Green recycled carbon fiber thermoplastic material building board and preparation method

A technology of thermoplastic materials and building boards, applied in the field of building boards, can solve the problems of short service life, large wood, inconvenience, etc., and achieve the effect of improving bonding strength, service life and bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

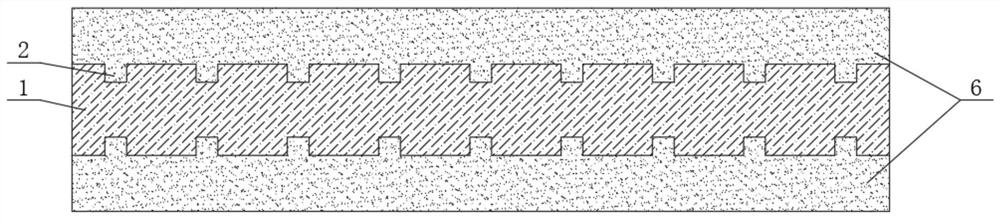

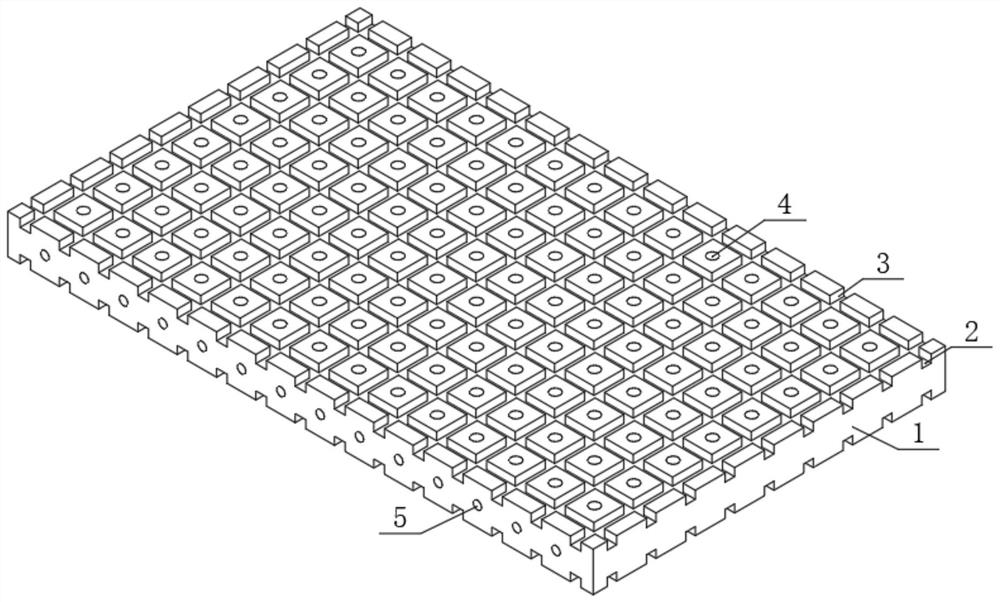

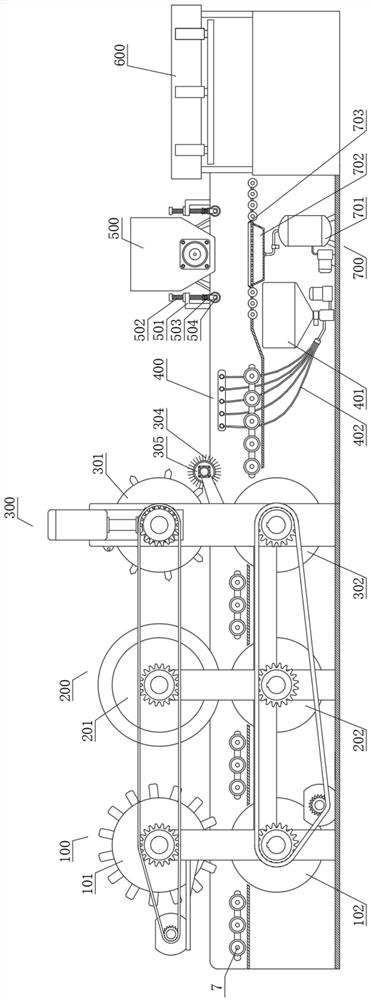

[0039] see Figure 1-2 , a green recycled carbon fiber thermoplastic material building board, including a carbon fiber felt 1 and a thermoplastic resin layer 6, the front and back of the carbon fiber felt 1 are provided with transverse grooves 3, longitudinal grooves 2 and vertical holes 4, the carbon fiber felt 1 There are transverse holes 5 parallel to the front side of the carbon fiber felt 1, and the front and back sides of the carbon fiber felt 1 are hot-pressed with the thermoplastic resin layer 6 by a hot press 600; The thermoplastic resin in the vertical hole 4 and the thermoplastic resin layer 6 are integrally thermoformed, the transverse groove 3 and the longitudinal groove 2 are both perpendicular to each other and have the same depth, and the vertical hole 4 is perpendicular to the front of the carbon fiber felt 1. , and the vertical hole 4 is located in the middle of the area formed by the intersection of the two transverse grooves 3 and the two longitudinal groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com