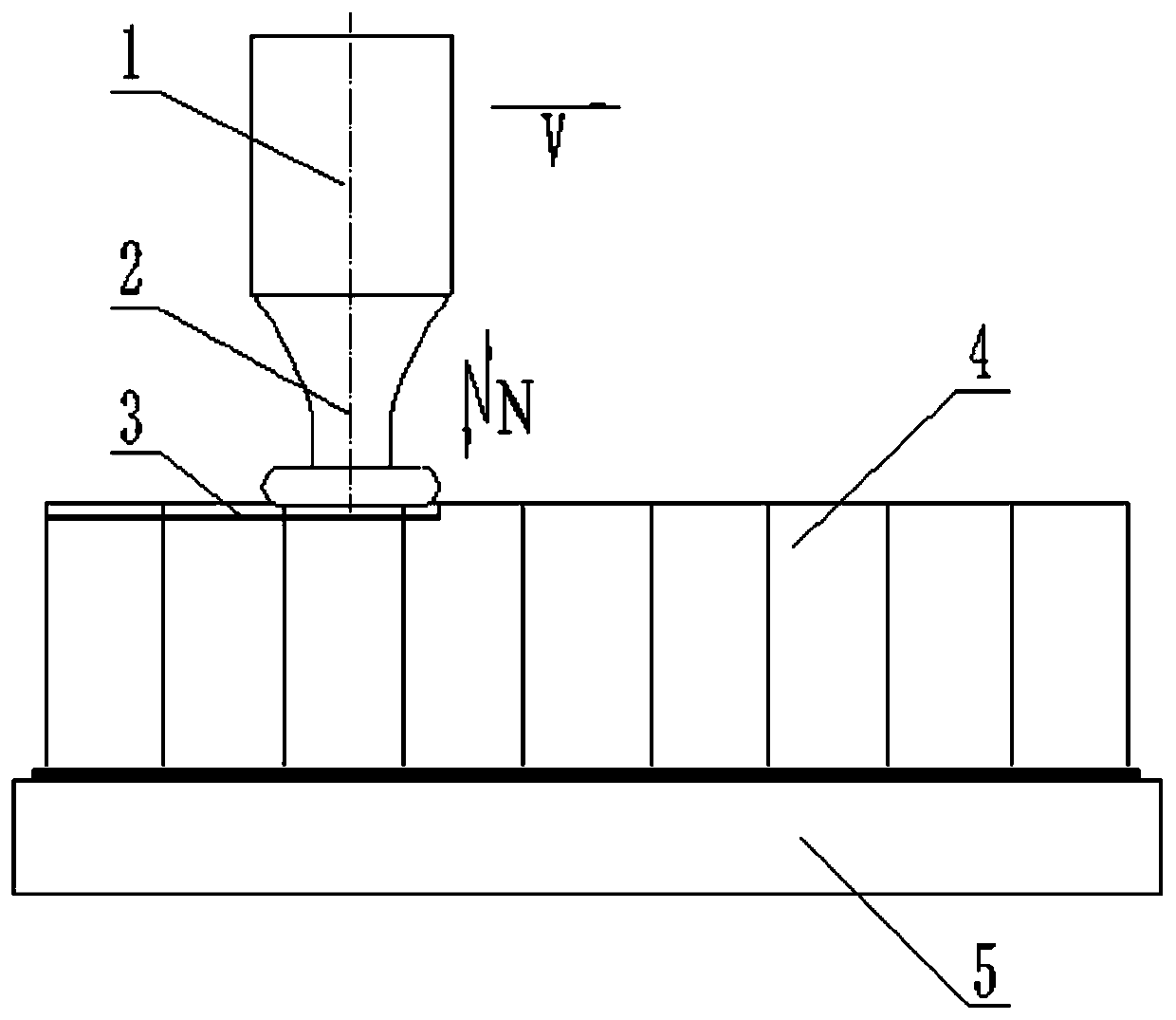

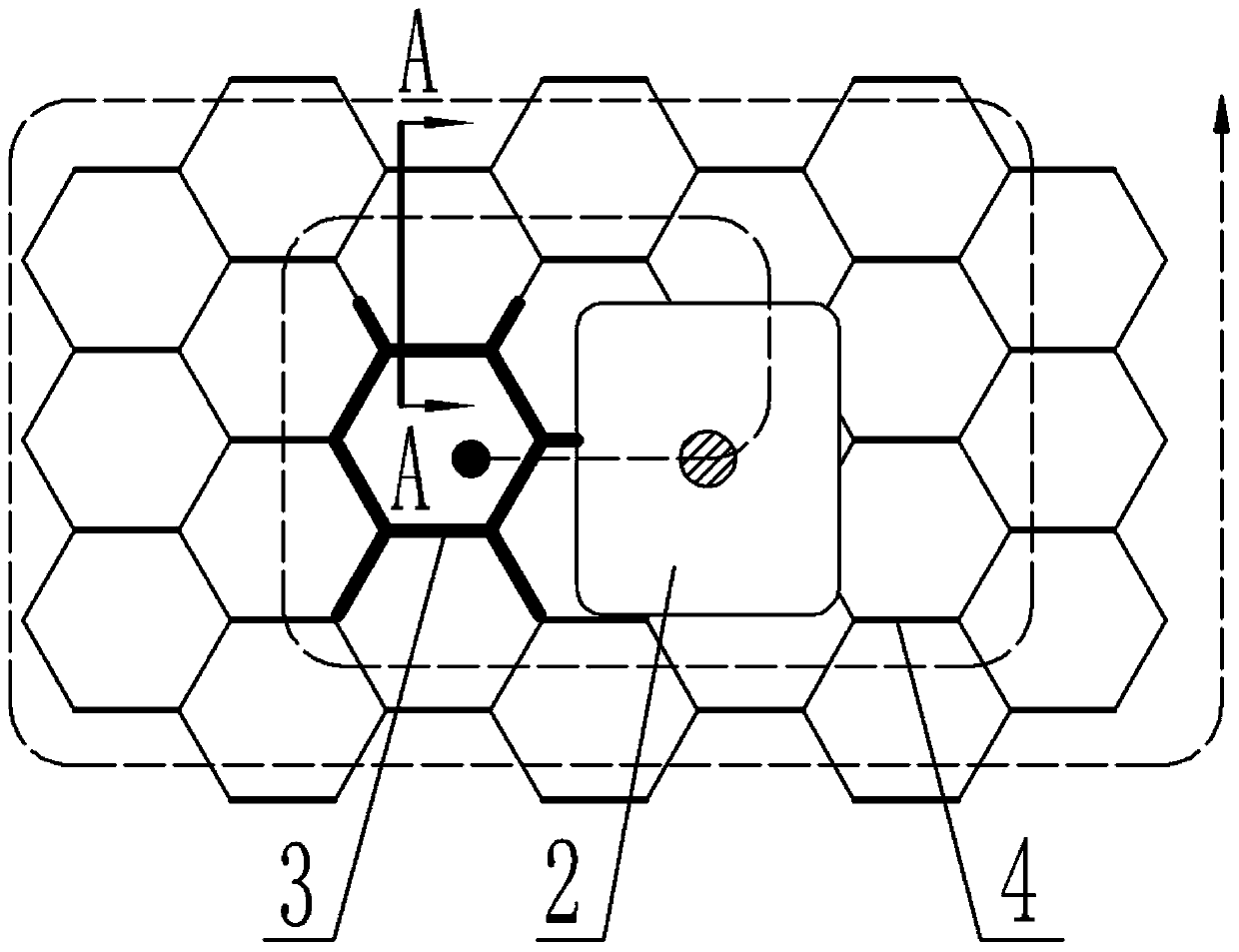

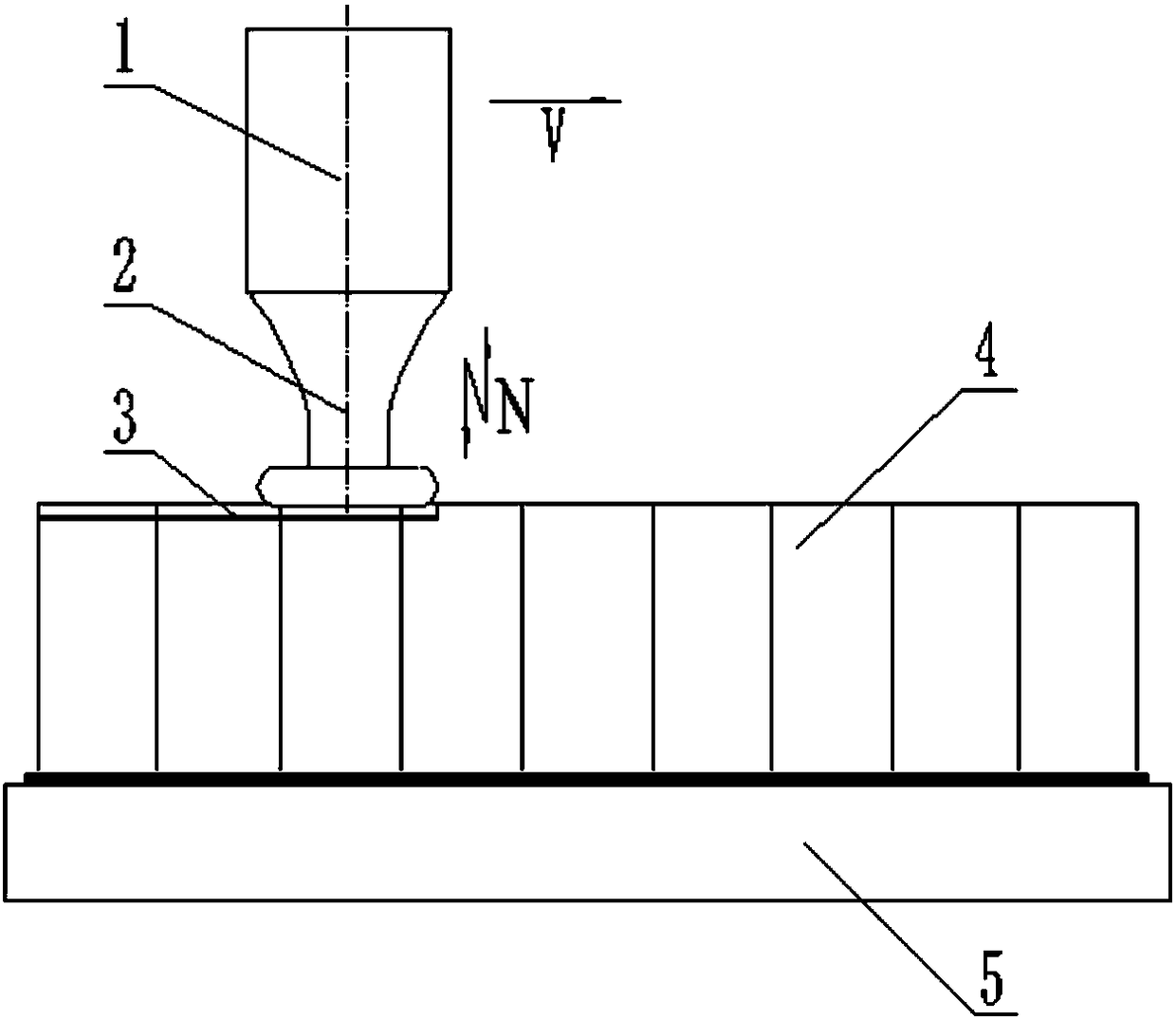

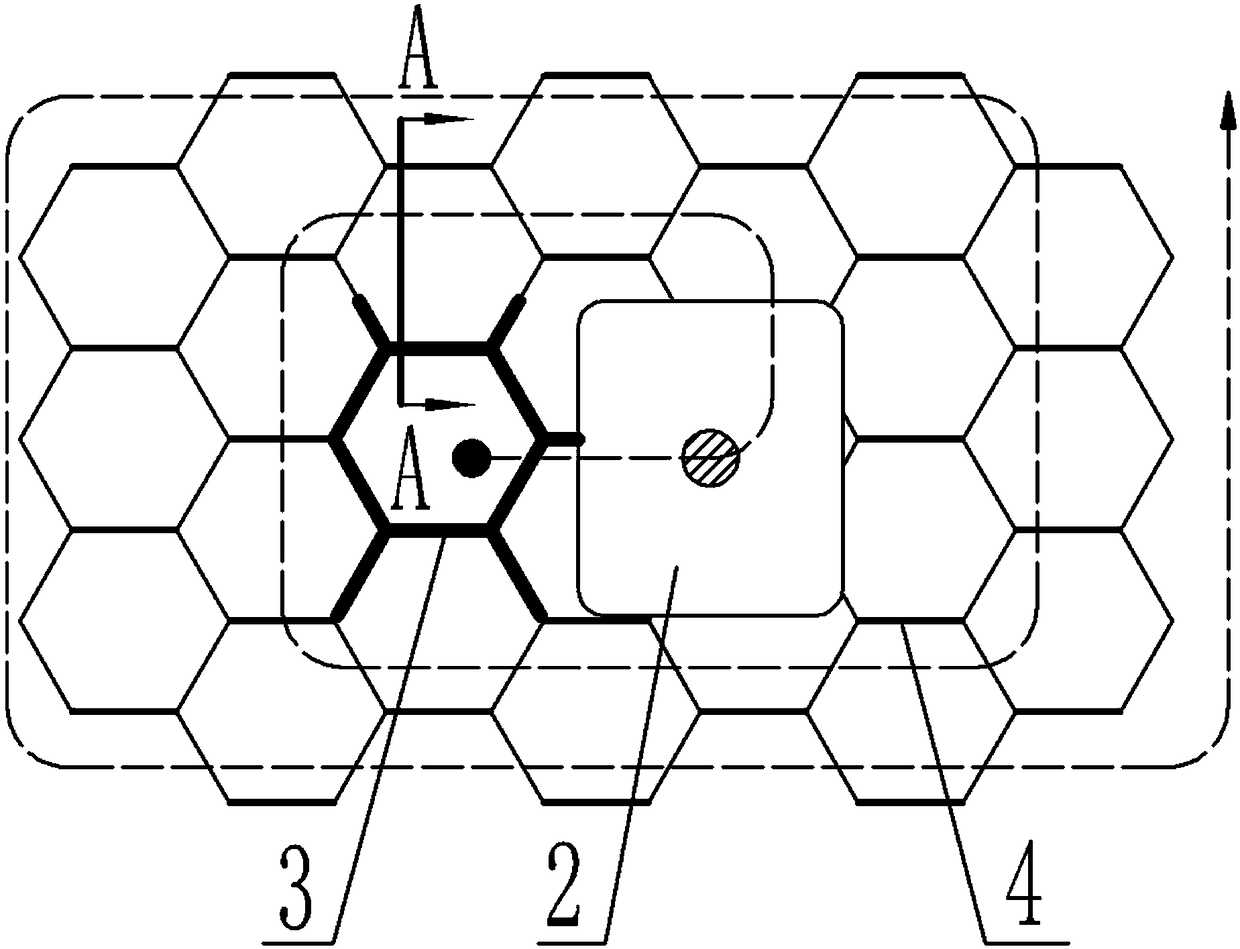

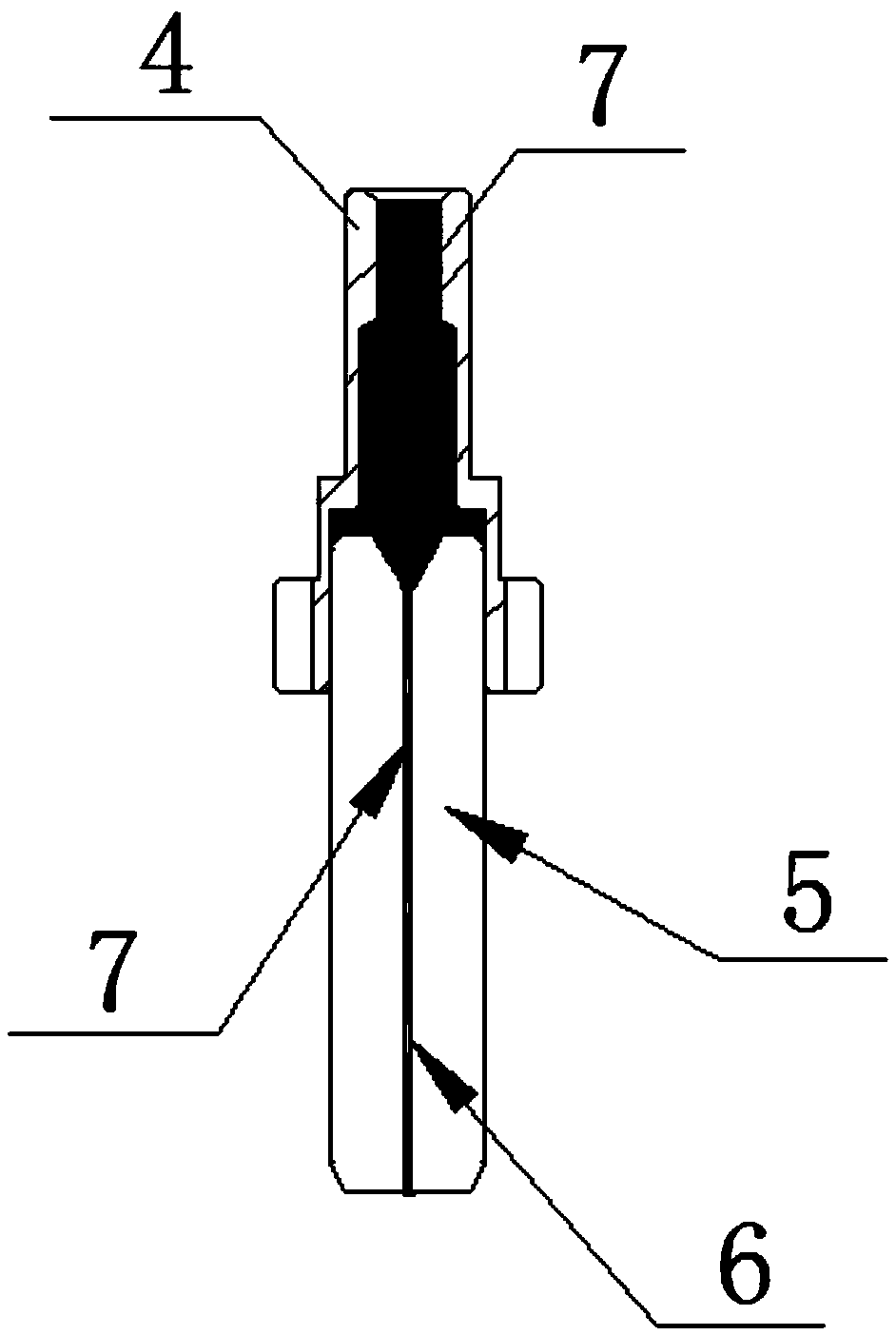

A high-frequency shock treatment method for the end face of aluminum honeycomb cells

ActiveCN108435519BIncrease surface areaRegular shapeMechanical vibrations separationOther manufacturing equipments/toolsAluminum honeycombUltimate tensile strength

The invention discloses a high-frequency impact treatment method for aluminum honeycomb cell end faces. The high-frequency impact treatment method for the aluminum honeycomb cell end faces is characterized by comprising the following steps that S1, a to-be-treated aluminum honeycomb is fixed, and to-be-treated aluminum honeycomb cell end faces are upward; S2, the initial relative positions betweena high-frequency impact tool and the to-be-treated aluminum honeycomb cell end faces are determined, and the machining path is determined; and S3, the high-frequency impact tool moves along the movement path and conducts high-frequency impact treatment on the to-be-treated aluminum honeycomb cell end faces on the movement path, and the aluminum honeycomb cell end faces undergoing high-frequency impact treatment are obtained. According to the aluminum honeycomb treated by the adoption of the high-frequency impact treatment method, the cell end face area is increased, the width of the honeycombwalls near the end faces are increased, the effective adhesion binding area is increased, the adhesion binding strength is improved, and then the mechanical performance of an aluminum honeycomb structural component is improved. In addition, the high-frequency impact treatment method for the aluminum honeycomb cell end faces has the advantages of being high in adhesion strength controllability, clean and environmentally friendly.

Owner:DALIAN UNIV OF TECH

Fabrication method of motor rotor assembly

ActiveCN106787509AIncrease surface tensionEasy to wetMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectroplatingMaterials science

