Assembled-type aluminum alloy bridge deck slab-steel girder combined structure

A technology for combining structures and bridge decks, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as weak tensile and shear resistance of connecting parts, large deformation of bridge deck unit joints, and restrictions on the wide application of such structures. , to achieve the effect of low maintenance cost, increased span and sustainable development of maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

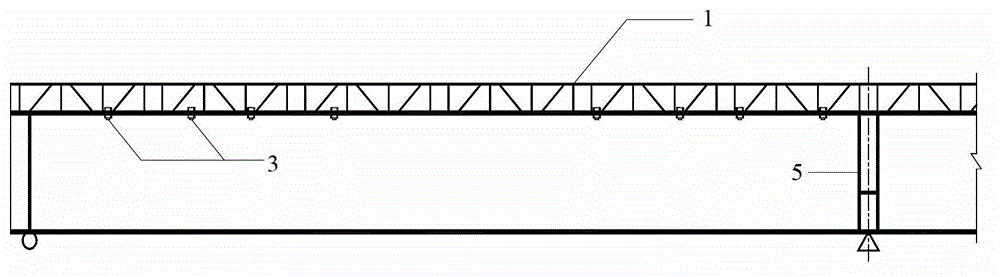

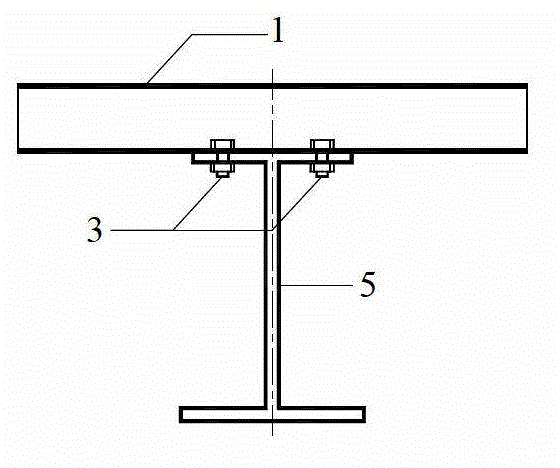

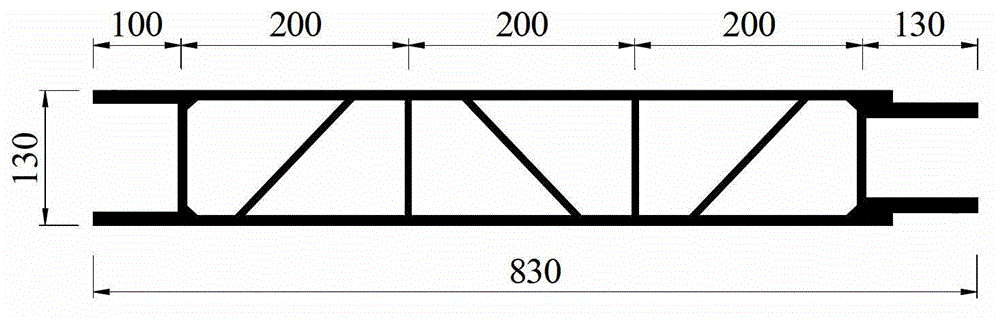

[0022] Such as Figure 1 to Figure 5 As shown, the assembled aluminum alloy bridge deck-steel girder composite structure of the present invention mainly includes an aluminum alloy bridge deck 1 and a steel girder 4, the aluminum alloy bridge deck 1 is laid on the steel girder 4, and the aluminum alloy bridge deck 1 and the steel girder 4 Connected by high-strength bolts 2; adjacent aluminum alloy bridge deck units ( image 3 ) are connected to form an overall bridge deck structure by extruding and screwing stainless steel screws 3 into joint plates. This way of connecting high-strength bolts 2 and stainless steel screws 3 changes the traditional welding connection method, and avoids the problem of lowering the strength of the aluminum alloy base material due to welding. At the same time, the above connection method is faster than welding in on-site construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com