Method of manufacturing solar cell

A technology for solar cells and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as affecting the reliability of solar modules, poor bonding force, and difficulty in the packaging process of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

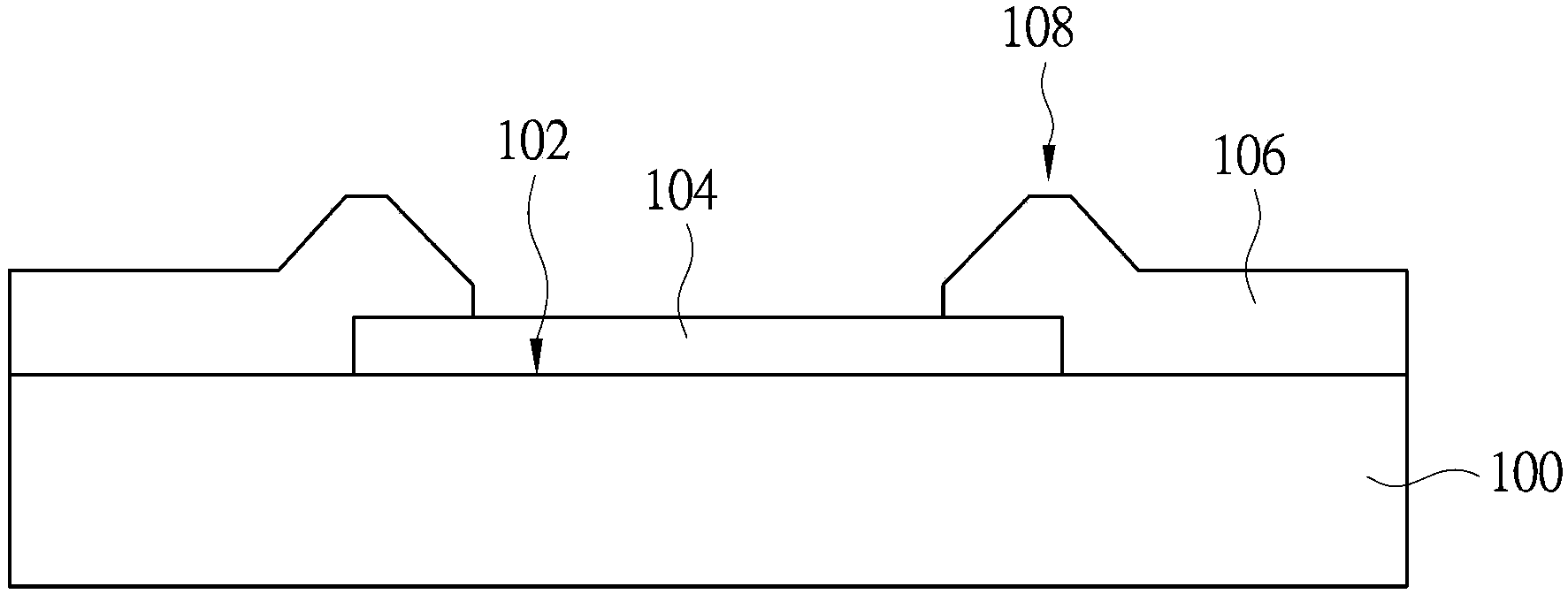

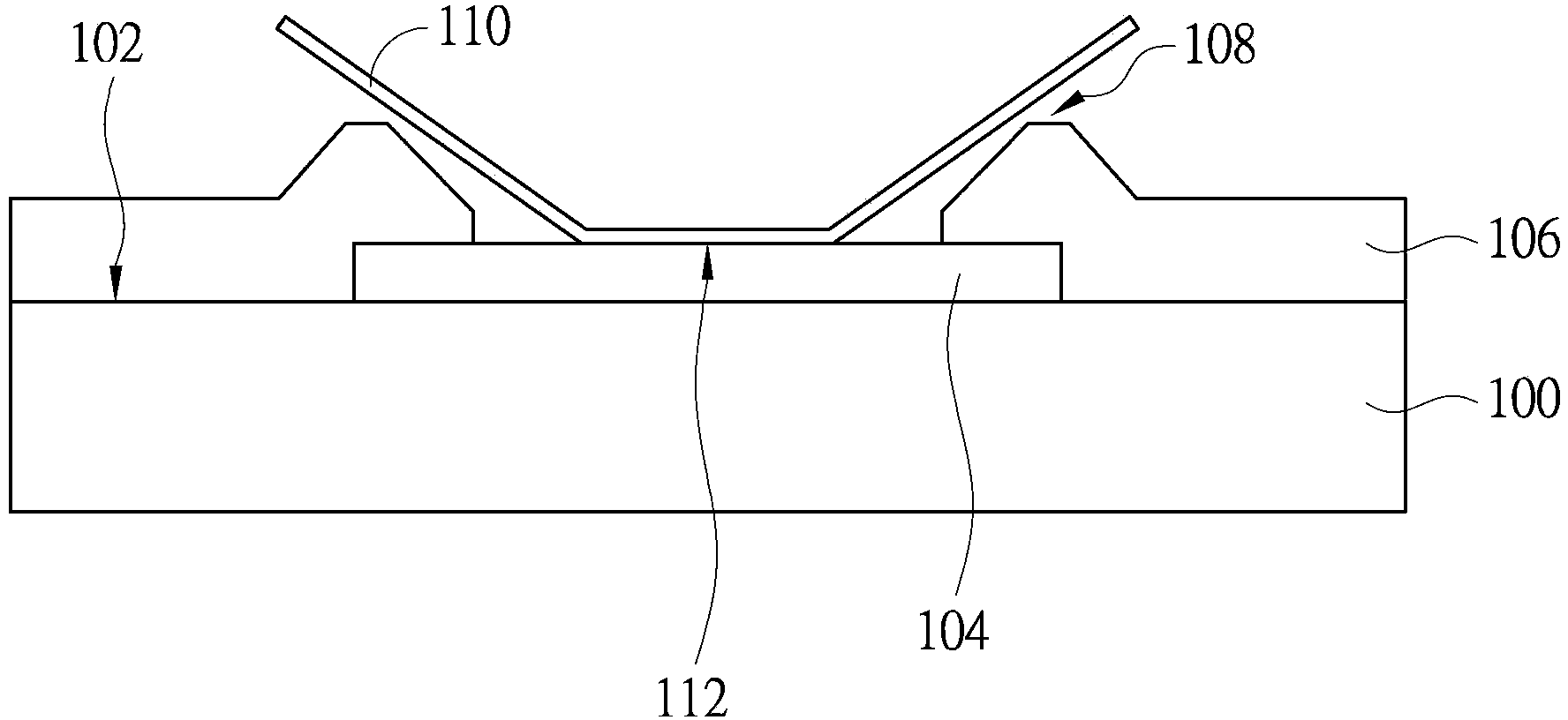

[0046] Please refer to Figure 3A to Figure 3C , which is a cross-sectional view illustrating a process of a solar cell according to an embodiment of the present invention. In this embodiment, when manufacturing a solar cell, the photoelectric conversion substrate 200 may be prepared first, wherein the photoelectric conversion substrate 200 has a P / N junction structure to convert light energy such as sunlight into electrical energy. Such as Figure 3A As shown, the photoelectric conversion substrate 200 includes a light-receiving surface 204 and a backlight surface 202 respectively located on two opposite sides of the photoelectric conversion substrate 200 . The light-receiving surface 204 of the photoelectric conversion substrate 200 is a surface receiving incident light from a light source such as sunlight, and the backlight surface 202 is a surface facing away from the incident light. In the photoelectric conversion substrate 200 , the light-receiving surface 204 is usual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com