The invention discloses a fabrication method of a motor rotor assembly. The fabrication method comprises the steps of firstly, processing an inner hole of annular magnetic steel; secondly, electroplating the annular magnetic steel, attaching electroplating layers onto other surfaces except an inner surface of the annular magnetic steel after being electroplated, and enabling an axial direction of the annular magnetic steel to be in a horizontal direction; thirdly, coating a layer of binding agent on the inner hole of the annular magnetic steel, inserting a cylindrical core shaft into the annular magnetic steel from a first inner hole, and then allowing the cylindrical core to extent out of a second inner hole; fourthly, rotating the annular magnetic steel by 90 degrees so that the axial of the annular magnetic steel is in a vertical direction, and encapsulating a gap between of the second inner hole and the cylindrical core shaft with the binding agent, wherein the second inner hole is arranged above the first inner hole; and finally, maintaining the position of the annular magnetic steel unchanged after the encapsulation of the binding agent is completed, and completing the fabrication of the motor rotor assembly after the binding agent is naturally cured. The fabrication method has the advantages that no noise is generated during the high-speed rotation process, the motor rotor assembly has relatively large twisting force, the annular magnetic steel cannot be separated from the cylindrical core shaft, and the service lifetime of the motor is prolonged.

Owner:NINGBO YUNSHENG

Wall anti-seismic mortar

InactiveCN108868034AHigh affinityImprove seismic performanceCovering/liningsShear capacityEngineering

The invention provides wall anti-seismic mortar, comprising a wall body and a reinforcing mesh, wherein the wall surface of the wall body is uniformly provided with a plurality of holes, the hole diameter is 20-30 mm, the hole spacing is 100-120 mm, the hole depth is 120-180 mm, tie bars with diameter of 4-8 mm are inserted into the holes and are fixed by the mortar poured in the holes, the reinforcing mesh is tied on a wall surface by the tie bars and comprises a plurality of steel bars arranged in an X shape, and the wall surface and the reinforcing mesh are coated with a mortar layer with thickness of 30-80 mm. The wall anti-seismic mortar has strong structural shear capacity and good structure ductility.

