Motor joint for bullet train bogie and manufacture method thereof

A manufacturing method and bogie technology, applied to bogies, motor vehicles, locomotive propulsion methods, etc., can solve problems such as product quality impact and effective bonding area reduction, so as to improve quality and service life, improve product quality, and avoid The effect of axial instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

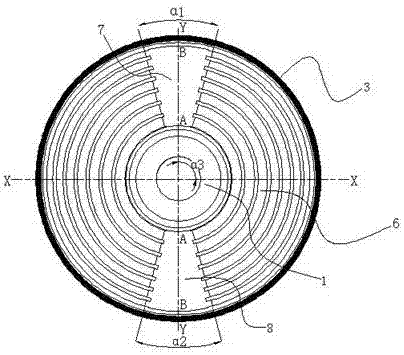

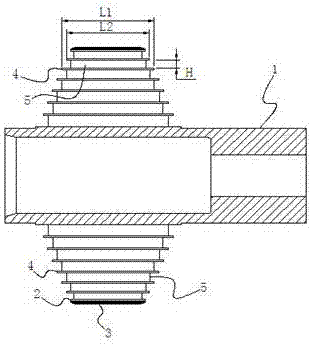

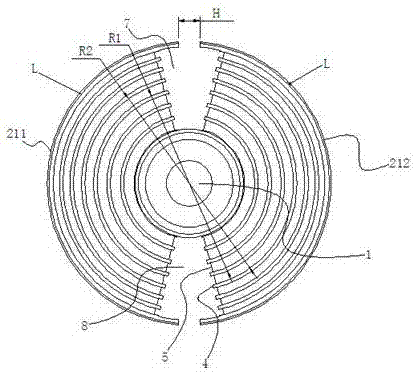

[0026] Example: such as Figure 1 to Figure 3 As shown, a motor node for a motor vehicle bogie includes a metal mandrel 1, a first layer of metal jacket 2, a second layer of metal jacket 3, a multilayer metal spacer 4, a multilayer elastic rubber body 5, and a multilayer elastic rubber The body 5, the metal mandrel 1, the multilayer metal spacer 4, and the first metal jacket 2 are vulcanized into an elastic body 6, and the elastic body 6 is pressed into the second metal jacket 3; the metal spacer 4, the elastic Both the rubber body 5 and the first layer of metal jacket 2 are of a two-petal structure; the elastic body 6 is pressed into the second layer of metal jacket 3 after closing the first layer of metal jacket 2 of the two petals through the tooling, and the elastic rubber body 5 Pre-compression stress is generated, and air isolation section 1 7 and air isolation section 2 8 are formed between the two-petal metal spacer 4 and the elastic rubber body 5. Along the radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com