Owner:JIAXING BOHONG NOVEL BUILDING MATERIALS

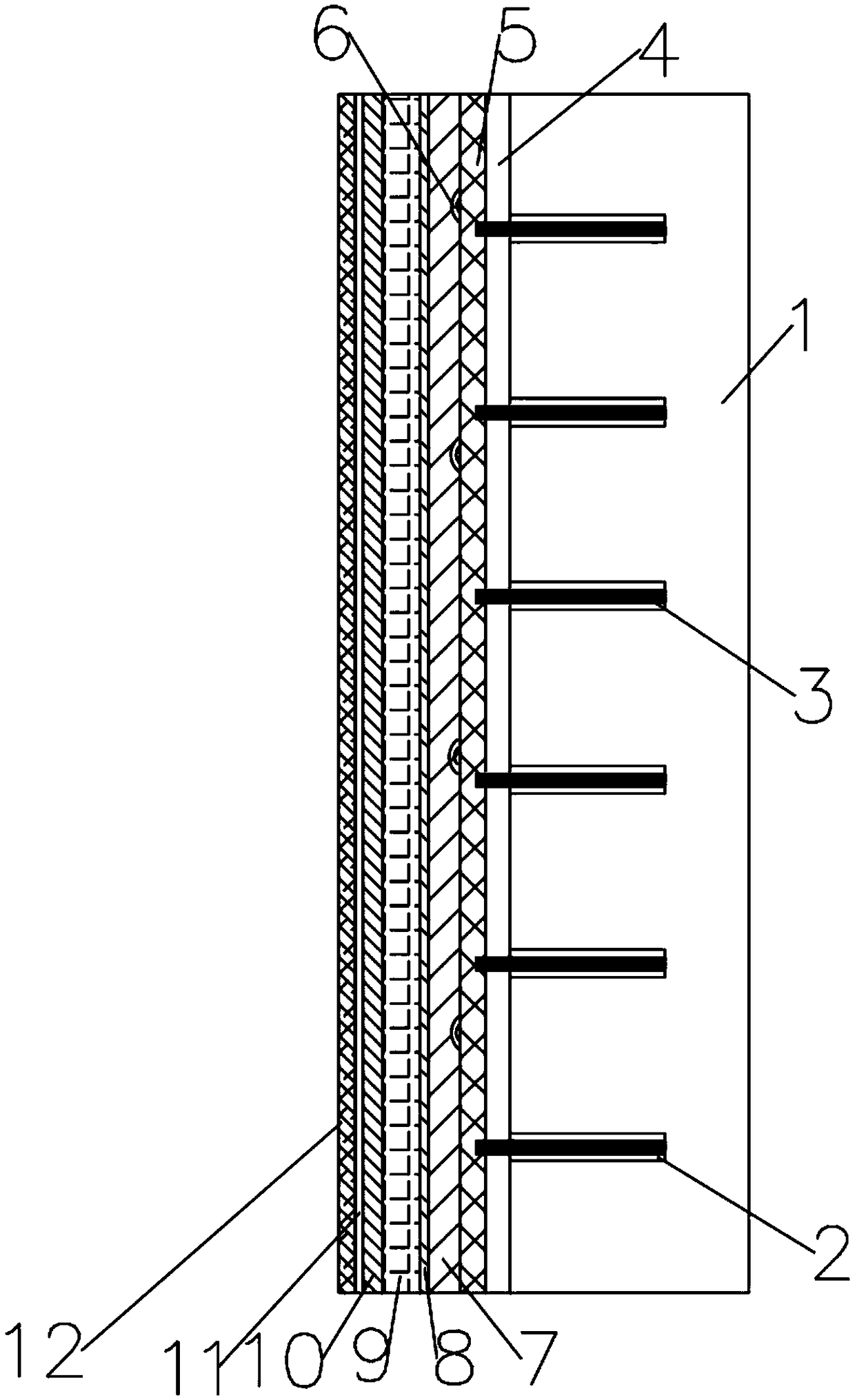

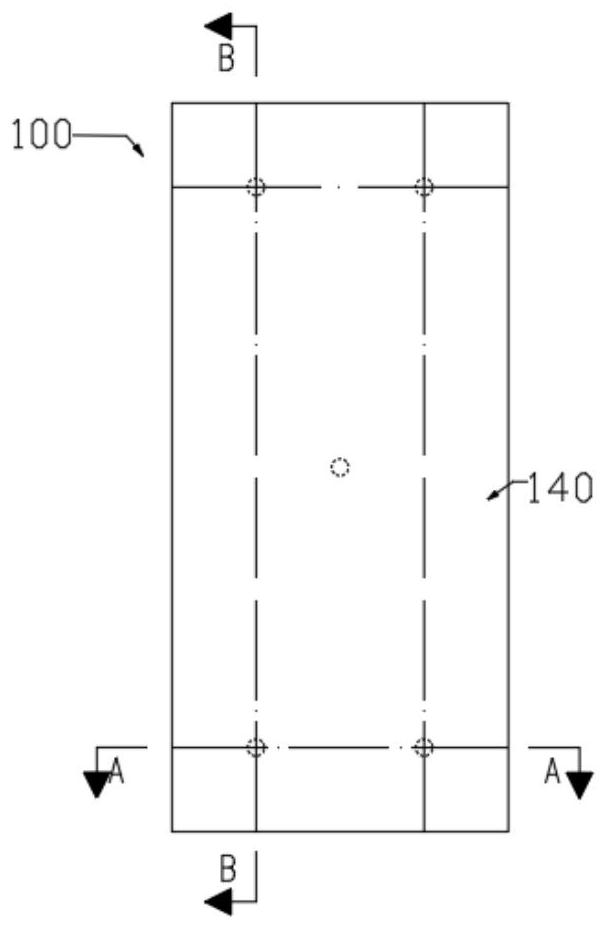

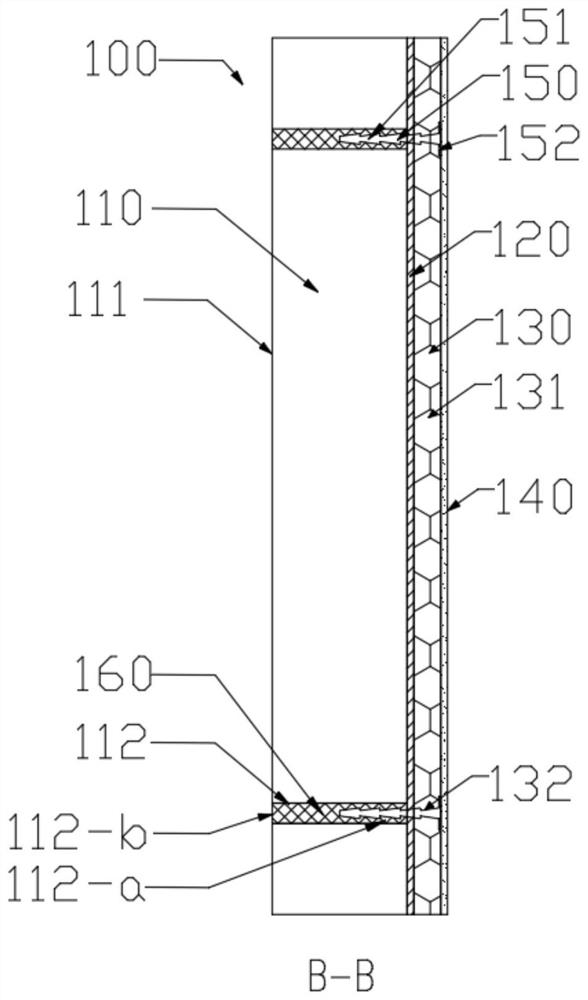

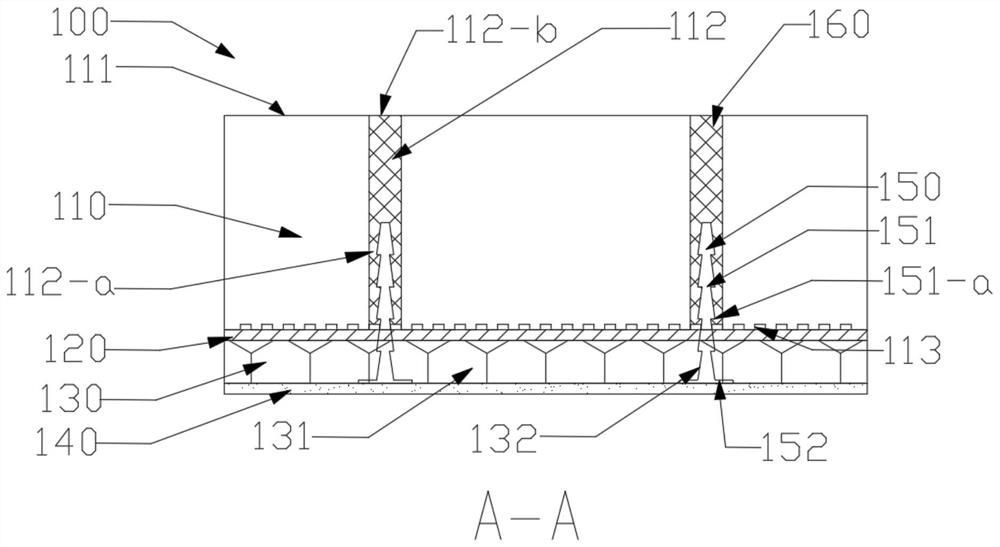

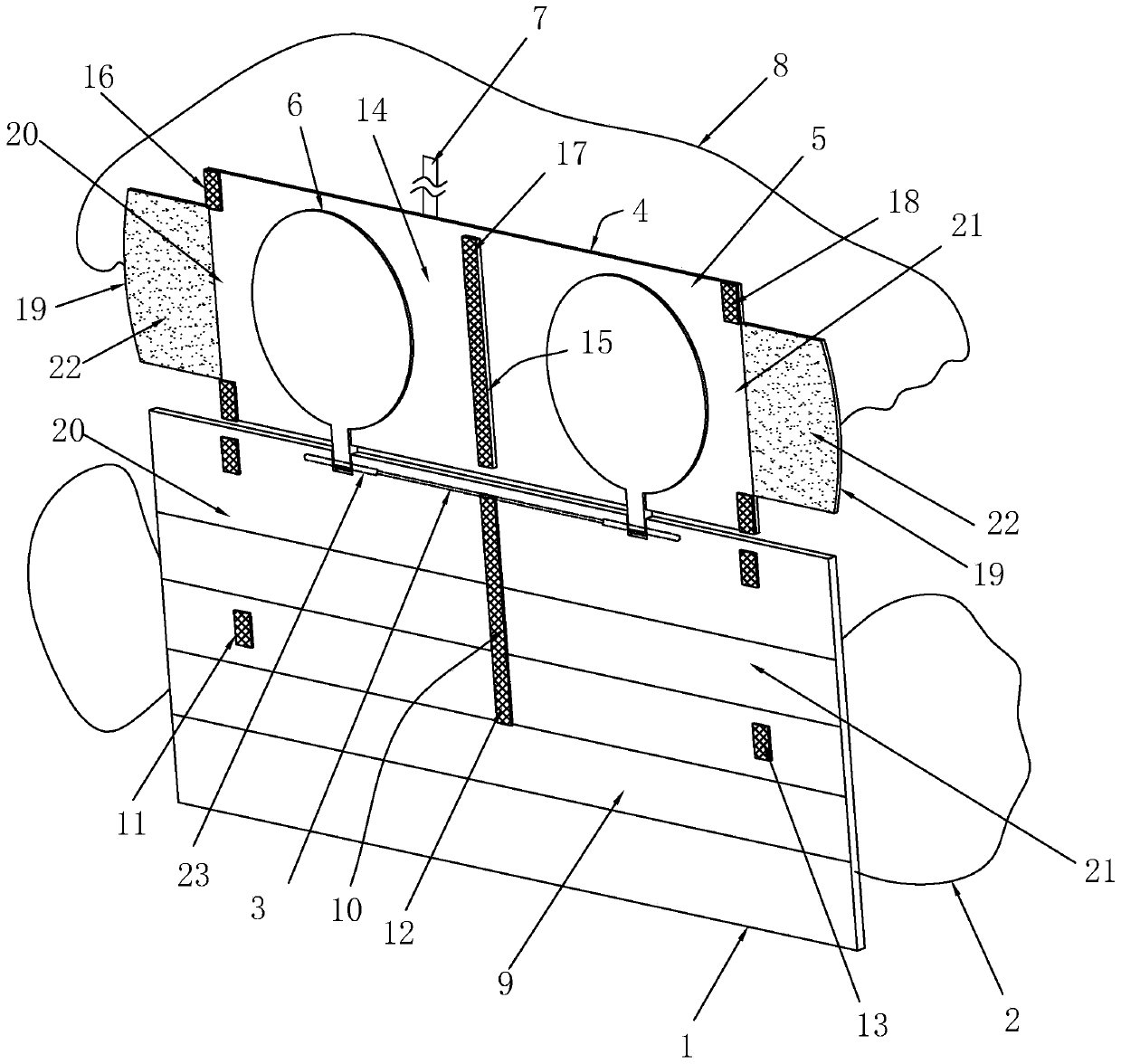

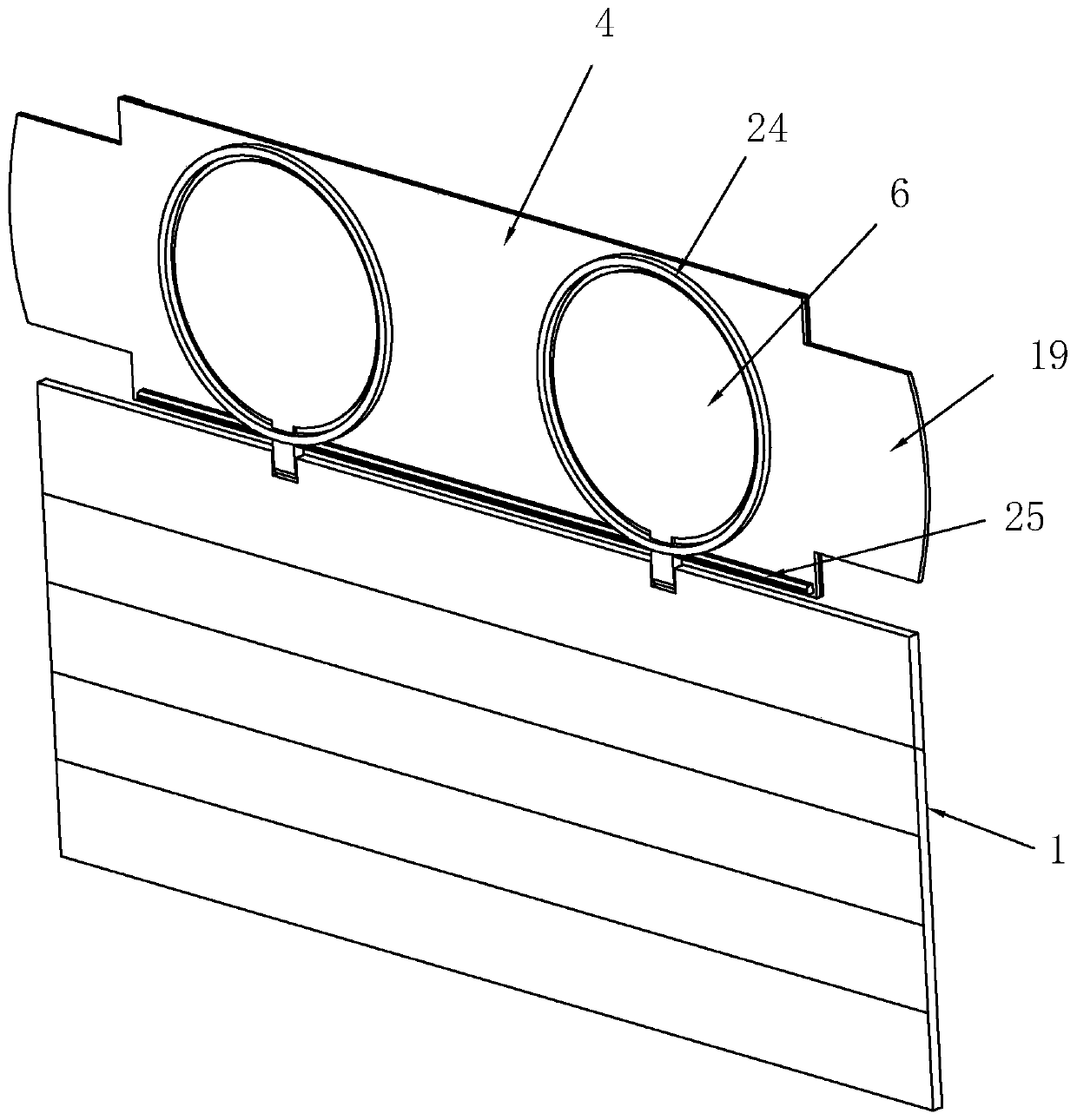

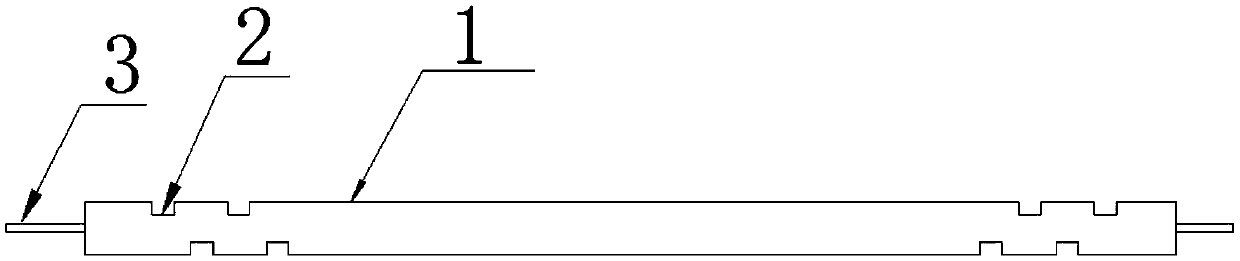

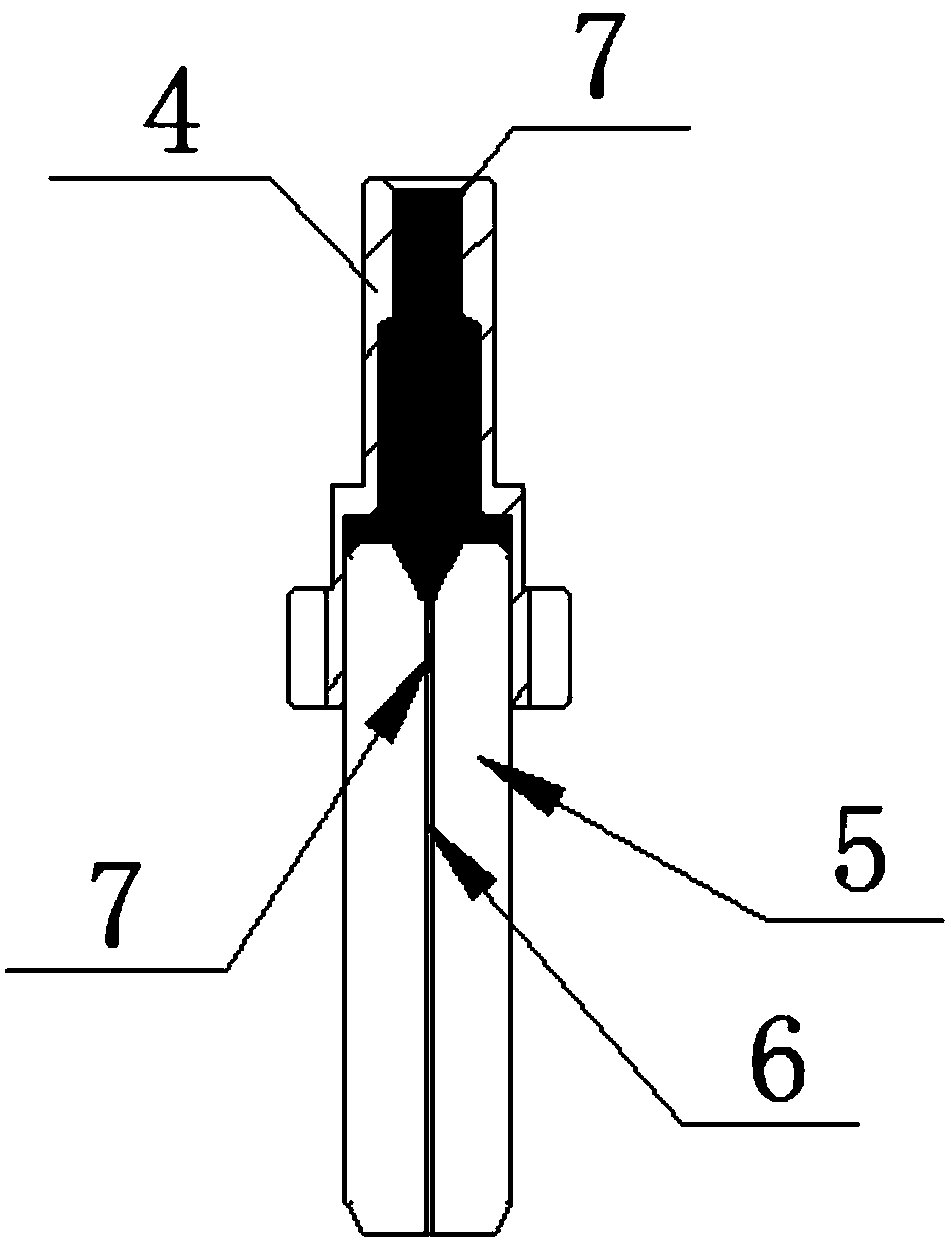

Non-bearing wall integrated heat preservation structure

The invention discloses a non-bearing wall integrated heat preservation structure. The non-bearing wall integrated heat preservation structure comprises a light strip plate, a bonding layer and a heat preservation layer which are sequentially arranged; a plurality of first mounting through holes are formed in the light strip plate in the thickness direction of the light strip plate; a heat preservation plate and the light strip plate are pre-connected through the bonding layer, and a plurality of second mounting through holes are formed in the surface of the heat preservation plate; and anchoring parts are mounted in the first mounting through holes and the second mounting through holes and matched with the second mounting through holes, and the diameter of the first mounting through holes is larger than that of the anchoring parts, so that filling gaps are formed between the interiors of the first mounting through holes and the anchoring parts. The ends, away from the heat preservation layer, of the filling gaps serve as injection openings, grouting materials are injected into the filling gaps, and the grouting materials are fixedly connected with the anchoring parts and the light strip plate correspondingly after reaching the design strength so as to fix the light strip plate and the heat preservation plate secondarily. Through the specific form of the non-bearing wall integrated heat preservation structure, the purposes that the non-bearing wall integrated heat preservation structure is simple in structure, good in heat preservation effect and firm in fixing are achieved.

Owner:SHANGHAI JOHNSON ARCHITECTURAL & ENG DESIGN CONSULTANTS

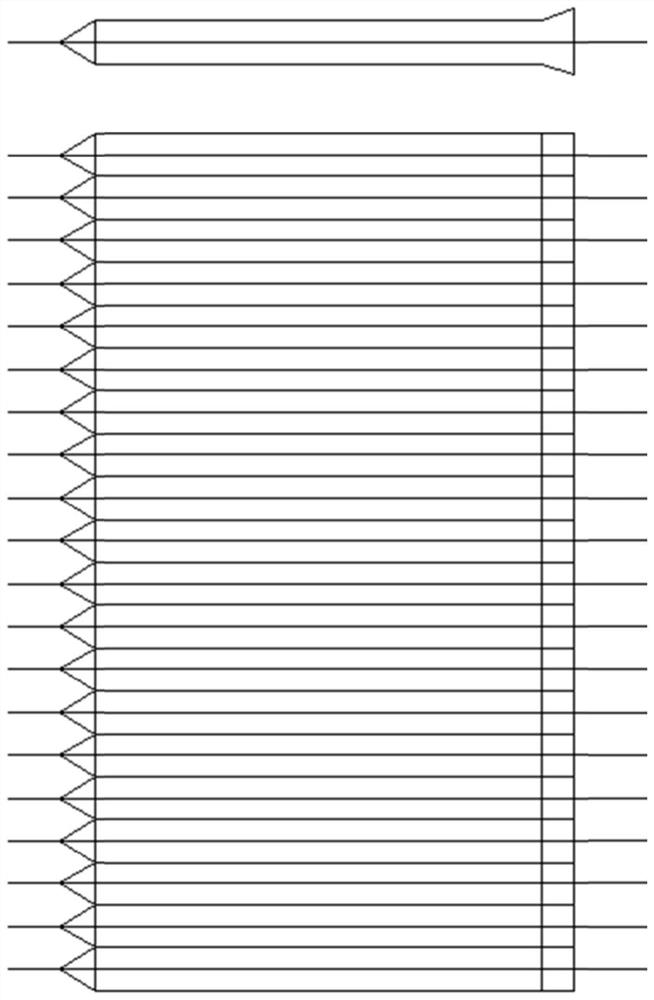

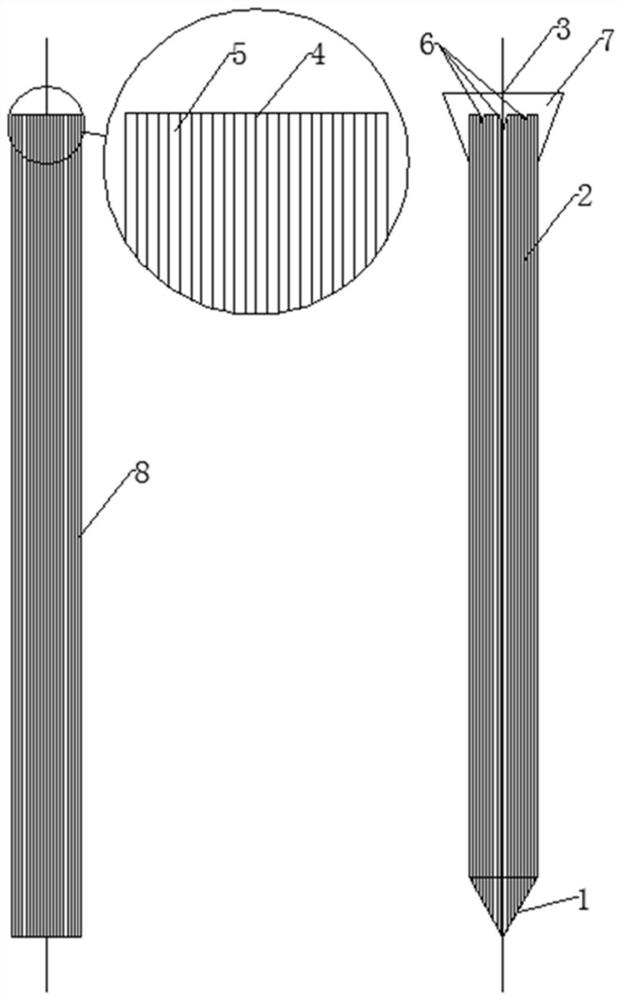

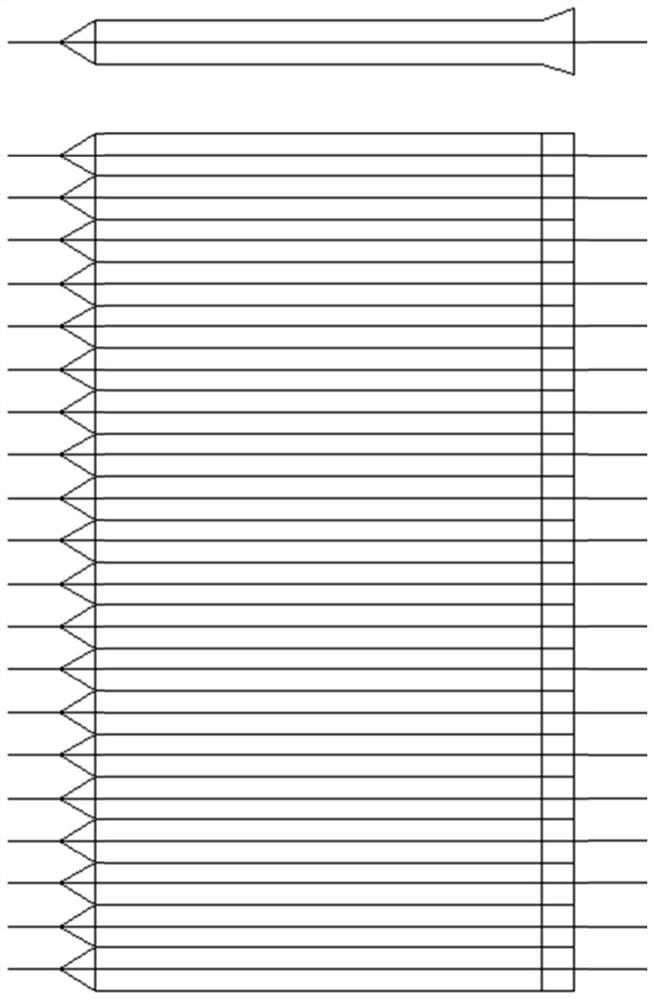

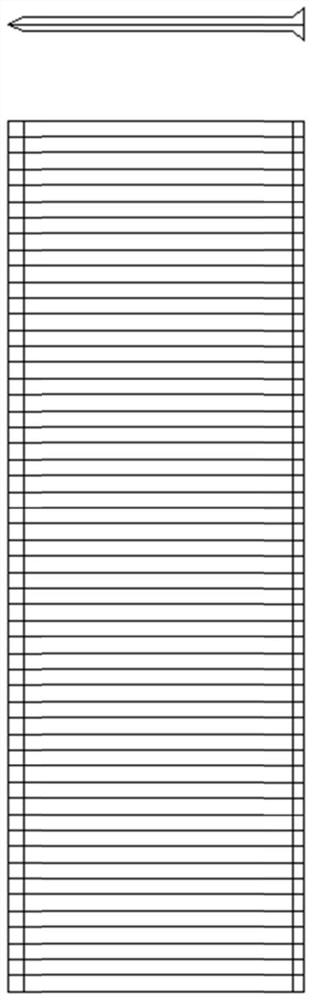

Bamboo gun nail and production method thereof

ActiveCN113681669BSolve the problem of impermeabilitySolve the problem of high requirements for milling cutter sharpeningBio-packagingWood treatment detailsAdhesiveMechanical engineering

This application discloses a bamboo gun nail and its production method. The bamboo gun nail is made of a plurality of bamboo nails with equal thickness and width bonded in parallel to form a row. The nail heads of the bamboo nails are polygonal wedge-shaped or conical. The nail body of two adjacent bamboo nails is separated by adhesive. The thickness of the nail tail of the bamboo nail is greater than the thickness of the nail body, which are respectively square or rectangular. The bamboo nail is a reinforcement layer and a thin Bamboo layer-a layered structure at intervals, with a density greater than 1200kg / m 3 .

Owner:钱一辰

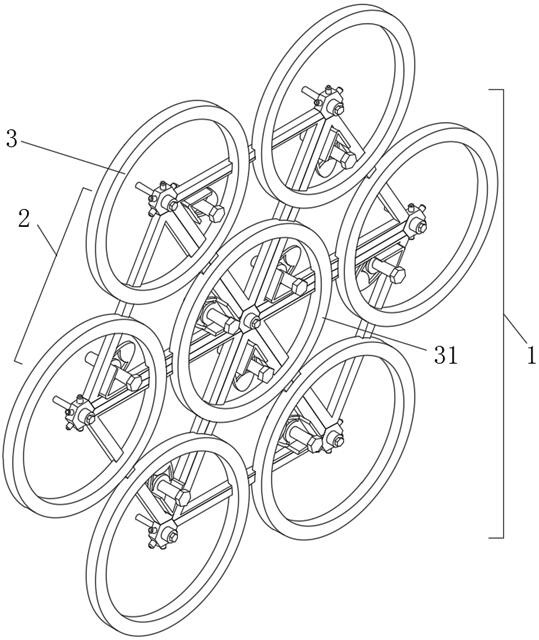

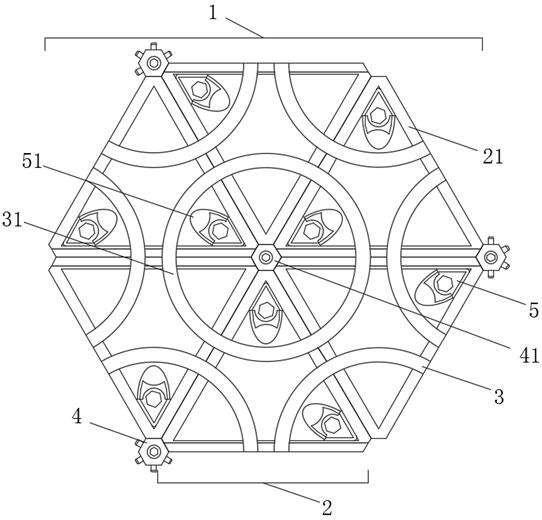

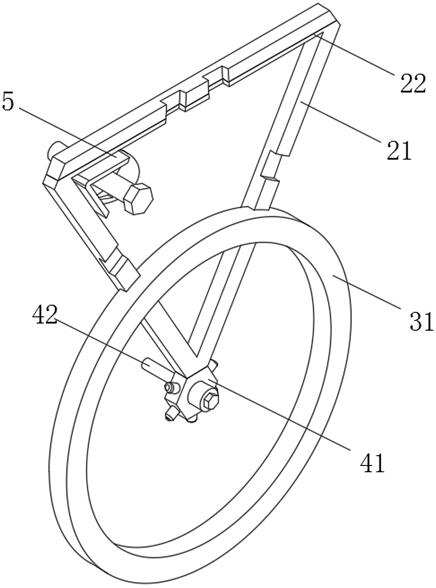

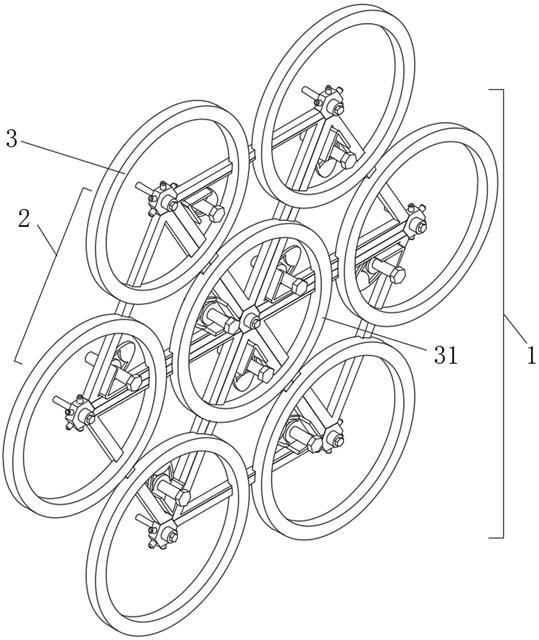

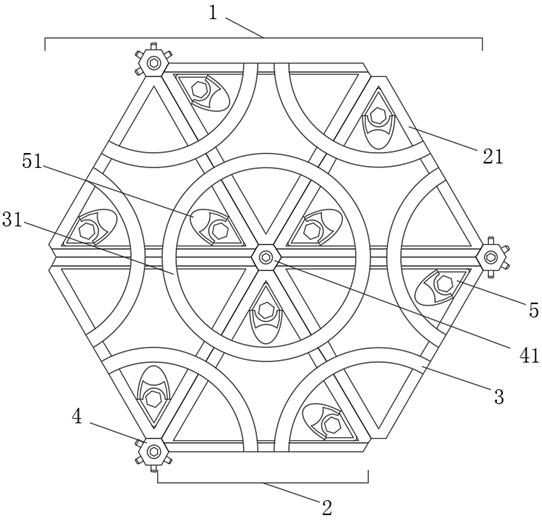

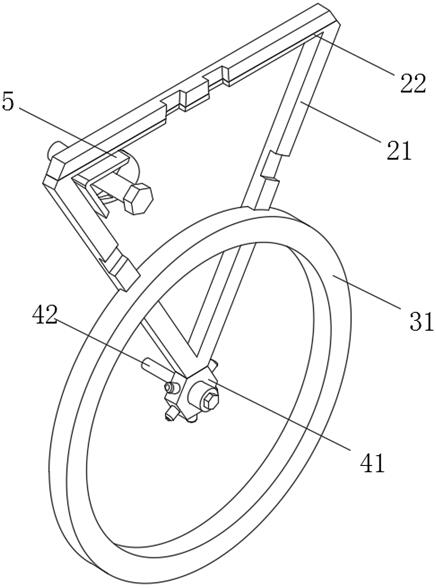

A kind of stone dry hanging installation type fixed keel steel frame for curtain wall

The invention discloses a stone dry-hanging installation type fixed keel steel frame for a curtain wall, which includes a skeleton mechanism, the whole of the skeleton mechanism is made of steel material, and the sides of the skeleton mechanism are installed in a circular array with a plurality of triangles. Steel frame, the whole of the triangular steel frame is arranged in an equilateral triangle, and the front end of the triangular steel frame is installed with an outer ring plate frame; the invention relates to the field of building curtain walls; the keel steel frame can pass the various groups of the triangular steel frame The end corners are fitted and installed corresponding to each corner slot, so that the chuck rod is inserted into the inside of the shrinking rod hole, and at the same time, multiple sets of triangular steel frames are assembled in a circular array through the external fixed body as a whole to form a hexagonal stable structure. The frame can stably support, fix and install large areas of stone.

Owner:江苏沪港新材料科技有限公司

Manufacturing method of solar cell

InactiveCN104112791BReduce thicknessIncrease the effective bonding areaFinal product manufacturePhotovoltaic energy generationEngineeringSolar cell

Owner:MOTECH INDUSTRIES

A rubber-modified multi-component resin material for disc brake pads and its application

ActiveCN107061574BIncrease the effective bonding areaIncrease coefficient of frictionFriction liningPolymer scienceAramid

The invention discloses a rubber modified multielement resin material for disc brake pad and purposes. With the total mass of raw material components of the rubber modified multielement resin material as reference, the rubber modified multielement resin material comprises the following raw material components in percentage by mass: 1-5% of benzoxazine resin, 1-5% of cashew nut shell oil modified phenolic resin, 1-5% of epoxy resin, 1-15% of powder nitrile rubber, 0.5-3% of aramid fiber pulp, 5-20% of mineral fiber, 2-5% of red copper fiber, 1-7% of aluminum oxide, 1-5% of calcium hydroxide, 3-9% of synthesized graphite, 3-9% of granular coke, 2-9% of antimony sulfide, 5-15% of potassium titanate, and 15-45% of barite. The material is applied to the disc brake pad, reduces the wear of the brake pad, reduces the generation frequency of braking noise, and shows better performances on such aspects as friction loss, noise and heat stability.

Owner:SHANDONG GOLD PHOENIX

Bamboo gun nail and production method thereof

ActiveCN113681669ASolve the problem of impermeabilitySolve the problem of high requirements for milling cutter sharpeningBio-packagingWood treatment detailsAdhesiveMechanical engineering

The invention discloses a bamboo gun nail and a production method thereof. The bamboo gun nail is formed by connecting and bonding a plurality of bamboo nails with the same thickness and width in parallel into a row, the nail head of each bamboo nail is in a polygonal wedge shape or a conical shape, nail bodies of every two adjacent bamboo nails are separated through an adhesive, and the thickness of the nail tail of each bamboo nail is larger than that of the nail bodies. The bamboo nails are square or rectangular, each bamboo nail is of a layered structure with a reinforcing layer and a thin bamboo piece layer spaced one by one, and the density is larger than 1200 kg / m<3>.

Owner:钱一辰

Stone dry-hanging installation type fixed keel steel frame for curtain wall

The invention discloses a stone dry-hanging installation type fixed keel steel frame for a curtain wall which comprises a framework mechanism; the whole framework mechanism is made of steel materials; a plurality of triangular steel frames are installed on the side of the framework mechanism in a circular array mode; the whole triangular steel frames are arranged in an equilateral triangle mode; an outer ring plate frame is mounted at the front end of the triangular steel frame. The invention relates to the field of building curtain walls. According to the keel steel frame, the end corners of the triangular steel frame and corner grooves are correspondingly installed in an embedded mode, so that when clamping head rods are inserted into the inner sides of rod shrinkage holes, the multiple sets of triangular steel frames are integrally combined and installed in a circular array mode through external fixing bodies, a hexagonal stable structure frame is jointly formed, and large-area stones can be stably supported, fixed and mounted.

Owner:江苏沪港装饰集团有限公司

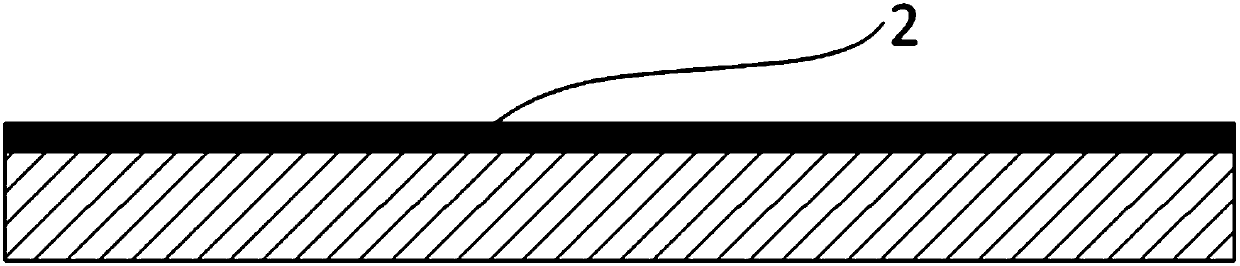

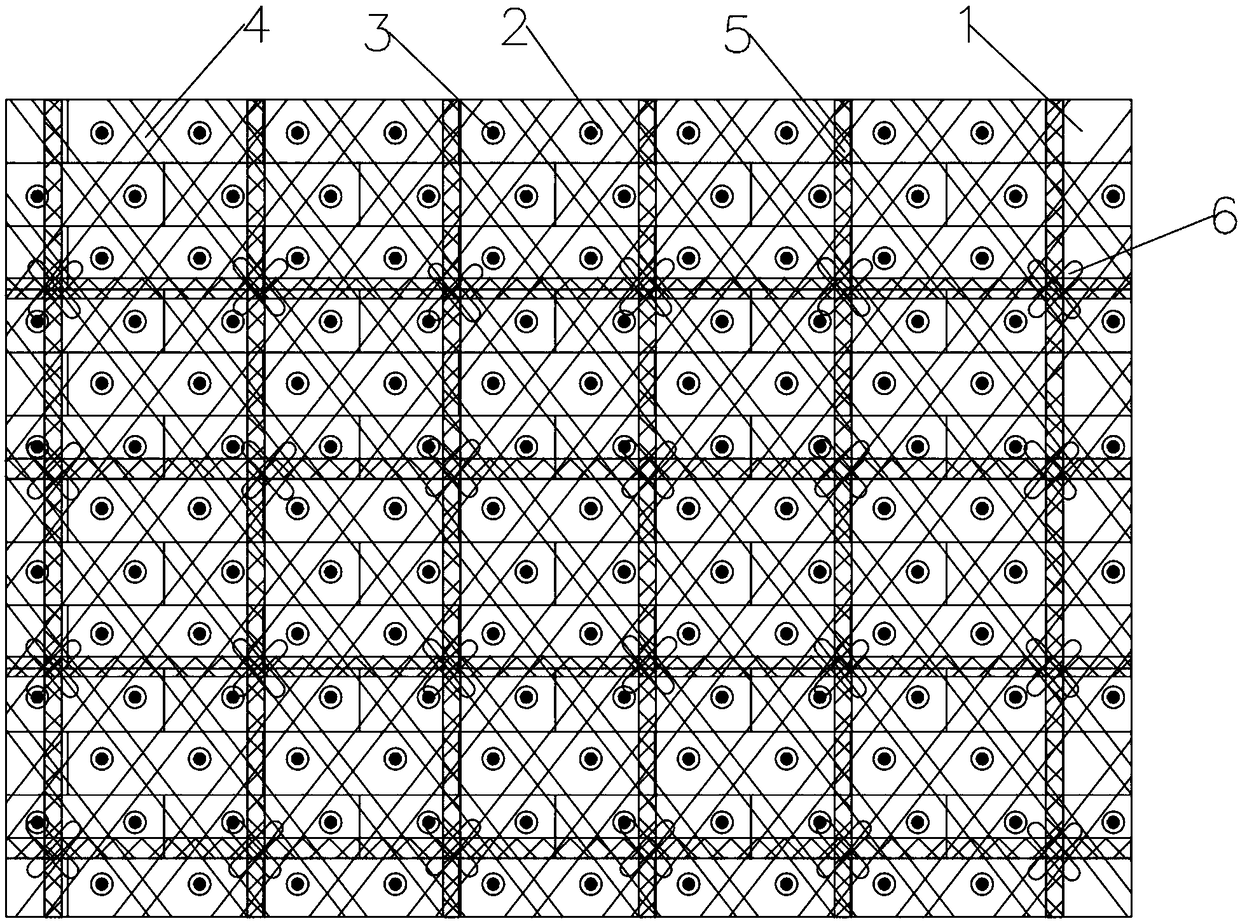

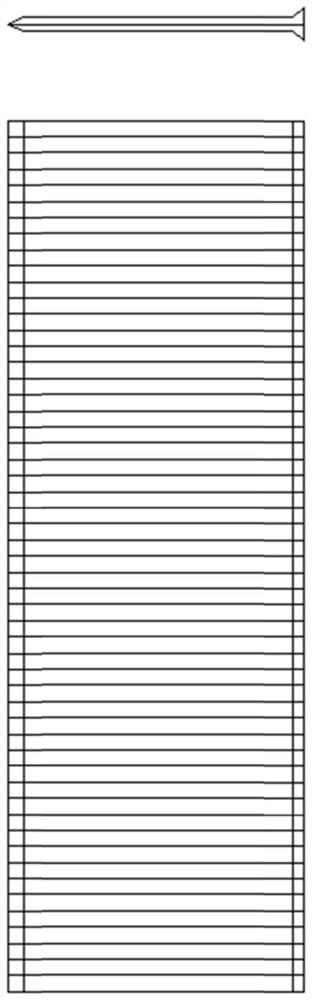

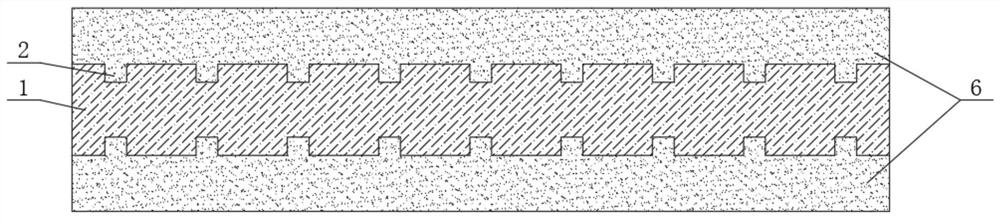

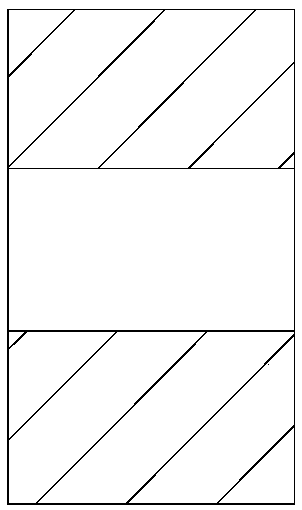

Green recycled carbon fiber thermoplastic material building board and preparation method

ActiveCN112497787BIncrease the effective bonding areaHigh bonding strengthPlastic recyclingFiberPolymer science

The invention discloses a building board made of green recycled carbon fiber thermoplastic material, which includes a carbon fiber felt and a thermoplastic resin layer. The front and back sides of the carbon fiber felt are provided with transverse grooves, longitudinal grooves and vertical holes. Horizontal holes parallel to the front of the carbon fiber felt are opened on the facade, and the thermoplastic resin layer is heat-pressed on the front and back of the carbon fiber felt by a hot press. In the present invention, uniform transverse grooves, longitudinal grooves and vertical holes are pressed out on the front and back of the carbon fiber felt, which not only increases the effective bonding area between the carbon fiber felt and the thermoplastic resin layer, but also makes the carbon fiber felt and the thermoplastic resin layer form unevenness Combined structure, so as to improve the bonding strength between the thermoplastic resin layer and the carbon fiber felt; the thermoplastic resin powder in the vertical hole can be melted during hot pressing, so that the thermoplastic resin layer on the front and back of the carbon fiber felt is integrated with the thermoplastic resin in the vertical hole Thermoforming.

Owner:深圳市恒和装饰设计工程有限公司

Method for manufacturing a motor rotor assembly

ActiveCN106787509BIncrease surface tensionEasy to wetMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectroplating

The invention discloses a fabrication method of a motor rotor assembly. The fabrication method comprises the steps of firstly, processing an inner hole of annular magnetic steel; secondly, electroplating the annular magnetic steel, attaching electroplating layers onto other surfaces except an inner surface of the annular magnetic steel after being electroplated, and enabling an axial direction of the annular magnetic steel to be in a horizontal direction; thirdly, coating a layer of binding agent on the inner hole of the annular magnetic steel, inserting a cylindrical core shaft into the annular magnetic steel from a first inner hole, and then allowing the cylindrical core to extent out of a second inner hole; fourthly, rotating the annular magnetic steel by 90 degrees so that the axial of the annular magnetic steel is in a vertical direction, and encapsulating a gap between of the second inner hole and the cylindrical core shaft with the binding agent, wherein the second inner hole is arranged above the first inner hole; and finally, maintaining the position of the annular magnetic steel unchanged after the encapsulation of the binding agent is completed, and completing the fabrication of the motor rotor assembly after the binding agent is naturally cured. The fabrication method has the advantages that no noise is generated during the high-speed rotation process, the motor rotor assembly has relatively large twisting force, the annular magnetic steel cannot be separated from the cylindrical core shaft, and the service lifetime of the motor is prolonged.

Owner:NINGBO YUNSHENG

High-frequency impact treatment method for aluminum honeycomb cell end faces

ActiveCN108435519AIncrease surface areaRegular shapeMechanical vibrations separationOther manufacturing equipments/toolsAluminum honeycombUltimate tensile strength

The invention discloses a high-frequency impact treatment method for aluminum honeycomb cell end faces. The high-frequency impact treatment method for the aluminum honeycomb cell end faces is characterized by comprising the following steps that S1, a to-be-treated aluminum honeycomb is fixed, and to-be-treated aluminum honeycomb cell end faces are upward; S2, the initial relative positions betweena high-frequency impact tool and the to-be-treated aluminum honeycomb cell end faces are determined, and the machining path is determined; and S3, the high-frequency impact tool moves along the movement path and conducts high-frequency impact treatment on the to-be-treated aluminum honeycomb cell end faces on the movement path, and the aluminum honeycomb cell end faces undergoing high-frequency impact treatment are obtained. According to the aluminum honeycomb treated by the adoption of the high-frequency impact treatment method, the cell end face area is increased, the width of the honeycombwalls near the end faces are increased, the effective adhesion binding area is increased, the adhesion binding strength is improved, and then the mechanical performance of an aluminum honeycomb structural component is improved. In addition, the high-frequency impact treatment method for the aluminum honeycomb cell end faces has the advantages of being high in adhesion strength controllability, clean and environmentally friendly.

Owner:DALIAN UNIV OF TECH

Medical epidemic prevention eye protection mask

InactiveCN111264930AEffective blockingIncrease the effective bonding areaProtective garmentProtecting eyeOphthalmology

The invention provides a medical epidemic prevention eye protection mask. The mask comprises a mask body, fixing lines are arranged on the left side and the right side of the mask body respectively, and fixing strips are installed on the side edges, adjacent to the fixing lines, of the mask body; the mask includes an eye protector, the eye protection comprises an air bag piece and two eye protection pieces which are installed on the air bag piece and made of transparent materials. The fixing strip penetrates through the two eye protection pieces, the eye protection pieces can turn over aroundthe fixing strip, the two eye protection pieces can be opposite to the eyes of a user respectively, an inflation inlet is formed in the air bag piece, a pull wire is arranged on the eye protector, andthe pull wire is used for fixing the eye protection body to the face of the user. The mask can effectively block viruses, and is light in overall weight, high in wearing comfort and high in use convenience.

Owner:邢义平

An optical fiber manufacturing process

The invention provides an optical fiber manufacturing technique including a line cutting step, a pre-treatment step, a negative pressure glue absorbing step, a pre-heating step, a step of penetrating fibers through a sleeve and a solidification step. The invention has beneficial effects that excessive concave or convex volume of optical fibers relative to an end face of a ceramic insert core is prevented and fiber breakage proportion is also reduced; optical fiber height of an optical fiber patch cord product is controlled in a range from -100nm to +50nm and the optical fiber height reject ratio is controlled within 0.1 %.

Owner:OPCONN COMM TECH

A method of three-dimensional jet printing forming casting core

ActiveCN105057601BHigh viscosityIncrease surface tensionFoundry mouldsFoundry coresFine structureLarge size

The invention discloses a method for three-dimensional jet-printing, forming and casting of a core. The method comprises the comprises the following steps: (1) spreading film covering sand to form a thin layer, and selectively injecting bonding liquid into the film covering sand by using a three-dimensional jet-printing device so that particles in the film covering sand can be bonded with one another to form a first layer; (2) forming a second layer by using the same method in the step (1), repeating the step (1) until a part is formed completely, and standing the part in a powder bed for a period of time so as to obtain an initially formed blank; and (3) heating the initially formed blank at the temperature of 170-220 DEG C until the bonding liquid completely volatilizes, and cross-linking and curing with phenolic resin, so that the casting of the core is finished. According to the method, the method for three-dimensional jet-printing, forming and casting of the core is simplified; the film covering sand can be accumulated layer by layer without drying conditions among layers, so that the fast casting forming of the core is finished; finally, a produced piece is relatively high in intensity, low in cost and high in efficiency; the method can be used for producing the casting core with the large size and a fine structure, and has a wide application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

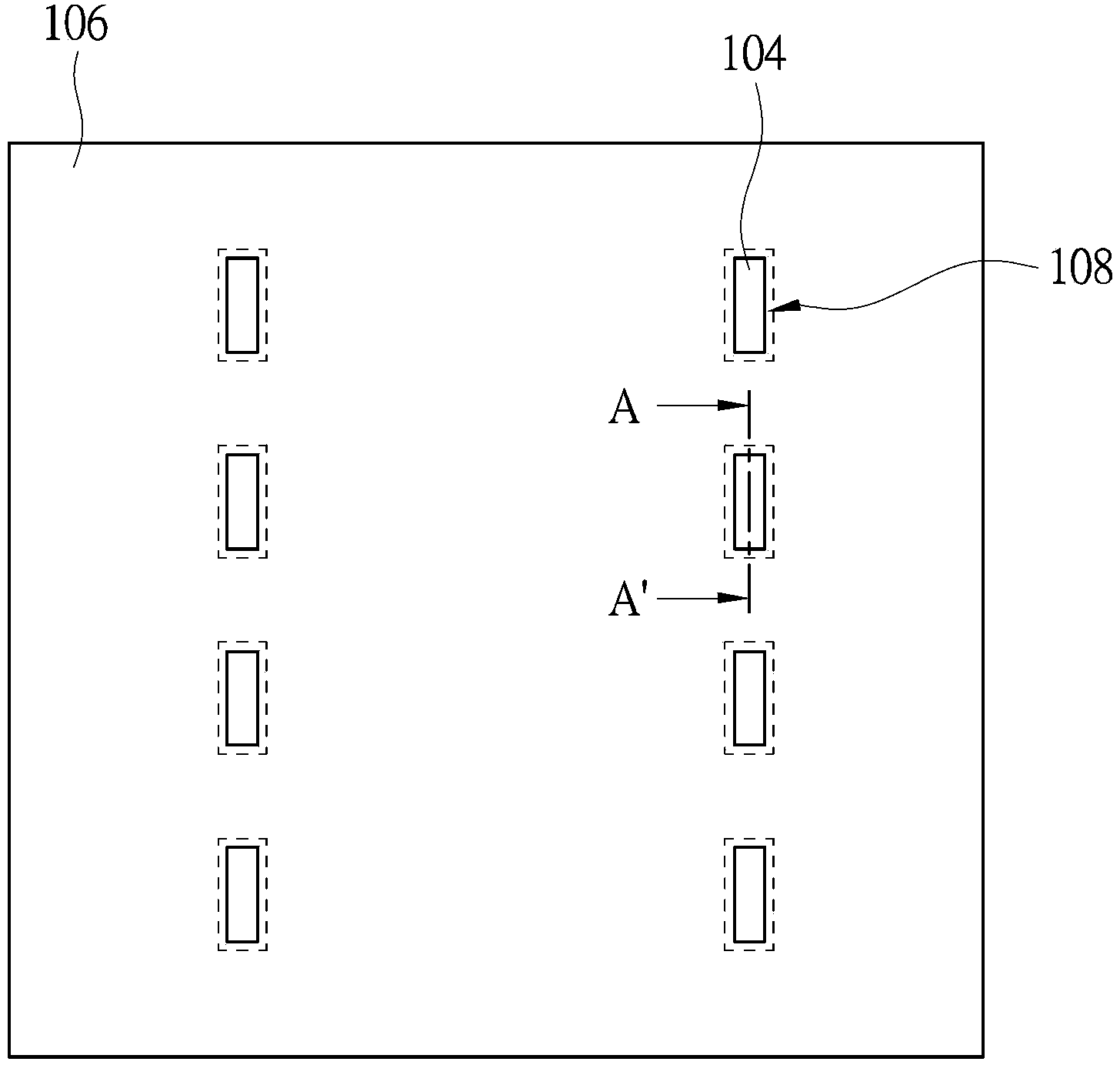

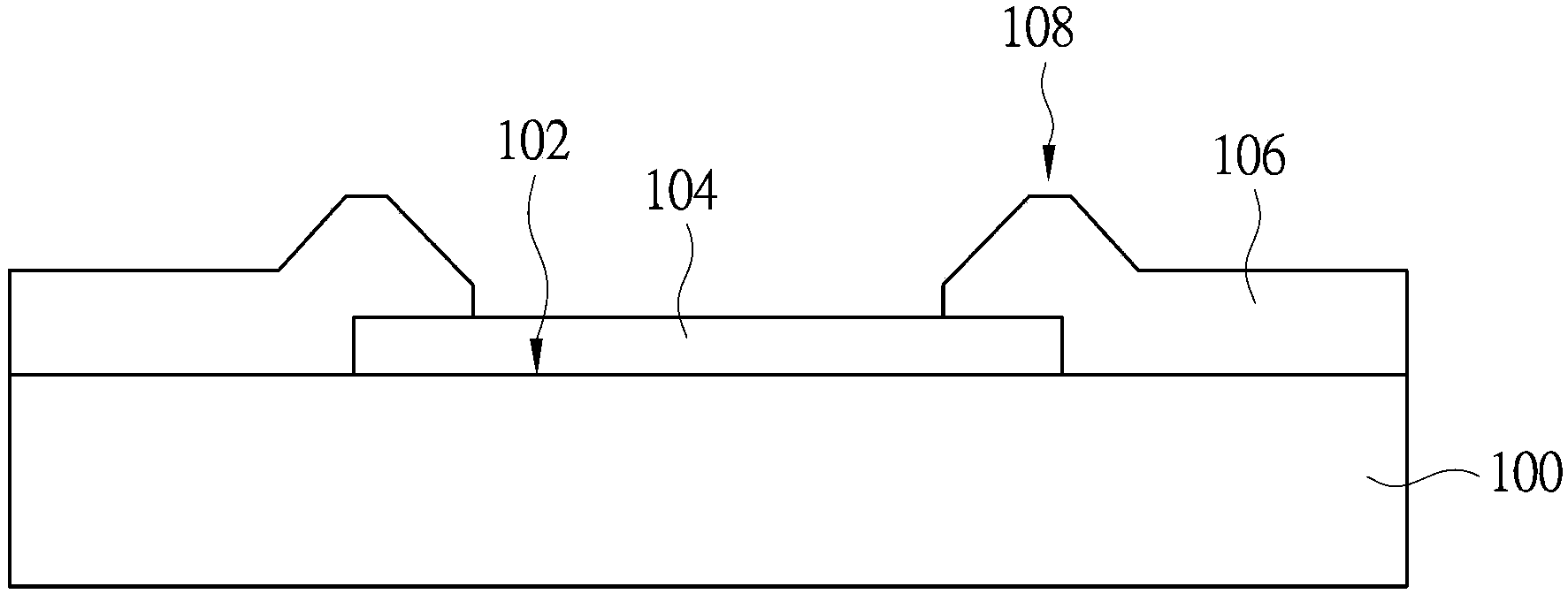

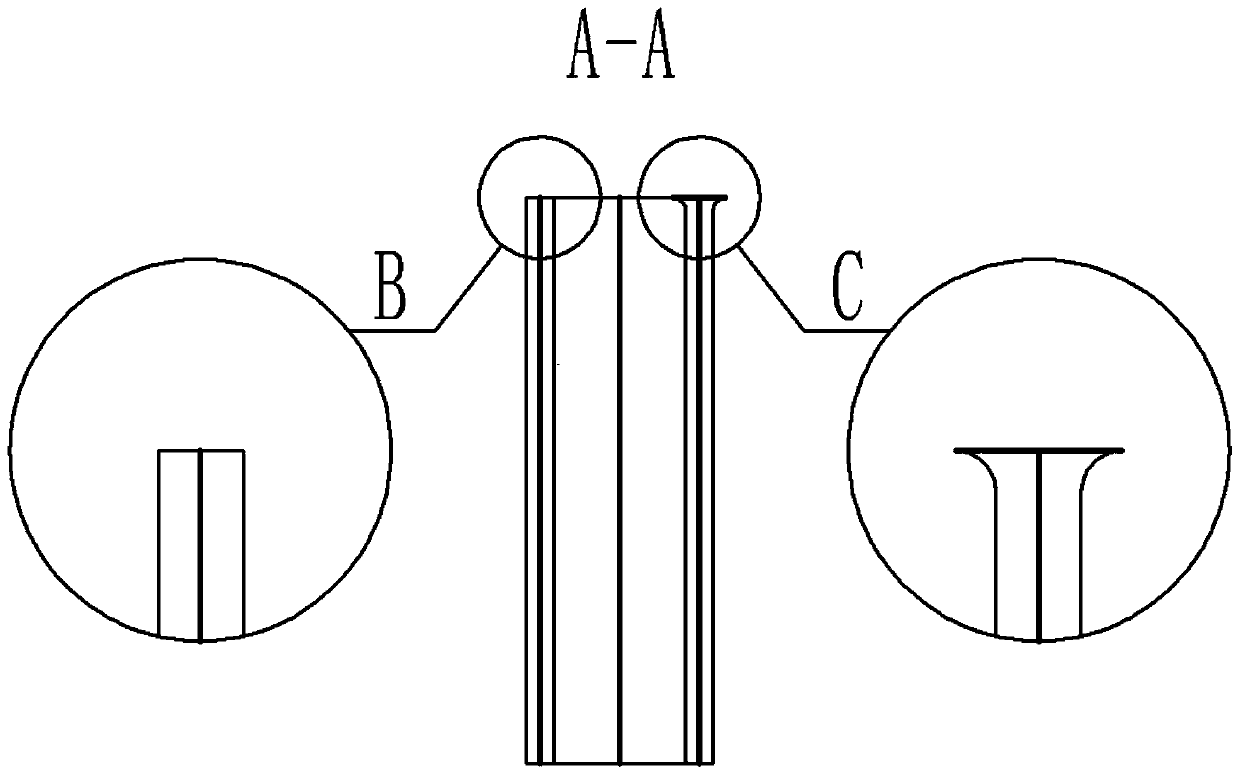

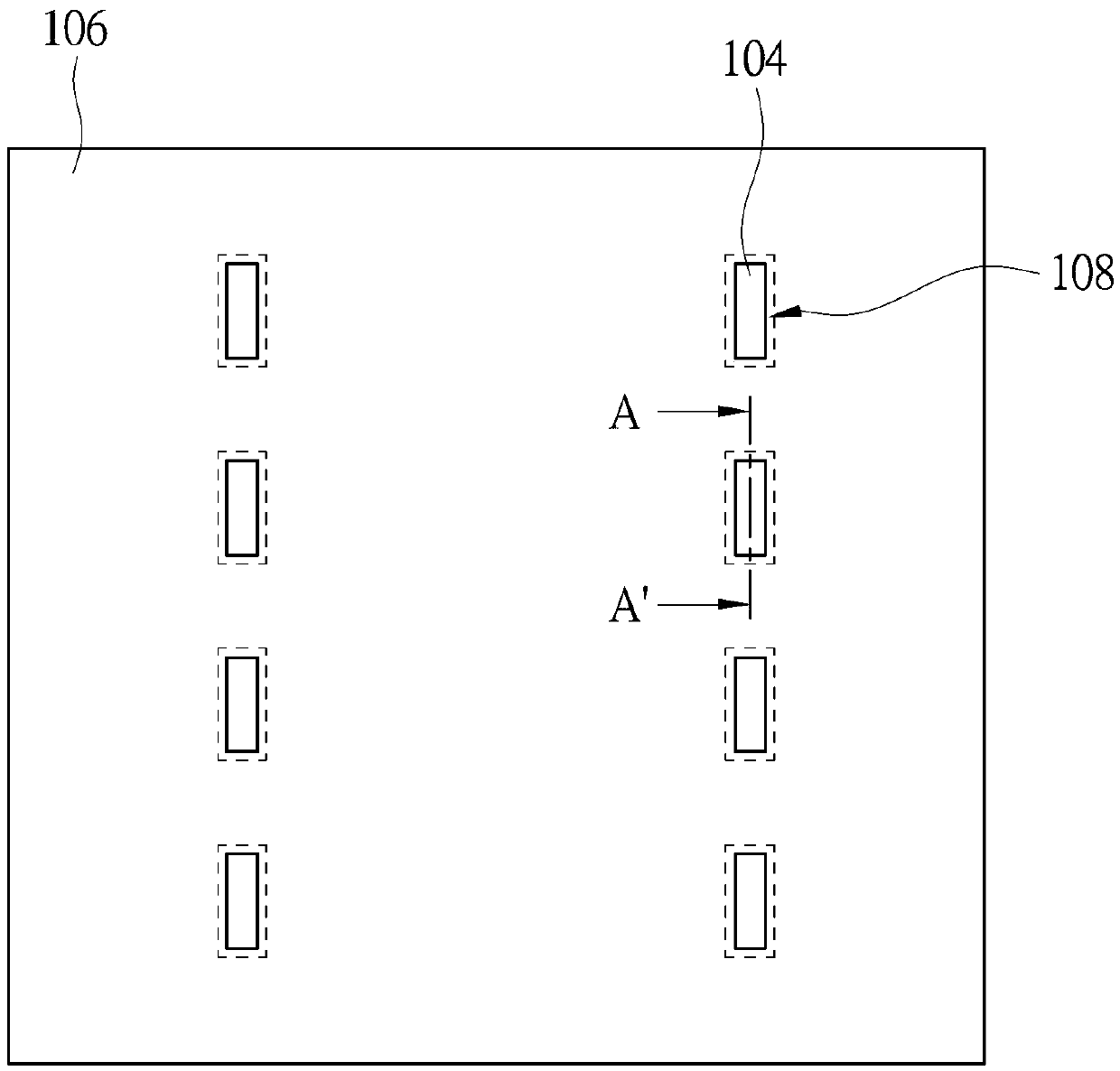

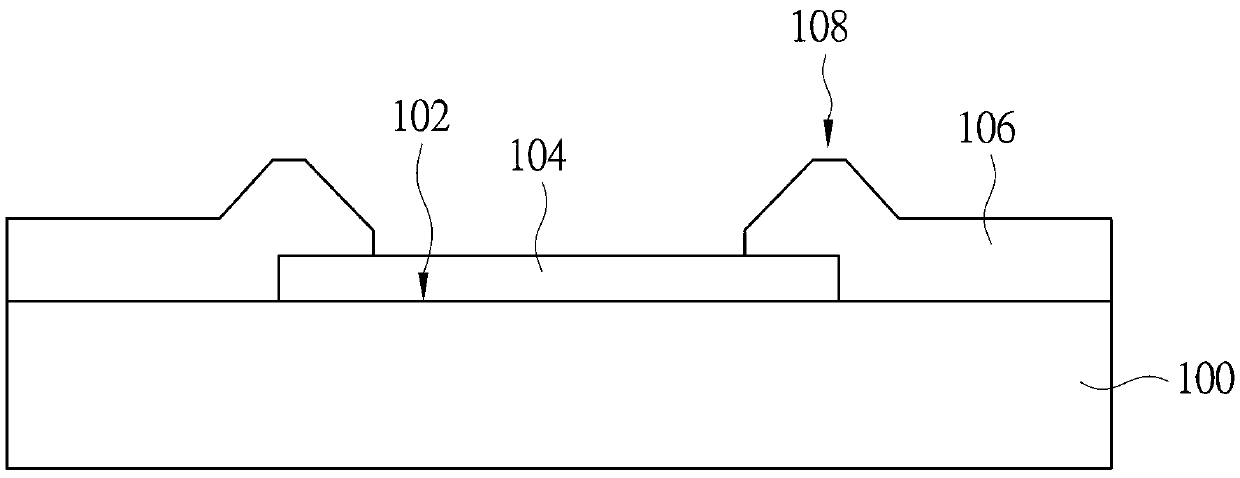

MEMS presser sensor chip and manufacturing method thereof

InactiveCN101776501BReduce Fragmentation RateImprove yieldTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrical resistance and conductanceLinear region

The invention relates to an MEMS presser sensor chip, which can effectively improve sensitivity of a chip and enhance yield of the chip. The presser sensor chip comprises a silicon slice, a vacuum cavity, a glass substrate, a sensitive resistor configuration region, an outer electric connecting piece of the sensitive resistor configuration region and an alignment mark component and is characterized in that: the four corners of the positive face and the negative face of the silicon slice are respectively provided with an alignment mark structure; the maximum stress linear region of the positive face of the silicon slice is the sensitive resistor configuration region which is rectangular and comprises a piezoresistor, p+connection, an N+ isolation groove and an aluminum electrode; and the piezoresistor consists of two pairs of bridging resistors concretely, each bridging resistor comprises one pair of sensitive resistors which are linear resistors, each bridging resistor in each pair of the bridging resistors is arranged at two opposite sides of the four sides of the sensitive resistor configuration region respectively in a symmetric manner, and each bridging resistor is encircled by the N+ isolation groove.

Owner:淮安纳微传感器有限公司

Method for raising hot pressing bonding rate of PMMA micro fluidic chip formed by injection moulding

InactiveCN102190287BNo change in performanceImprove bonding qualityPrecision positioning equipmentSoldering apparatusManufacturing technologyUltraviolet

Provided is a method for raising the hot pressing bonding rate of a PMMA micro fluidic chip formed by injection moulding. The invention is directed to the field of micro manufacture technology, especially relates to a method for raising the hot pressing bonding quality of a micro fluidic chip. The method is characterized in that carrying out water processing before hot pressing bonding; unlike a traditional hot pressing bonding process flow of from ultrasonic cleaning to drying in a baking oven to hot pressing bonding, a new process flow of from ultrasonic cleaning to water processing to drying the surface with nitrogen to hot pressing bonding is adopted. According to the invention, problems of complex processing method, high cost and negative influence on system operational performance in processing methods such as ultraviolet ray and MMA monomer surface modification and the like are overcome. The processing method is characterized by high efficiency, low cost, unchanged microfluid system performance and simple operation. At a same hot pressing bonding technological parameter, compared to untreated chips, the effective bonding areas of the chips treated with the method provided in the invention substantially increase, the bonding rates averagely increase 20 percent, thereby the bonding quality of the chips is effectively improved.

Owner:DALIAN UNIV OF TECH

A radial adjustment and fastening device for processing ultra-precision optical grazing incidence mirrors

ActiveCN112246561BSolve the sinking situationImprove coaxialityLiquid surface applicatorsCoatingsRadial positionEngineering

A radial adjustment and fastening device for processing ultra-precision optical grazing incidence mirrors, which relates to the field of optical design and manufacture, includes a fastening seat for mounting the mirror, a plurality of radial adjustment mechanisms installed on the fastening seat, and a Multiple glue blocks on the fastening seat; the radial position of the reflector in the fastening seat is adjusted by a radial adjustment mechanism; the circumferential position of the reflector in the fastening seat is adjusted by the glue blocks. Fastening the radial position of the reflector through the radial adjustment mechanism can effectively solve the sinking caused by the influence of gravity on the reflector during the processing process, improve the coaxiality between the axis of the mirror surface and the axis of the fastening seat, and at the same time The axiality should be controlled within 0.1μm, which improves the machining accuracy of the mirror surface. Two injections of glue through the glue block can increase the effective bonding area between the reflector and the fastening seat, improve the bonding force between the reflector and the fastening seat, play a role in stabilizing the fastening, and realize the mirror in the Radial fixation and circumferential fixation during machining.

Owner:CHANGCHUN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com